Synthetic method with MWW structure si/b molecular sieve

A synthesis method and molecular sieve technology are applied in the direction of crystalline aluminosilicate zeolite, etc., which can solve the problems of highly toxic preparation and complexity of template agents, and achieve the effect of less template agent usage and avoiding environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

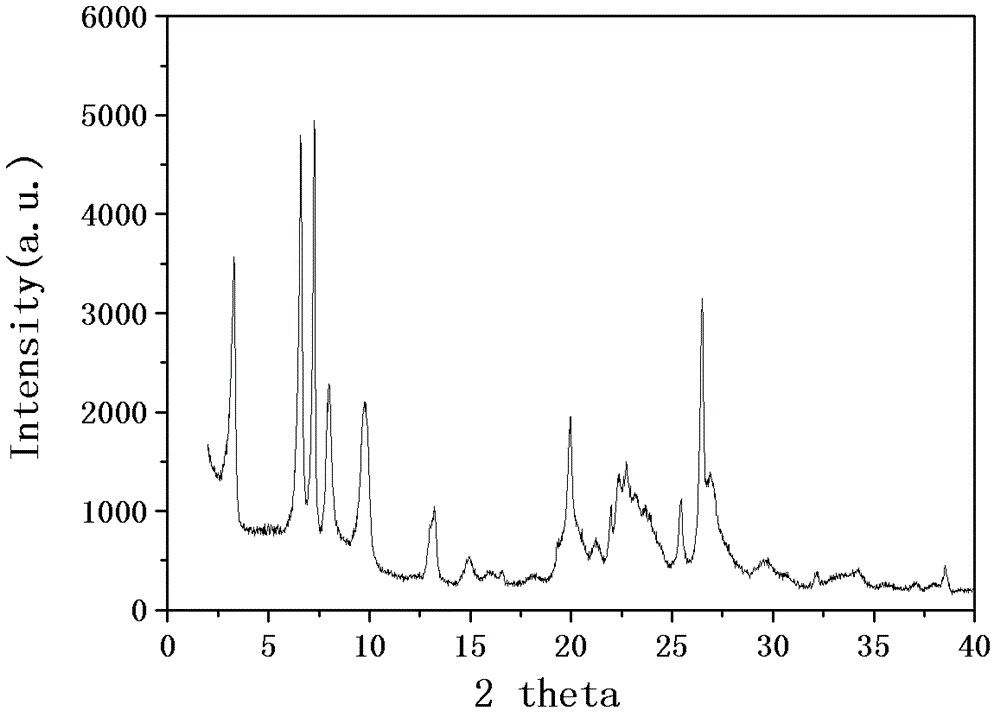

[0019] Dissolve 0.4 grams of sodium hydroxide in 37.8 grams of water, then add 3.6 grams of diethyldimethylammonium hydroxide (DEDMAOH), add 12.5 grams of boric acid under the condition of uniform stirring, add 22.5 grams of 40% boric acid after fully dissolving Silica sol, continue to stir for 1 hour, the molar ratio of gained reaction mother liquor is 0.67B 2 o 3 : SiO 2 :0.06OH - : 0.20DEDMAOH : 19.0H 2 O. Then put the mother liquor into a 100 ml high-pressure crystallization kettle, and conduct dynamic crystallization at 170° C. for 3 days, filter after cooling, wash, and dry to obtain a Si / B molecular sieve with a MWW structure. The XRD spectrum pattern of obtained molecular sieve is shown in figure 1 , XRD diffraction peaks with a typical MWW structure.

Embodiment 2

[0021] Dissolve 2.0 grams of sodium hydroxide in 35.0 grams of water, then add 4.5 grams of diethyldimethylammonium hydroxide, add 10.8 grams of boric acid under the condition of uniform stirring, add 25.0 grams of 30% silica sol after fully dissolving, Continue stirring for 1 hour, the molar ratio of the resulting reaction mother liquor is 0.70B 2 o 3 : SiO 2 : 0.40OH - : 0.30DEDMAOH : 23.0H 2 O. Then put the mother liquor into a 100 ml high-pressure crystallization kettle, and conduct dynamic crystallization at 170° C. for 3 days, filter after cooling, wash, and dry to obtain a Si / B molecular sieve with a MWW structure. The XRD spectrum pattern of obtained molecular sieve and figure 1 Similarly, it is a molecular sieve with a typical MWW structure.

Embodiment 3

[0023] Dissolve 0.5 gram of lithium hydroxide in 56.2 gram of water, then add 3.8 gram of diethyldimethylammonium hydroxide, add 13.2 gram of boric acid under the condition of uniform stirring, add 22.5 gram of ethyl orthosilicate after fully dissolving, Continue stirring for 1 hour, the molar ratio of the resulting reaction mother liquor is 0.98B 2 o 3 : SiO 2 : 0.19OH - : 0.30DEDMAOH : 28.9H 2 O. Then put the mother liquor into a 100 ml high-pressure crystallization kettle, and dynamically crystallize at 160° C. for 4 days. After cooling, filter, wash, and dry to obtain a Si / B molecular sieve with a MWW structure. The XRD spectrum pattern of obtained molecular sieve and figure 1 Similarly, it is a molecular sieve with a typical MWW structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com