Cellulose solution and dissolving method and application thereof

A cellulose solution and cellulose technology, applied in the field of natural polymers, can solve the problems of low molecular weight, harsh conditions, and high cost of dissolving cellulose, and achieve easy recovery and recycling, simple waste liquid treatment and recovery, and strong solubility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

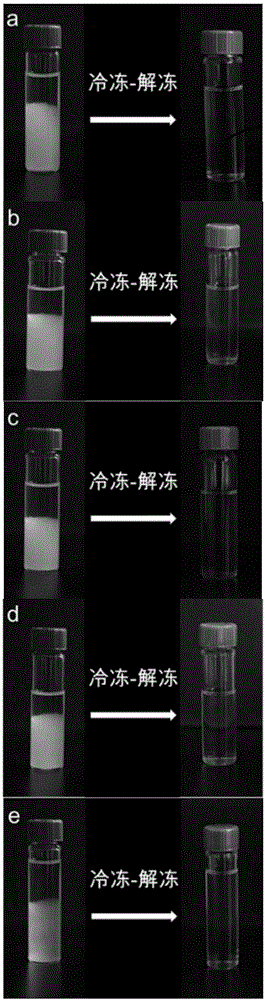

[0028] Take cotton linter pulp (viscosity average molecular weight M η =0.7×10 5 ) 5 grams, put it into 95 grams of 1.88M tetramethylammonium hydroxide aqueous solution, shake evenly at room temperature (25°C), put it in the freezer of the refrigerator and cool it at -22°C until the mixture is completely frozen, and place it at room temperature ( 25°C) to obtain a transparent cellulose solution after thawing. The content of cellulose in the prepared cellulose solution is 5 wt%, the concentration of tetramethylammonium hydroxide is about 1.88M, and the rest is water.

Embodiment 2

[0030] Take cotton linter pulp (M η =0.7×10 5 ) 6 grams, put it into 94 grams of 1.88M triethylmethylammonium hydroxide aqueous solution, shake evenly at room temperature (25°C), put it in the freezer of the refrigerator and cool it down to -22°C until the mixture is completely frozen, and place it for 4 hours. Thaw at room temperature (25°C) to obtain a transparent cellulose solution. The content of cellulose in the prepared cellulose solution is 6 wt%, the concentration of triethylmethylammonium hydroxide is about 1.88M, and the rest is water.

Embodiment 3

[0032] Take cotton linter pulp (M η =0.7×10 5 ) 8 grams, put it into 92 grams of 1.88M tetraethylammonium hydroxide aqueous solution, shake evenly at room temperature (25°C), put it in the freezer of the refrigerator and cool it at -22°C until the mixture is completely frozen, and place it at room temperature ( 25°C) to obtain a transparent cellulose solution after thawing. The cellulose content in the prepared cellulose solution is 8 wt%, the concentration of tetraethylammonium hydroxide is about 1.88M, and the rest is water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com