Preferred orientation growth method of MFI type zeolite

A technology of preferred orientation and growth method, which is applied in the field of preferred orientation growth of MFI zeolite, can solve the problems of high toxicity of template agents, and achieve the effects of avoiding environmental pollution, wide sources of raw materials, and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

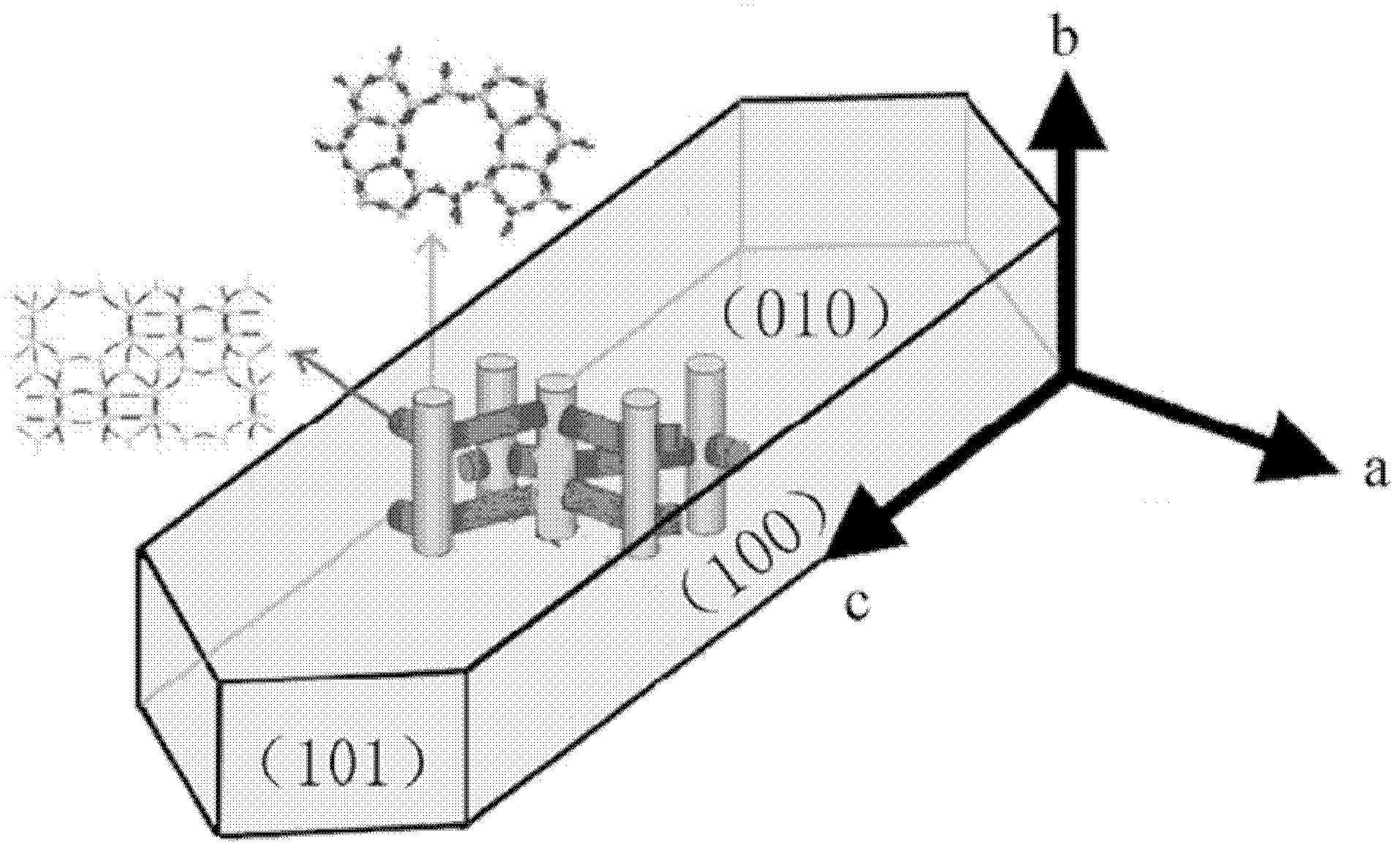

[0015] By 1SiO 2 : 0.01Al 2 o 3 : 0.41TEAOH: 0.31 acetylacetone: 31.76H 2 O Weigh each material, dissolve sodium aluminate in distilled water, add tetraethylammonium hydroxide dropwise, stir for 1 hour, then add ethyl orthosilicate dropwise, stir for 1 hour, then add acetylacetone, stir for 1 hour , adjusted to pH = 13.0 with 0.1N sodium hydroxide solution, and continued to stir for 5 hours. The obtained mixture was crystallized under hydrothermal conditions at 170°C for 4 days, washed, filtered and dried. The obtained product had the characteristic diffraction peak of MFI and preferentially grew in the (010) direction (b-axis).

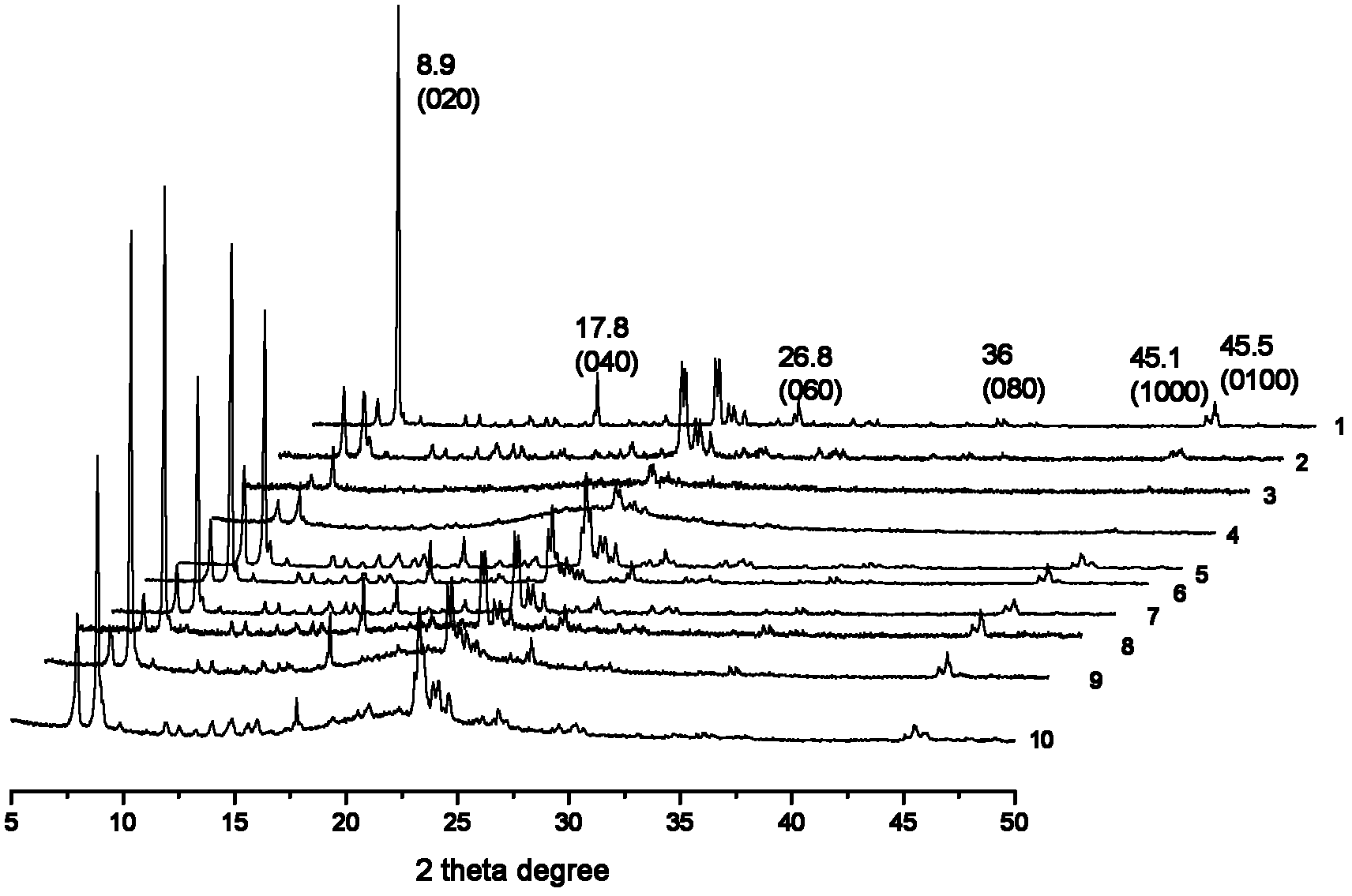

[0016] XRD spectrum see figure 2 In the middle curve 1, the relative intensity of (020), (040), (060) and (080) peaks in the diffraction spectrum is significantly increased, which is obviously due to the preferred orientation of the MFI single crystal on the powder diffraction sample plate, and its (0h0) plane, That is, the cylindrical surface ...

Embodiment 2

[0018] By 1SiO 2 : 0.01Al 2 o 3 : 0.25TPAOH : 0.05 sodium oxalate : 32.0H 2 O Weigh each material, dissolve sodium aluminate in distilled water, add tetrapropylammonium hydroxide dropwise, stir for 1 hour, then add silica sol dropwise, stir for 1 hour, then add sodium oxalate, stir for 1 hour, use 0.1 N sodium hydroxide solution was used to adjust the pH to 12.0, and stirring was continued for another 5 hours. The resulting mixture was crystallized under hydrothermal conditions at 200°C for 3 days, washed, filtered and dried. XRD spectrum see figure 2 In the middle curve 2, the relative intensity of (020), (040), (060) and (080) peaks in the same diffraction spectrum is obviously increased.

Embodiment 3

[0020] By 1SiO 2 : 0.02Al 2 o 3 : 0.23TEAOH: 0.278-hydroxyquinoline: 44.64H 2 O Weigh each material, dissolve aluminum triethoxide in distilled water, add tetraethylammonium hydroxide dropwise, stir for 1 hour, then add silica sol dropwise, stir for 1 hour, then add 8-hydroxyquinoline, stir for 1 hour , adjust pH=11.0 with 0.1N sodium hydroxide solution, and continue stirring for 5 hours. The resulting mixture was crystallized under hydrothermal conditions at 150°C for 6 days, washed, filtered and dried. XRD spectrum see figure 2 In the middle curve 3, the relative intensity of (020), (040), (060) and (080) peaks in the same diffraction spectrum is obviously increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com