A method for recovering nickel sulfate from copper smelting high-impurity high-nickel anode copper plate

A high-nickel anode and nickel sulfate technology, applied in the field of metallurgy and chemical industry, can solve the problems of increase of suspended anode sludge, insufficient copper grade, long "particles" on the surface of cathode copper, etc. Liquid specific gravity and acidity, the effect of optimizing purification and impurity removal parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

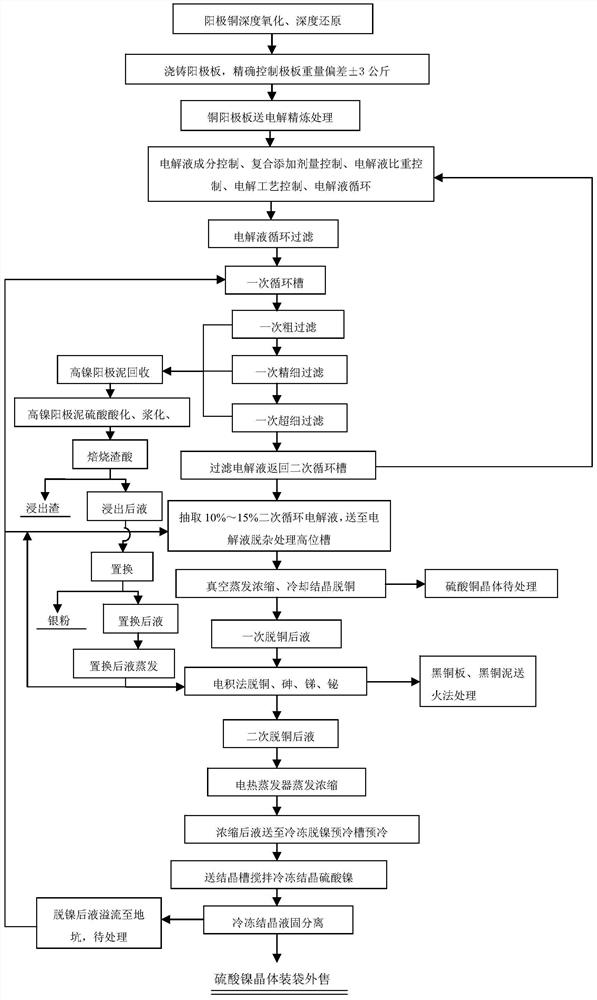

[0035] Such as figure 1 As shown, a method for recovering nickel sulfate from copper smelting high-impurity high-nickel anode copper plate according to the present invention is to adopt anode copper deep oxidation and deep reduction, combined with anode copper electrolytic refining process parameter control, to realize high Nickel sulfate by-product is recovered from high-impurity nickel anode copper plate. Specific steps are as follows:

[0036] (1) Refining copper to smelt high-impurity and high-nickel anode copper plates, deeply oxidize until the oxygen content of the anode copper reaches 12000-15000ppm, and then perform deep reduction on the deeply oxidized anode copper, reduce the oxygen content of the anode copper to 500-800ppm, and then cast it into High-impurity and high-nickel anode copper plate, the weight deviation of the casting anode copper plate is controlled within the range of ±3 kg; the high-impurity high-nickel anode copper plate contains 0.15-0.30% of As, 0...

Embodiment 2

[0053] A method for recovering nickel sulfate from copper smelting high-impurity high-nickel anode copper plate, the specific steps are as follows:

[0054](1) Refining copper to smelt high-impurity and high-nickel anode copper plate, deeply oxidize the anode copper to 12000ppm of oxygen, and then deeply reduce the deeply oxidized anode copper, reduce the copper content of the anode copper to 800ppm, and reduce the deeply reduced anode Copper is cast into copper anode plates, and the weight of the cast copper anode plates is controlled within the range of 380±3 kg, and the anode plates exceeding the weight control range are isolated and classified for disposal. The high-impurity high-nickel anode copper plate contains 0.15% As, 0.09% Sb, 0.10% Bi, 0.10% Pb, 0.8% Ni, and the balance is Cu and a small amount of other unavoidable impurities;

[0055] (2) Electrolysis of high-impurity high-nickel anode copper plate, the electrolyte composition Cu 2+ 45g / L, H 2 SO 4 is 180g / L, C...

Embodiment 3

[0072] A method for recovering nickel sulfate from copper smelting high-impurity high-nickel anode copper plate, the specific steps are as follows:

[0073] (1) Refining copper to smelt high-impurity and high-nickel anode copper plates, deeply oxidize the anode copper to 15,000ppm oxygen, and then deeply reduce the deeply oxidized anode copper, reduce the copper content of the anode copper to 600ppm, and oxidize the deeply reduced anode Copper is cast into copper anode plates, and the weight of the cast copper anode plates is controlled within the range of 370±3 kg, and the anode plates exceeding the weight control range are isolated and classified; the composition of high-impurity and high-nickel anode copper plates contains As 0.16%, Sb 0.12 %, Bi0.09%, Pb 0.15%, Ni 1.9%, the balance is Cu and a small amount of other unavoidable impurities;

[0074] (2) Electrolysis of high-impurity high-nickel anode copper plate, the electrolyte composition Cu 2+ 40g / L, H 2 SO 4 is 200g / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com