Cleaning agent composition for metal processing product surface as well as preparation method and using method thereof

A surface cleaning agent and metal processing technology, applied in the field of industrial cleaning, can solve the problems of difficult biodegradation, many components, complicated compatibility, etc., and achieve the effect of prolonging the service life, reducing the quantity and good foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

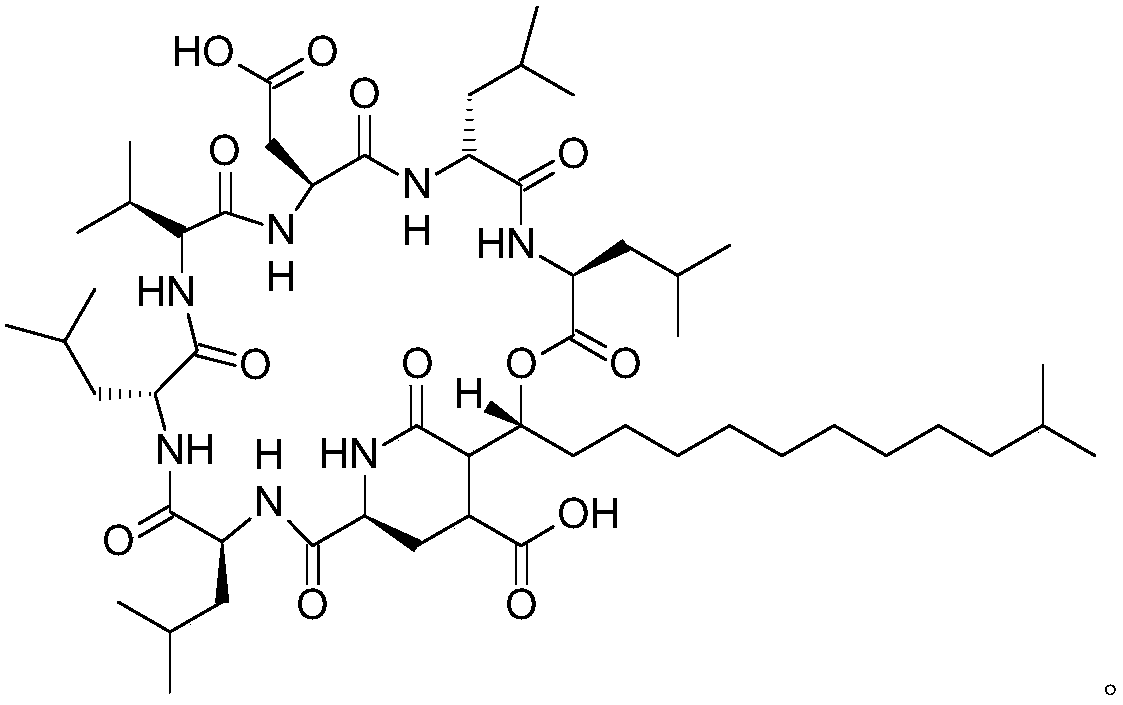

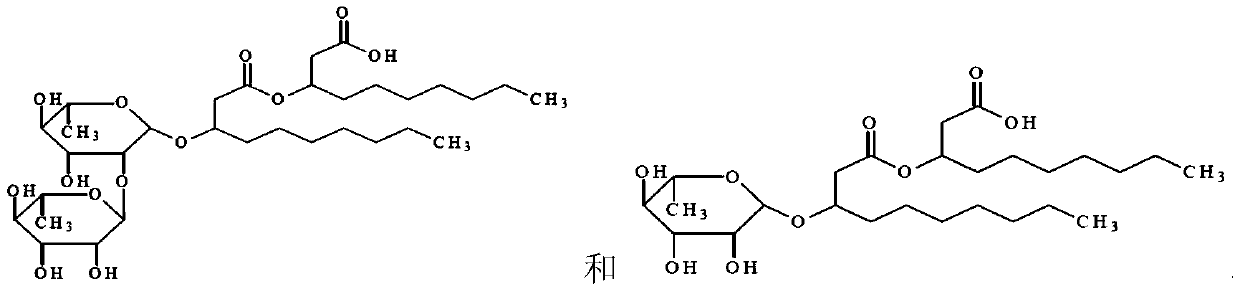

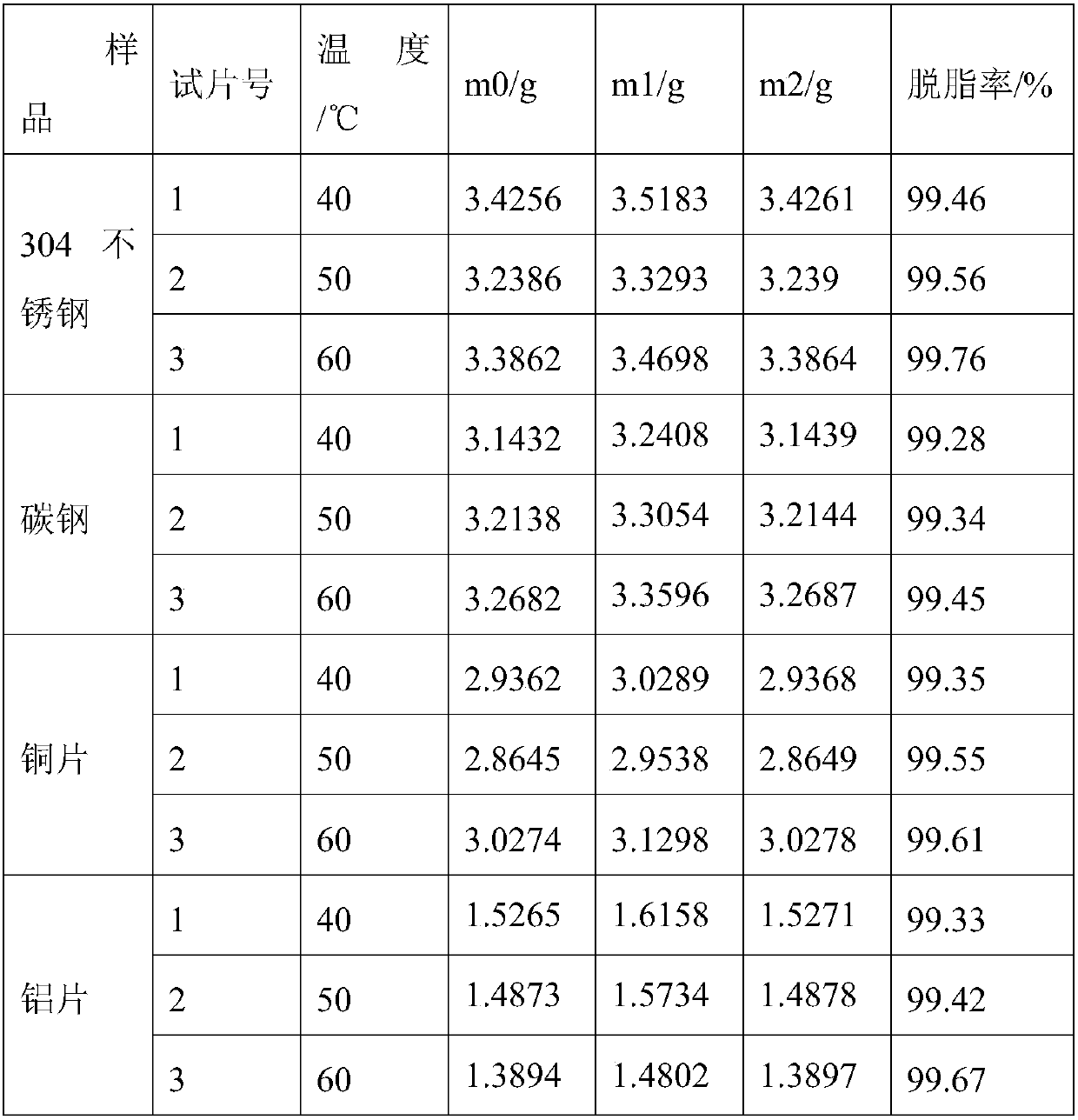

[0045] Weigh each raw material according to the following mass fractions: 1% Surfactin, 2% rhamnolipid, 3% polyaspartic acid, 3% lysine, 3% sodium oxalate, 0.2% defoamer, and the balance is deionized water . The rhamnolipid is a mixture obtained from the fermentation of Pseudomonas, containing 50% wt of monosaccharide ring rhamnolipid, 20% wt of disaccharide ring rhamnolipid, and the molecular weight of polyaspartic acid is 1000.

[0046] According to the mass content of each substance, put deionized water, lysine and surfactant peptide Surfactin into the reaction kettle, mix and dissolve at 50°C for 3 hours, then add rhamnolipid, sodium polyaspartate and Sodium oxalate is placed in the reaction kettle, stirred at 50°C for 3 hours, so that the raw materials in the reaction kettle are mixed evenly, and finally the defoamer is added to obtain an environmentally friendly cleaning agent.

Embodiment 2

[0048] Weigh each raw material according to the following mass fraction: Surfactin 2%, rhamnolipid 4%, polyaspartic acid 1%, lysine 5%, sodium oxalate 5%, defoamer 0.5%, and the balance is deionized water . The rhamnolipid is a mixture obtained by fermentation of Burkholderia, containing 60% wt of monosaccharide ring rhamnolipid, 25% wt of disaccharide ring rhamnolipid, and the molecular weight of polyaspartic acid is 2000.

[0049] According to the mass content of each substance, put deionized water, lysine and surfactant peptide Surfactin into the reaction kettle, mix and dissolve at 55°C for 4 hours, then add rhamnolipid, sodium polyaspartate and Sodium oxalate is placed in the reaction kettle, stirred at 55°C for 2 hours, so that the raw materials in the reaction kettle are evenly mixed, and an environmentally friendly cleaning agent is obtained.

Embodiment 3

[0051] The raw materials were weighed according to the following mass fractions: 1% Surfactin, 5% rhamnolipid, 2% polyaspartic acid, 3% lysine, 4% sodium oxalate, 0.1% defoamer, and the balance was deionized water . The rhamnolipid is a mixture obtained by fermentation of Pseudomonas, containing 55% wt of monosaccharide ring rhamnolipid, 30% wt of disaccharide ring rhamnolipid, and the molecular weight of polyaspartic acid is 4000.

[0052] According to the mass content of each substance, put deionized water, lysine and surfactant peptide Surfactin into the reaction kettle, mix and dissolve at 60°C for 2 hours, then add rhamnolipid, sodium polyaspartate and Sodium oxalate is placed in the reaction kettle, stirred at 60°C for 2 hours, so that the raw materials in the reaction kettle are evenly mixed, and an environmentally friendly cleaning agent is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com