Preparation method of spinel lithium manganate

A type of lithium manganate and spinel technology, applied in the field of preparation of spinel type lithium manganate, can solve the problems of slow reaction rate and high energy consumption, and achieve the effects of low cost, reduced energy consumption and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

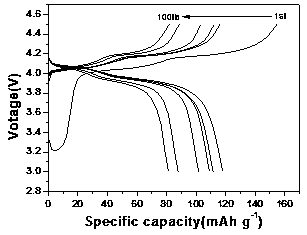

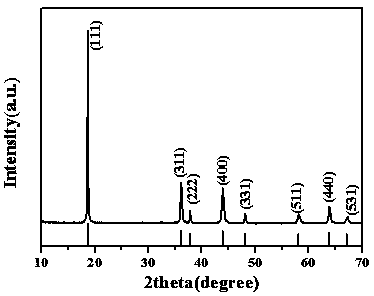

Embodiment 1

[0052] The implementation steps of this embodiment are as follows: according to the molar ratio of lithium and manganese 1:1.8, the Mn(AC) 2 4H 2 O and LiNO 3 Put it into an alumina crucible and mix evenly to obtain a mixture, then add concentrated nitric acid and deionized water to the mixture, and mix well to make the NO in the entire reaction system 3 - with Ac - The molar ratio is 1:0.67; then let the reaction system be heated at a temperature of 104°C for 15 minutes in a blast drying oven sold by Shanghai Yiheng Scientific Instrument Co., Ltd. under the trade name electric blast drying oven, during the heating process Stir and mix evenly in the medium, and then in the microwave oven sold by Galanz under the brand name Galanz frequency conversion, the microwave power is 360W and the microwave power density is 130W / m 2 Treated under the conditions for 20 minutes, the gray-black porous porous sample was obtained, and it was determined according to the X-ray diffraction a...

Embodiment 2

[0055] The implementation steps of this embodiment are as follows: according to the molar ratio of lithium and manganese 1:2.2, the Mn(AC) 2 4H 2 O and LiNO 3 Put it into an alumina crucible and mix evenly to obtain a mixture, then add concentrated nitric acid and deionized water to the mixture, and mix well to make the NO in the entire reaction system 3 - with Ac - The molar ratio is 1:1.90; then let the reaction system be heated at a temperature of 106° C. for 20 minutes in a blast drying oven sold by Shanghai Yiheng Scientific Instrument Co., Ltd. under the trade name electric blast drying oven. Stir and mix evenly in the medium, and then in the microwave oven sold by Galanz Company under the brand name Galanz Inverter Microwave Oven, microwave power 900W and microwave power density 200W / m 2 Treated under the conditions for 10 minutes, the gray-black porous porous sample was obtained, and it was determined according to the X-ray diffraction analysis described in this sp...

Embodiment 3

[0058] The implementation steps of this embodiment are as follows: according to the molar ratio of lithium and manganese 1:2.0, the Mn(AC) 2 4H 2 O and LiNO 3 Put it into an alumina crucible and mix evenly to obtain a mixture, then add concentrated nitric acid and deionized water to the mixture, and mix well to make the NO in the entire reaction system 3 - with Ac - The molar ratio was 1:0.90; then the reaction system was heated at a temperature of 102°C for 16 minutes in a blast drying oven sold by Shanghai Yiheng Scientific Instrument Co., Ltd. under the trade name Electric Blast Drying Oven. Stir and mix evenly in the medium, and then in the microwave oven sold by Galanz Company under the brand name Galanz Inverter Microwave Oven, microwave power 540W and microwave power density 90W / m 2 Treated under the conditions for 30 minutes, the gray-black porous porous sample was obtained, and it was determined according to the X-ray diffraction analysis described in this specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com