Method for preparing metal modified SAPO-34 molecular sieve

A SAPO-34 and metal modification technology, applied in the field of molecular sieves, can solve the problems of poor dispersion of SAPO-34 molecular sieves and low metal content, and achieve the effects of lowering temperature, reducing difficulty, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

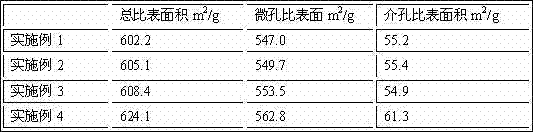

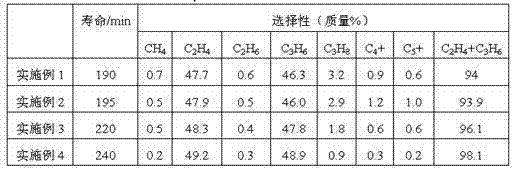

Examples

preparation example Construction

[0025] A kind of preparation method of metal modified SAPO-34 molecular sieve, comprises the steps:

[0026] (1) Mix the aluminum source and the mixed template agent and stir evenly, add deionized water, phosphorus source, and silicon source in turn, and stir at 20~30°C for 1~2 hours to mix evenly to obtain a mixed reaction solution; the mixed reaction Al in liquid 2 o 3 :P 2 o 5 : SiO 2 : mixed templating agent: H 2 The molar ratio of O is 0.8~1.2: 0.8~1.2: 0.2~0.4: 1.5~2.5: 50~70; the mixed templating agent is composed of tetraethylammonium hydroxide and morpholine, tetraethylammonium hydroxide and morpholine The molar ratio of morphine is 1:2~4;

[0027] (2) Mix the sodium carboxymethyl cellulose and the mixed reaction solution obtained in step (1) evenly, then put it into a high-temperature reactor and pre-crystallize it at 140-160°C for 20-24 hours, then raise the temperature to 160-180°C Crystallize for 40-50 hours, and centrifuge the mixed reaction solution to ob...

Embodiment 1

[0043] A kind of preparation method of copper metal modified SAPO-34 molecular sieve, comprises the steps:

[0044] (1) Mix the aluminum source and the mixed template agent and stir evenly, add deionized water, phosphorus source, and silicon source in turn, and stir at 30°C for 2 hours to mix evenly to obtain a mixed reaction solution; the Al in the mixed reaction solution 2 o 3 :P 2 o 5 : SiO 2 : mixed templating agent: H 2 The molar ratio of O is 0.8:0.8:0.2:1.5:50; the mixed template is composed of tetraethylammonium hydroxide and morpholine, and the molar ratio of tetraethylammonium hydroxide and morpholine is 1:2;

[0045] (2) Mix the sodium carboxymethyl cellulose and the mixed reaction liquid obtained in step (1) evenly, then put it into a high-temperature reactor and pre-crystallize at 160°C for 24 hours, then raise the temperature to 180°C for 50 hours, and put The mixed reaction solution is centrifuged to obtain filter cake and mother liquor; the mass ratio of s...

Embodiment 2

[0050] A kind of preparation method of nickel metal modified SAPO-34 molecular sieve, comprises the steps:

[0051] (1) Mix the aluminum source and the mixed template agent and stir evenly, add deionized water, phosphorus source, and silicon source in turn, and stir at 20°C for 1 hour to mix evenly to obtain a mixed reaction solution; the Al in the mixed reaction solution 2 o 3 :P 2 o 5 : SiO 2 : mixed templating agent: H 2 The molar ratio of O is 1.2:1.2:0.4:2.5:70; the mixed template is composed of tetraethylammonium hydroxide and morpholine, and the molar ratio of tetraethylammonium hydroxide and morpholine is 1:4;

[0052] (2) Mix the sodium carboxymethyl cellulose and the mixed reaction solution obtained in step (1) evenly, then put it into a high-temperature reaction kettle for pre-crystallization at 140°C for 20 hours, then raise the temperature to 160°C for crystallization for 40 hours, and mix The reaction solution is centrifuged to obtain filter cake and mother ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com