Patents

Literature

34results about How to "Rapid crystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

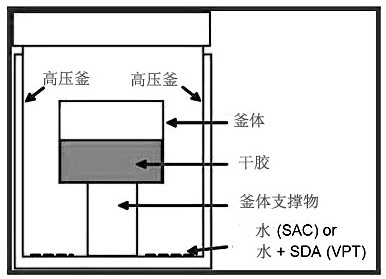

Preparation method of europium oxide (EUO) type molecular sieve

ActiveCN102040230AHigh reactivityImprove solubilityCrystalline aluminosilicate zeolitesMolecular sieveOrganic solvent

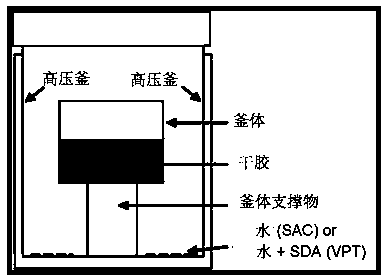

The invention provides a preparation method of a europium oxide (EUO) type molecular sieve. The preparation process comprises the steps: adding one or more of ethanol, propylene glycol, methyl alcohol and acetone with a proper amount to be taken as an organic solvent; filling a high-pressure inert gas into a high-pressure kettle, and carrying out sectional type crystallization under a certain condition; filtering and washing the product to be neutral; and drying, roasting to obtain the EUO molecular sieve. The organic solvent is added, so that a template agent precursor is promoted to be dissolved in an aqueous phase, and the generation of a template agent is accelerated; and therefore, the crystallization speed of the molecular sieve is accelerated, and the crystallization time of the molecular sieve is remarkably shortened.

Owner:CHINA PETROLEUM & CHEM CORP +1

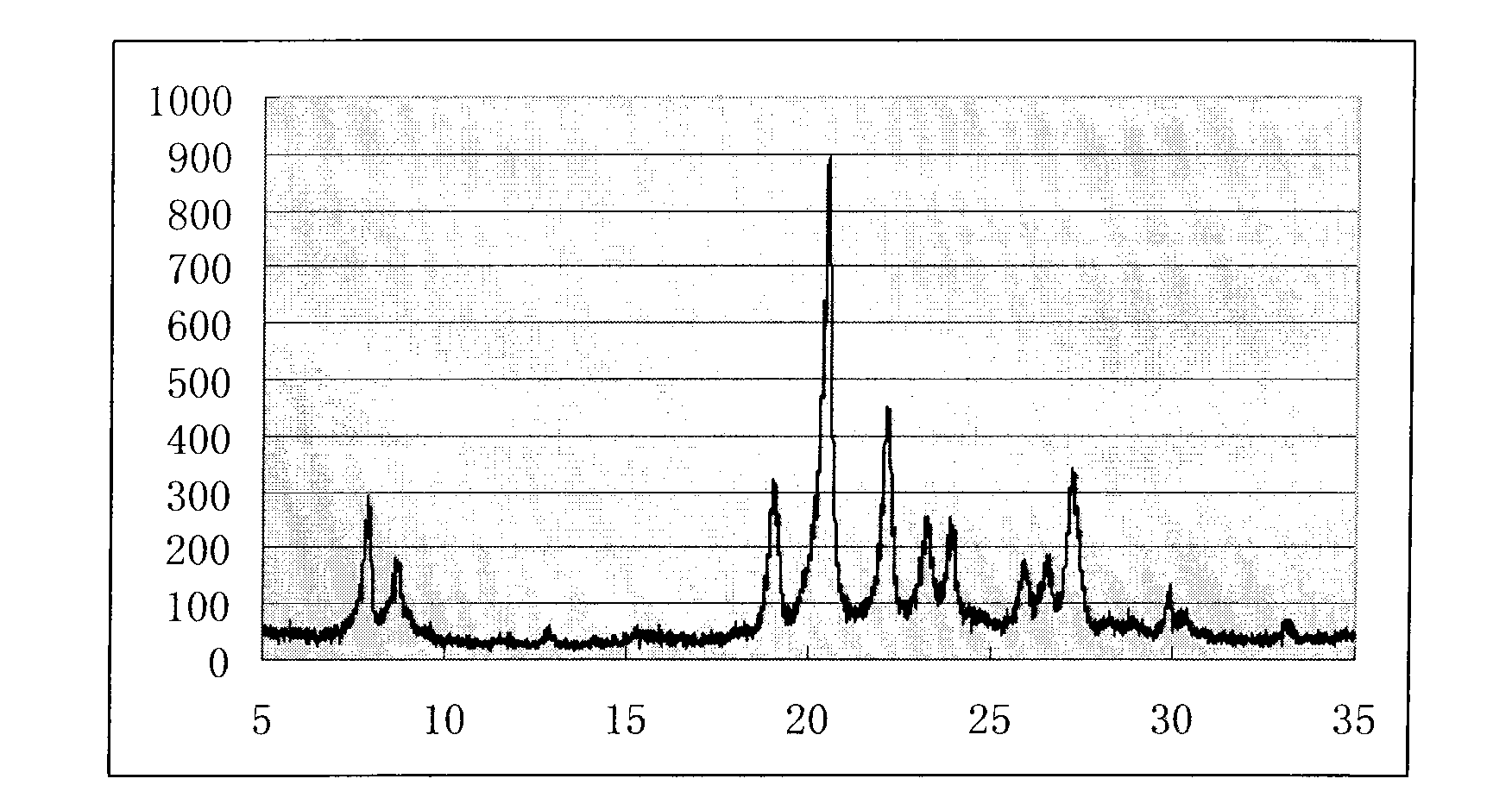

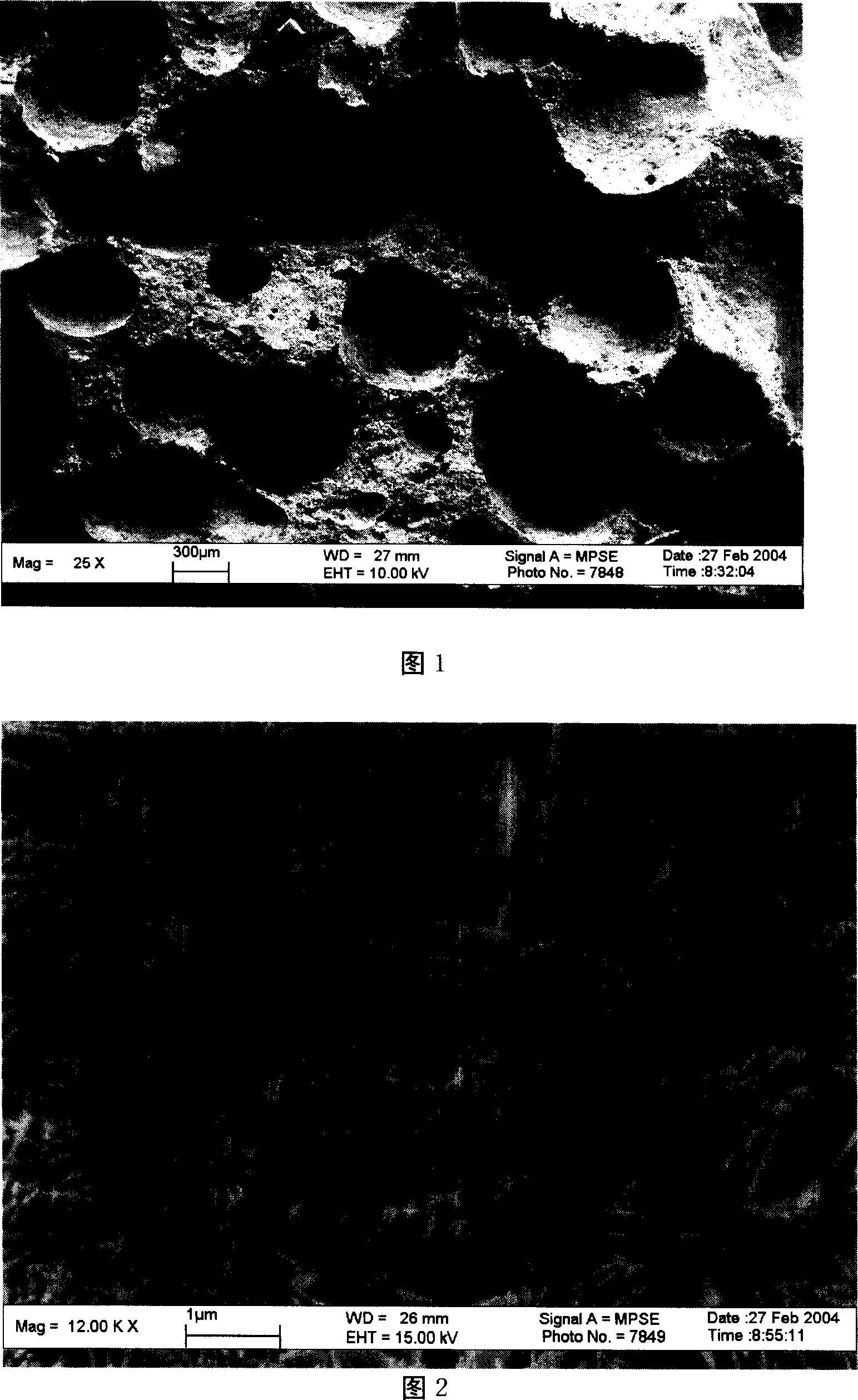

Porous calcium silicate filter material for water treatment

InactiveCN101015755AInhibition formationImprove filtering effectFiltration separationSilicon compoundsCalcium silicateDecomposition

A porous calcium silicate filter material used in water treatment is made from coagulation, steam foaming and high-temperature high-pressure steam treatment, characterized in that it uses domestic powder quartz (SiO2), general silicate cement, powder calcium oxide (CaO), power calcium sulfate (CaSO4), and aluminum powder (Al). The inventive product has strong adsorption and decomposition on organic, phosphor, and nitrogen, to be used in small life sewage treatment system.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

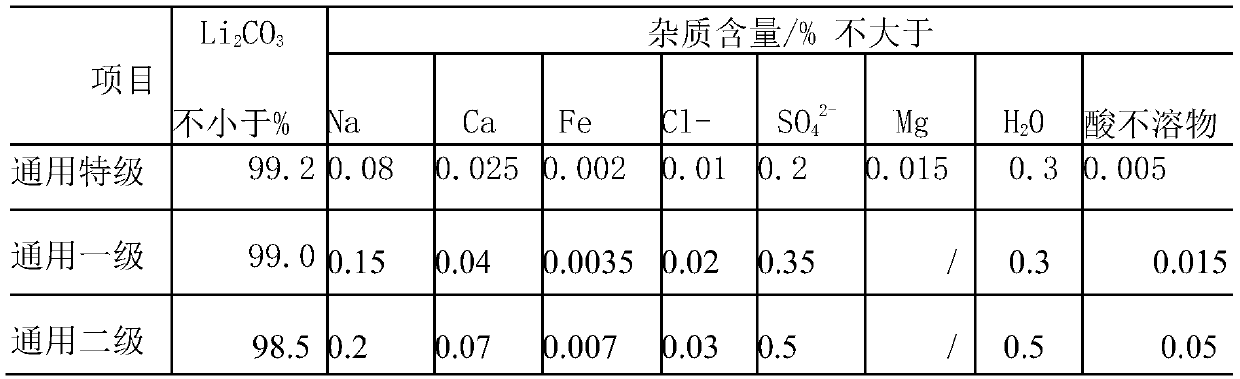

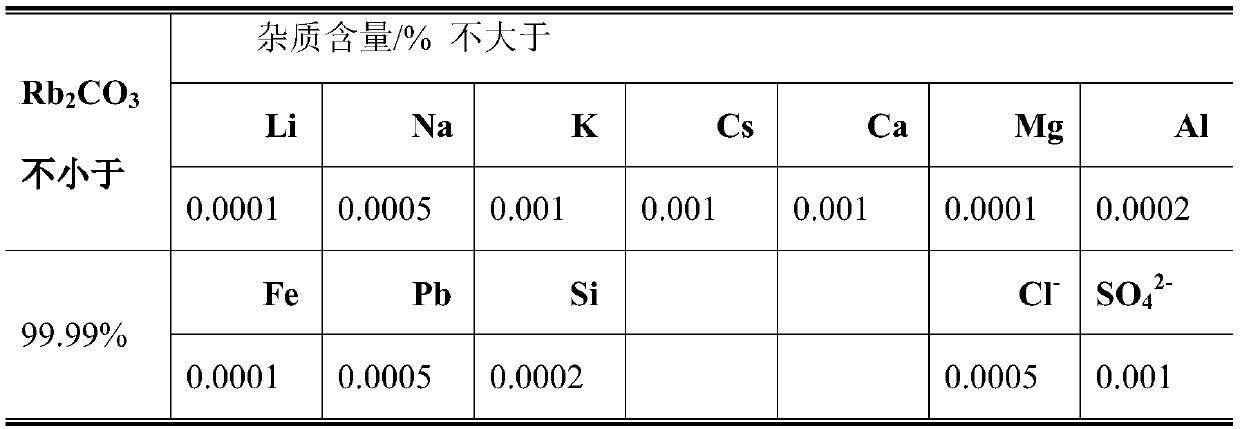

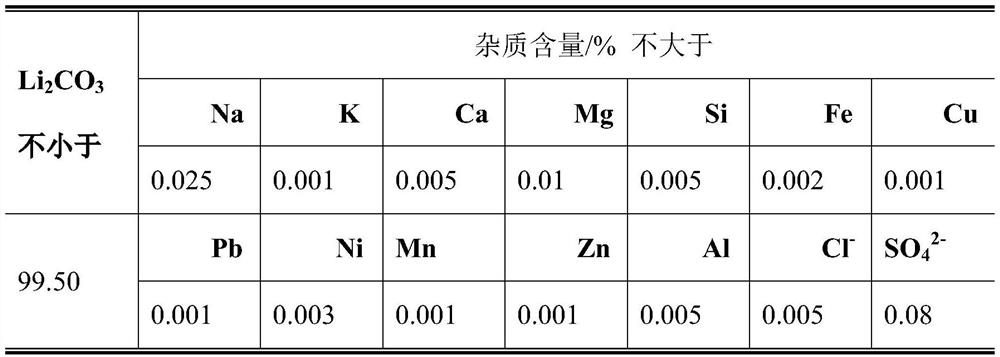

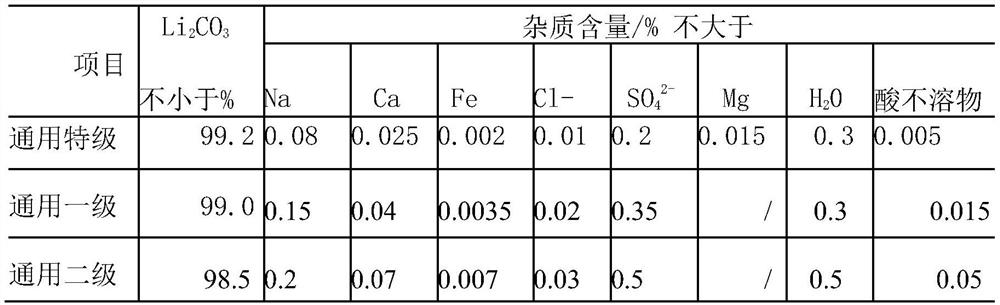

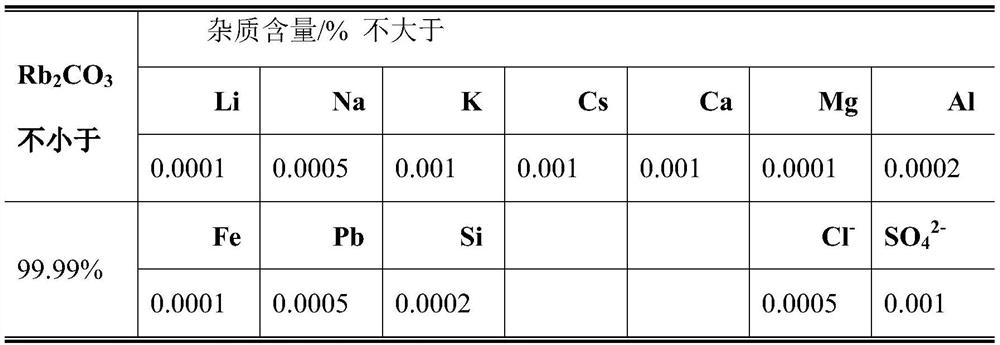

Method for separating and extracting battery-grade lithium carbonate and rubidium and cesium salts from lepidolite

ActiveCN110550644AReduce manufacturing costIncrease contentSulfate/bisulfate preparationRubidium/caesium/francium compoundsLithium carbonateRubidium

The invention discloses a method for separating and extracting battery-grade lithium carbonate and rubidium and cesium salts from lepidolite. Lepidolite is adopted as a raw material, an acidificationroasting method is implemented, and the method comprises steps of crushing, material feeding and pulping, acidification leaching, material mixing, drying, acidification roasting, water leaching reactions, twice cooling crystallization, alkali neutralization, gypsum solid dreg separation, decontamination with a decontamination agent, evaporation concentration, preparation of crude lithium carbonateand rubidium and cesium salts, and the like. The comprehensive cost of lepidolite extraction can be greatly reduced, the comprehensive competitiveness of lepidolite extraction can be greatly improved, and the method is high in equipment utilization rate, environment-friendly and small in waste emission and low in production cost for preparing battery-grade lithium carbonate and rubidium and cesium salts.

Owner:河北铸合集团兴隆县矿业有限公司

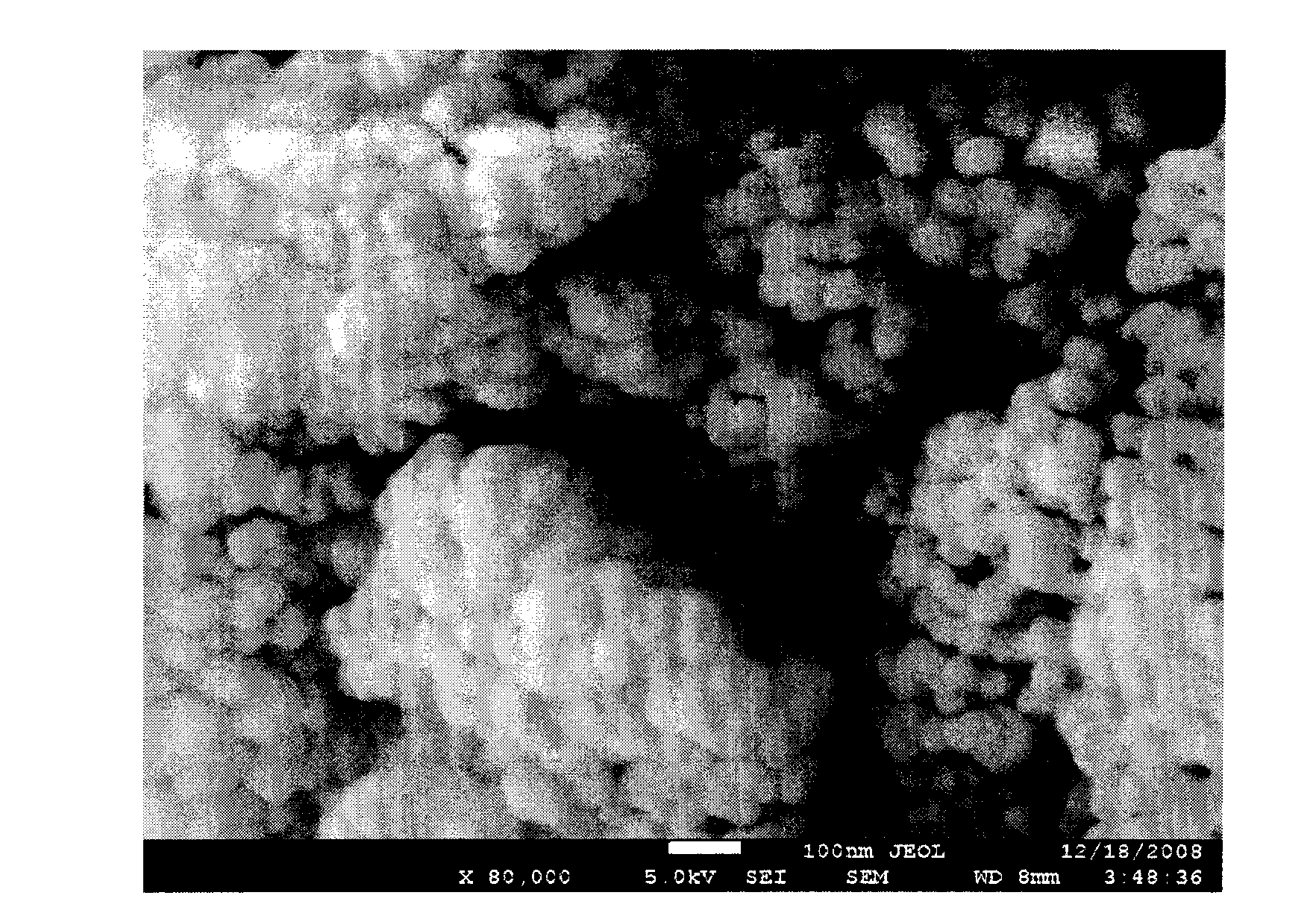

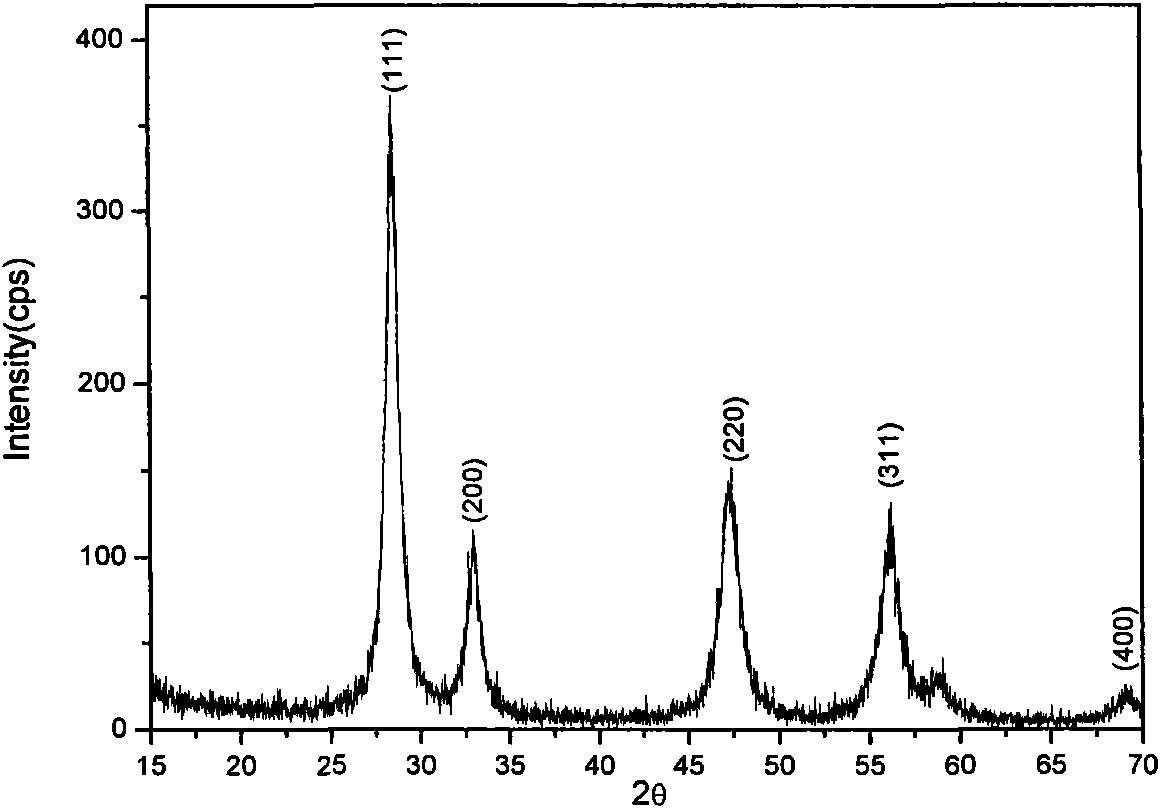

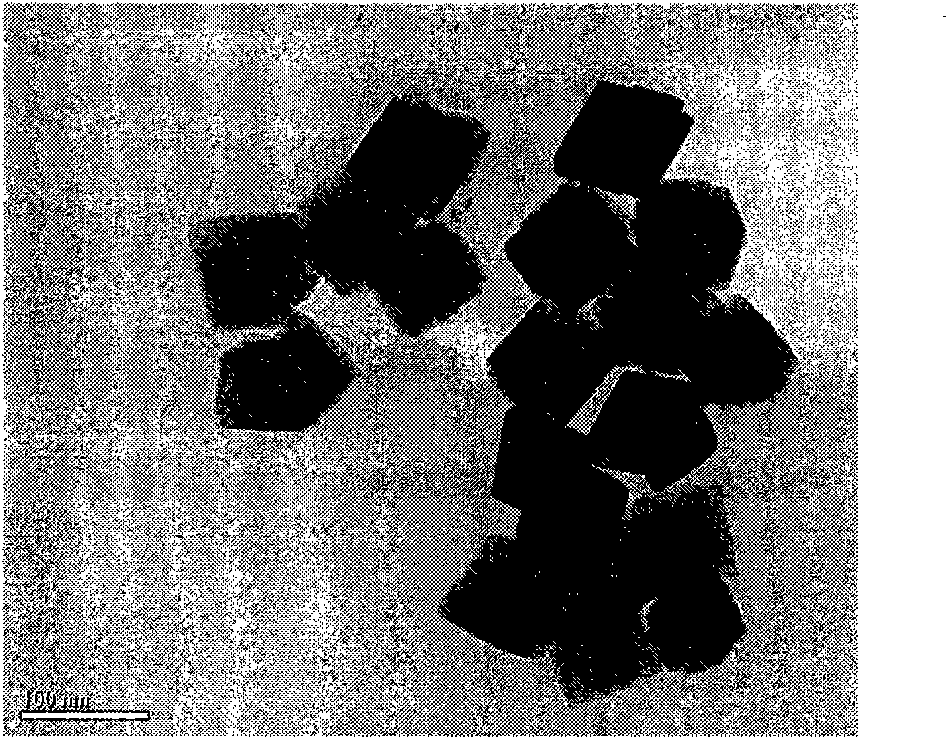

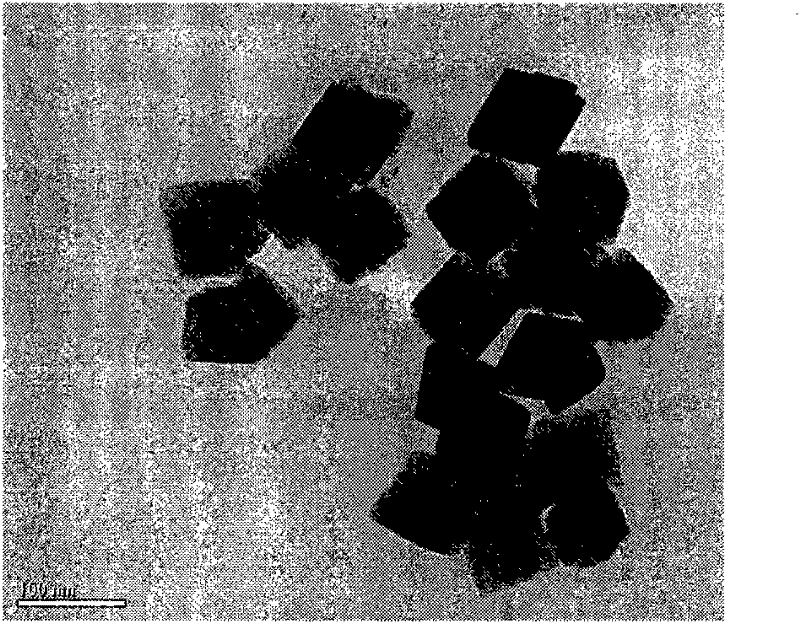

Method for synthesizing monodisperse samarium-doped rare earth cerium oxide nanocrystal

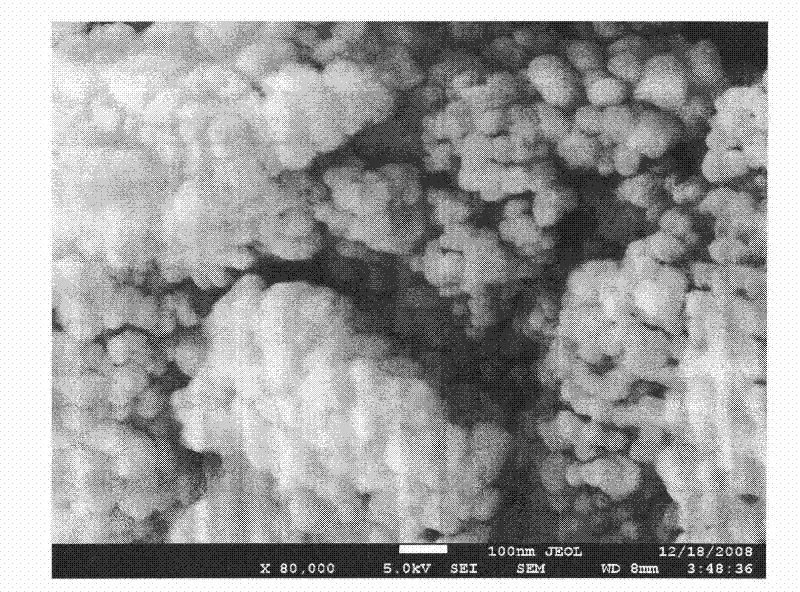

InactiveCN101891236AHigh reactivityUniform particle sizeNanostructure manufactureRare earth metal compoundsCerium nitrateRare earth

The invention relates to a method for synthesizing a monodisperse samarium-doped rare earth cerium oxide nanocrystal, belonging to the functional material preparation technical field. The method comprises the following steps: firstly, preparing an aqueous phase solution by using soluble cerium nitrate and samarium nitrate as raw materials and carbamide as a precipitant; forming an inverse microemulsion by using cetyl-trimethyl ammonium bromide as a surfactant, normal butyl alcohol as a cosurfactant and normal octane as an oil phase and adding the aqueous phase solution; filling the inverse microemulsion into a high-pressure reaction kettle the inner lining of which is made of polytetrafluoroethylene, heating for reaction, removing the normal octane from the reaction product by centrifugal separation, and removing the cetyl-trimethyl ammonium bromide and the normal butyl alcohol by washing to obtain a precursor product; and carrying out light irradiation on the precursor product to obtain the shape-controllable crystallized synthesized monodisperse samarium-doped rare earth cerium oxide nanocrystal which is uniform in particle size.

Owner:南京睿磐内尔环保复合新材料有限公司

Method for preparing hydrogen cyanide desorption catalyst by using combined supercritical carbon dioxide/supercritical hydrothermal method

InactiveCN108187677AGood dispersionShorten the soaking timeGas treatmentMolecular sieve catalystsDispersityDesorption

The invention discloses a method for preparing a hydrogen cyanide desorption catalyst by using combined supercritical carbon dioxide / supercritical hydrothermal methods and belongs to the technical field of industrial waste gas purification. The method comprises the following steps: by taking a transition metal salt as a precursor of an active component, mixing the active component precursor solution with a carrier, performing contact soaking in supercritical carbon dioxide, and synthesizing a carried type catalyst by using a supercritical hydrothermal method. Compared with a conventional soaking method, the supercritical carbon dioxide soaking method is short in soaking time and uniform in active component distribution; due to supercritical hydrothermal reactions, separation and carrying of the active component on the surface of the carrier can be rapidly completed, and in addition, the dispersity of the active component is further improved; the carried type catalyst prepared by usingthe combined supercritical carbon dioxide / supercritical hydrothermal methods has relatively high desorption efficiency upon hydrogen cyanide.

Owner:KUNMING UNIV OF SCI & TECH

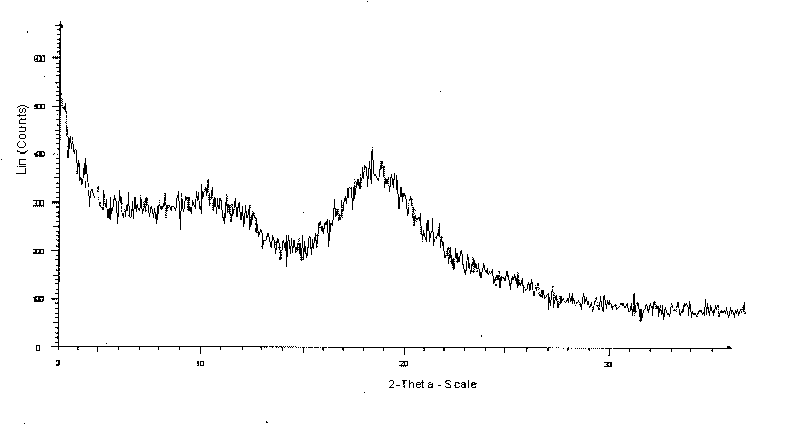

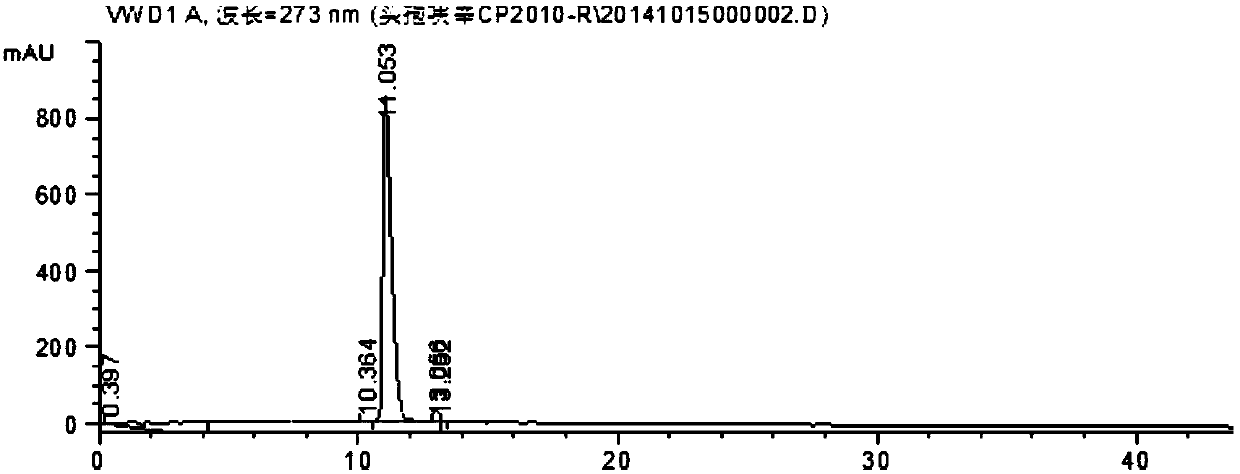

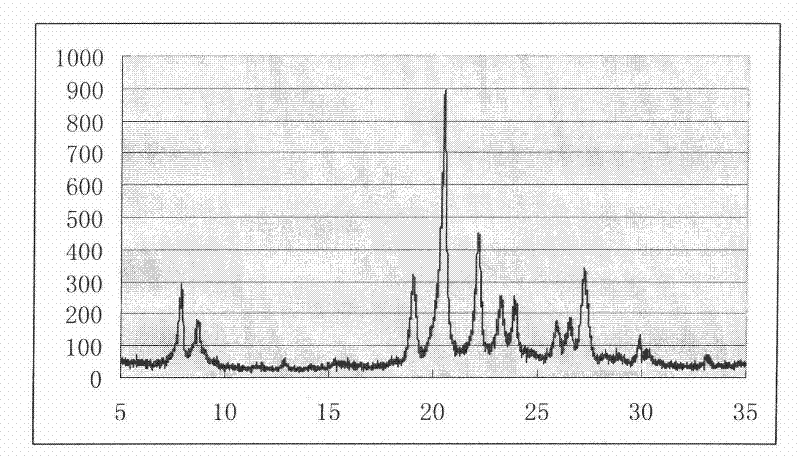

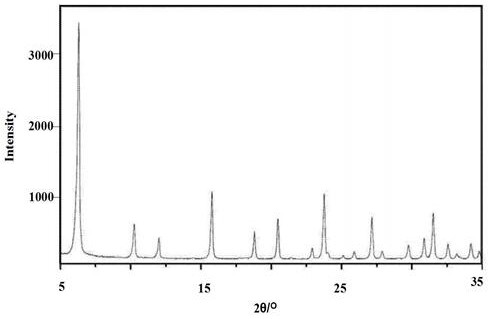

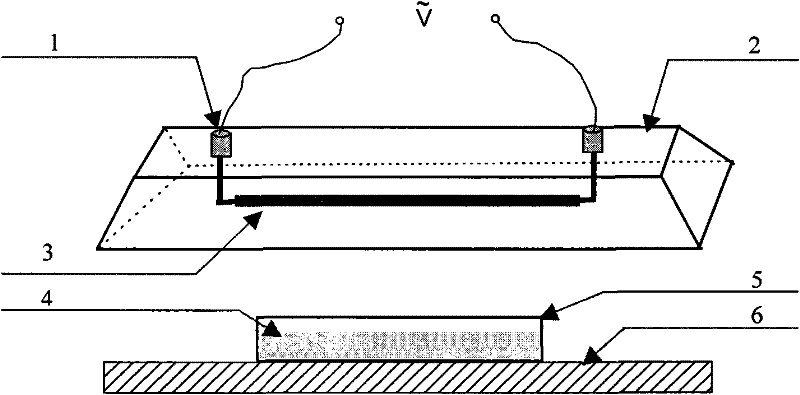

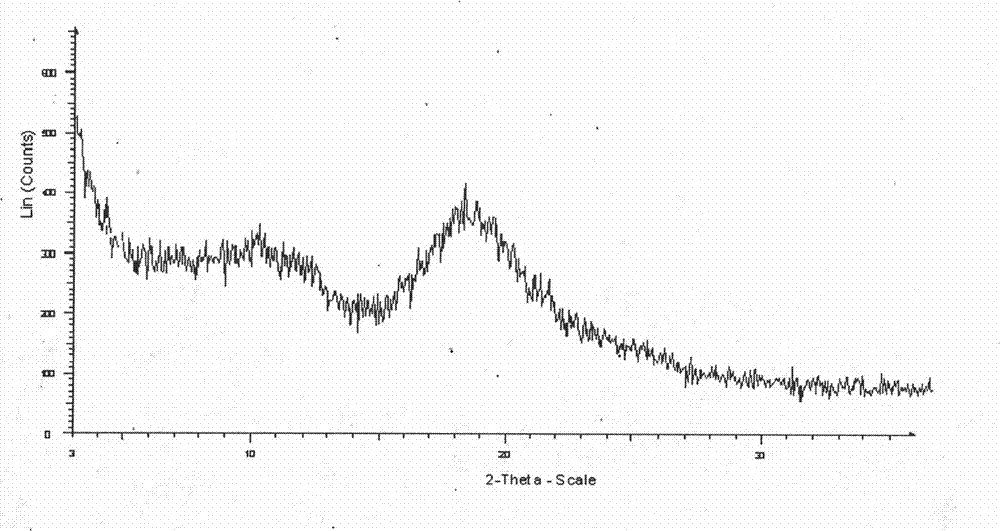

Preparation technology for water-soluble resveratrol particle, and product and application thereof

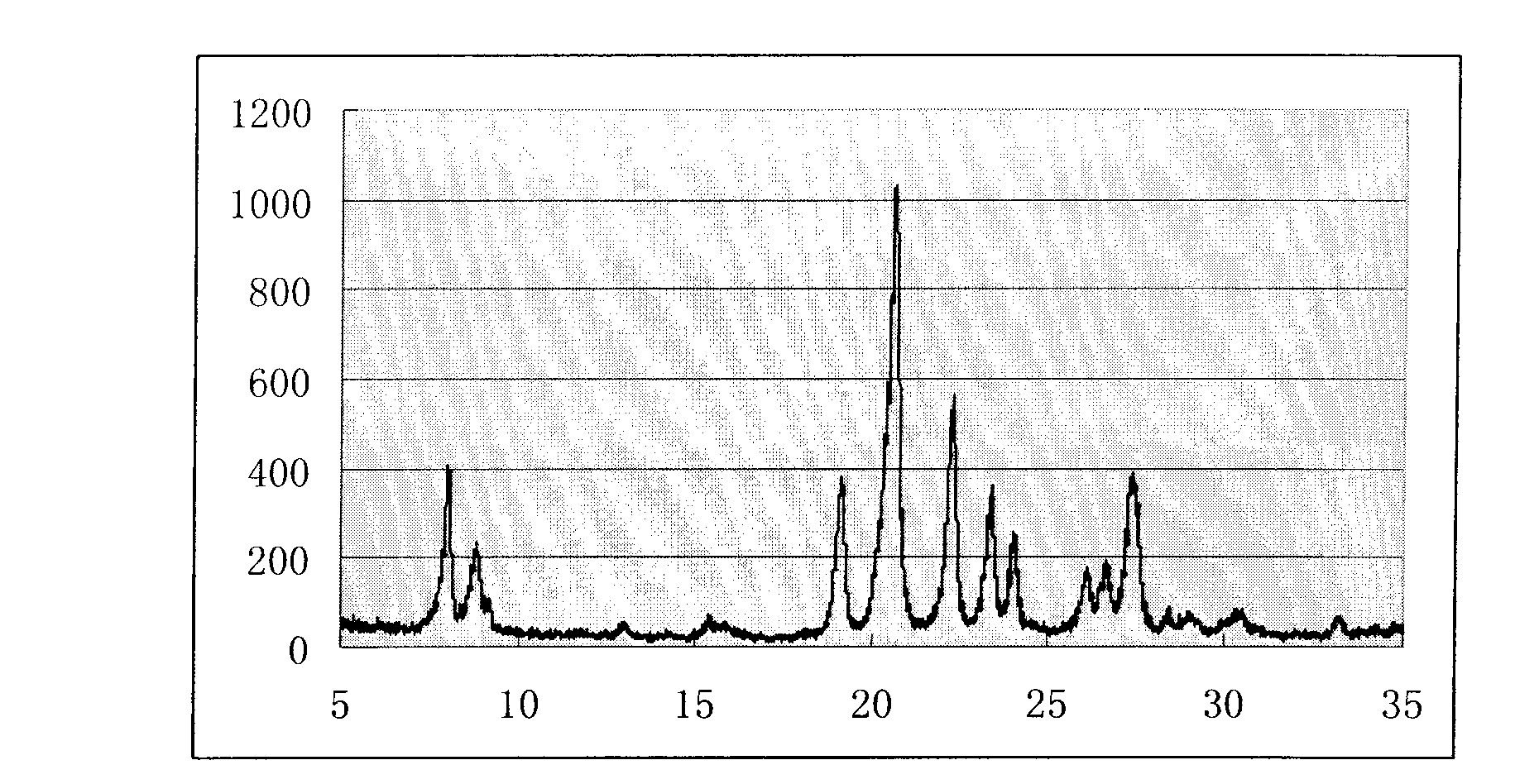

InactiveCN101759531AChange natureImprove solubilityOrganic chemistryHydroxy compound active ingredientsSolubilityFood additive

The invention relates to a preparation technology for water-soluble resveratrol particles. The preparation technology is that: (1) resveratrol transparent solution is prepared; (2) the prepared resveratrol transparent solution is pumped to the crystallizing kettle of a supercritical fluid crystallizing device; (3) residual chemical solution in a pipeline is flushed after chemical solution is fed; and (4) a pump is shut down, pressure and temperature are regulated to the natural state and the obtained particles are water-soluble resveratrol particles. The diameter of the water-soluble resveratrol particles is 50nm-200nm. X-ray diffraction shows that the particles are in the indefinite state. The water-soluble resveratrol particles can be used in medicines, healthcare foods, feeds, food additives, cosmetics and the chemical field. The invention has the advantages that the nature of indissoluble resveratrol is changed, the water solubility of the resveratrol is obviously improved and the dissolution speed in water is very fast; and since the resveratrol is rapidly precipitated in the supercritical fluid, the finished product is enabled to be loose and the dissolution speed in water is very fast.

Owner:TIANJIN GUONA TECH DEV CO LTD

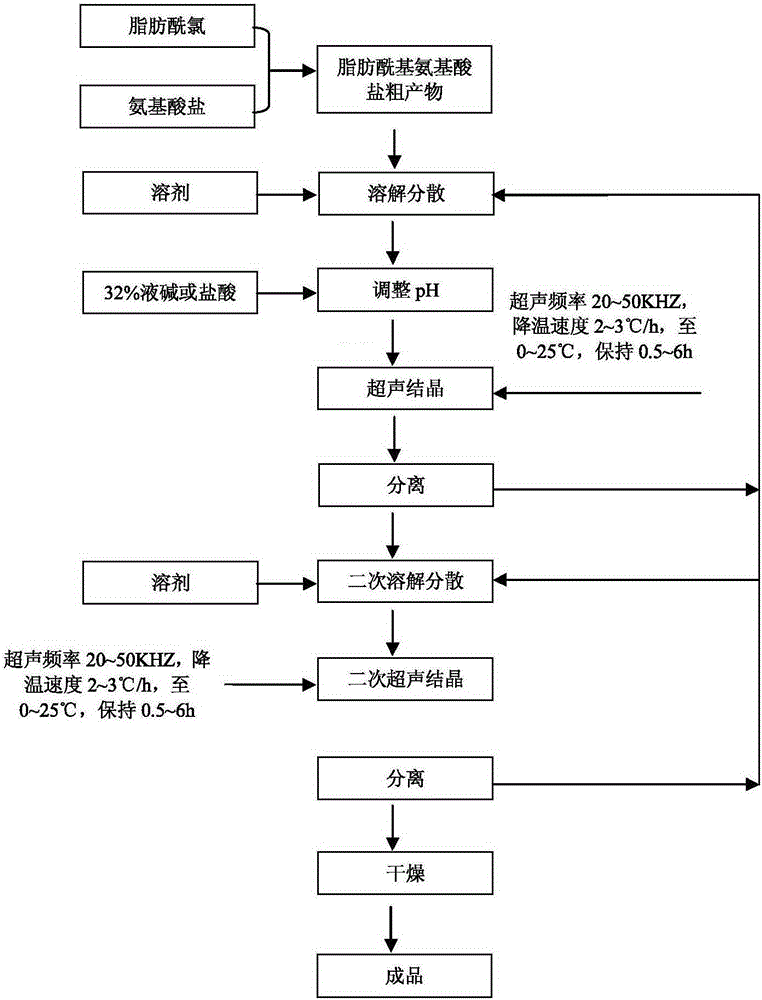

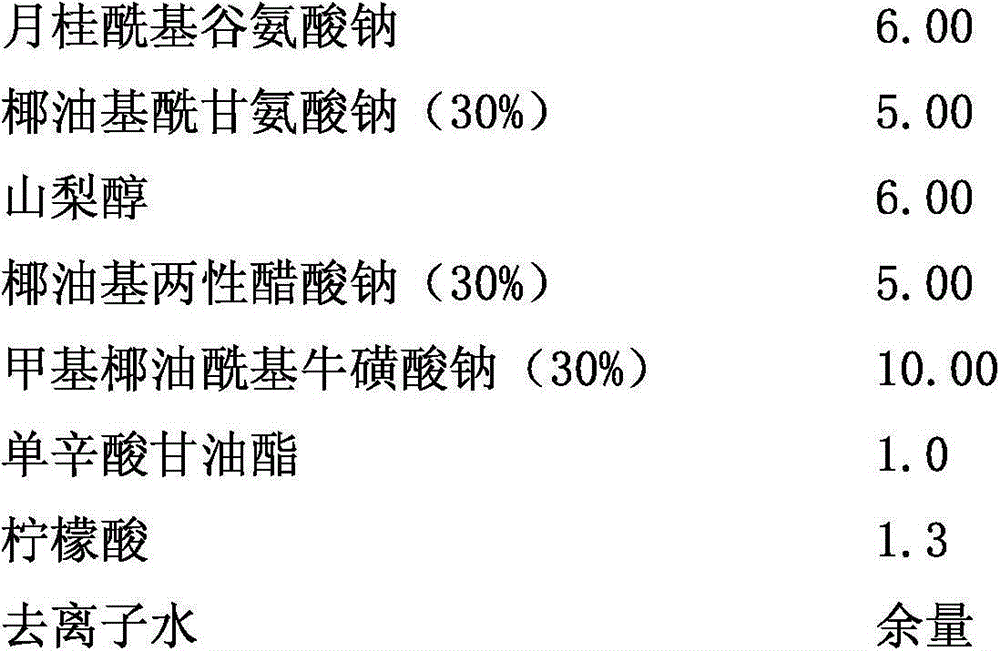

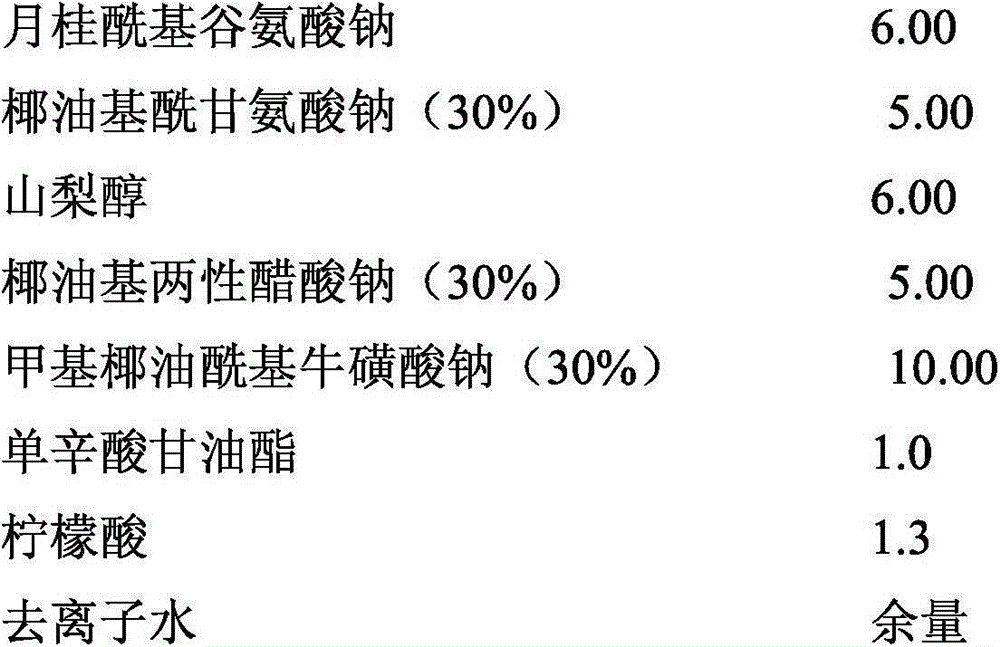

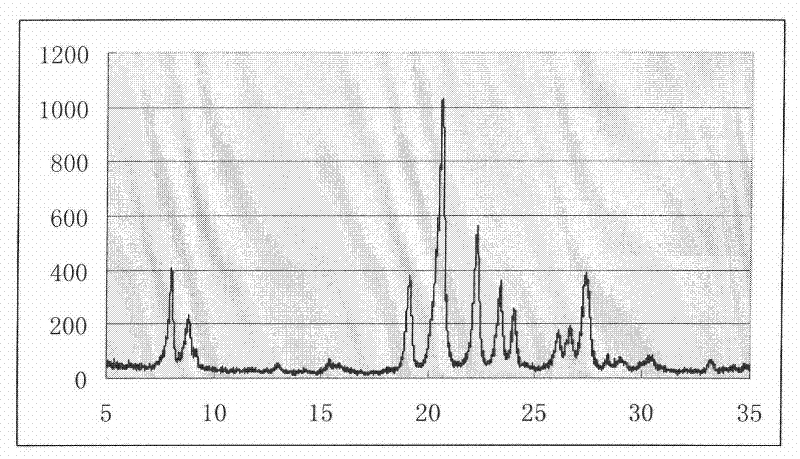

Method for preparation of high-purity fatty acyl amino acid salt

InactiveCN105198765APromote growthResidue reductionOrganic compound preparationTransportation and packagingGranularitySolvent

The invention discloses a method for preparation of a high-purity fatty acyl amino acid salt, wherein the method includes the following steps: a) carrying out a reaction of amino acid with fatty acyl chloride, neutralizing released hydrochloric acid with an alkaline substance, and generating a fatty acyl amino acid salt crude product; b) adding a solvent to the crude product, heating to dissolve and dispersing to obtain a solution, and adjusting the pH value of the solution; c) placing the solution on an ultrasonic apparatus, slowly cooling to 20-25 DEG C, carrying out ultrasonic crystallization of the solution for the first time, and separating through reduced pressure suction filtration, to obtain a filter cake for standby application; and d) adding a solvent to the filter cake obtained in the former step, heating to dissolve and dispersing to obtain a solution, carrying out ultrasonic crystallization for the second time, separating through reduced pressure suction filtration, to obtain a filter cake, carrying out vacuum drying of the filter cake, and thus obtaining the high-purity fatty acyl amino acid salt finished product. The high-purity fatty acyl amino acid salt having less impurity residue, good crystal shape and uniform granularity can be obtained by using the method; the method has the advantages of reasonable process, easy operation, high production efficiency, good production preparation reproducibility, and stable product quality.

Owner:ZHANGJIAGANG GREAT CHEM

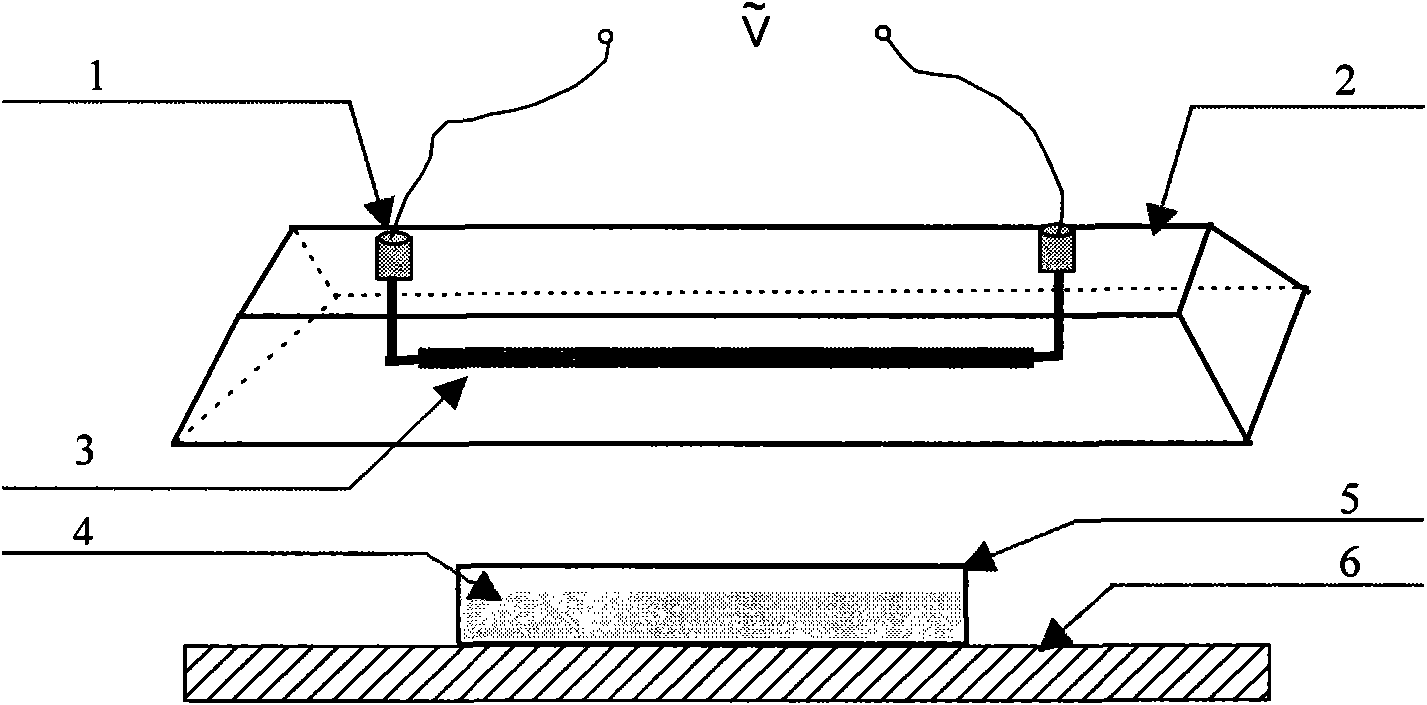

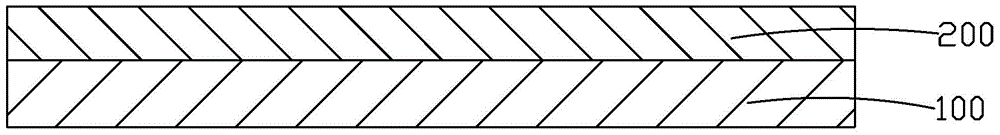

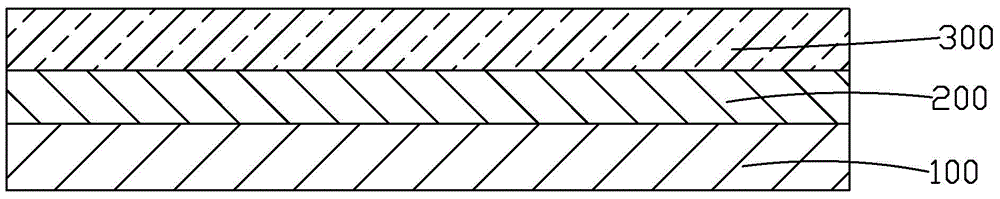

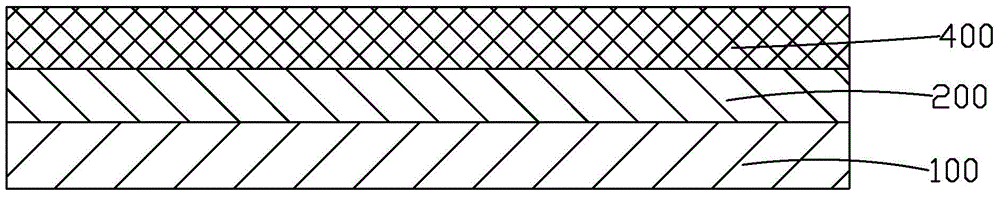

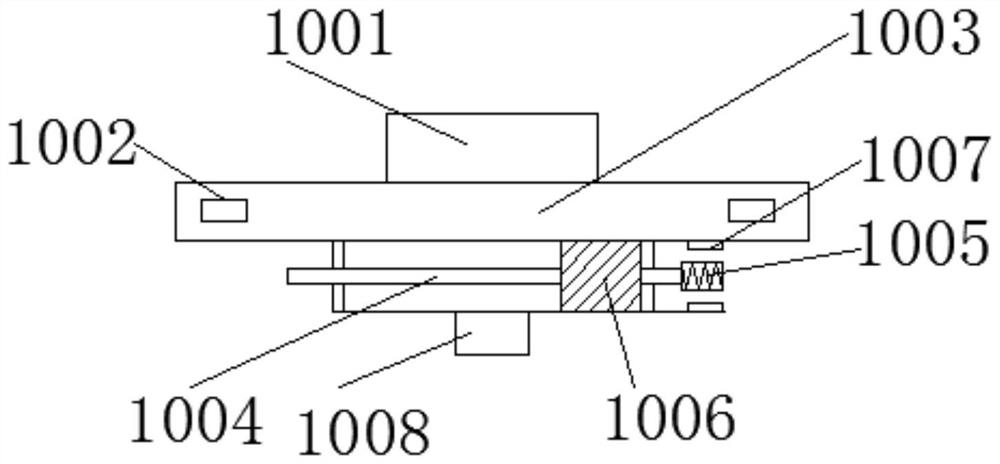

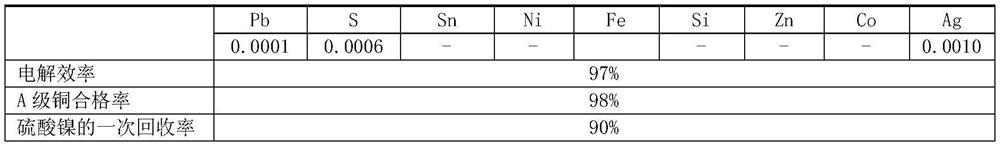

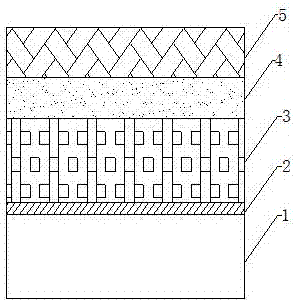

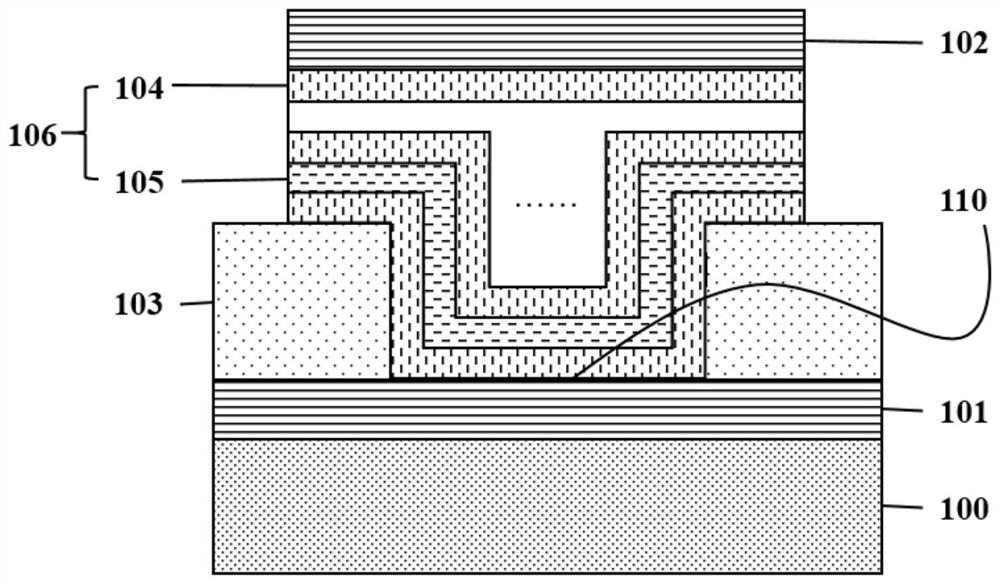

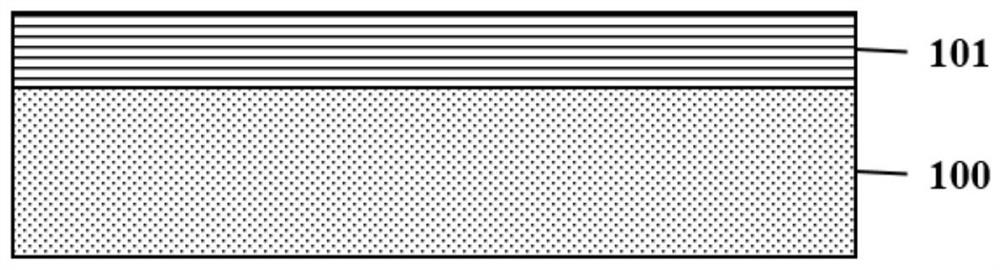

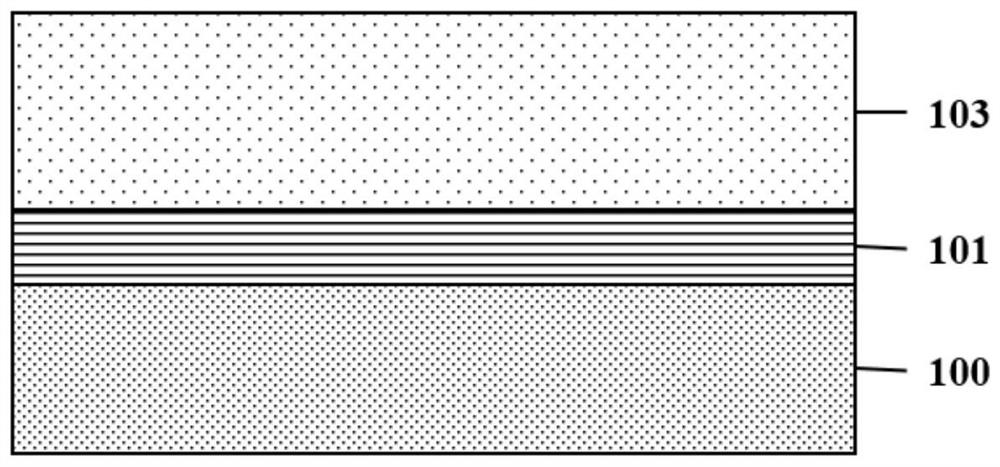

Manufacturing method for low-temperature polycrystalline silicon and manufacturing method for TFT substrate

ActiveCN104465319ARapid crystallizationLow costSolid-state devicesSemiconductor/solid-state device manufacturingAmorphous siliconOptoelectronics

The invention provides a manufacturing method for low-temperature polycrystalline silicon and a manufacturing method for a TFT substrate. The manufacturing method for the low-temperature polycrystalline silicon includes the following steps that S1, a substrate (1) is provided; S2, a buffering layer (2) is deposited on the substrate (1); S3, a metal mesh film (3) is plated on the buffering layer (2); S4, an amorphous silicon layer (4) is deposited on the metal mesh film (3); S5, rapid thermal annealing is carried out on the amorphous silicon layer (4), and therefore the amorphous silicon layer (4) is crystallized and converted into a polycrystalline silicon layer (5); S6, the metal mesh film (3) is removed. The method can effectively reduce the temperature of the crystallization manufacture procedure, shorten the time for the crystallization manufacture procedure, reduce the cost for preparing polycrystalline silicon thin films in a large-area mode, improve the crystallization effect and make crystalline grains larger and more uniform.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

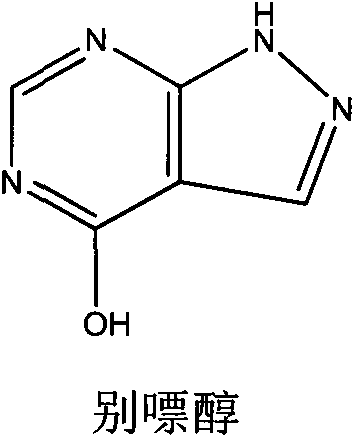

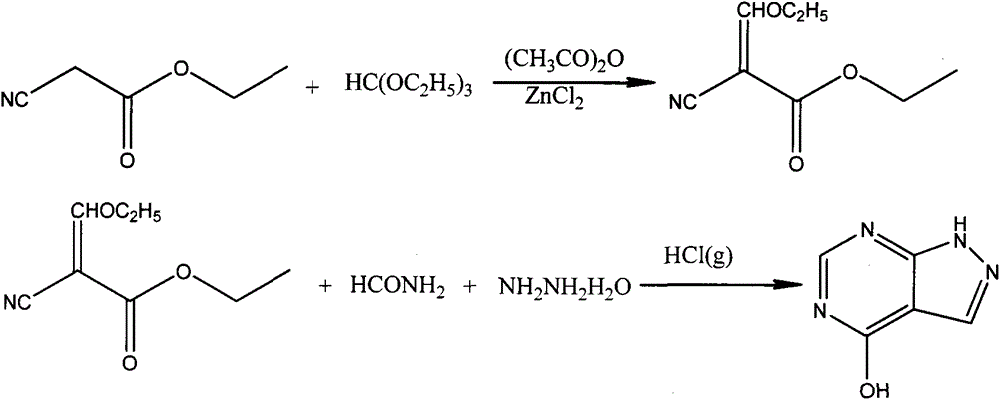

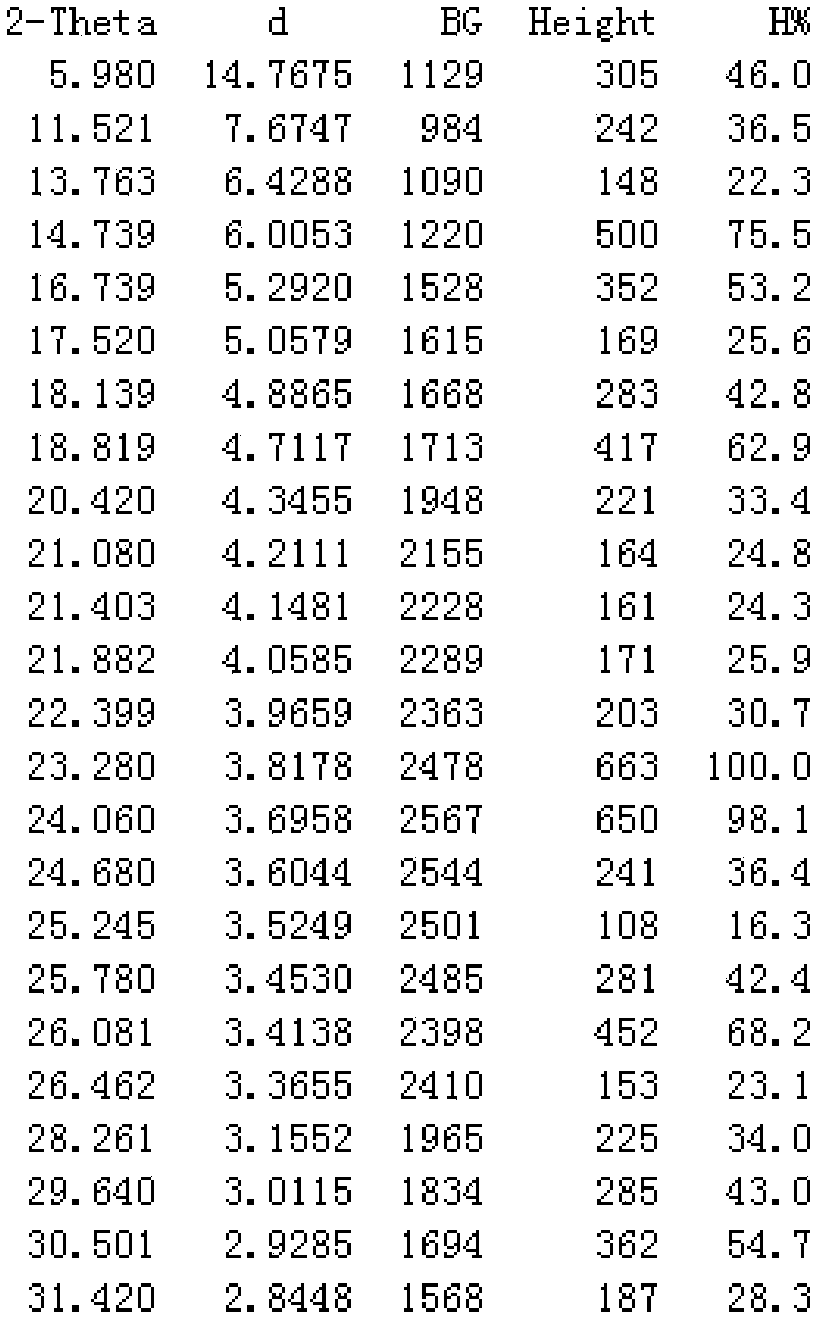

Method for carrying out solvent-out crystallization on allopurinol

The invention provides a method for carrying out solvent-out crystallization on allopurinol. The method comprises the following steps: (1) dissolving a crude allopurinol product into a sulfones solvent at the temperature of 98-148 DEG C; (2) adding a solution obtained from the step (1) to an antisolvent for crystallization, and separating to obtain the allopurinol. The finished allopurinol product obtained through the method provided by the invention can achieve the yield as high as 95% or more than 95% and achieve the purity more than 99.88% of the purity achieved through an HPLC normalization method. The method provided by the invention has the advantages of simple process, small occupied equipment size, output increase of equipment with same size, solvent recycling, environmental pollution reduction and suitability for industrialized production.

Owner:CHONGQING KANGLE PHARMA

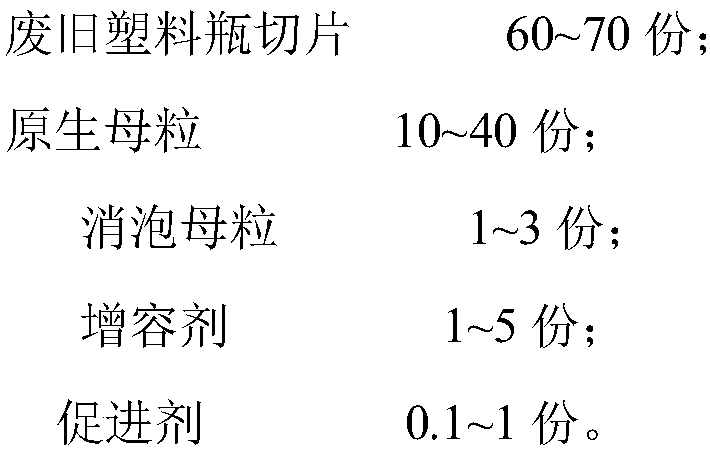

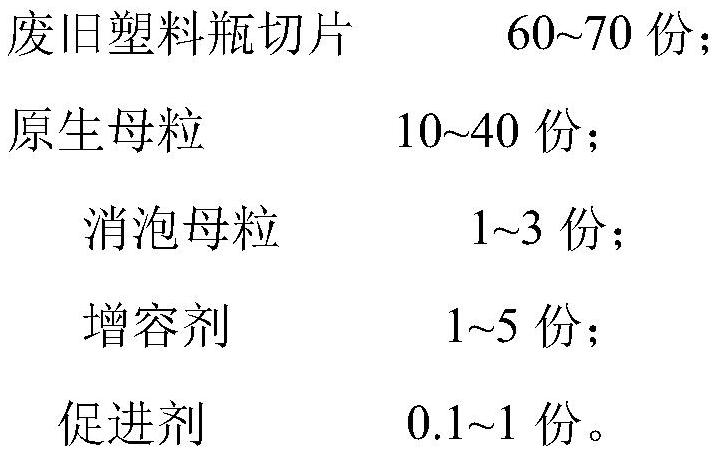

Master batches for production of polyester filaments, and preparation method and application thereof

ActiveCN107778785ALow costTight textureConjugated synthetic polymer artificial filamentsArtifical filament manufacturePolyesterEngineering

The invention discloses master batches for production of polyester filaments, and a preparation method and application thereof. The problems that the traditional regenerated master batches cannot havethe characteristics of properties close to those of the original master batches and low cost are solved. According to the key point of the technical scheme, the master batches comprise the followingcomponents in parts by weight: 60 to 70 parts of waste plastic bottle sections, 10 to 40 parts of original master batches, 1 to 3 parts of defoaming master batches, 1 to 5 parts of compatibilizer and0.1 to 1 part of accelerant. The master batches prepared by the above formula have low cost, have excellent properties close to those of the original master batches, can be compatible with the waste plastic bottle sections well in the production of the polyester filaments and enables the polyester filaments to be uniform in character and color.

Owner:苏州市苏宏塑料有限公司

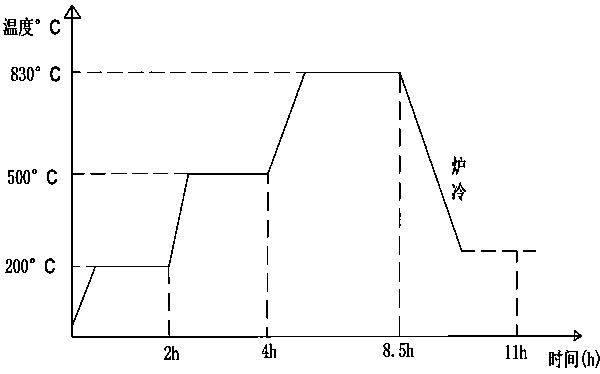

Plaster mold dewaxing and roasting process

The invention relates to a plaster mold dewaxing and roasting process. The plaster mold dewaxing and roasting process comprises the following steps: (S1) a plaster mold is dried to put in a dewaxing and roasting furnace; (S2) the temperature in the dewaxing and roasting furnace is increased to 180-220 DEG C and maintained by 2 hours; (S3) the temperature in the dewaxing and roasting furnace is further increased to 480-520 DEG C and maintained by 2 hours; (S4) the temperature o the dewaxing and roasting furnace is increased to 800-850 DEG C and maintained by 4.5 hours; and (S5) the plaster moldin the dewaxing and roasting furnace is cooled in the furnace. In the plaster mold dewaxing and roasting process, through quick segmented increment and maintenance of the temperature in the dewaxingand roasting furnace, the dehydration, the dewaxing and the roasting of the plaster mold are realized; the temperature of 180-220 DEG C is maintained by 2 hours to gradually eliminate crystallized water in the plaster mold; a wax model in the plaster mold can be removed at 480-520 DEG C; the plaster mold can be quickly crystallized at 800-850 DEG C; the energy is saved; the quality of the plastermold is better; the internal defects are few; and the efficiency is high.

Owner:太仓黑龙智能工业科技有限公司

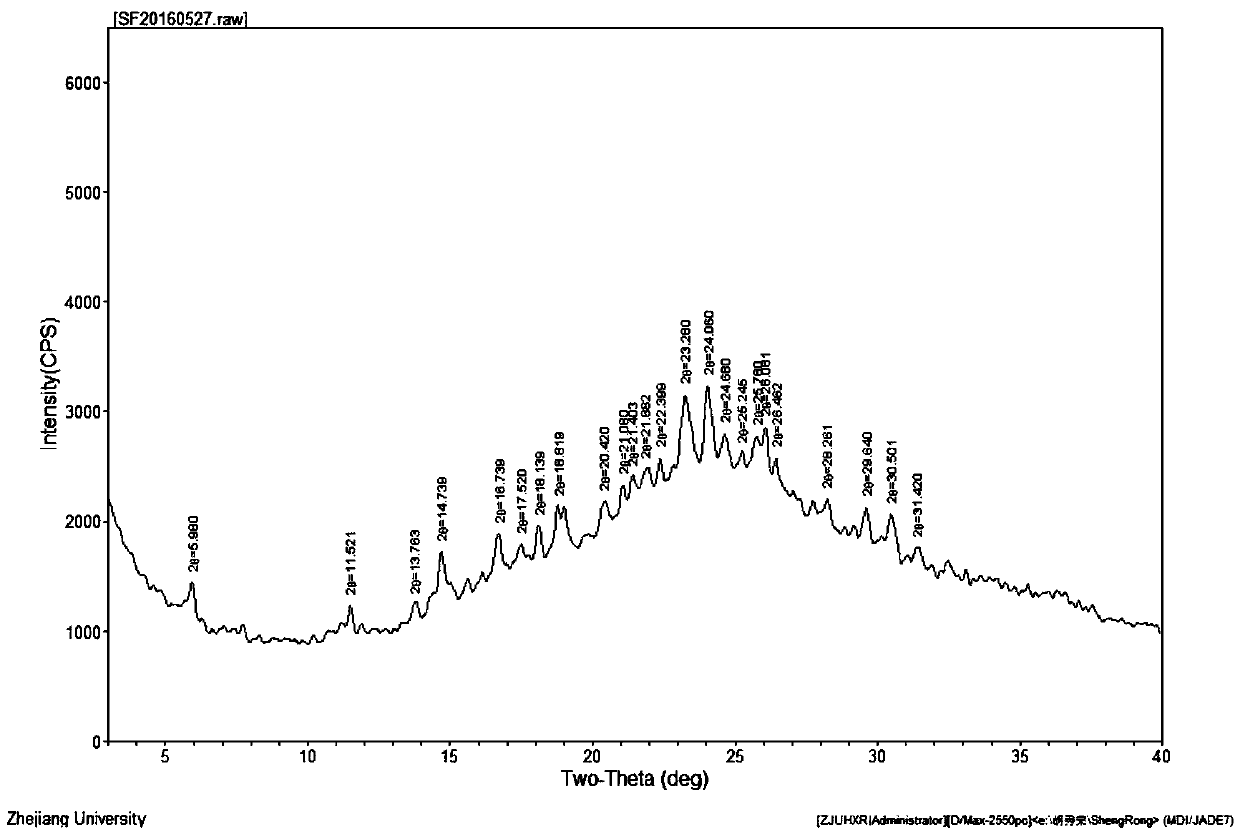

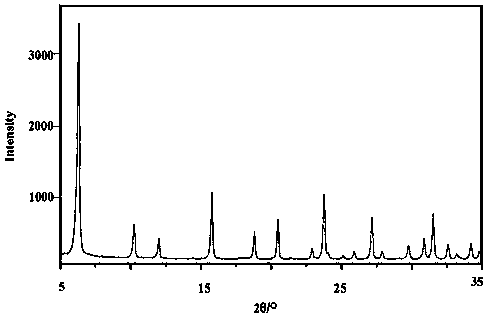

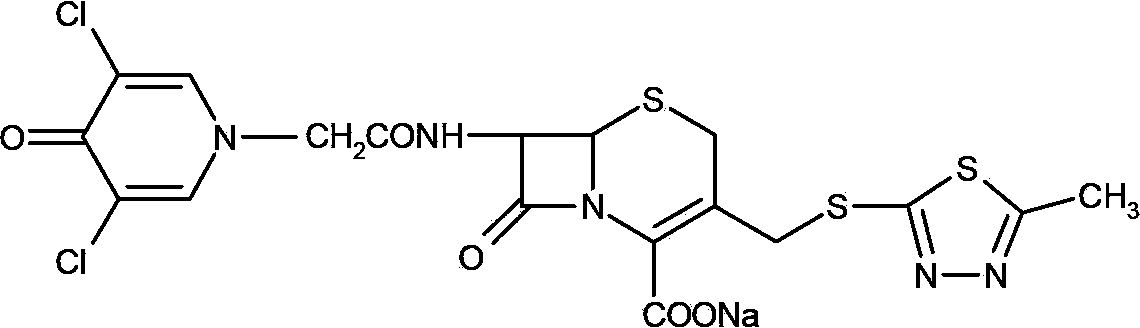

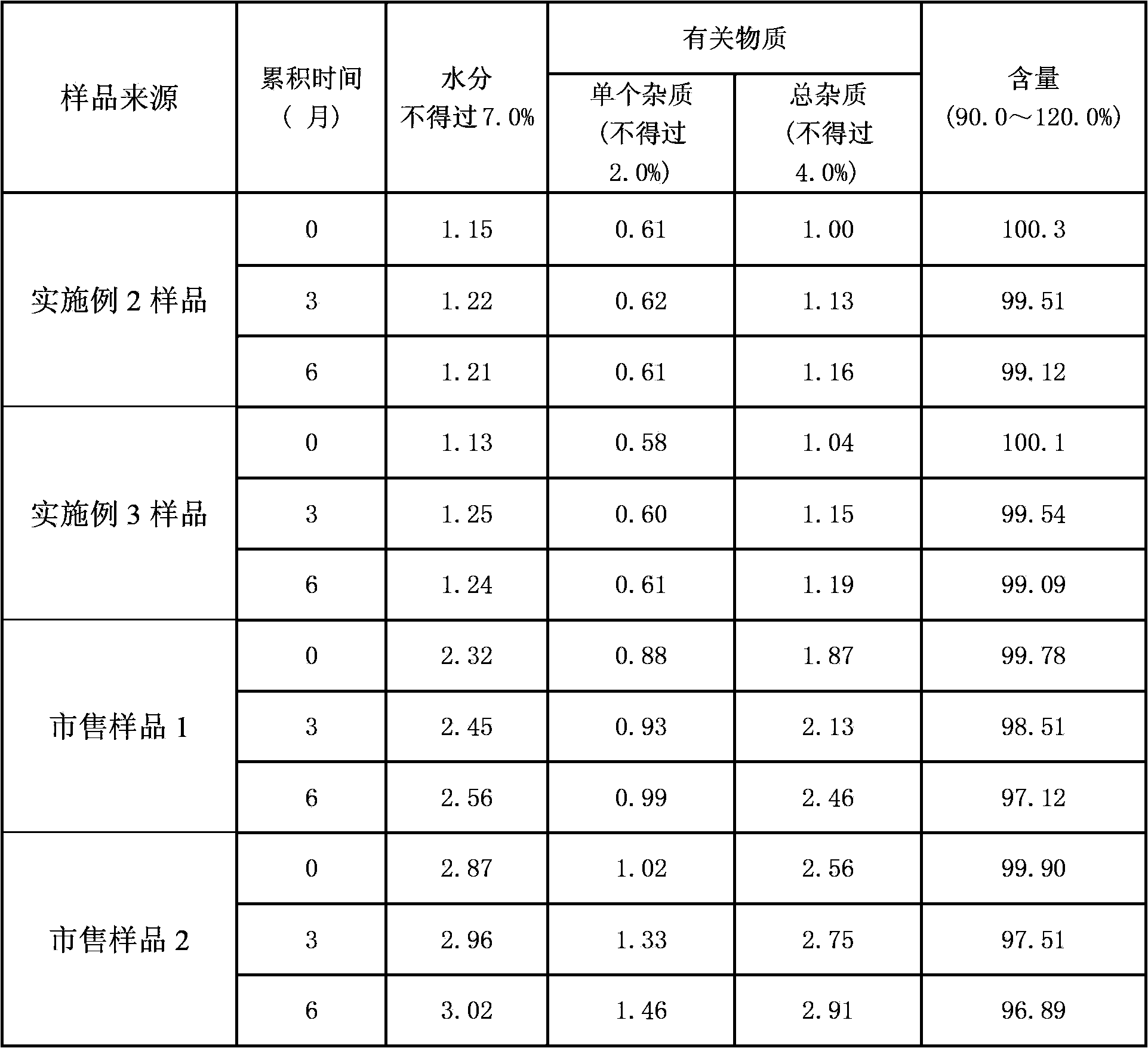

Cefuroxime sodium crystal compound and preparation method thereof

InactiveCN107586304ACases to prevent coalescenceHigh purityOrganic chemistryOrganic solventCefuroxime Sodium

The invention relates to the field of medicines, and relates to a new crystal form of cefuroxime sodium, and a preparation method thereof. The preparation method of the cefuroxime sodium crystal formsample comprises the following steps: dissolving crude cefuroxime sodiumin water, adding an organic solvent for crystallization into the above obtained organic phase, crystallizing the cefuroxime sodium under an ultrasonic condition, and filtering the obtained crystals to obtain the cefuroxime sodium. Ultrasonic waves have a strong orientation effect, has a ripple effect needed by the enhancementof the formation of critical crystal nuclei, can accelerate the crystallization process, allows the crystal nuclei to be fast produced, and can prevent coalescence during the growth of the crystals, to the cefuroxime sodium crystal form sample has the advantages of high purity, good stability, good fluidity, and suitableness for being sub-packaged. The method has the advantages of high yield in the production process, simplicity, easiness in control, low preparation cost, and good safety and reliability.

Owner:ZHEJIANG YONGNING PHARMA

Preparation method of europium oxide (EUO) type molecular sieve

ActiveCN102040230BImprove solubilityPromote generationCrystalline aluminosilicate zeolitesOrganosolvEuropium

Owner:CHINA PETROLEUM & CHEM CORP +1

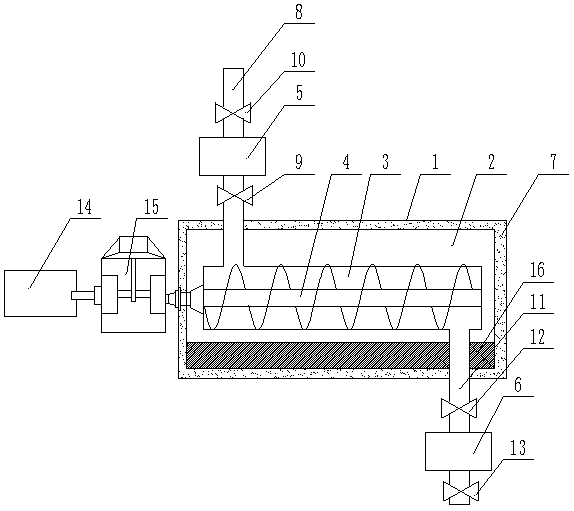

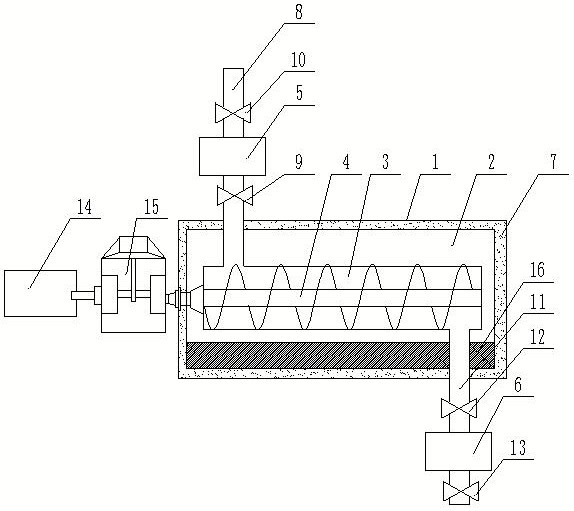

Method for preparing zeolite molecular sieve through quick crystallization of dry glue

ActiveCN110156045AUniform coordinationPromote nucleation growthFaujasite aluminosilicate zeoliteMolecular sieveCrystallinity

The invention discloses a method for preparing a zeolite molecular sieve through quick crystallization of dry glue, and relates to the field of molecular sieve solid phase synthesis. The method specifically comprises the following steps: adding an aluminum source and a fluoride into a silicon-aluminum type molecular sieve mother solution for crystallizing to obtain a silicon-aluminum type molecular sieve guiding agent; adding an alkali source, a silicon source, a template agent R and deionized water into the silicon-aluminum type molecular sieve guiding agent, uniformly carrying out mixing, and then carrying out drying to obtain dry glue powder; and crystallizing the dry glue powder in a steam atmosphere in a continuous crystallization kettle to obtain the zeolite molecular sieve, whereinthe crystallization time is 2-10 hours. The guiding agent disclosed by the invention is obtained by secondary crystallization, and is high in activity and strong in guiding action, so that the usage amount of the template agent can be reduced, crystallinity can be improved, generation of hybrid crystal phases formed by solid-phase synthesis is avoided, and the crystallization period is shortened.The continuous crystallization kettle can be used for continuous production without need of cooling and pressure relief, so that the required crystallization time is short, and efficiency and yield are high. The prepared zeolite molecular sieve is good in stability, high in crystallinity and high in silicon-aluminum ratio.

Owner:TAIYUAN DACHENG ENVIRONMENTAL ENERGY CHEM TECH

Synthetic method with MWW structure si/b molecular sieve

ActiveCN102874834BReduce usageAvoid pollutionCrystalline aluminosilicate zeolitesMolecular sieveSevere toxicity

The invention relates to a synthetic method of an MWW structured Si / B molecular sieve and mainly solves problems of severe toxicity of a template or complex preparation in the prior art. The synthetic method provided by the invention comprises the following steps: mixing a boron source, a silicon source, alkaline MOH, a template R and water, wherein the mol ratio of the mixture is B2O3:SiO2:OH-:R:H2O=(0.01-1.00):1:(0.02-0.30):(0.01-0.50):(5-50); carrying out hydrothermal crystallization on the above mixture at the temperature of 100-200 DEG C for 1-10 days; separating, washing and drying to obtain the MWW structured Si / B molecular sieve, wherein the template R is diethyldimethylammonium hydroxide. The technical scheme can be applied in industrial production of the MWW structured Si / B molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

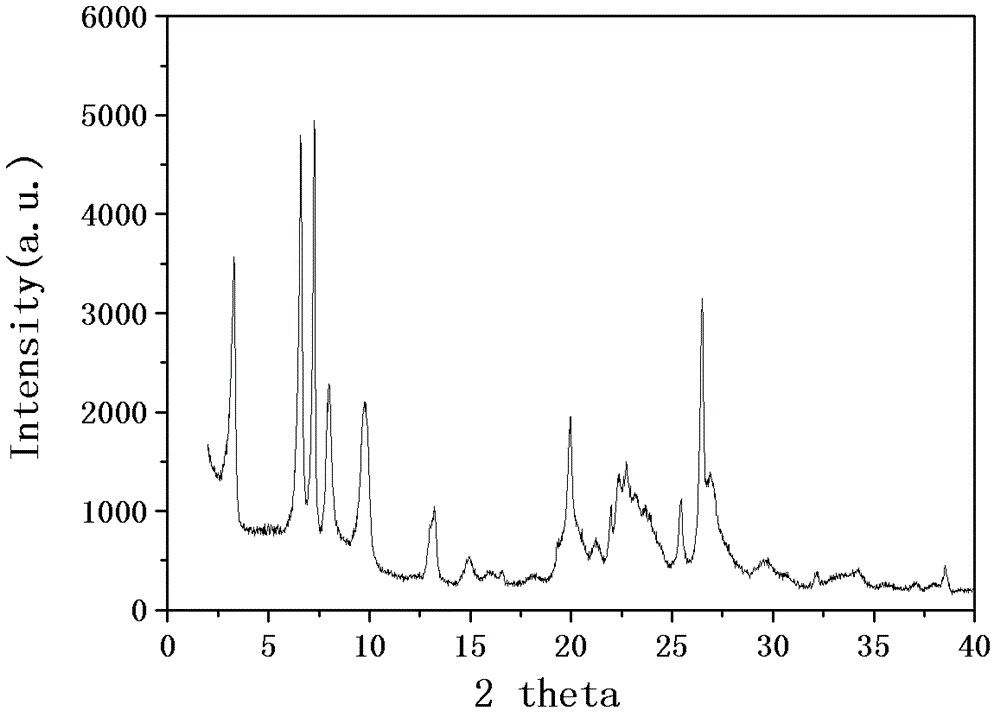

Preparation method for cefazedone sodium with low water content

The invention relates to a preparation method for cefazedone sodium with low water content. The method includes the following steps: performing salifying: placing cefazedone and sodium methoxide into dried methyl alcohol for a salifying reaction, and cooling a reaction solution to 10-30DEG C when the cefazedone is completely dissolved; decoloration: adding activated carbon into the reaction solution, stirring for decoloration, filtering out the activated carbon, and then performing ultrafiltration; crystallization; and drying: filtering and washing filter cake to obtain the cefazedone sodium with low water content. According to the method, the cefazedone and sodium methoxide are placed into the dried methyl alcohol for the salifying reaction so as to obtain cefazedone sodium with low water content, and simultaneously, ultrafiltration and ultrasonic crystallization technologies are adopted to produce the cefazedone sodium which is low in water content, few in impurities, uniform in particles, good in liquidity and high in stability.

Owner:天津新丰制药有限公司

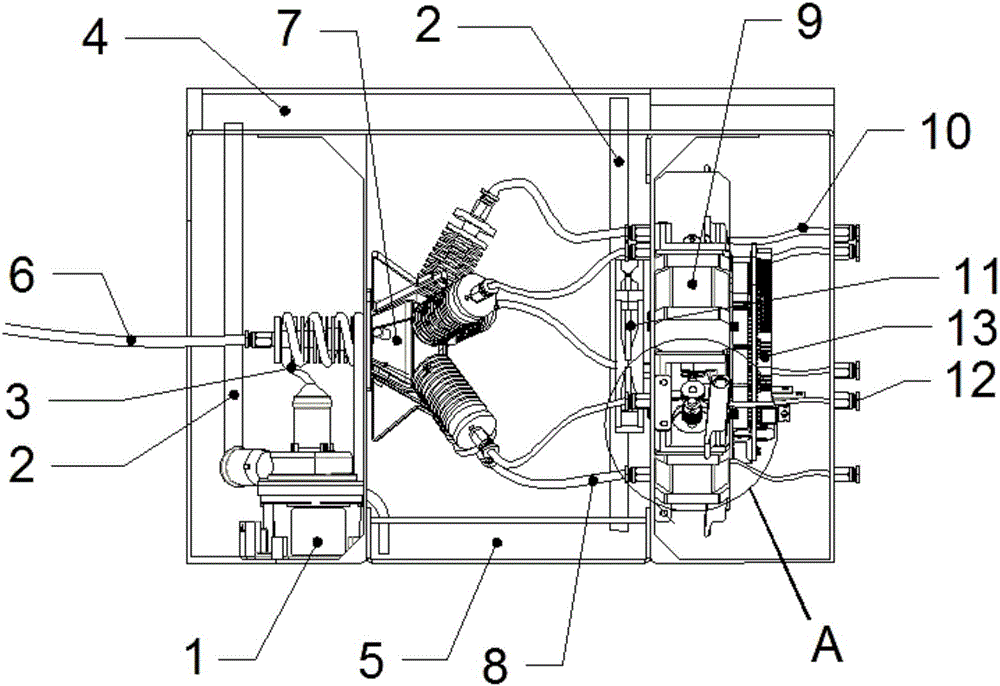

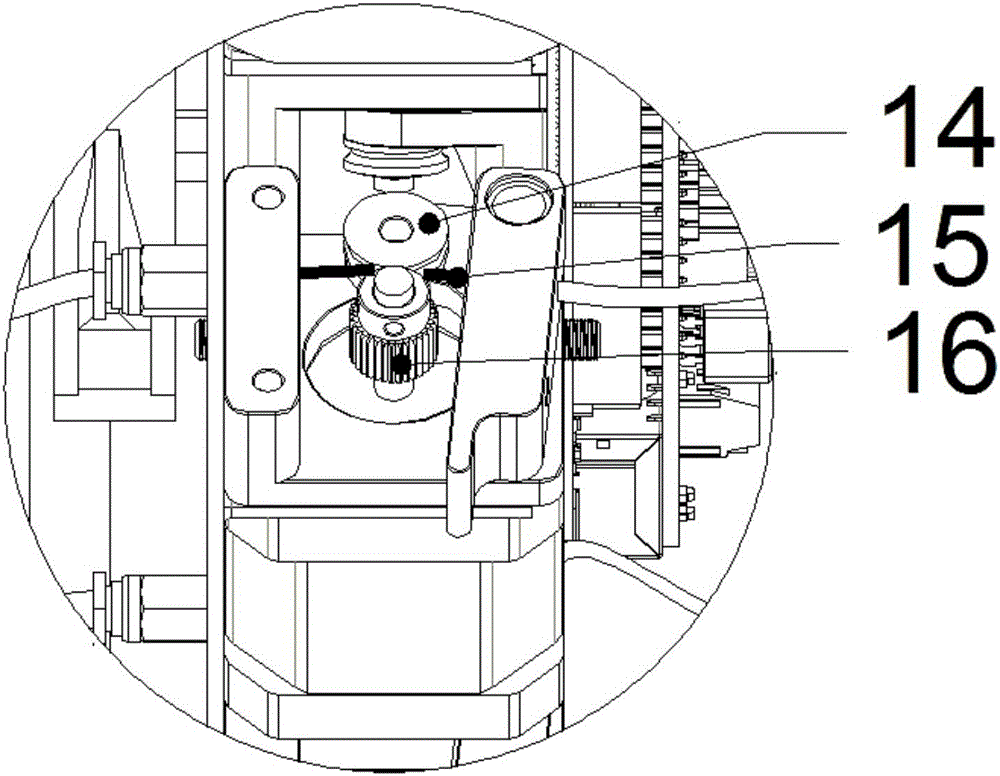

FDM-3D printer external-connected color mixer

PendingCN106738892ASmall footprintLow costManufacturing heating elements3D object support structuresWater cyclingWater tanks

The invention provides an FDM-3D printer external-connected color mixer. The FDM-3D printer external-connected color mixer comprises a box frame, a wire feeding device, a melting chamber, a wire discharge device and a cooling device; a feeding runner of the melting chamber is connected with feeding throat pipes; the wire feeding device is connected with the feeding throat pipes through wire feeding guide pipes; a discharge runner of the melting chamber is connected with a wire discharge guide pipe through a discharge throat pipe; the melting chamber is fixed in the box frame through a fixing device; two ends of a cooling pipe respectively communicate with a water pump and a lower water tank; and the water pump conveys water in the lower water tank into the cooling pipe, and drives the water in the lower water tank and water in an upper water tank to circulate. The FDM-3D printer external-connected color mixer uses the wire feeding device for controlling the wire feeding speed of wires with various colors and realizes different wire feeding quantities of wires with five colors of three primary colors, black and white; five mixed wires are fed to a wire melting and discharge device for heating and melting by the guide pipes to realize mixing and color matching so as to form different mixed colors; and the FDM-3D printer external-connected color mixer saves the space occupied by a printer, meanwhile, finishes upgrading of traditional equipment, and saves the cost.

Owner:北京交通大学海滨学院

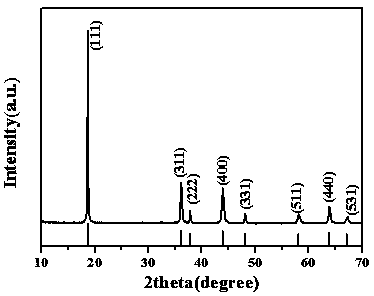

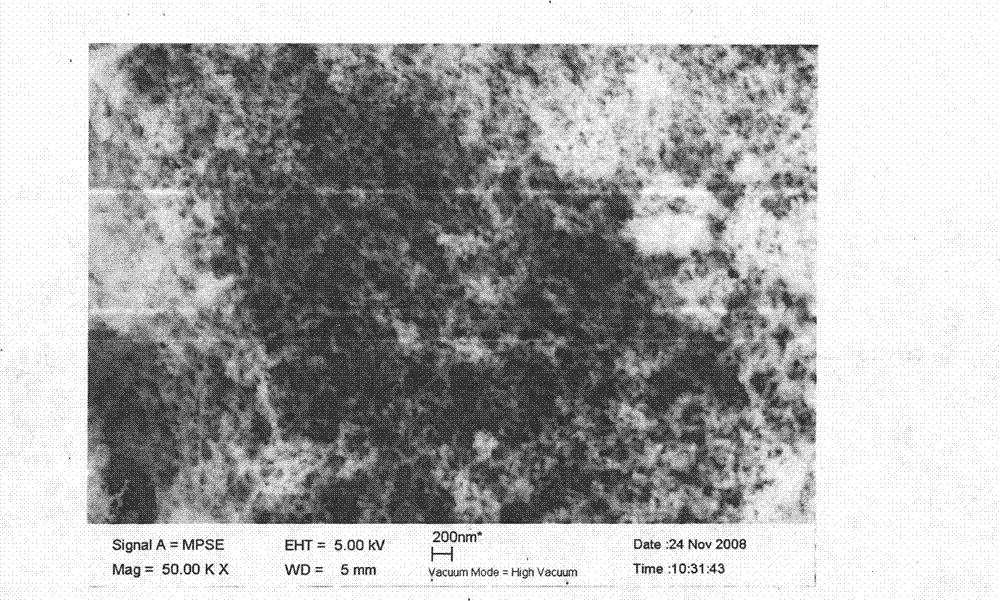

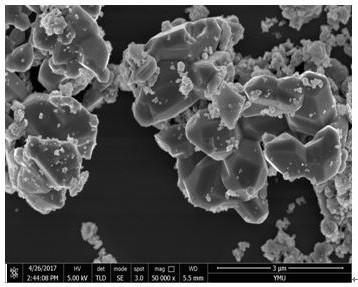

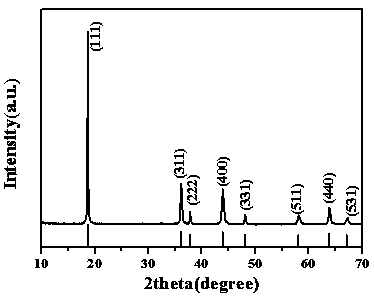

Preparation method of spinel lithium manganate

InactiveCN107739057ARapid crystallizationShort reaction timeCell electrodesManganates/permanganatesMANGANESE ACETATESpontaneous combustion

The invention relates to a preparation method of spinel lithium manganate. The preparation method comprises the following steps: uniformly mixing lithium or manganese acetate or nitrate, then heatingunder the temperature of 102-108 DEG C, and treating for 5-30 minutes in a microwave oven under microwave power of 360-900W and microwave power density of 90-250W / m<2> to obtain spinel lithium manganate. Through application of the inside heating characteristic of microwave heating, the whole system reaches the ignition temperature simultaneously; the system rapidly carries out spontaneous combustion to release high heat; lithium manganate can be rapidly crystallized and shaped by means of the heat released by the combustion reaction; through microwave heating, the reaction time is greatly reduced, and a large amount of energy consumption is reduced; meanwhile, the method is simple in process and low in cost, is suitable for popularization, and can achieve efficient industrial mass production of lithium manganate.

Owner:YUNNAN MINZU UNIV

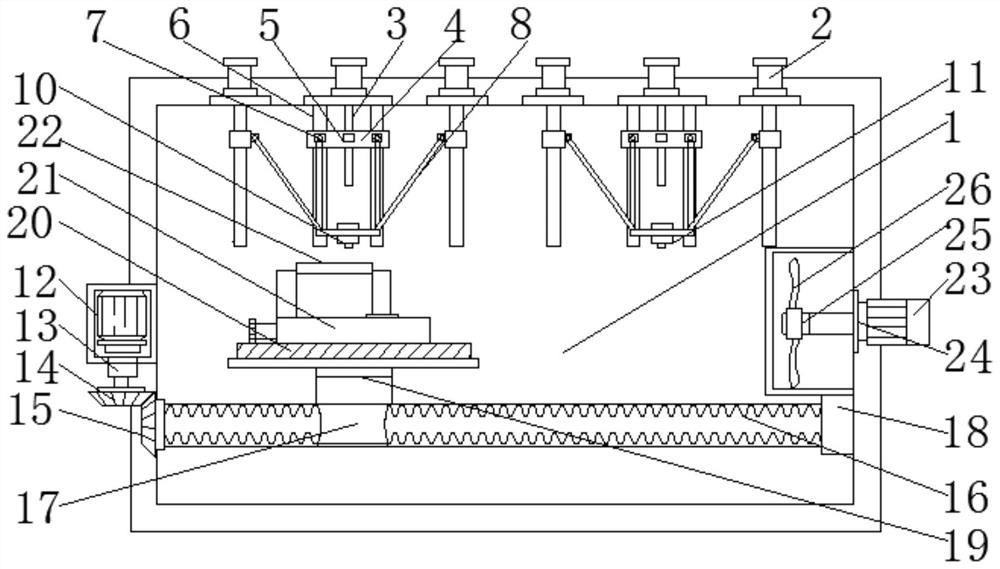

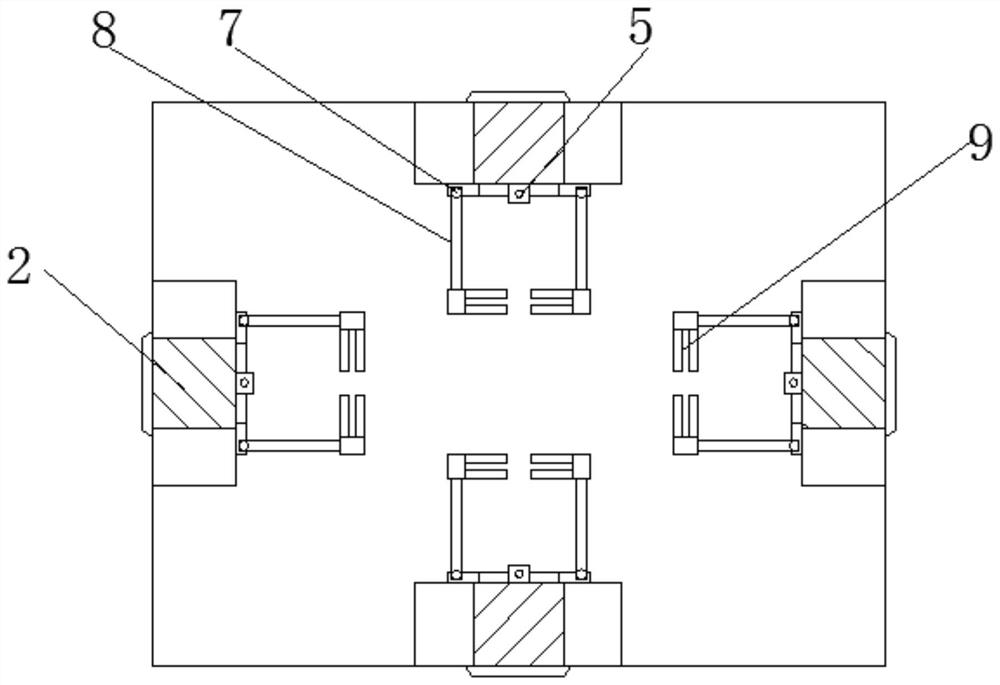

A film coating device for preventing offset in semiconductor production

ActiveCN110773381BAvoid offsetEasy to adjustPretreated surfacesCoatingsEngineeringMechanical engineering

The invention discloses a coating device for semiconductor production that prevents deviation. A coating device for semiconductor production that prevents deviation includes a device main body, a vertical screw rod, a connecting sleeve, a first rotating shaft, a slot, and a second coating device, a second rotating shaft, a second gear, a first threaded mandrel, a first bearing, a rotating turntable, semiconductors to be processed and fan blades. The upper end of the main body of the device is provided with a first motor. The fixing device provided in the semiconductor production coating device for preventing deviation, artificially turns the knob on the fixing device to make the second screw mandrel rotate, and the second screw mandrel is threadedly connected with the first clamping block, so that the first screw mandrel is screwed. The clamping block moves on the horizontal plane, driving the sliding block to move on the slide rail, so as to facilitate the adjustment of the position of the first clamping block. By adjusting the position of the first clamping block, it is convenient to adjust the distance between the first clamping block and the second clamping block, so that Clamp the semiconductor to be processed to prevent the semiconductor to be processed from shifting.

Owner:江苏钰晶半导体科技有限公司

A method for preparing zeolite molecular sieves by rapid crystallization of dry glue

ActiveCN110156045BUniform coordinationPromote nucleation growthFaujasite aluminosilicate zeoliteCrystallinitySolid-phase synthesis

Owner:TAIYUAN DACHENG ENVIRONMENTAL ENERGY CHEM TECH

Method for separating and extracting battery-grade lithium carbonate and rubidium and cesium salts from lepidolite

ActiveCN110550644BIncrease contentReduce contentSulfate/bisulfate preparationRubidium/caesium/francium compoundsLithium carbonatePhysical chemistry

Owner:河北铸合集团兴隆县矿业有限公司

Master batch for polyester filament production and its preparation method and application

ActiveCN107778785BTight textureHigh mechanical strengthConjugated synthetic polymer artificial filamentsArtifical filament manufacturePolyesterMasterbatch

The invention discloses master batches for production of polyester filaments, and a preparation method and application thereof. The problems that the traditional regenerated master batches cannot havethe characteristics of properties close to those of the original master batches and low cost are solved. According to the key point of the technical scheme, the master batches comprise the followingcomponents in parts by weight: 60 to 70 parts of waste plastic bottle sections, 10 to 40 parts of original master batches, 1 to 3 parts of defoaming master batches, 1 to 5 parts of compatibilizer and0.1 to 1 part of accelerant. The master batches prepared by the above formula have low cost, have excellent properties close to those of the original master batches, can be compatible with the waste plastic bottle sections well in the production of the polyester filaments and enables the polyester filaments to be uniform in character and color.

Owner:苏州市苏宏塑料有限公司

Porous calcium silicate filter material for water treatment

InactiveCN100467095CInhibition formationImprove filtering effectFiltration separationSilicon compoundsCalcium silicateDecomposition

A porous calcium silicate filter material used in water treatment is made from coagulation, steam foaming and high-temperature high-pressure steam treatment, characterized in that it uses domestic powder quartz (SiO2), general silicate cement, powder calcium oxide (CaO), power calcium sulfate (CaSO4), and aluminum powder (Al). The inventive product has strong adsorption and decomposition on organic, phosphor, and nitrogen, to be used in small life sewage treatment system.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

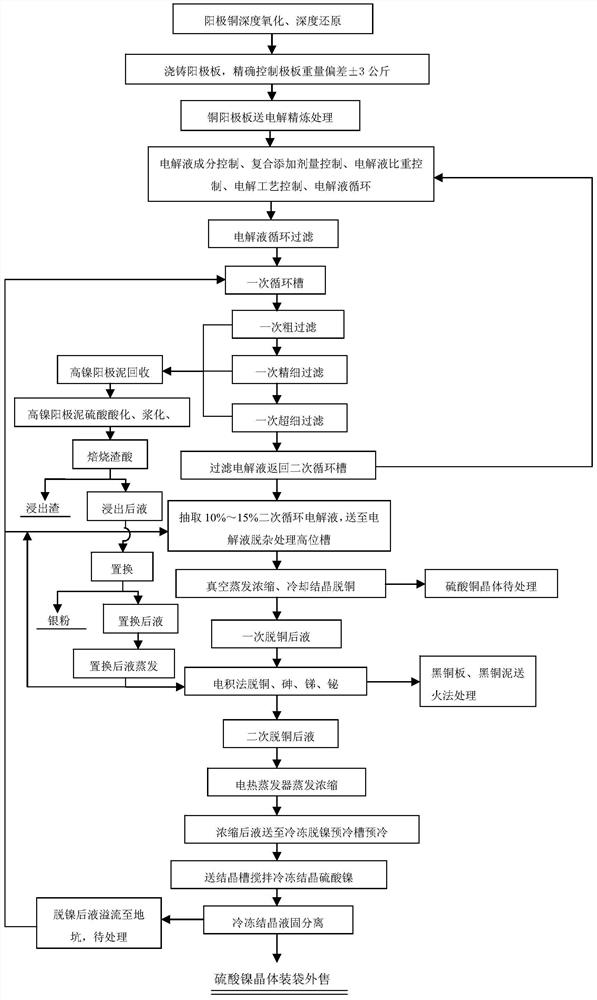

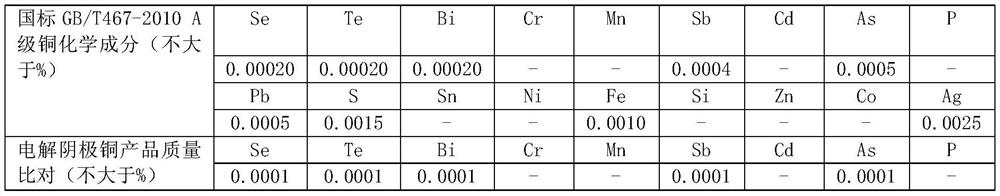

A method for recovering nickel sulfate from copper smelting high-impurity high-nickel anode copper plate

ActiveCN110079826BFacilitate electrolysisEasy to remove impuritiesPhotography auxillary processesNickel sulfatesElectrolytic agentCopper

Owner:KUNMING UNIV OF SCI & TECH +1

Method for synthesizing monodisperse samarium-doped rare earth cerium oxide nanocrystal

InactiveCN101891236BHigh reactivityUniform particle sizeNanostructure manufactureRare earth metal compoundsCerium nitrateRare earth

Owner:南京睿磐内尔环保复合新材料有限公司

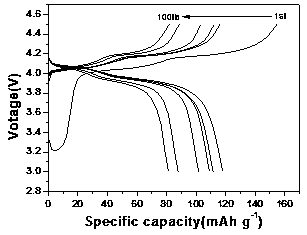

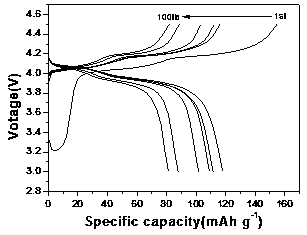

Solar battery

InactiveCN107146848AReduce the temperatureImprove photoelectric conversion rateFinal product manufactureSolid-state devicesPerovskite solar cellElectrical battery

The invention relates to a solar battery. The solar battery comprises a glass substrate and a compact layer, a perovskite layer, a hole transport layer and a metal electrode layer which are stacked on the substrate in sequence. The solar battery has the advantages as follows: by virtue of the perovskite solar battery with the structure, the preparation temperature of the perovskite battery can be greatly lowered; and meanwhile, a CH<3>NH<3>PbI<3> material can be rapidly generated by crystallization without being heated, so that the photoelectric conversion rate and stability of the battery are further improved remarkably.

Owner:RUGAO XIAYUAN SCI & TECH ESTABLISH A BUSINESS SERVICES CO LTD

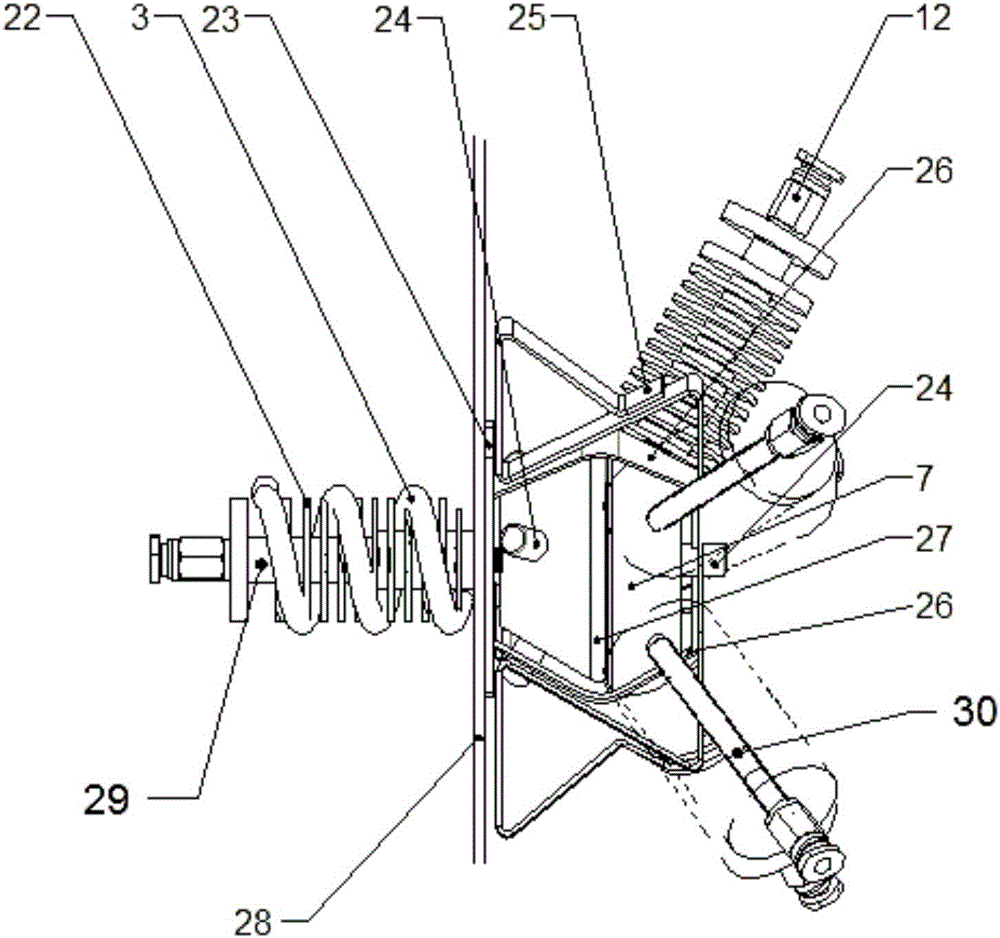

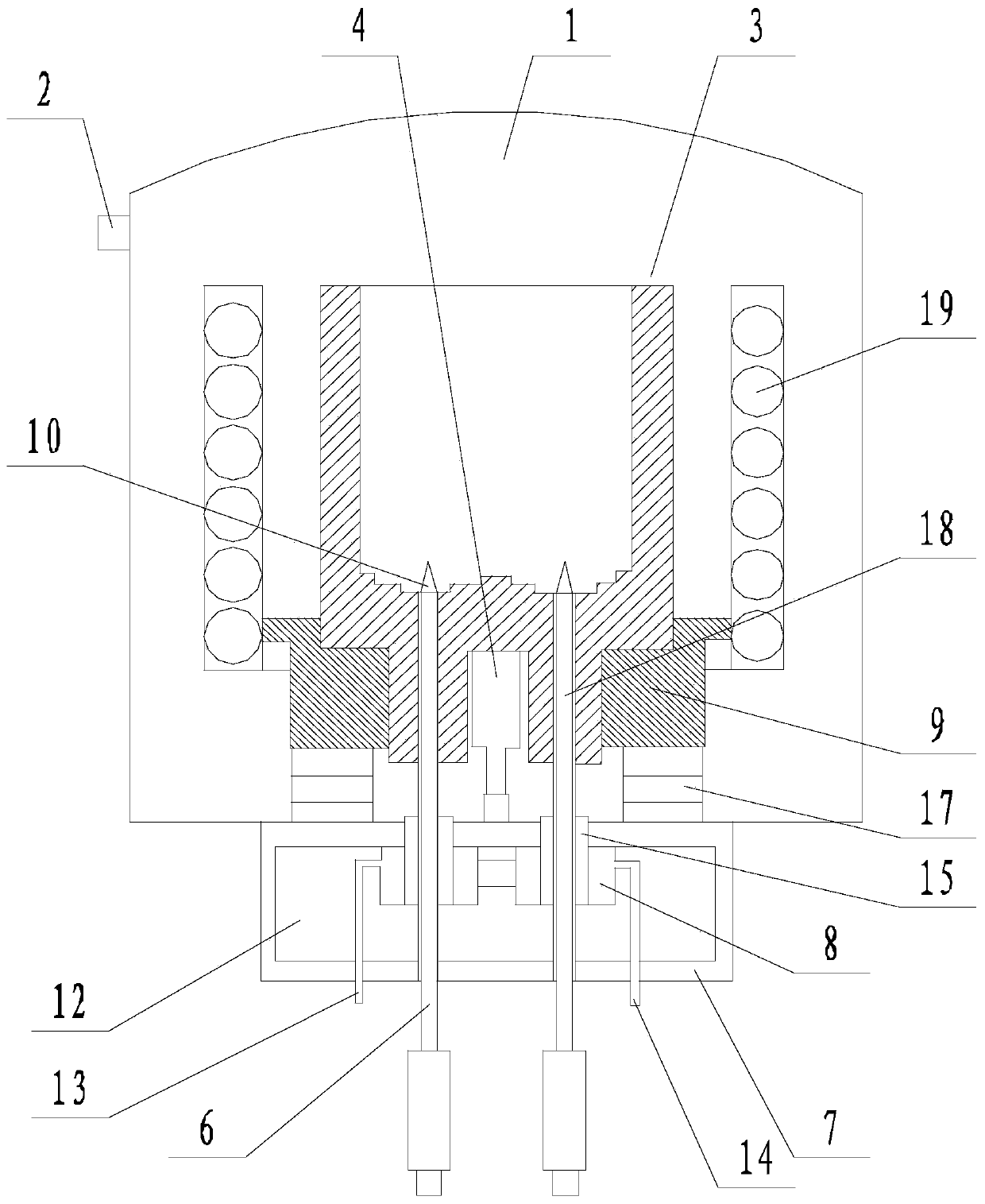

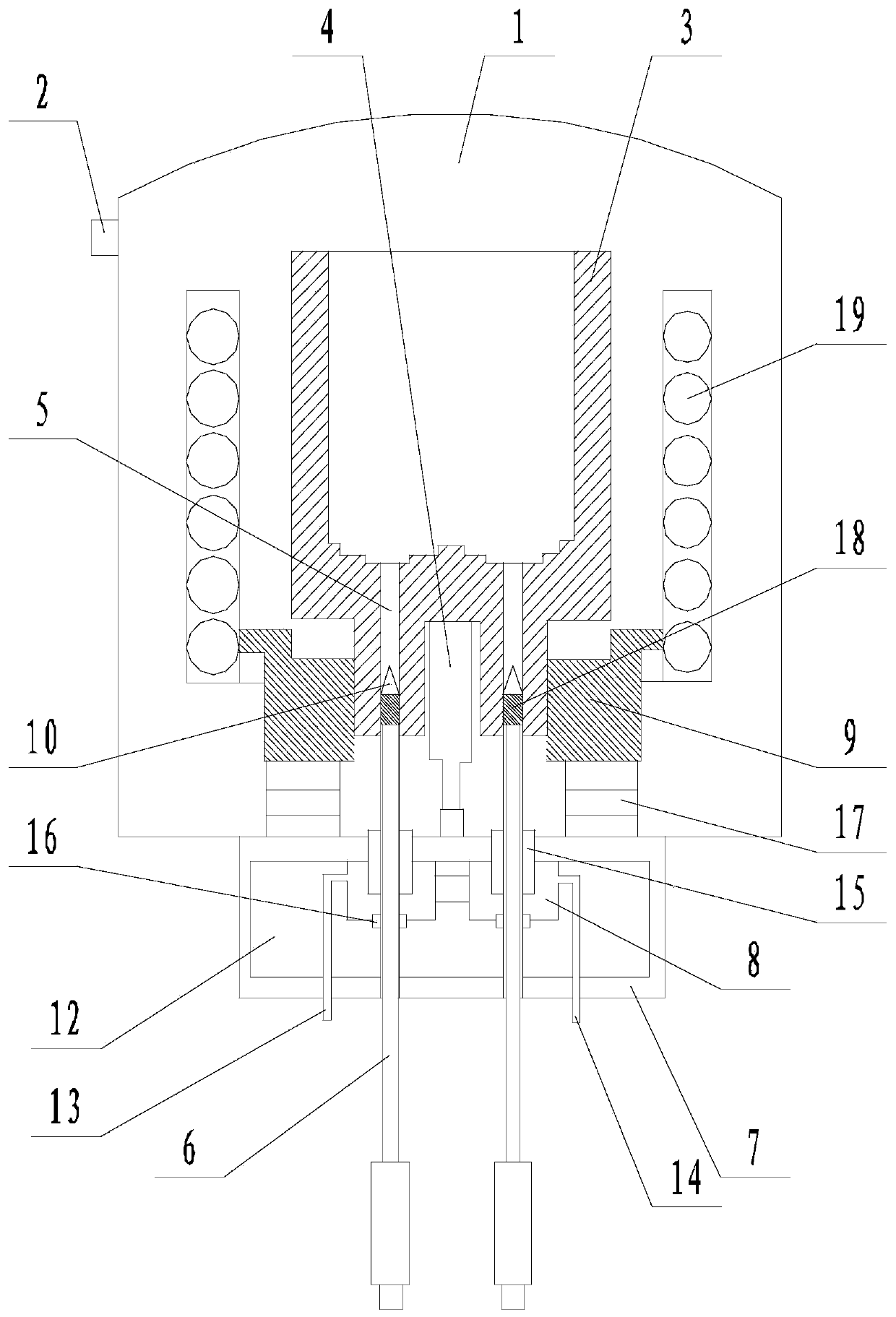

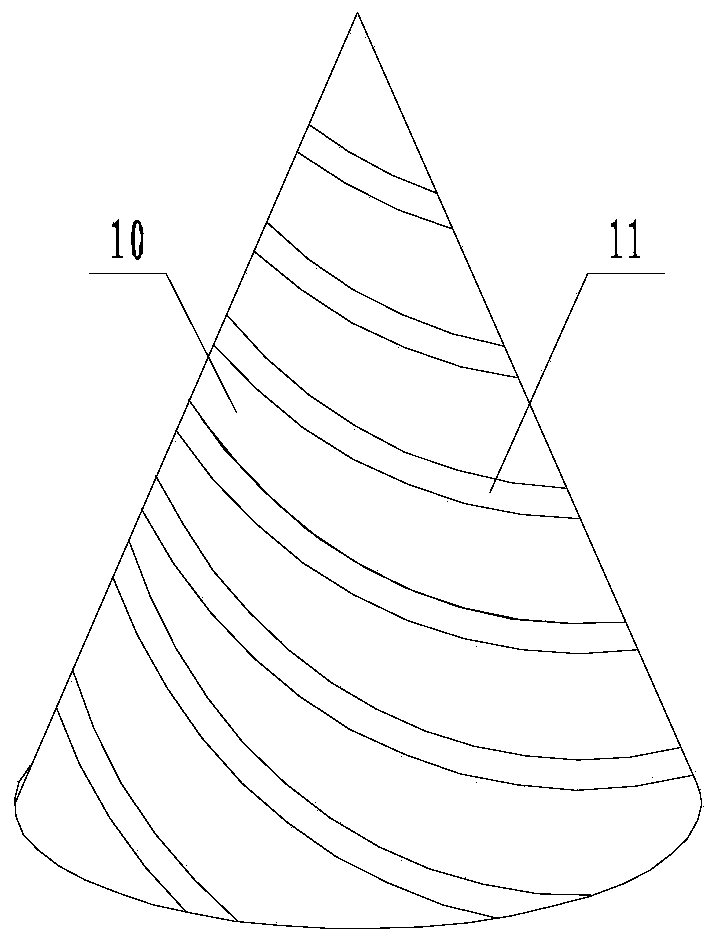

A directional drawing and discharging vacuum melting furnace

ActiveCN109556401BIncrease the lengthIncrease displacementSiliconCharge manipulationCrucibleWater cooling

The invention discloses a directional drawing discharging type vacuum melting furnace. The directional drawing discharging type vacuum melting furnace comprises a furnace body with a vacuum suction port, wherein a crucible is arranged in the furnace body, induction heating coils are located outside the crucible, a pushing device with the output end facing upwards is arranged on the bottom surfaceof the interior of the furnace body, the output end of the pushing device is in contact with the bottom of the crucible, and discharge pipes penetrating through the crucible are arranged at the bottomof the crucible; drawing rods are arranged in the discharge pipes, a crystallization chamber is arranged below the furnace body, and water cooling boxes are arranged on the top surface of the interior of the crystallization chamber; the discharge pipes penetrate through the water cooling boxes, and the bottom ends of the discharge pipes penetrate through the crystallization chamber from the bottom surface of the crystallization chamber; crystallization heads are fixedly connected to the tops of the drawing rods, the crystallization heads are small upper-small and lower-big cones, and spiral grooves are formed in the surfaces of the crystallization heads; the directional drawing discharging type vacuum melting furnace further comprises isolation blocks located inside the furnace body, andthe crucible is placed on the isolation blocks. According to the directional drawing discharging type vacuum melting furnace, the problem that industrial silicon often needs secondary molding in use in the prior art is solved, and the purposes that one molding is carried out, secondary molding is not required, and the cost is reduced are realized.

Owner:江苏斯力康科技有限公司

Preparation technology for water-soluble resveratrol particle, and product and application thereof

InactiveCN101759531BChange natureImprove solubilityOrganic chemistryHydroxy compound active ingredientsSolubilityFood additive

The invention relates to a preparation technology for water-soluble resveratrol particles. The preparation technology is that: (1) resveratrol transparent solution is prepared; (2) the prepared resveratrol transparent solution is pumped to the crystallizing kettle of a supercritical fluid crystallizing device; (3) residual chemical solution in a pipeline is flushed after chemical solution is fed; and (4) a pump is shut down, pressure and temperature are regulated to the natural state and the obtained particles are water-soluble resveratrol particles. The diameter of the water-soluble resveratrol particles is 50nm-200nm. X-ray diffraction shows that the particles are in the indefinite state. The water-soluble resveratrol particles can be used in medicines, healthcare foods, feeds, food additives, cosmetics and the chemical field. The invention has the advantages that the nature of indissoluble resveratrol is changed, the water solubility of the resveratrol is obviously improved and the dissolution speed in water is very fast; and since the resveratrol is rapidly precipitated in the supercritical fluid, the finished product is enabled to be loose and the dissolution speed in water is very fast.

Owner:TIANJIN GUONA TECH DEV CO LTD

A kind of preparation method of spinel lithium manganese oxide

InactiveCN107739057BRapid crystallizationShort reaction timeCell electrodesManganates/permanganatesMANGANESE ACETATESpontaneous combustion

The invention relates to a preparation method of spinel lithium manganate. The preparation method comprises the following steps: uniformly mixing lithium or manganese acetate or nitrate, then heatingunder the temperature of 102-108 DEG C, and treating for 5-30 minutes in a microwave oven under microwave power of 360-900W and microwave power density of 90-250W / m<2> to obtain spinel lithium manganate. Through application of the inside heating characteristic of microwave heating, the whole system reaches the ignition temperature simultaneously; the system rapidly carries out spontaneous combustion to release high heat; lithium manganate can be rapidly crystallized and shaped by means of the heat released by the combustion reaction; through microwave heating, the reaction time is greatly reduced, and a large amount of energy consumption is reduced; meanwhile, the method is simple in process and low in cost, is suitable for popularization, and can achieve efficient industrial mass production of lithium manganate.

Owner:YUNNAN MINZU UNIV

A kind of high reliability phase change material and phase change memory and preparation method

ActiveCN110571329BRapid crystallizationSteady OrientationElectrical apparatusCrystallographyElectrical resistance and conductance

The invention discloses a high-reliability phase-change material, which is a superlattice-like phase-change material layer formed by cyclically and alternately stacking a first phase-change material layer and a second phase-change material layer. The first phase-change material layer A superlattice-like interface is formed between the material layer and the second phase-change material layer, and the first phase-change material layer is Sb 2 Te 3 As an induction layer, the second phase change material layer is Ge 15 Te 85 , there are at least three layers of alternating overlapping layers. Amorphous Sb 2 Te 3 The crystallization of the layer requires low energy and is easy to form a stable lattice orientation, so the selected Sb2Te3 layer can be used as an induction layer to make the amorphous Ge 15 Te 85 The layer has a higher phase change speed during the phase change process, which can promote the rapid crystallization of the entire phase change material; and the selected Ge 15 Te 85 In the energy band structure of the layer, the defect state is mainly located in the local state of the band tail, rather than the defect energy level near the Fermi level in the band gap, and the resistance drift will not occur due to the relaxation of the defect energy level, so in the phase During the transformation process, it has a higher phase transformation speed.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com