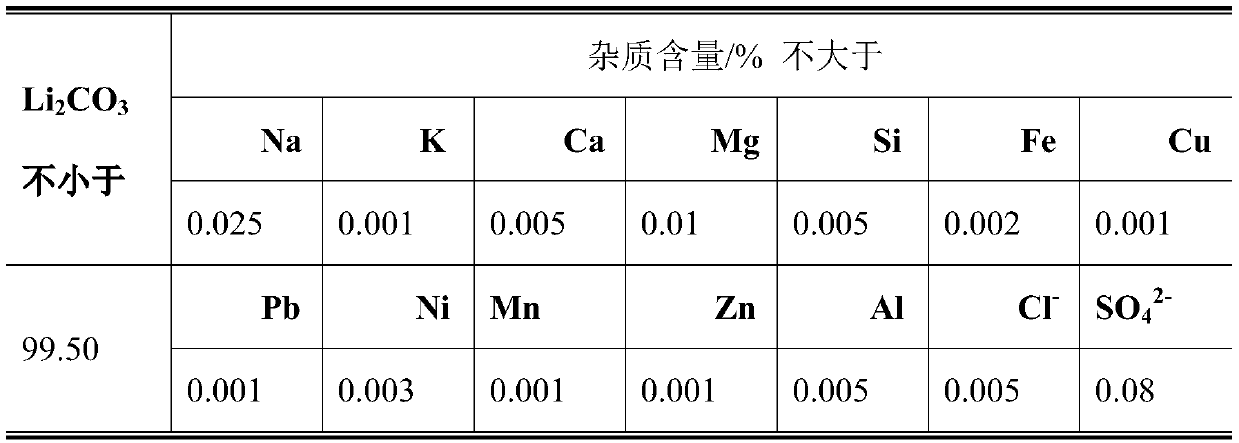

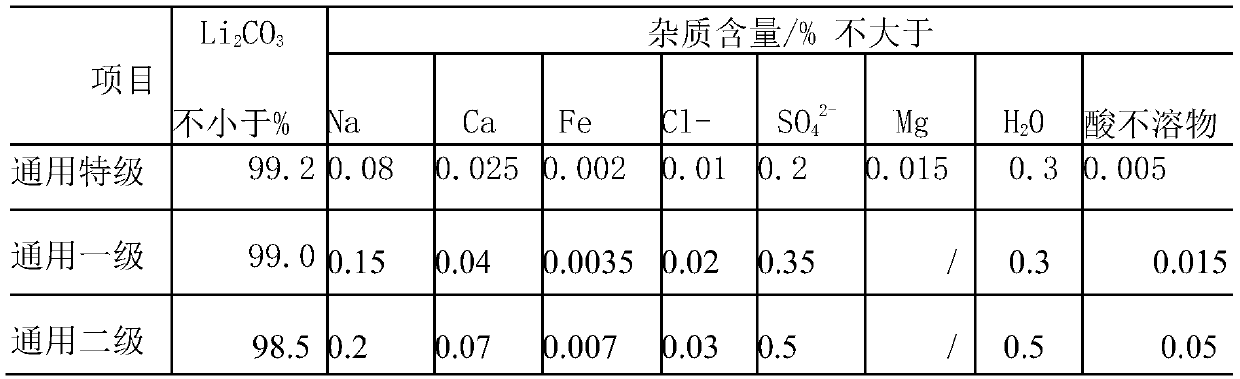

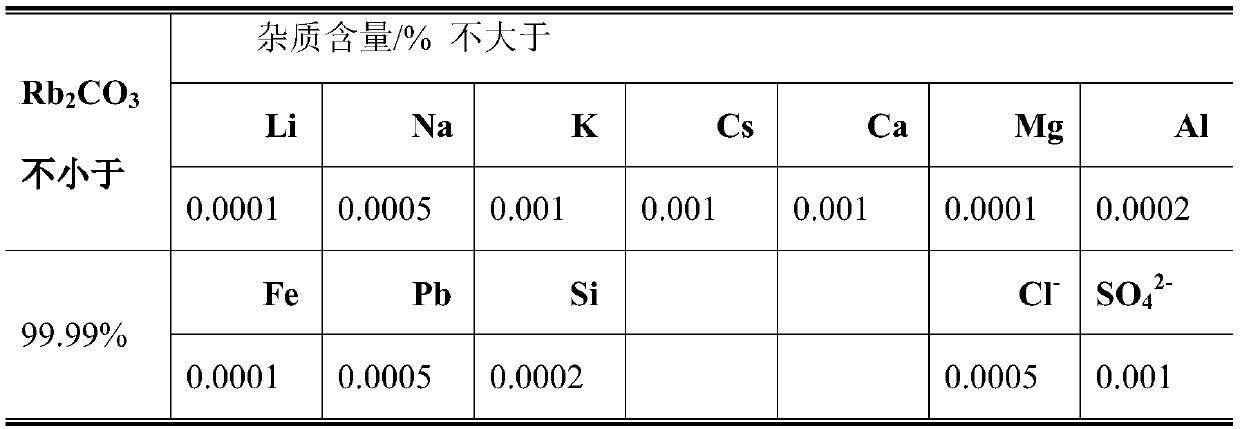

Method for separating and extracting battery-grade lithium carbonate and rubidium and cesium salts from lepidolite

A technology of lithium carbonate and lepidolite, applied in lithium carbonate;/acid carbonate, chemical instruments and methods, rubidium/cesium/francium compounds, etc., can solve the difficulty in realizing industrialized production, the ratio of input to output Insufficient, low comprehensive production efficiency and other problems, to achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The concentrations involved in the examples are all mass concentrations, and the descriptions of the above-mentioned embodiments shall prevail for the unspecified parts in the following examples.

[0067] The preparation method of the present invention is to carry out controllable directional reconstruction to the lepidolite mineral structure under the condition of variable temperature and normal pressure, so that alkali metals (lithium, potassium, sodium, rubidium, cesium) can be extracted from the lepidolite mineral in the form of soluble salts. Released; various circulation methods such as leaching solution circulation and lithium extraction mother liquor circulation are adopted to control the concentration of potassium, sodium, rubidium and cesium in the mother liquor of each process, and through the orderly combination of evaporation concentration and crystallization technologies, lithium, potassium, and sodium Effective separation and comprehensive utilization of r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com