Patents

Literature

107results about How to "Steady Orientation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

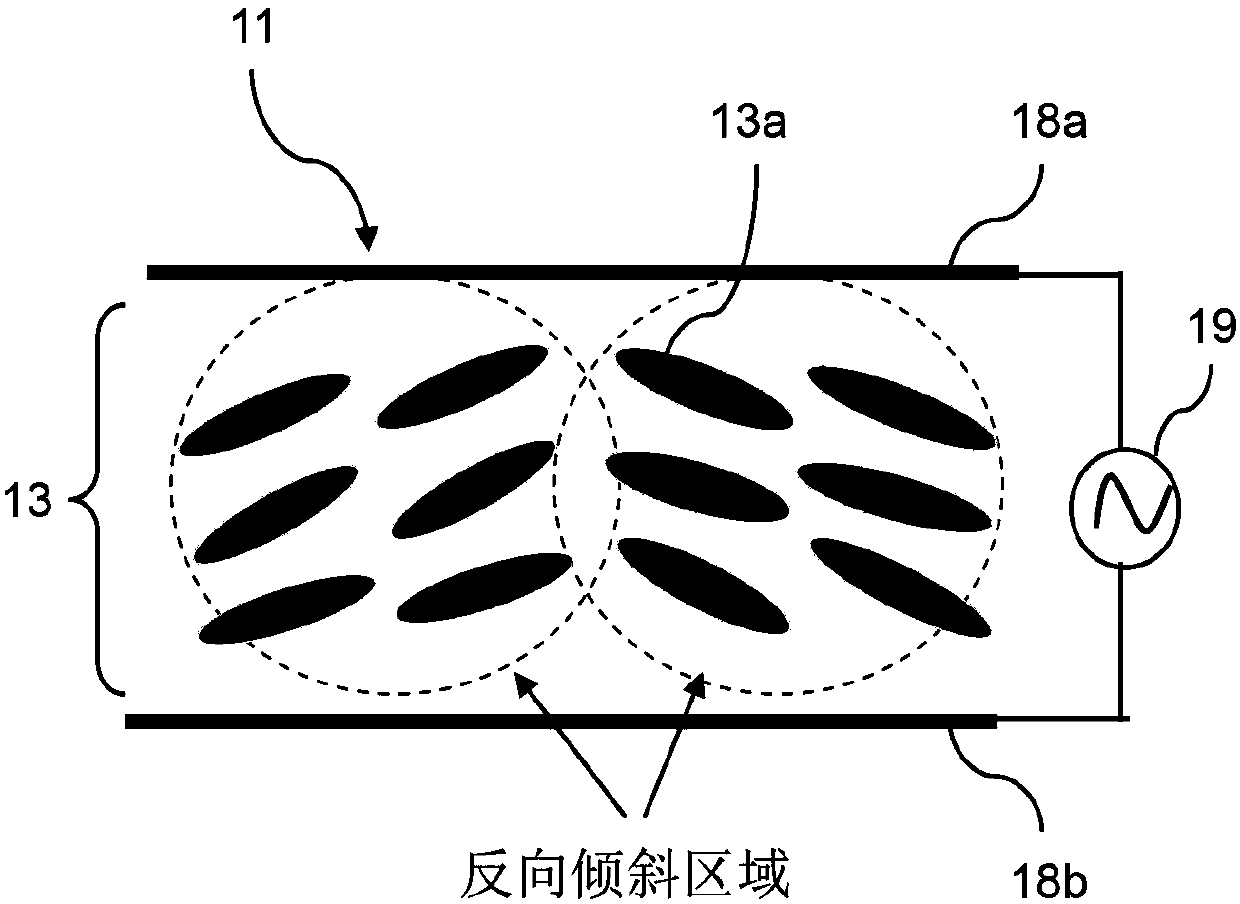

Liquid crystal display device

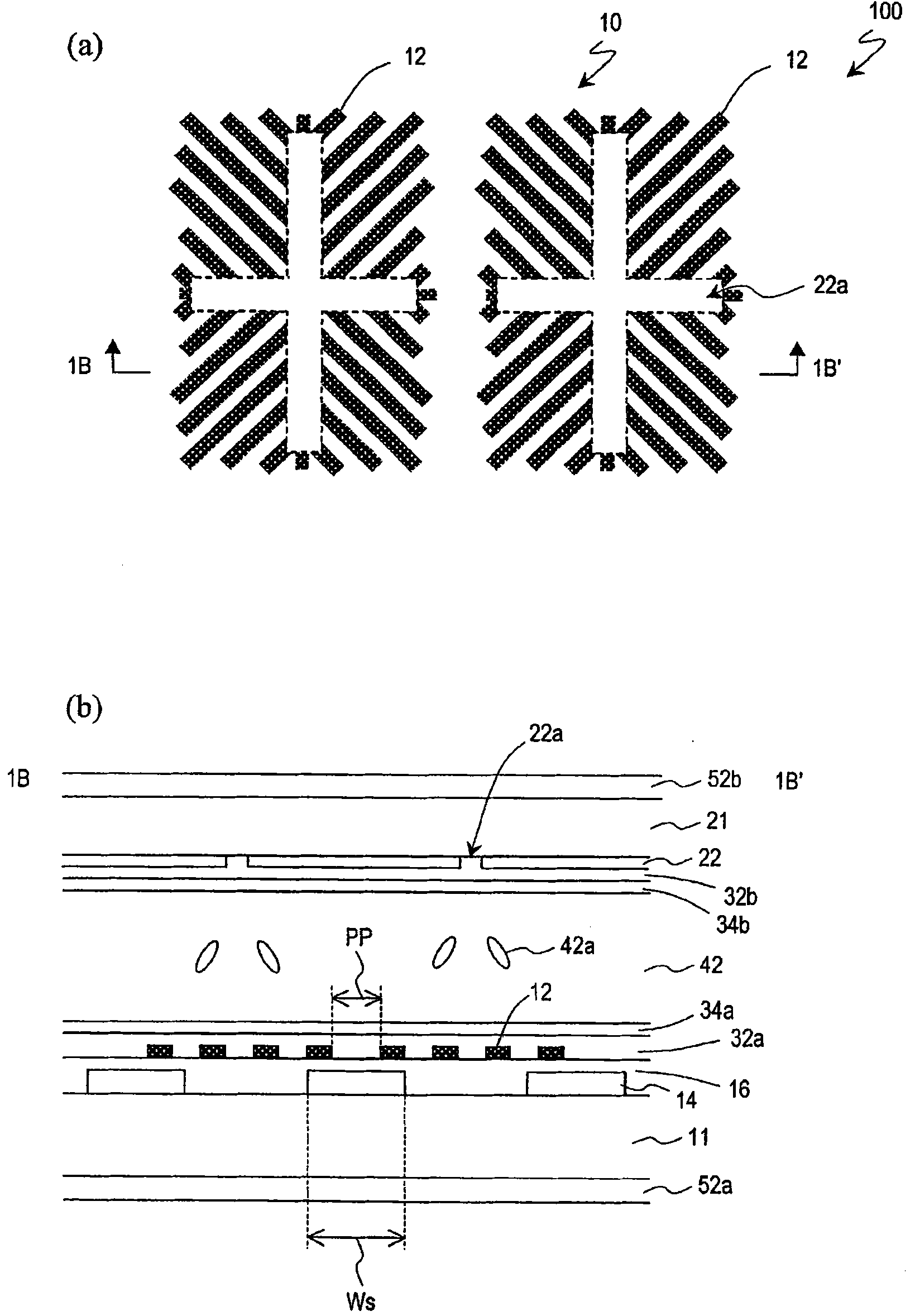

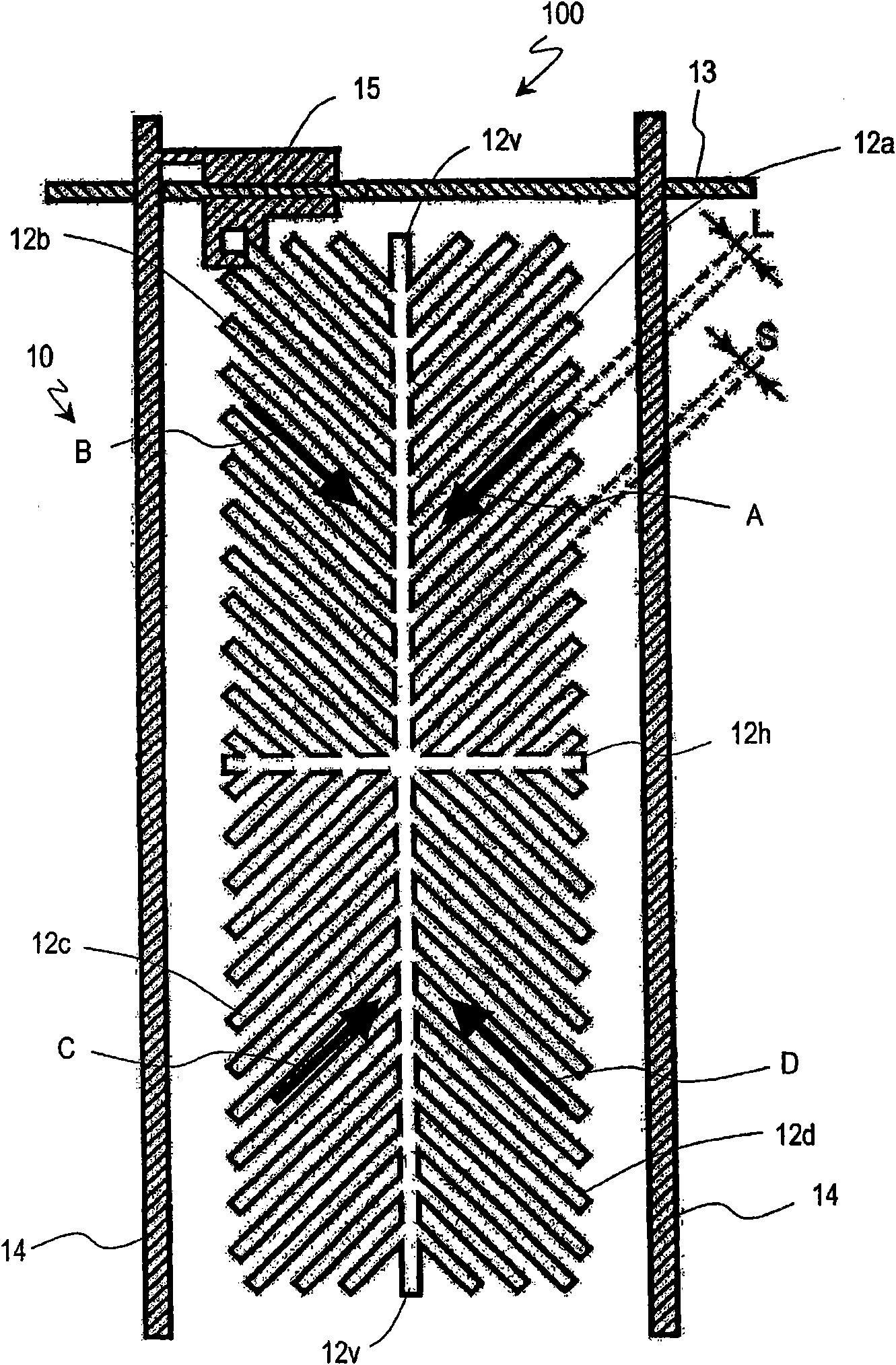

Provided is a liquid crystal display device having a pixel comprising a liquid crystal layer 42, a pixel electrode 12 and a counter electrode 22 confronting each other through the liquid crystal layer, a pair of vertically-oriented films 32a and 32b, and orientation maintaining layers 34a and 34b formed on the surfaces of the liquid crystal layer sides of the oriented films and made of a photochemically polymerized material. The pixel electrode includes cross-shaped trunks 12h and 12v arranged over the polarizing axes of a pair of polarizing plates, and a plurality of branches 12a, 12b, 12c and 12d extending in directions of about 45 degrees from the cross-shaped trunks. The counter electrode has a cross-shaped opening 22a arranged to confront the cross-shaped trunks. When a predetermined voltage is applied to the liquid crystal layer, four liquid crystal domains are formed, and the liquid crystal molecules of the regions corresponding individually to the four liquid crystal domains are specified in a pre-tilt azimuth by the orientation maintaining layers.

Owner:SHARP KK

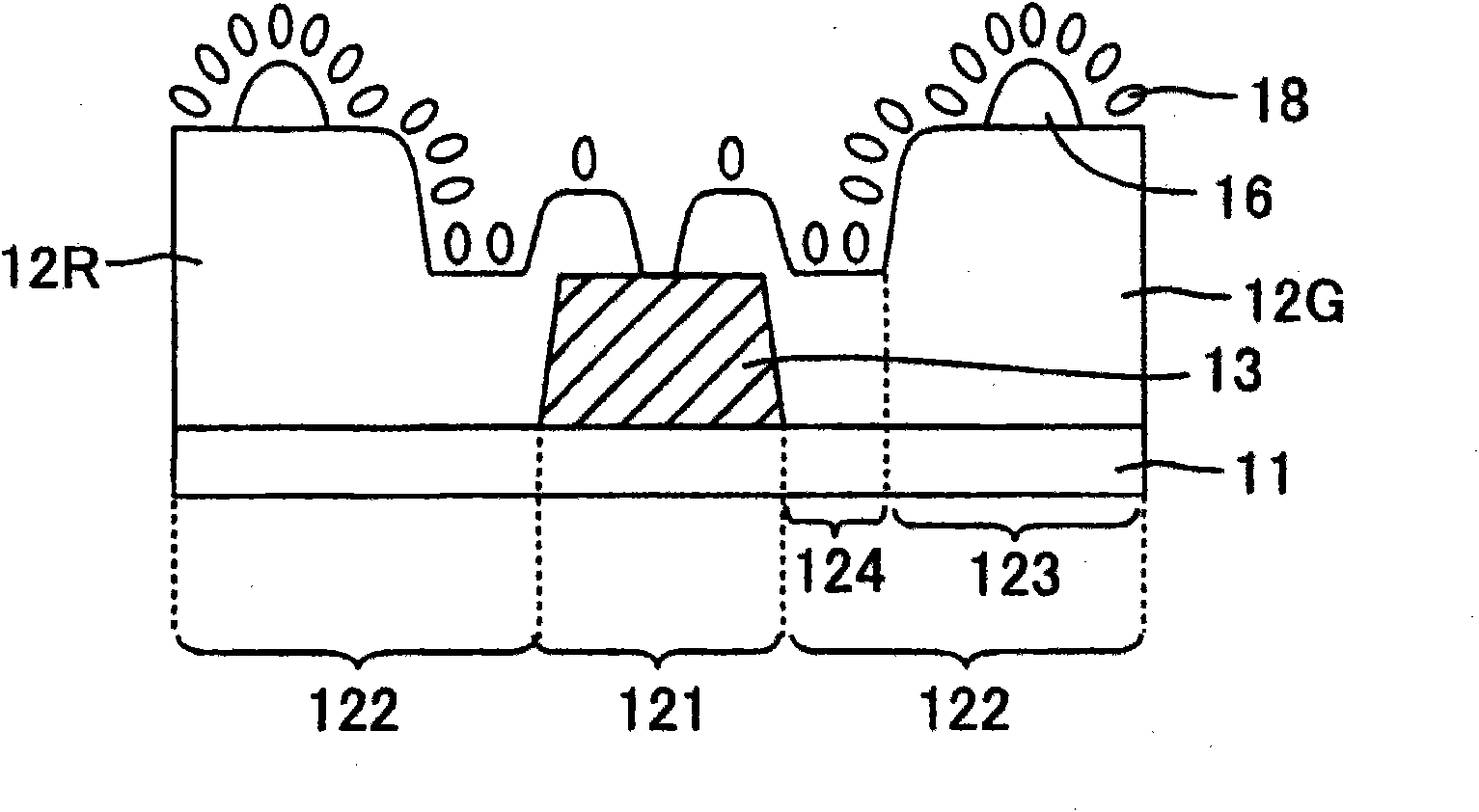

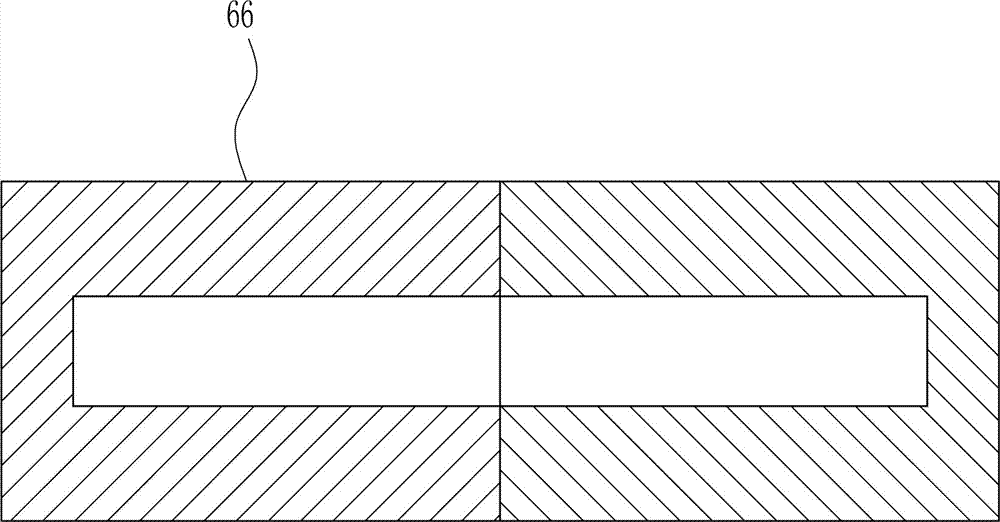

Color filter substrate, liquid crystal display panel, liquid crystal display device, and method for manufacturing color filter substrate

InactiveCN101861533ASteady OrientationFull contrastOptical filtersNon-linear opticsColor gelLight filter

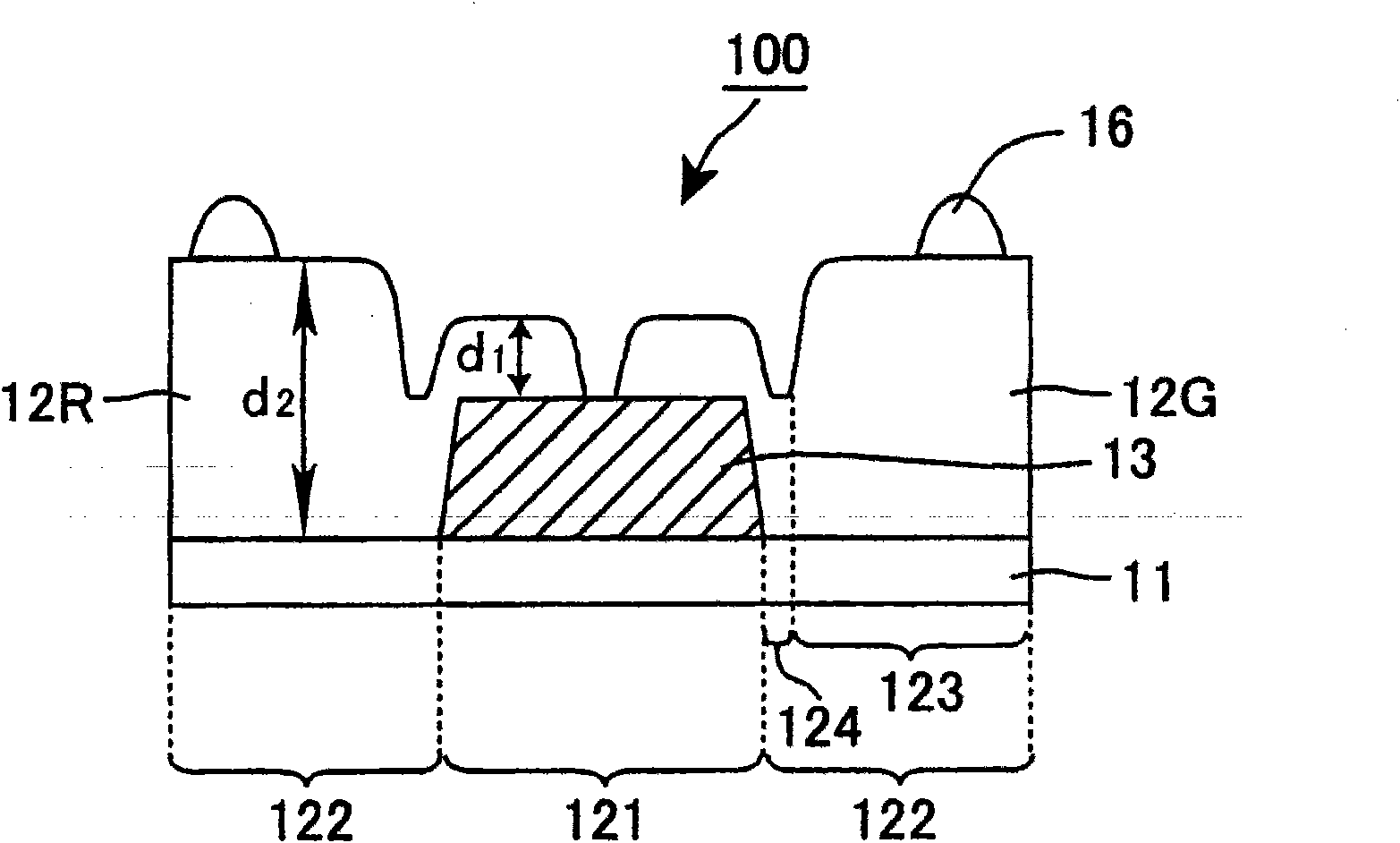

Disclosed is a color filter substrate which enables to suppress disorder in liquid crystal alignment near a light-shielded region, while attaining sufficient light-shielding performance in the light-shielded region. Specifically disclosed is a color filter substrate comprising, on a substrate, a light-blocking layer and a color layer composed of a photosensitive material or the like. The color layer is arranged from a light-transmitting region where the light-blocking layer is not arranged to a light-shielded region where the light-blocking layer is arranged. The thickness of the color layer in the light-shielded region is smaller than the thickness thereof in the light-transmitting region.

Owner:SHARP KK

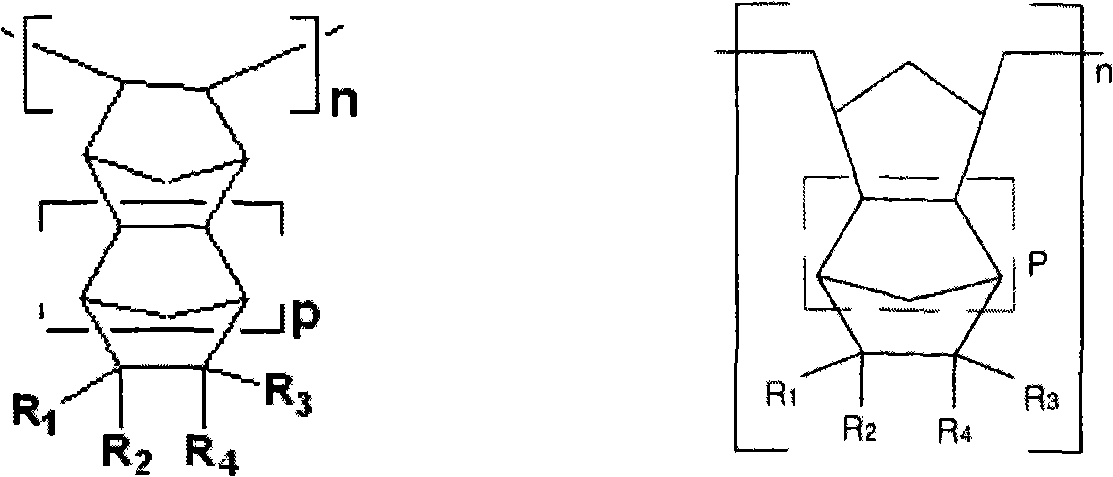

Composition for liquid crystal alignment layer and liquid crystal alignment layer

ActiveCN102344817AGood orientationSteady OrientationLiquid crystal compositionsNon-linear opticsCrystallographyLiquid crystal cell

The present invention relates to a composition for liquid crystal alignment layer, a liquid crystal alignment layer, and a liquid crystal cell. The composition for liquid crystal alignment layer is used to provide a liquid crystal alignment layer that exhibits excellent alignment and maintains stable alignment without disturbance despite external stress such as electrical / thermal stress in a TFT-Cell.

Owner:LG CHEM LTD

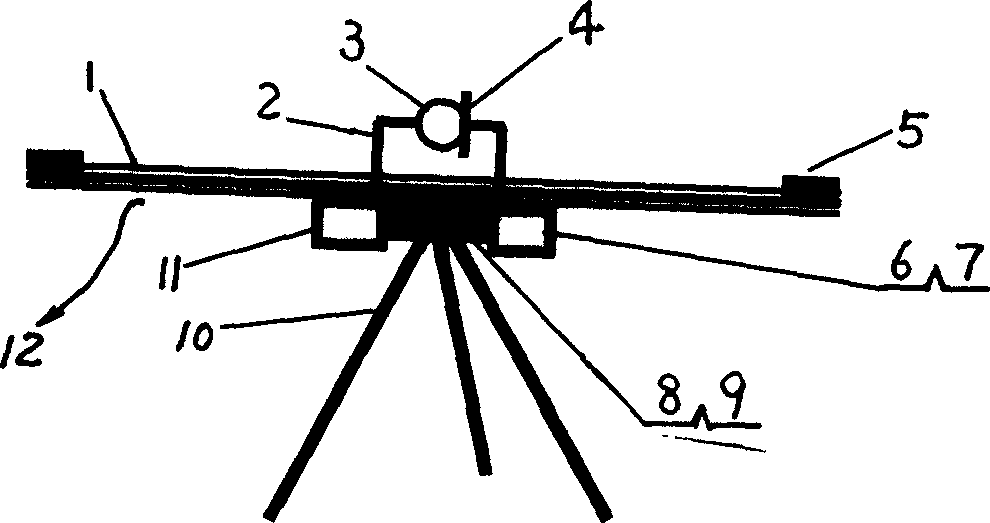

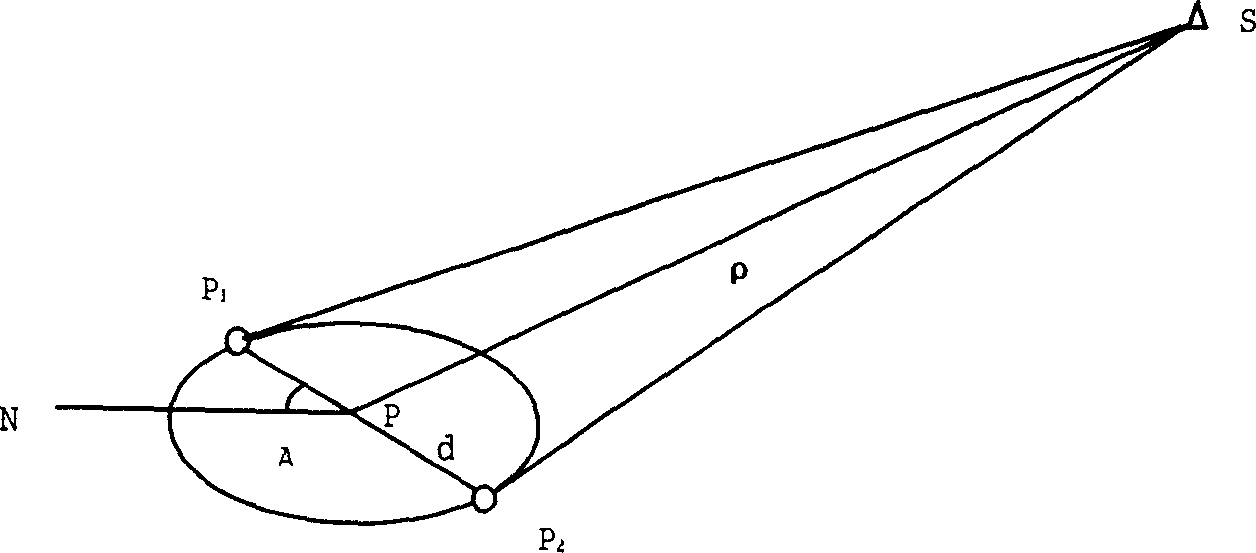

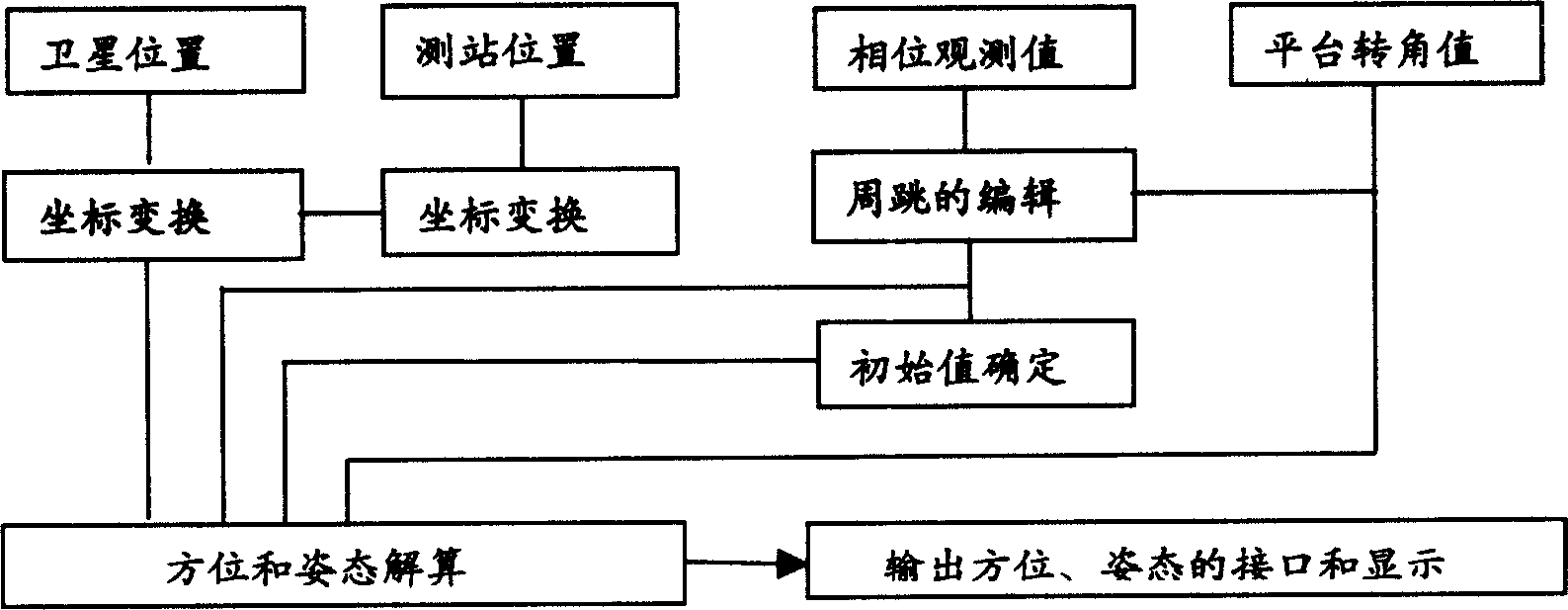

Satellite direction finder and direction finding method

InactiveCN1632465ASteady OrientationHigh orientation accuracyNavigation instrumentsMathematical modelCarrier signal

This invention relates to satellite direction detector, which fixes rotation platform on the rack with satellite wave carrier phase measurement and receive antenna fixed on the both ends of the rotation platform. The rotation platform is fixed with telescope, level rotation angle electrical recorder, vertical angel electrical recorder and wave carrier phase measurement and receive machine and its step sample output is connected with the data process unit. The measurement method is the following: to drive rotation platform; in the same time to rotate platform and record angle as second impulse; to process data according to the math model able to weaken the system error; to computer the direction angle of the panel zero position; then to read out the direction angle from the dial panel for any point direction of the telescope.

Owner:许其凤

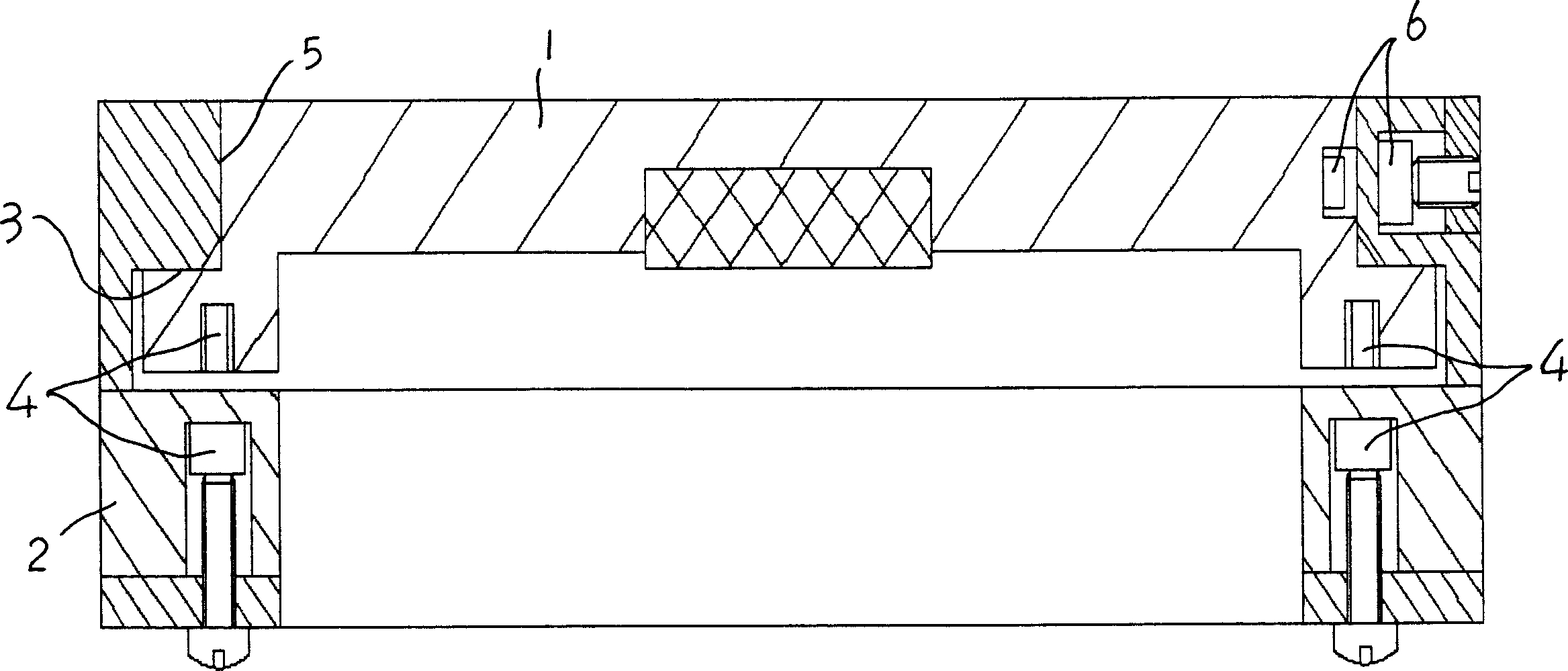

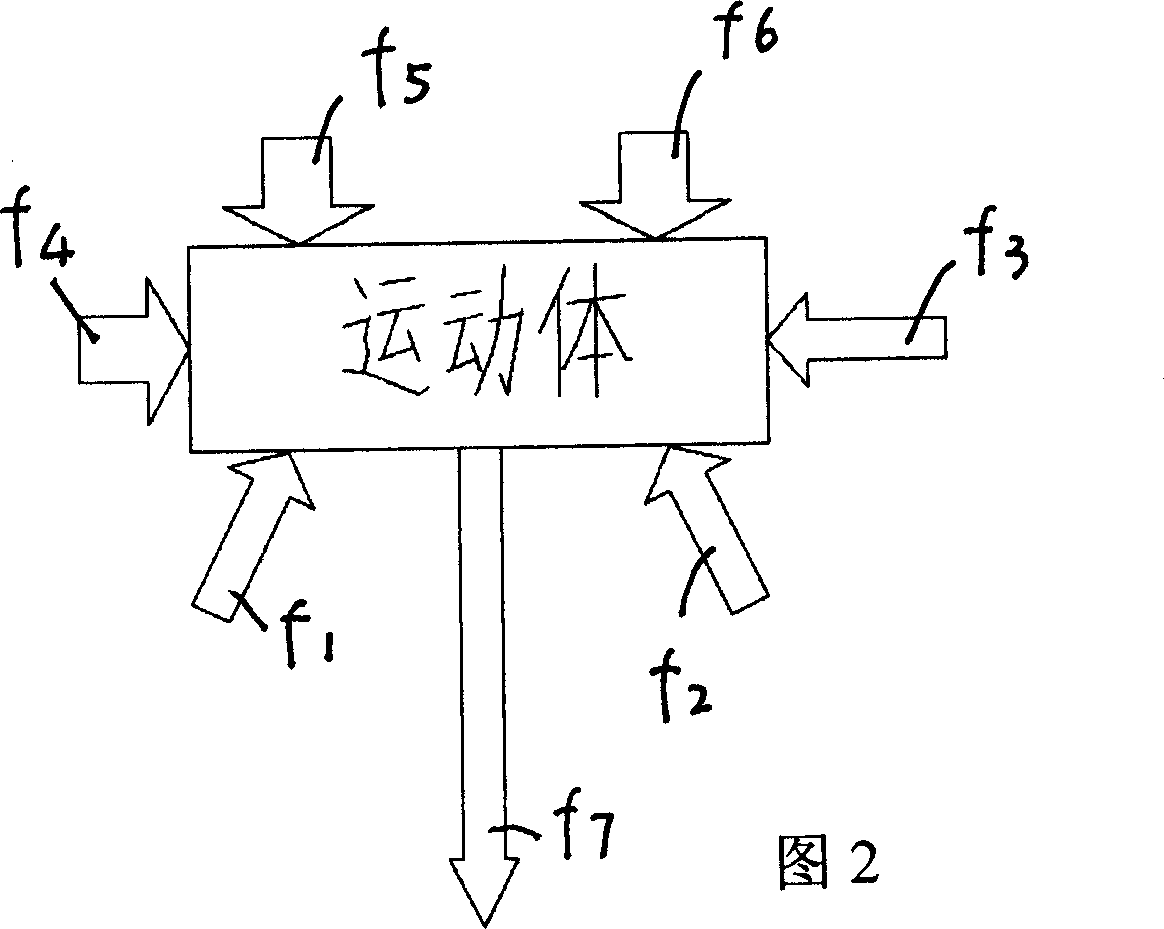

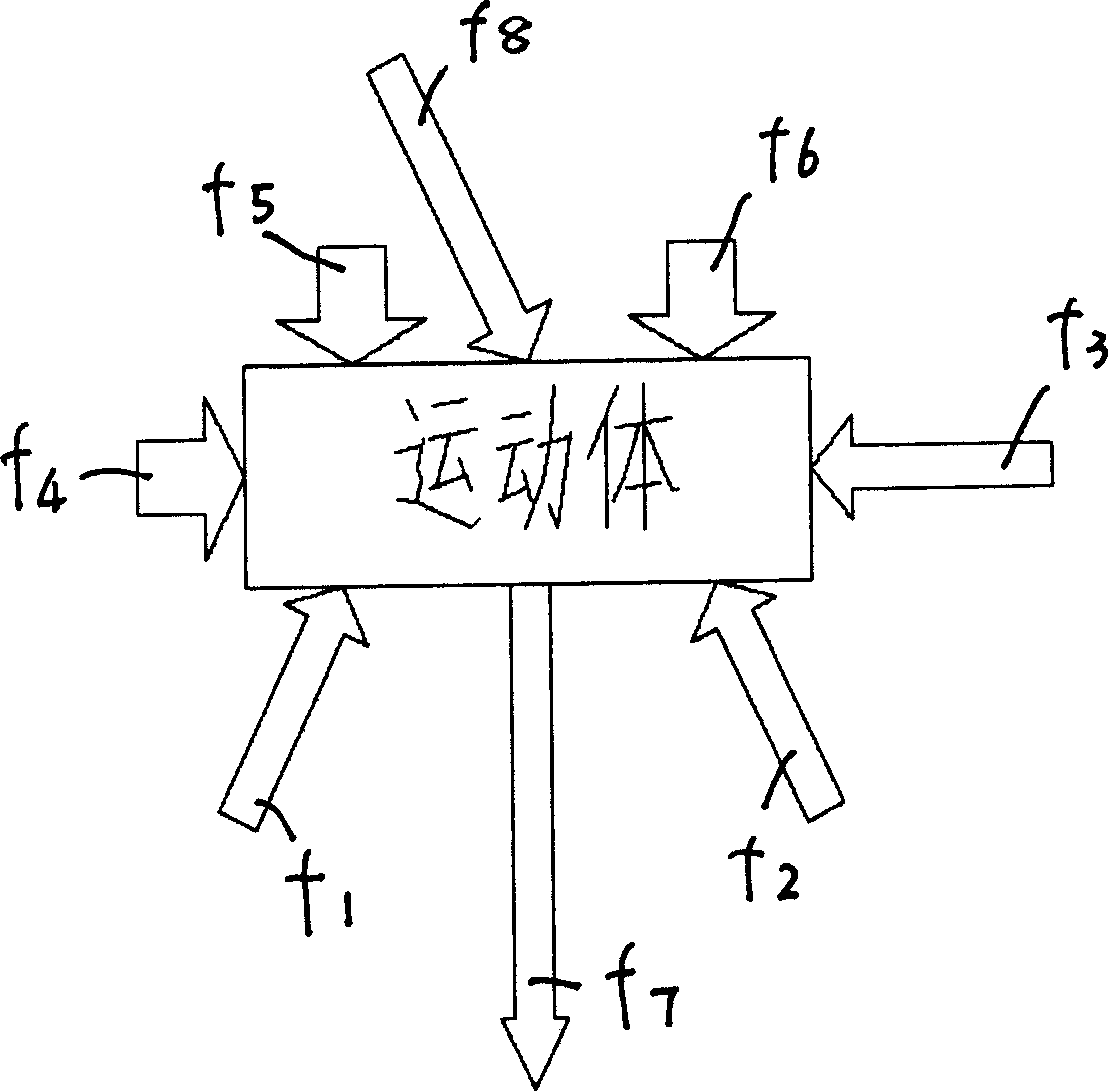

High-precision low-friction magnetic suspension sliding composite guid rail

InactiveCN1852019ASimple structureFrictional stabilityInstrumental componentsLarge fixed membersPositive pressureEngineering

This invention relates to a high accuracy low friction magnetic suspension-sliding compound guideway characterizing in mounting a pair of base like magnets oppositely between the end face of the bottom of a mobile piece and the supporting face of the guideway to keep them at an un-contact state by the repulsive force formed by it and form a positive pressure between the top guide faces of the mobile piece and the guideway, taking a side end face of the mobile piece and the guideway as the side guide face to mount a pair of like side magnets oppositely on the other end face opposite to the guide face of the side to keep the mobile piece and the guideway at an un-contact state at the side end face with the repulsive force formed by the pair of magnets to form a positive pressure on the guide face of the side part.

Owner:HEFEI UNIV OF TECH

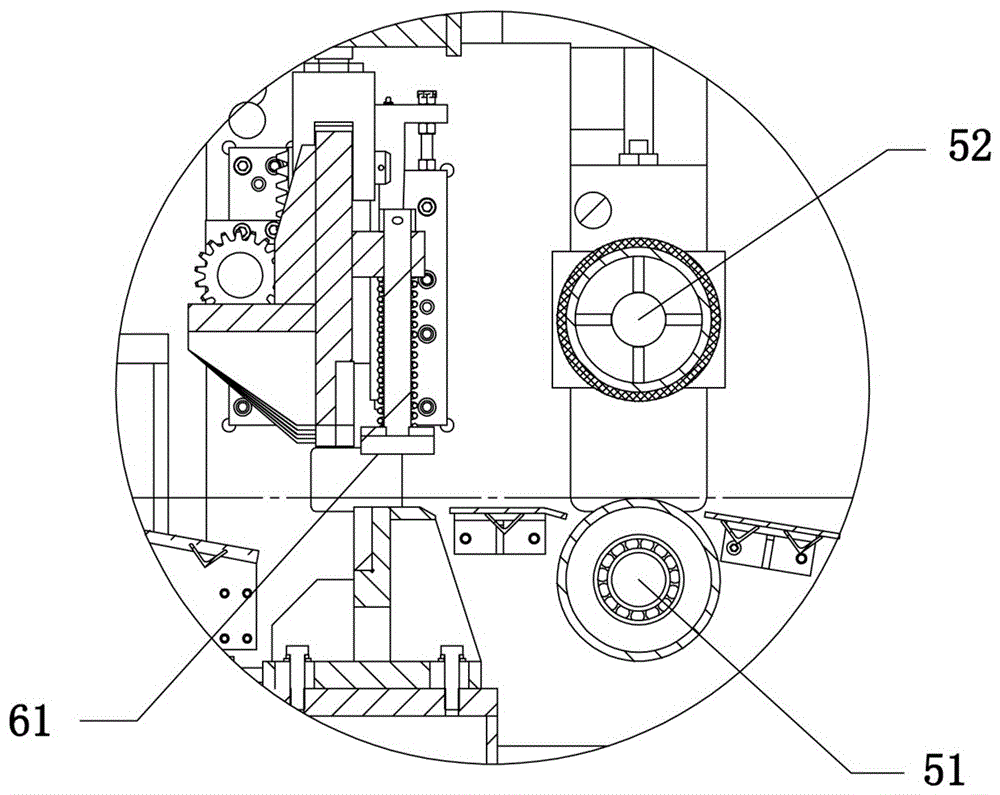

Buffing attachment with high stability for leather shoe factories

The invention relates a buffing attachment, in particular to a buffing attachment with high stability for leather shoe factories. The invention aims at solving the technical problem of providing a buffing attachment with high operation stability, sufficient polishing and high work efficiency for leather shoe factories. In order to solve the technical problems above, the invention provides the buffing attachment with high stability for leather shoe factories. The buffing attachment realizes the effects of high operation stability, sufficient polishing and high work efficiency, and an elevator mechanism of the buffing attachment can drive a buffing mechanism to move up and down to provide convenience for adjusting the height of the buffing mechanism.

Owner:李水旺

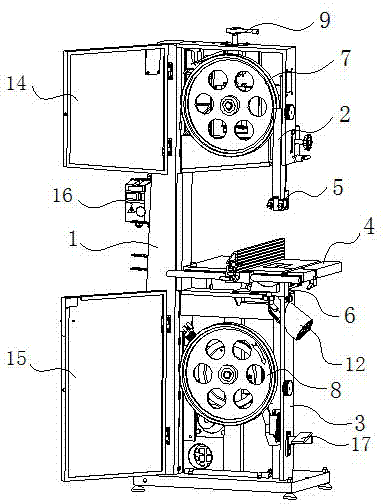

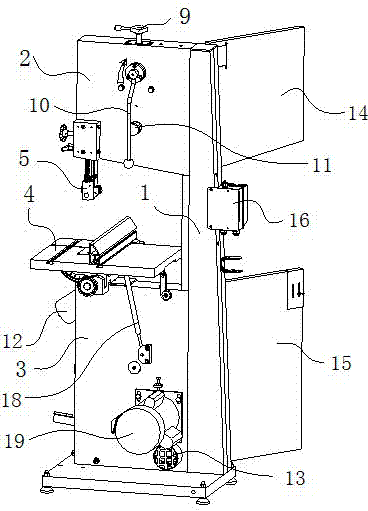

Band-sawing machine for carpenters

The invention discloses a band-sawing machine for carpenters. The band-sawing machine comprises a machine frame, an upper shield, a lower shield, a workbench, an upper saw clamp, a lower saw clamp, an upper wheel and a lower wheel. The upper wheel is arranged in the upper shield, the upper wheel is arranged on a shaft, and the shaft is arranged on a fixing frame. The upper end of the fixing frame is connected with a connecting frame, and the lower end of the fixing frame is connected with an adjusting plate. The connecting frame is fixed to a panel of the upper shield through a bolt. A deviation adjusting nut is arranged at the lower portion of the panel of the upper shield, the deviation adjusting nut is connected with an adjusting pin, and the adjusting pin penetrates through the panel of the upper shield to be in contact with the adjusting plate. An adjusting handle is arranged on the panel of the upper shield, and the adjusting handle is connected with the fixing frame. By the adoption of a novel saw clamping structure, the band-sawing machine for carpenters has better and more stable guiding performance. An air spring is adopted for assisting the workbench in adjusting the inclined degree, and an automatically adjusting function is achieved. An efficient, fast, and convenient adjusting and tension device is adopted to conduct fast adjusting and tensioning on a saw wheel, the use requirement is met, and economic efficiency is improved.

Owner:YANGZHOU HAIWEI MACHINERY MFG

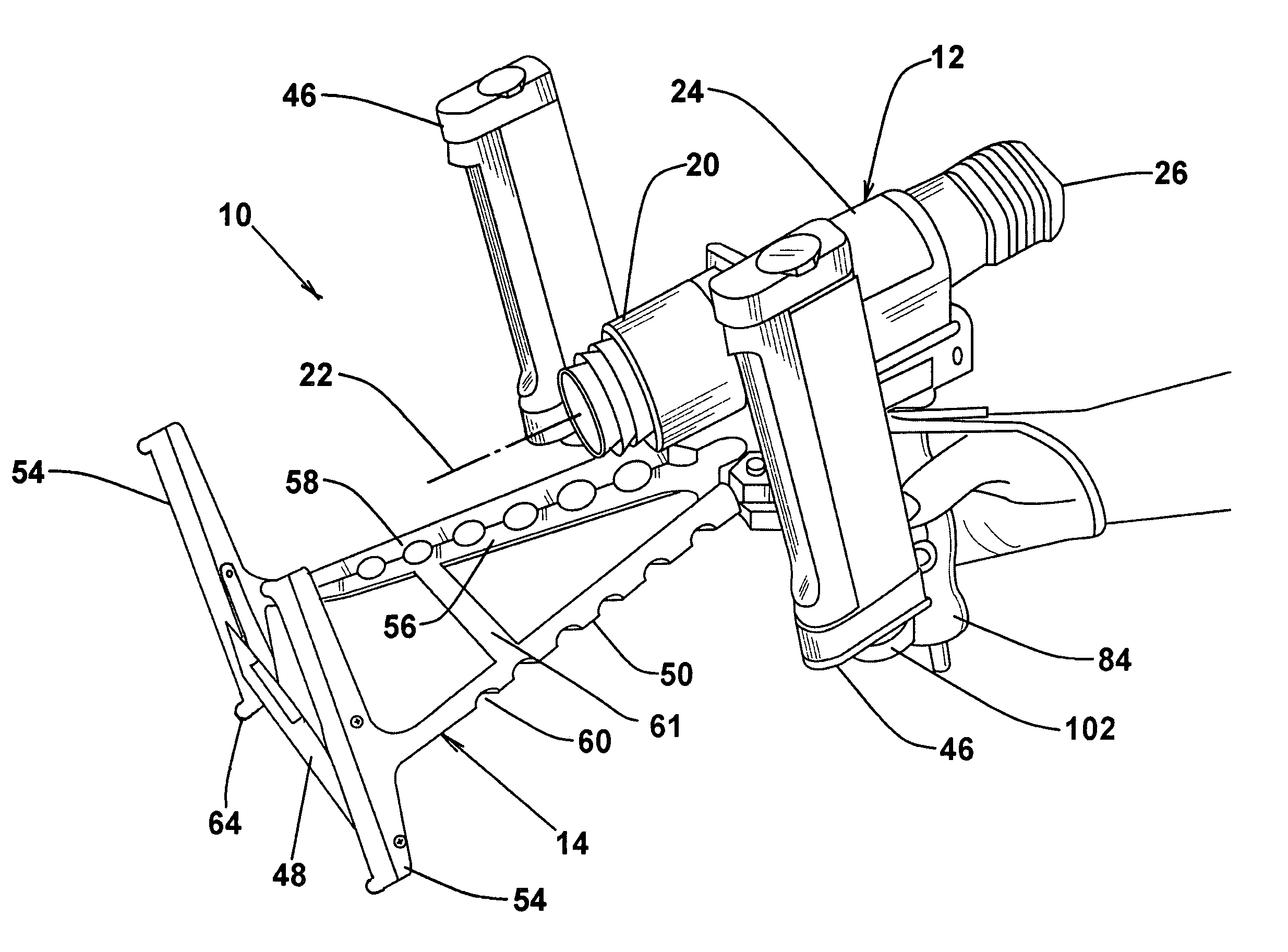

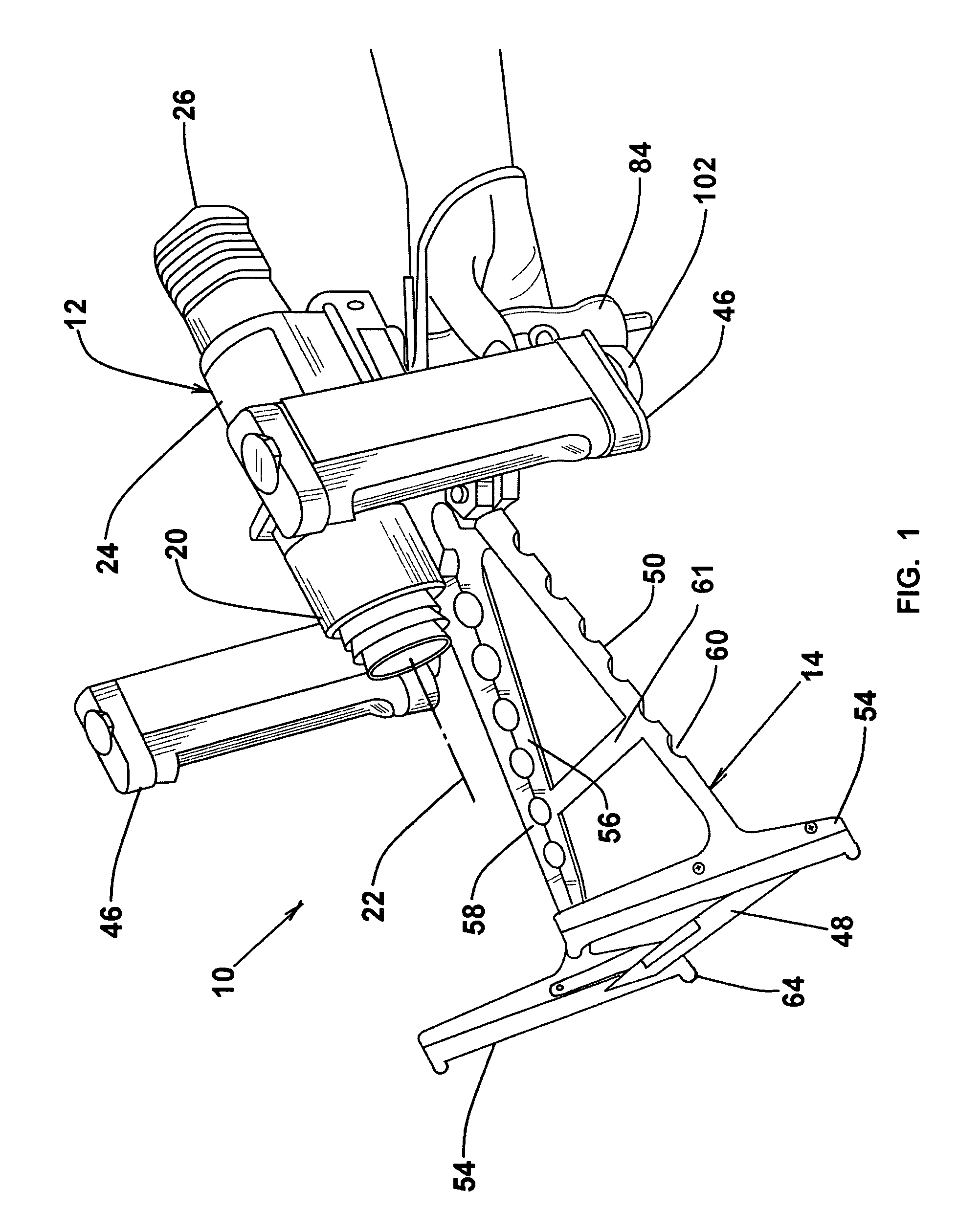

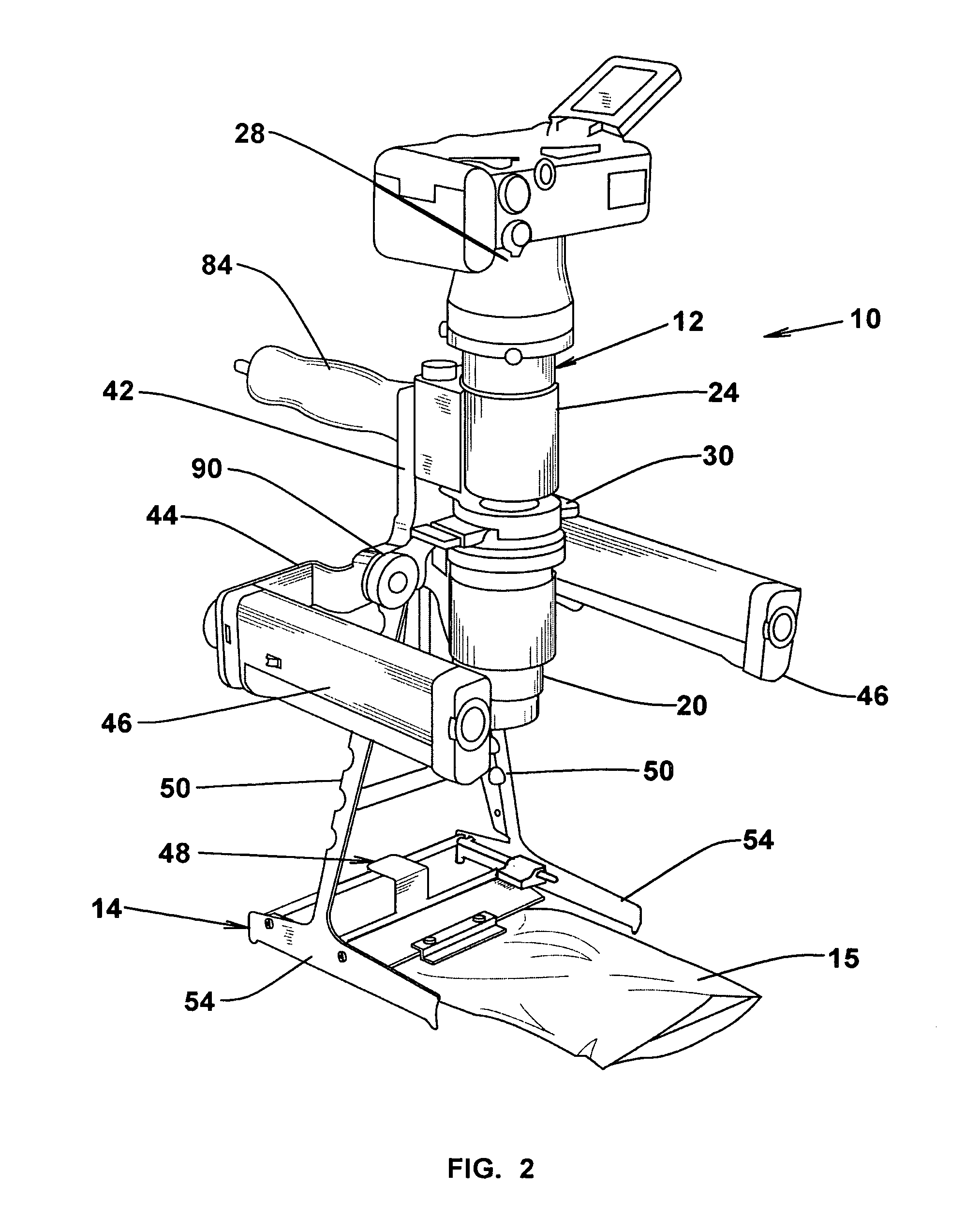

Forensic visualization and recording apparatus

ActiveUS7050715B1Stable focusStable recorded imageCamera body detailsPhotographyEngineeringSliding scale

An integrated imager and camera mounting assembly that allows a single operator to scan the crime scene for prints without assistance, and to attain an optimally illuminated and stably focused recorded image with single handed adjustments. The assembly includes an A-frame stand which carries a pair of UV lights on adjustable arms for single handled adjustment by the operator in the scanning and recording modes. The stand includes a footed base that allows the operator to securely engage the frame against vertical, horizontal and irregular surfaces using the imager handle thereby locating the imager at a fixed distance from the print area and permitting ready focusing of the image with the other hand. The base further includes a sliding scale for placement in the field of view for dimensional referencing.

Owner:SIRCHIE ACQUISITION COMPANY

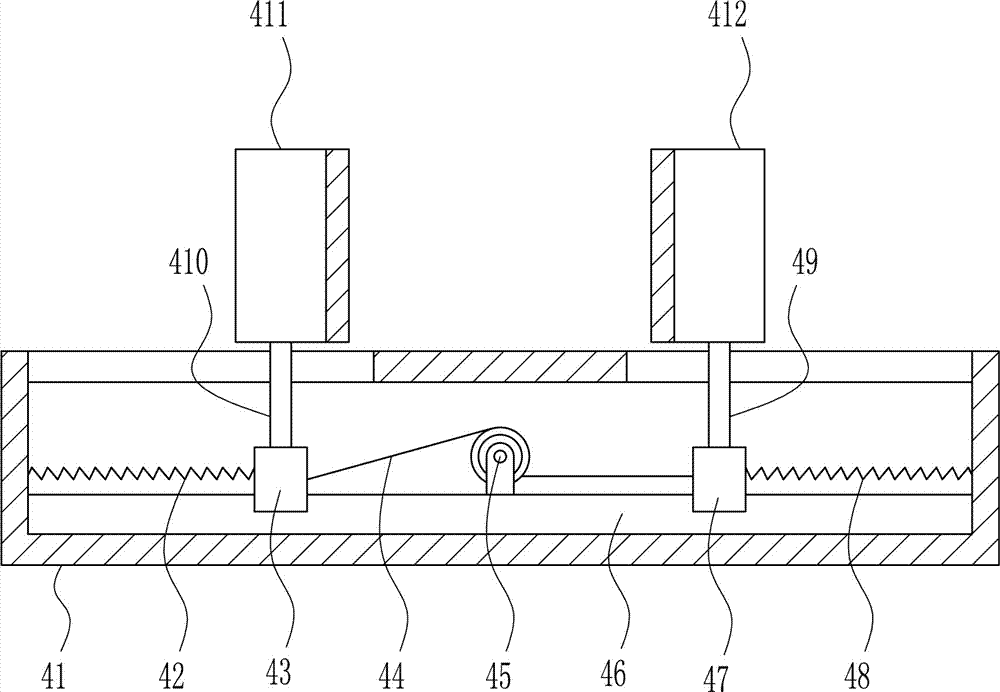

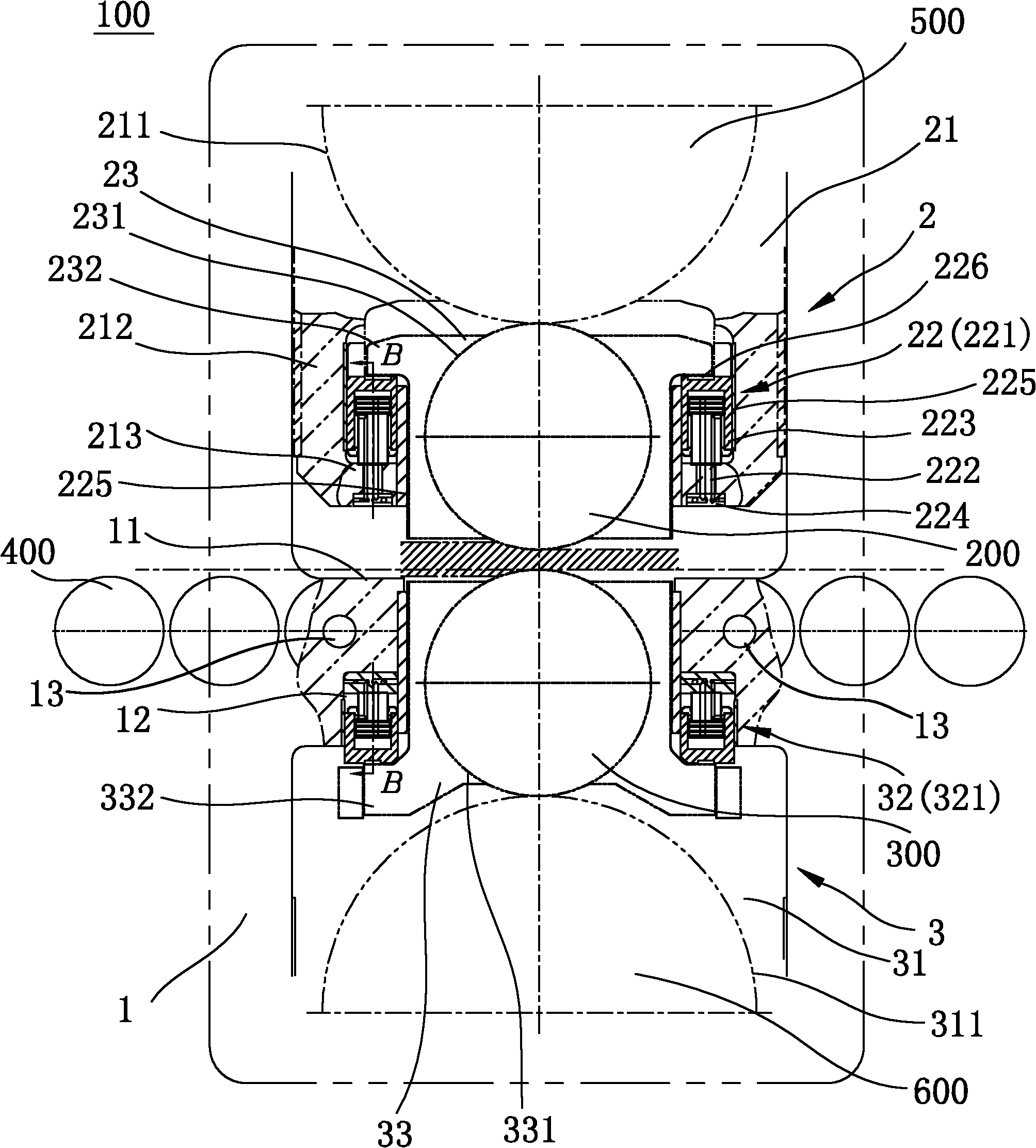

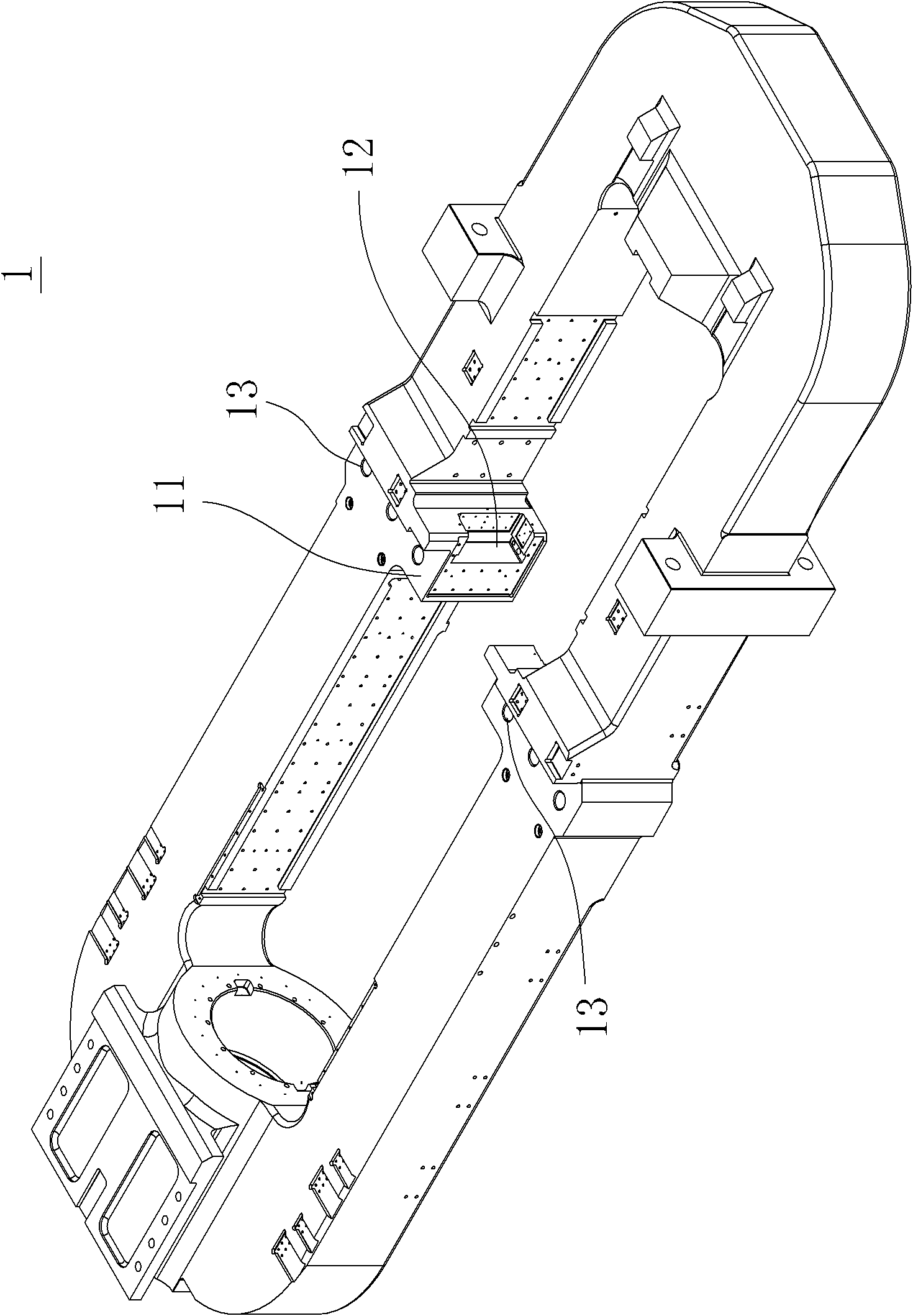

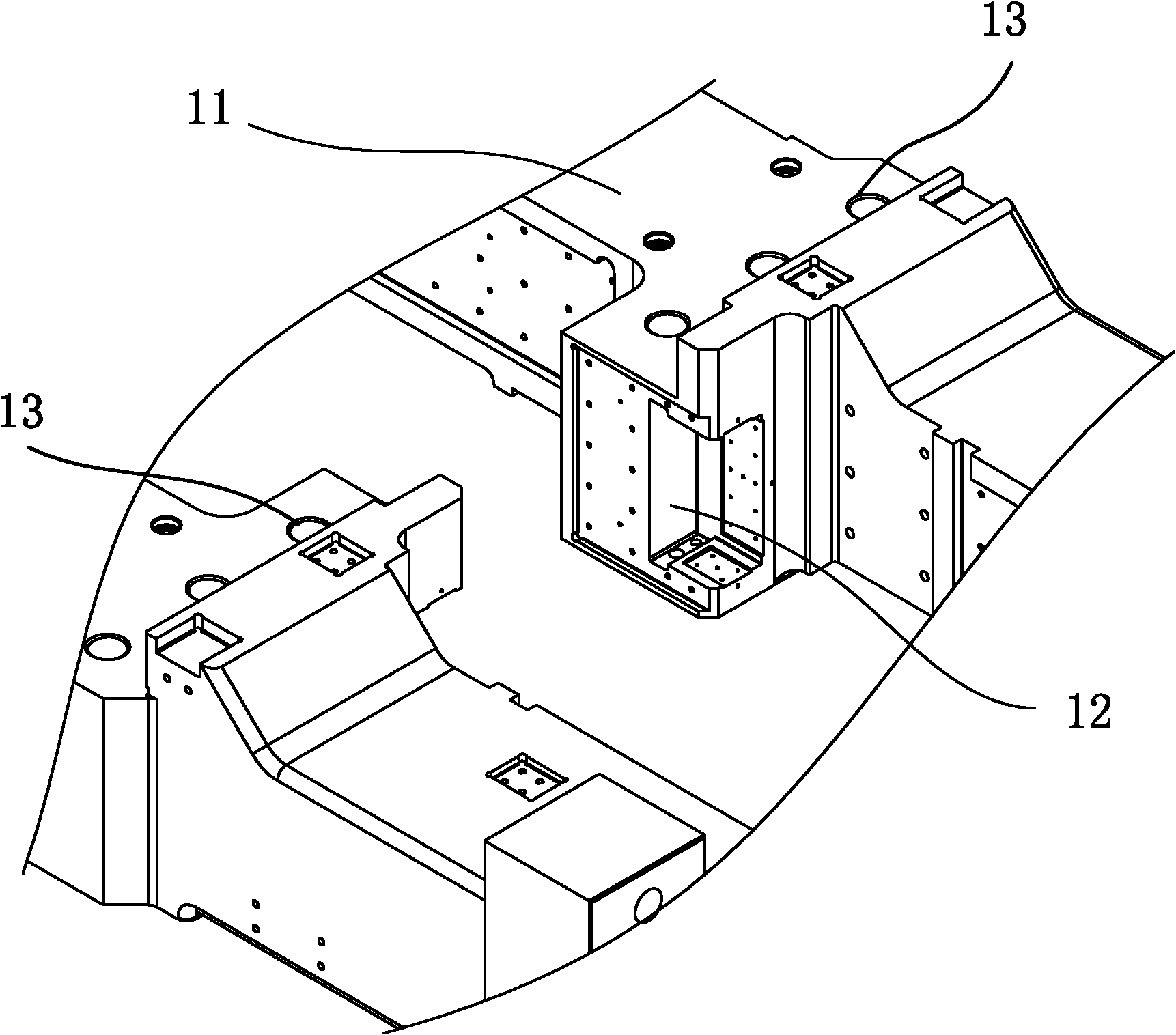

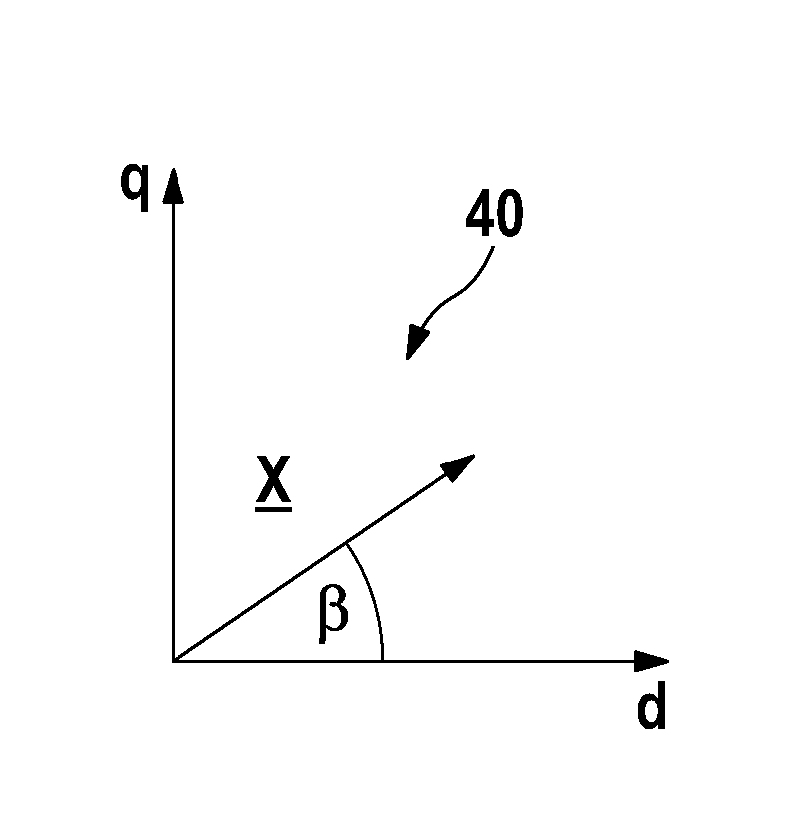

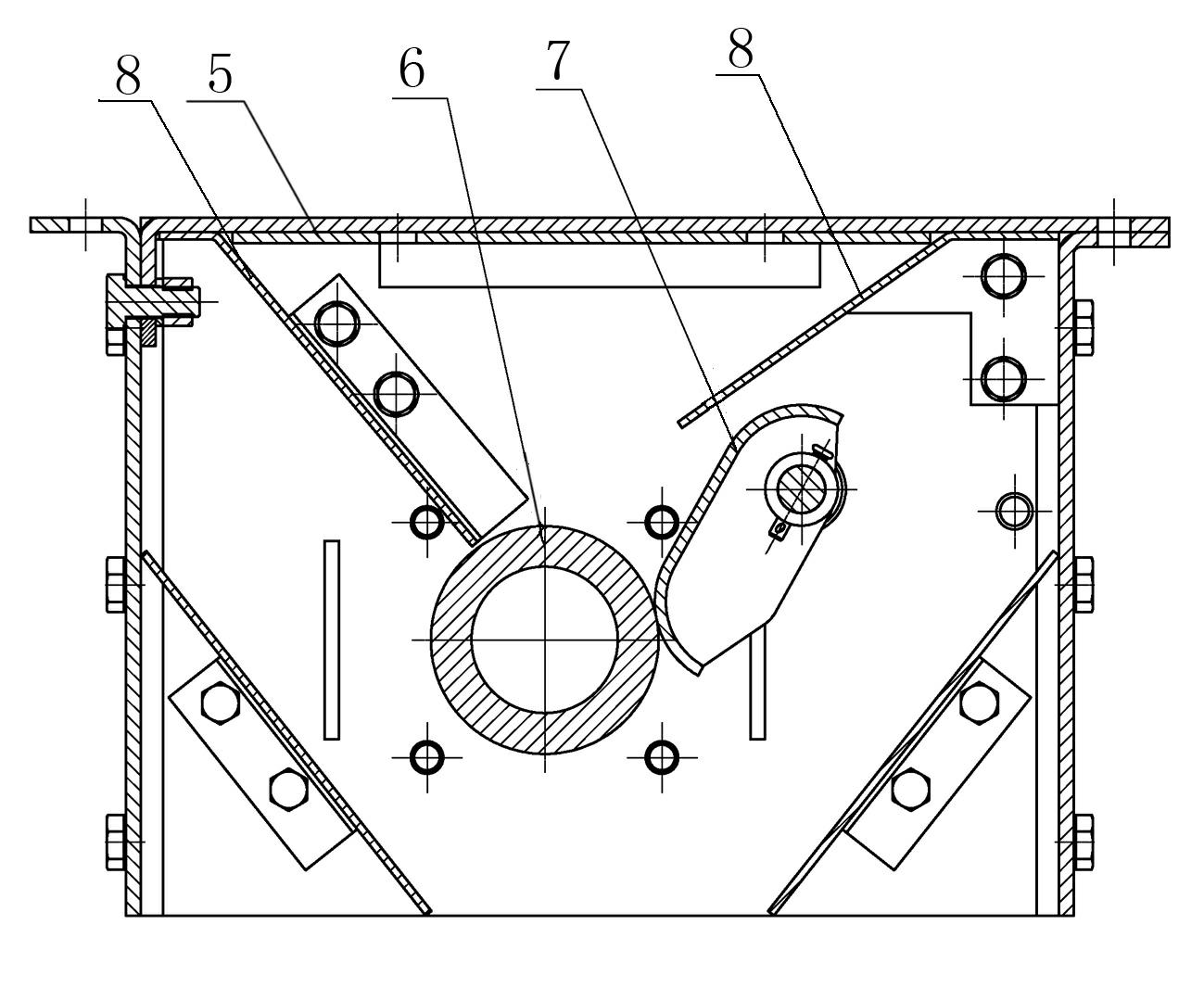

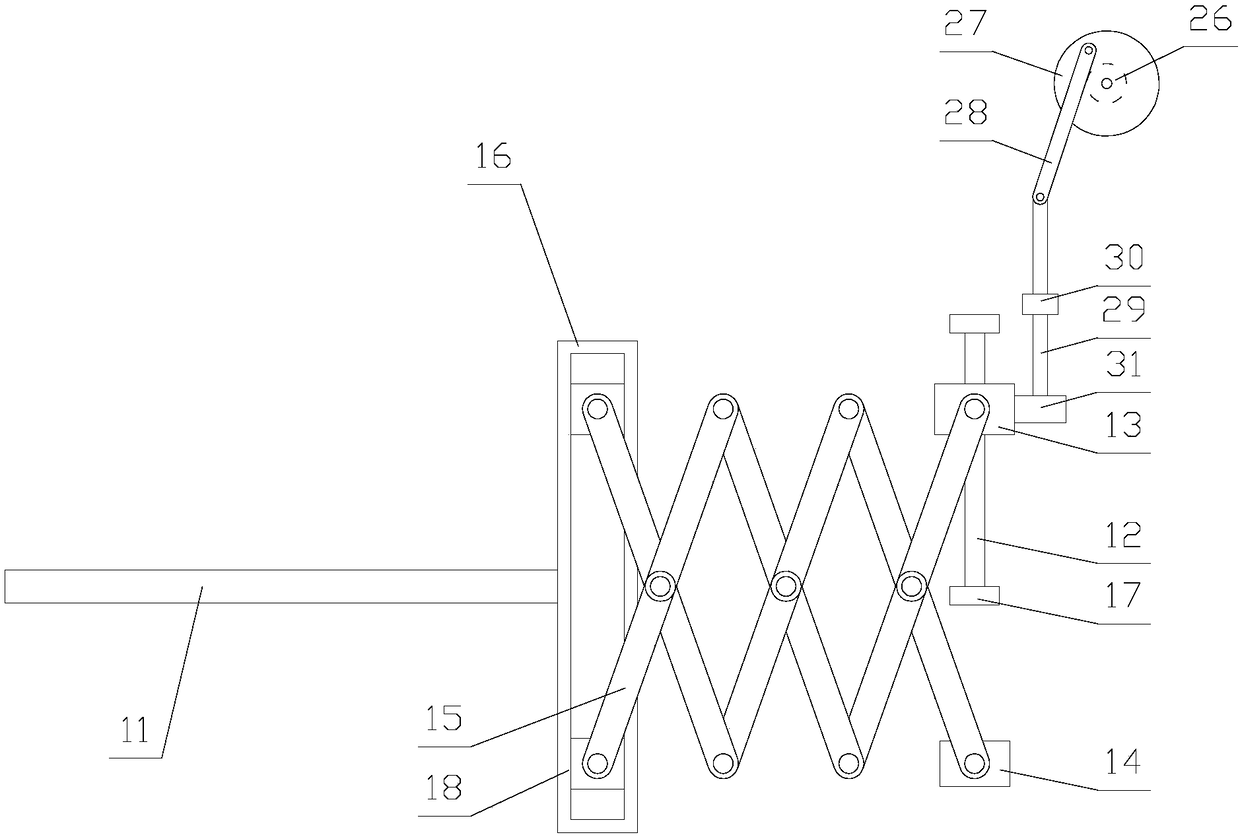

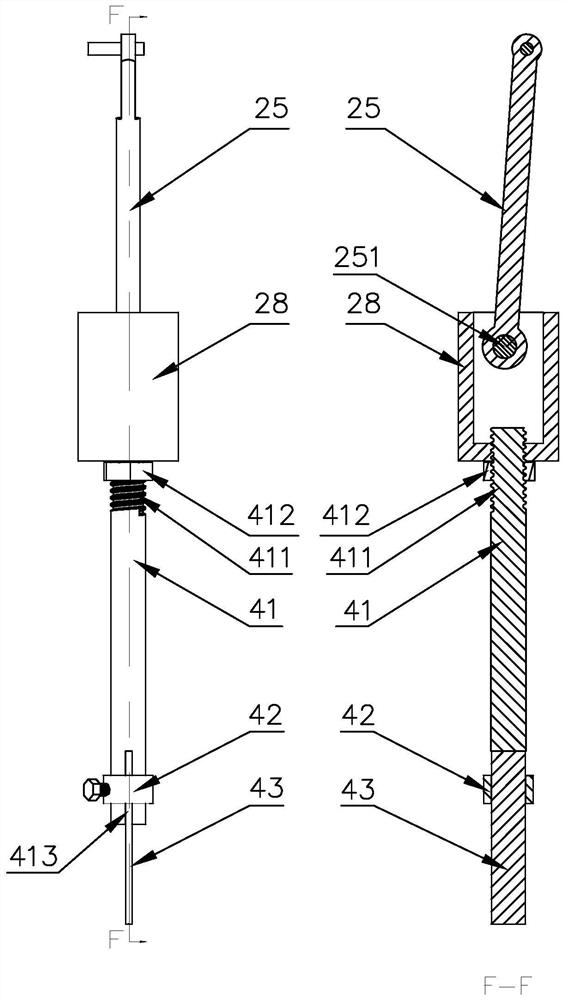

Working roll bending device of plate band rolling mill

ActiveCN101954381AShort tripReduce the number of movementsMetal rolling stand detailsMetal rolling arrangementsWork rollEngineering

The invention discloses a working roll bending device of a plate band rolling mill. The device is fixedly arranged on a rolling mill stand, and roll bending devices are arranged on two end parts of an upper working roll and a lower working roll so as to carry out supporting, balancing and roll bending control on the upper working roll and the lower working roll to improve the convexity of a loaded roll gap between the upper working roll and the lower working roll and control the plate shape. The roll bending device comprises a memorial archway, upper roll bending devices and lower roll bending devices, wherein the memorial archway is a framework body, and upright posts at the left side and the right side of the memorial archway are respectively inwards and convexly provided with a waist bump; the upper roll bending devices can be slidably arranged in the memorial archway, positioned above the waist bump and assembled at two ends of the upper working roll; and the lower roll bending devices can be slidably arranged in the memorial archway, positioned below the upper roll bending device and assembled at two ends of the lower working roll. The working roll bending device of the plate band rolling mill can meet the working requirement of a large large-openness plate band rolling mill and has the advantages of reliable rolling quality and long service life.

Owner:MCC CAPITAL ENGINEERING & RESEARCH +1

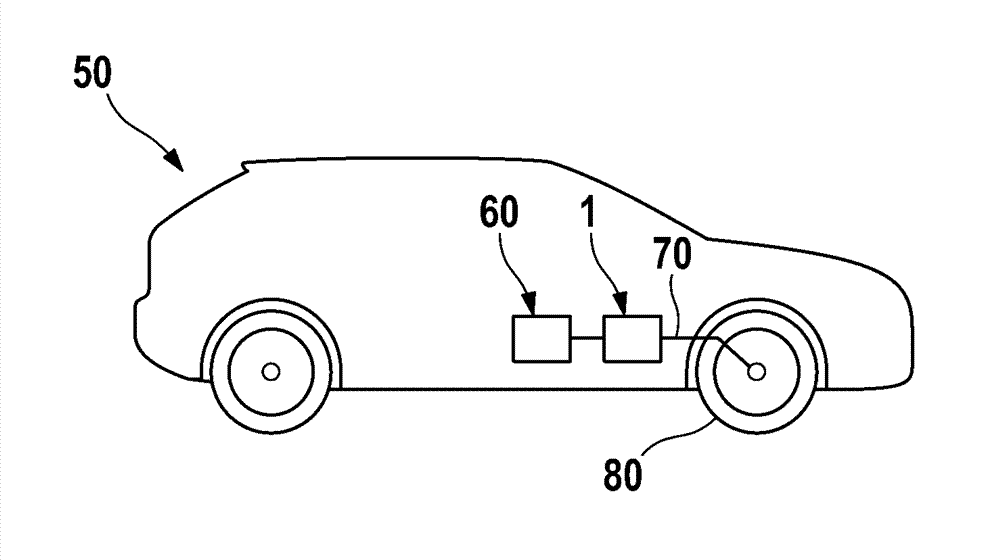

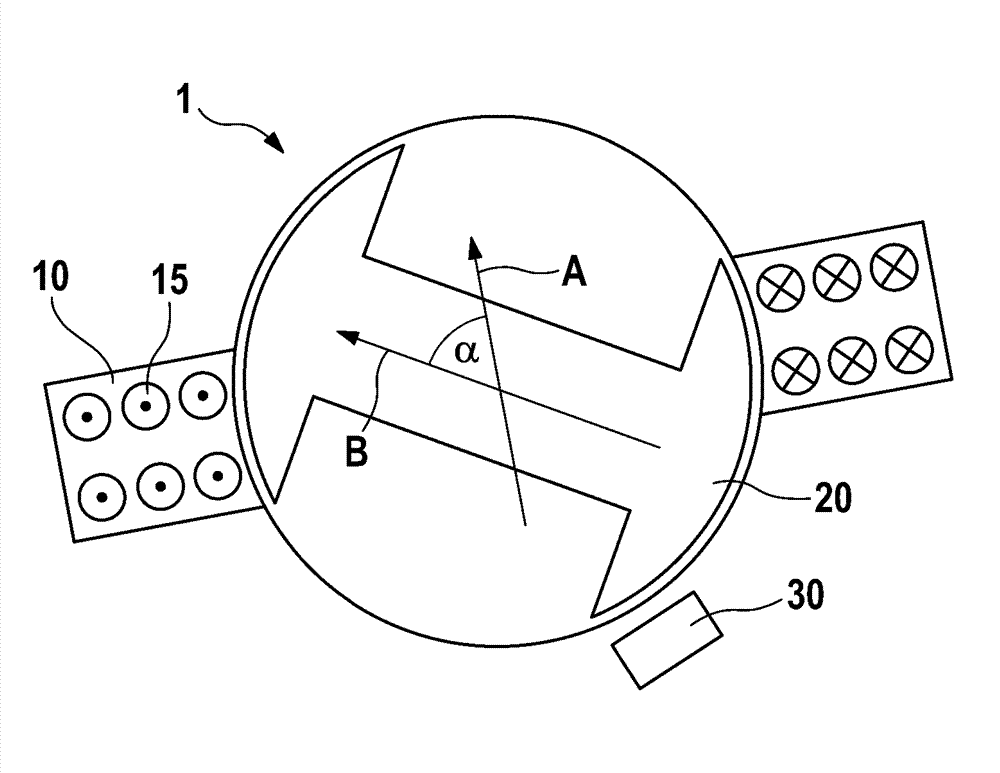

Method, device, and computer program for determining an offset angle in an electric machine

InactiveCN103329426AStable absolute valueConstant absolute valueSpeed controllerAC motor controlElectric machineEngineering

Owner:ROBERT BOSCH GMBH

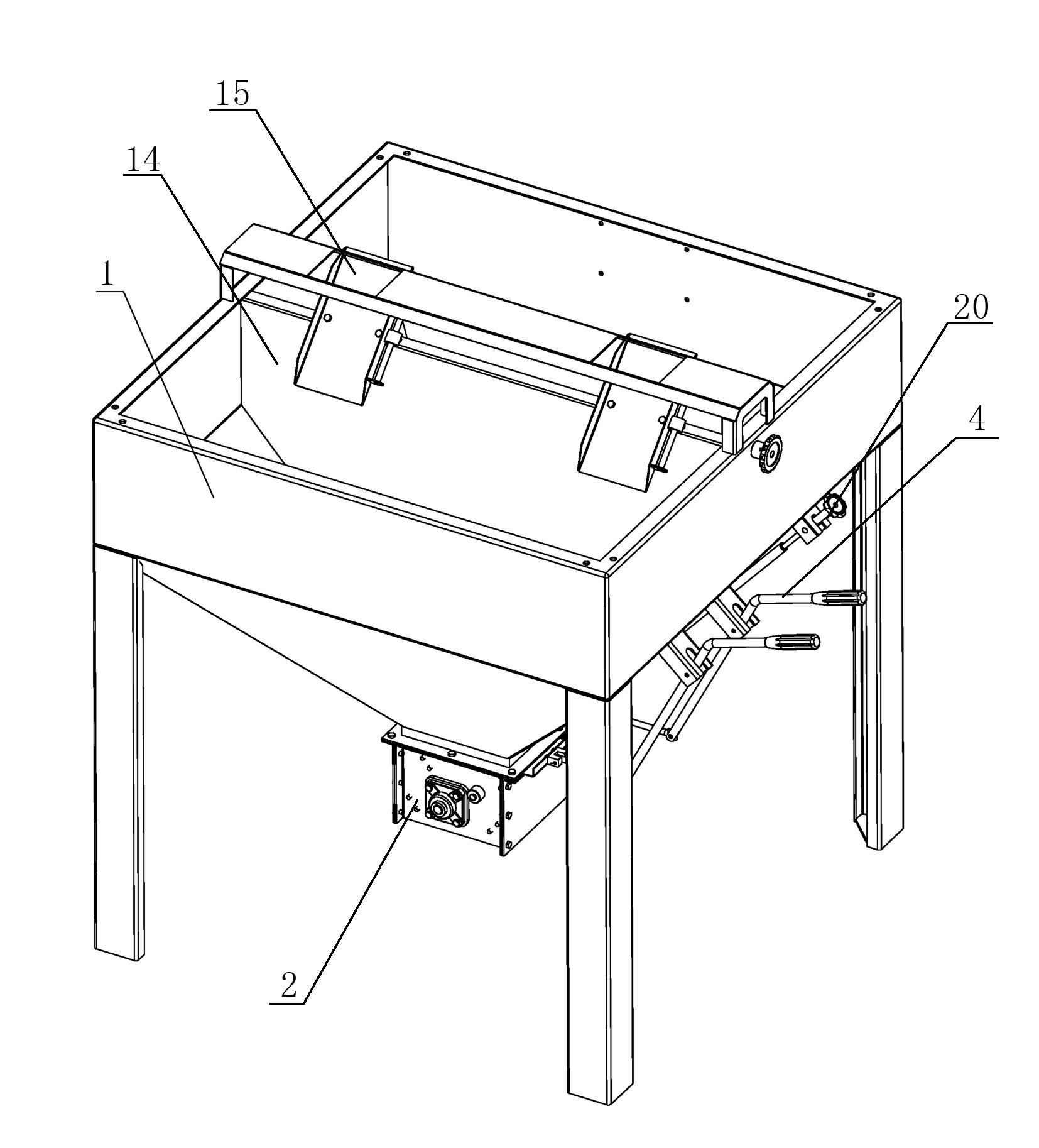

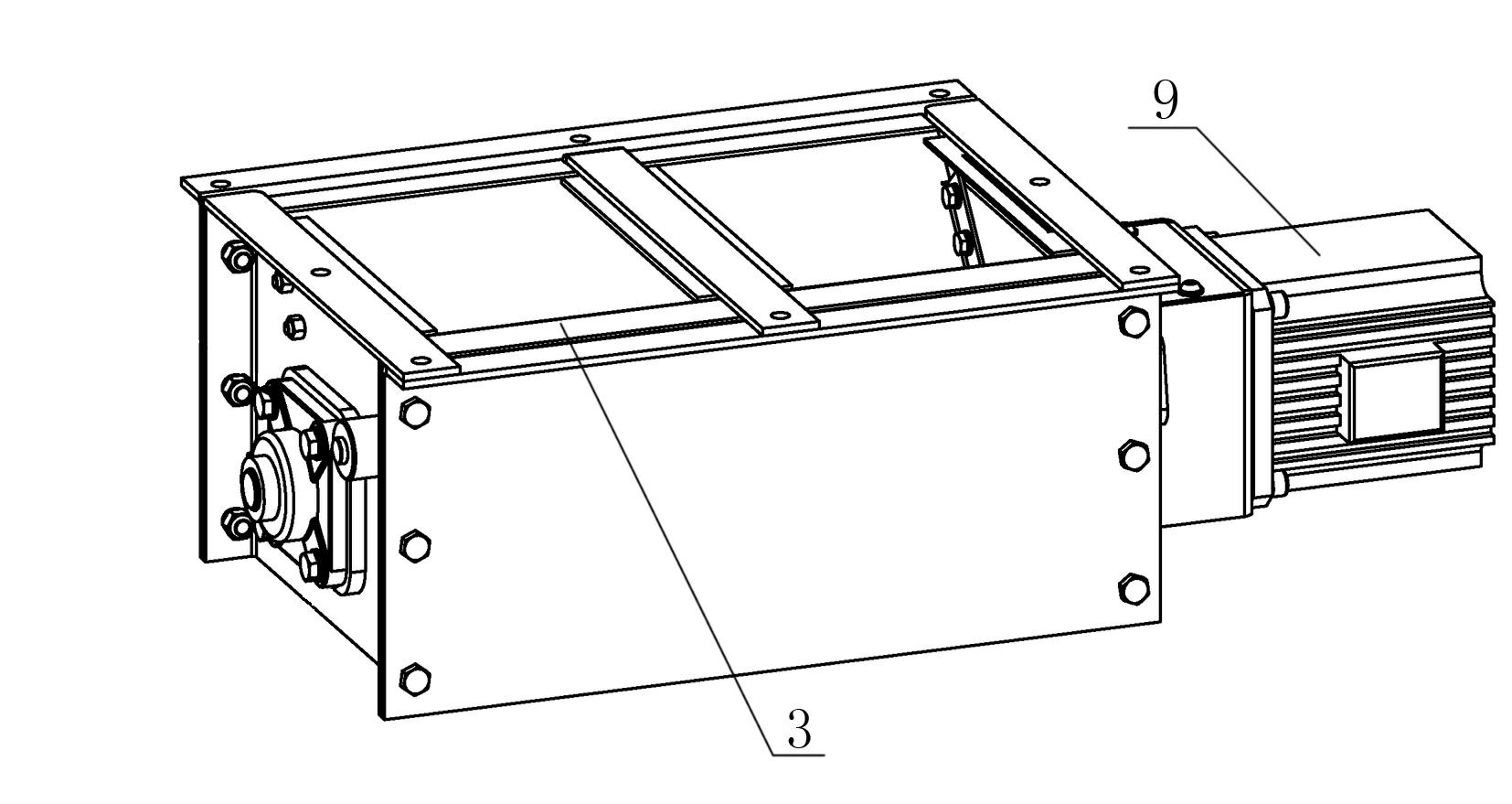

Material dividing and feeding large hopper

InactiveCN102320434APrevent archingGuaranteed continuityLarge containersLoading/unloadingEngineeringMaterial storage

The invention relates to a material dividing and feeding large hopper, which consists of a hopper casing and a feeding material dividing device arranged in the hopper casing, wherein the feeding material dividing device consists of a feeding box and a pull plate type material door, the feeding box is provided with more than two cabin storage passages, the pull plate type material door is used for controlling the opening and closing of the cabin storage passages, and the upper end of the feeding box is provided with a referral plate for separating the cabin storage passages. The feeding box part of the material dividing and feeding large hopper adopts a feeding roller for feeding, and a circular arc groove is milled on the feeding roller, so the flow speed of the materials is stable and uniform, and in addition, the material blockage and the material arching can be prevented. The closing and the opening of different material storage spaces are controlled through the pull plate type material door, and the material flow speed is precisely controlled through combining a material pressing cutter and a fine adjusting device of the material pressing cutter. Therefore, the material discharge flow rate can be precisely controlled, and the material dividing and feeding large hopper can preferably adapt to the requirements of subsequent equipment.

Owner:HEBEI PINGLE FLOUR MACHINERY GROUP

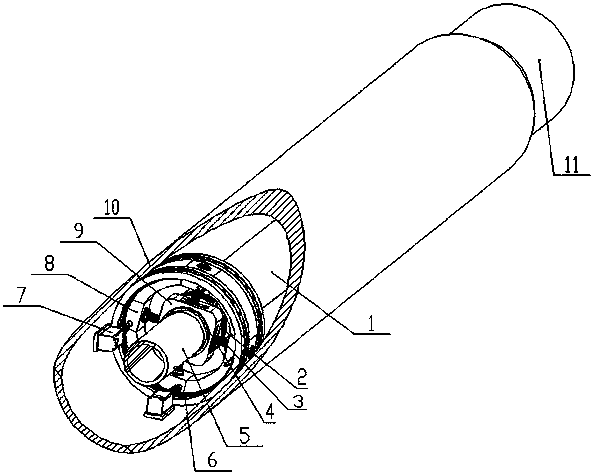

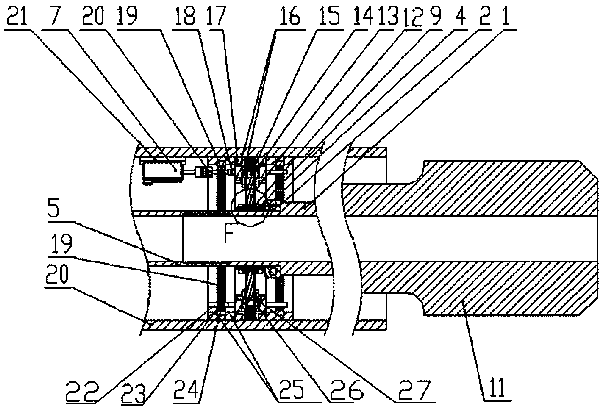

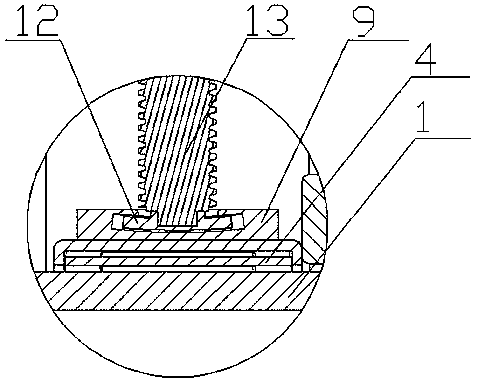

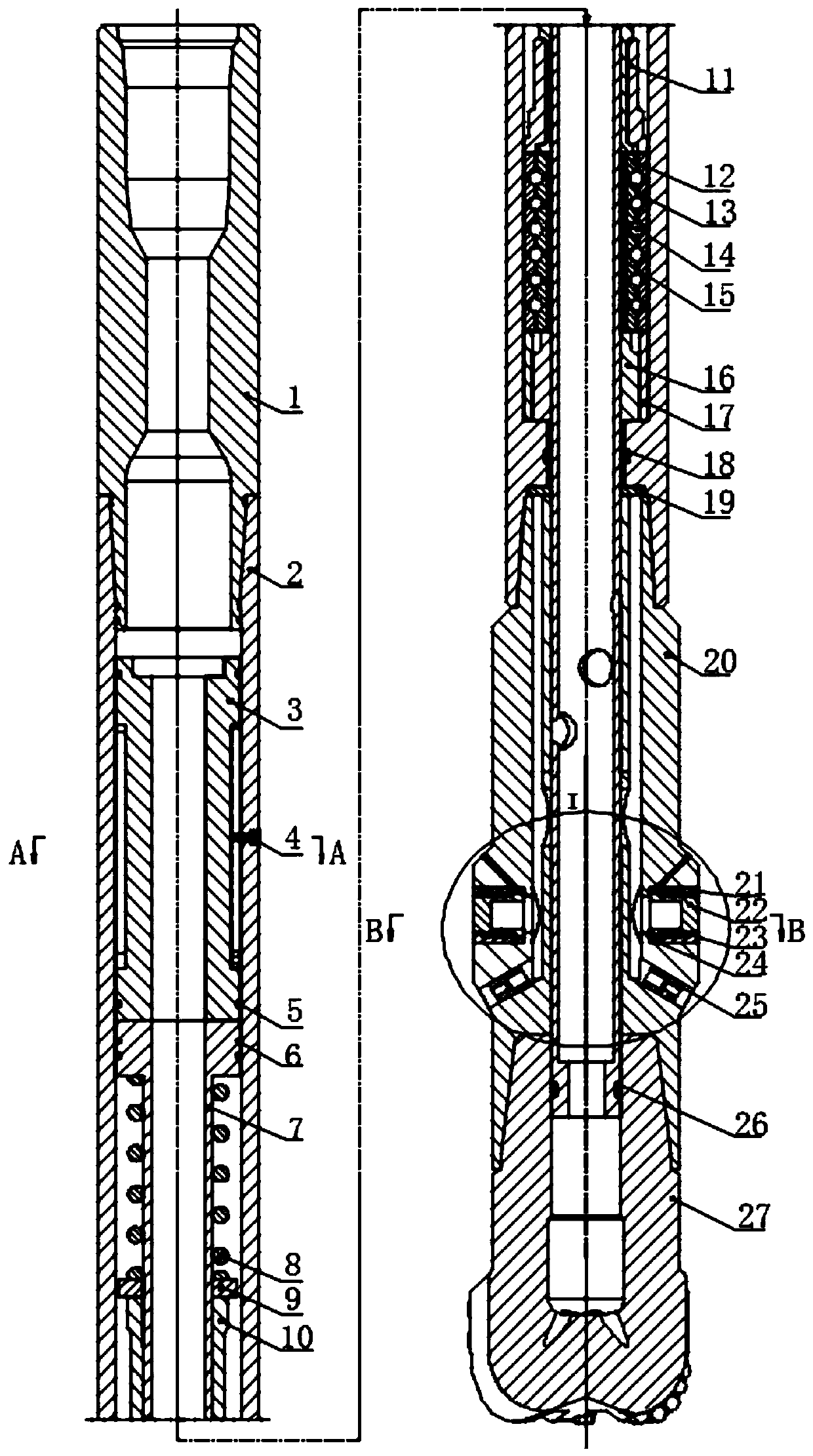

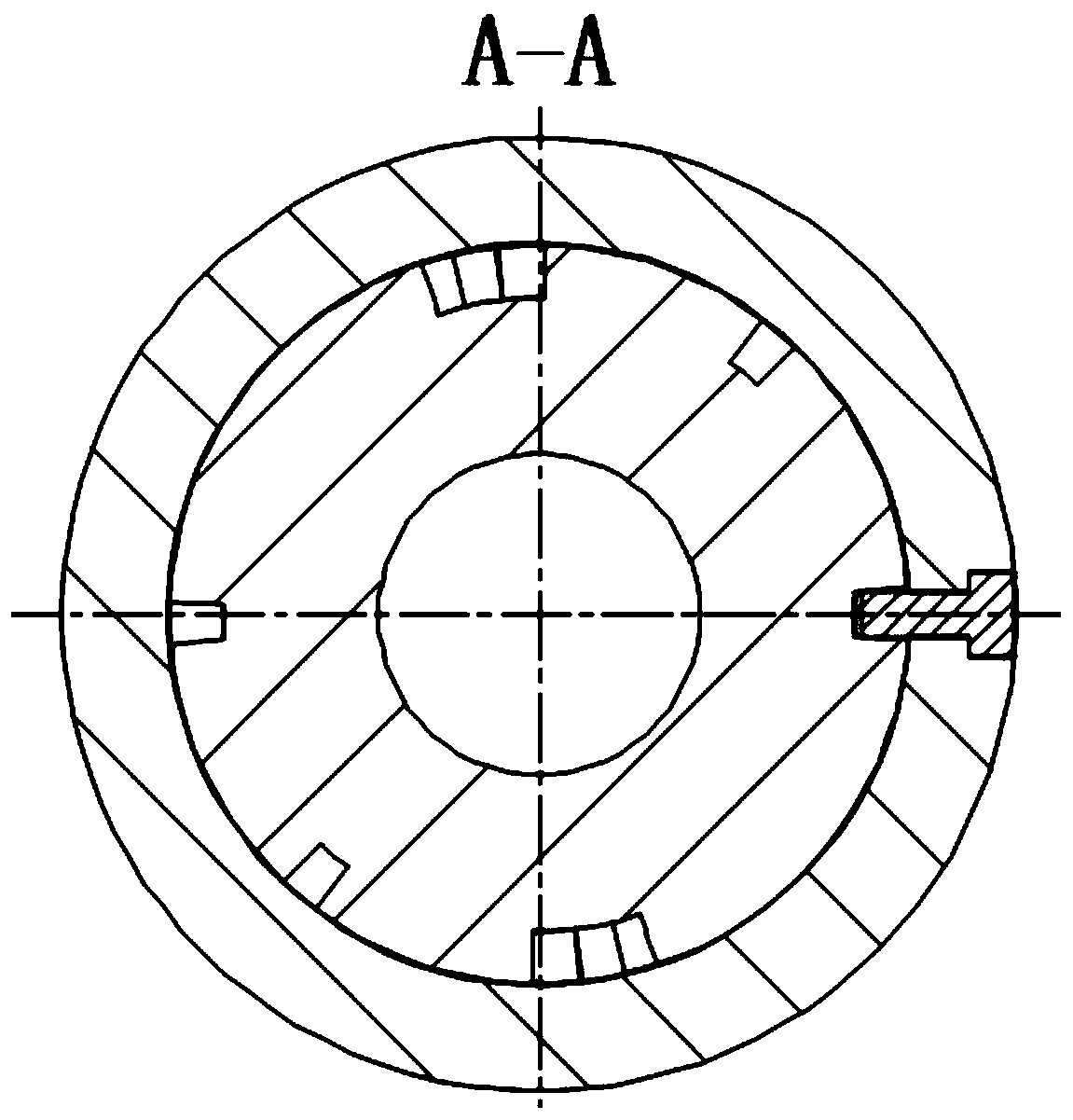

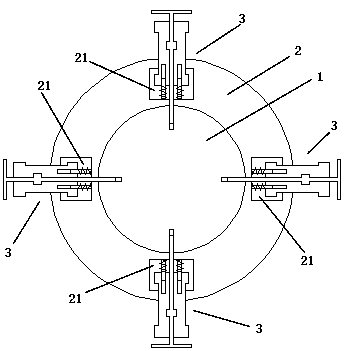

Bias guiding mechanism of static pointing type rotary steering well drilling tool and control method

ActiveCN110043188AReduce the difficulty of orientationSimple implementationDirectional drillingBorehole drivesElectric energyPetroleum

The invention discloses a bias guiding mechanism of a static pointing type rotary steering well drilling tool and a control method, and belongs to the technical field of petroleum and natural gas welldrilling. The bias guiding mechanism of the static pointing type rotary steering well drilling tool comprises a drill bit connecting shaft and a non-rotary outer cylinder, and further comprises a flexible hose, bias mechanisms and a sliding block connecting piece; the flexible hose is connected with the drill bit connecting shaft, and the bias mechanisms are installed in the non-rotary outer cylinder; the bias mechanisms comprise center adjusting sliding blocks, spiral telescopic mechanisms and control motors; the sliding block connecting piece is arranged on the outer part of the drill bit connecting shaft in a sleeving mode; and the center adjusting sliding blocks are connected with the control motors through the spiral telescopic mechanisms and are installed in the sliding block connecting piece, the center adjusting sliding blocks are driven by the control motors to move forward and backward to push the drill bit connecting shaft, and control over structure bend angles and tool face angles is realized. The disturbance and the load applied on the motors are both small and stable in the process of making a connection, the electric energy requirement of a system is reduced obviously, and the service life of the guiding tool is prolonged; and the scheme is simple and easy to operate, and the structure is compact.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

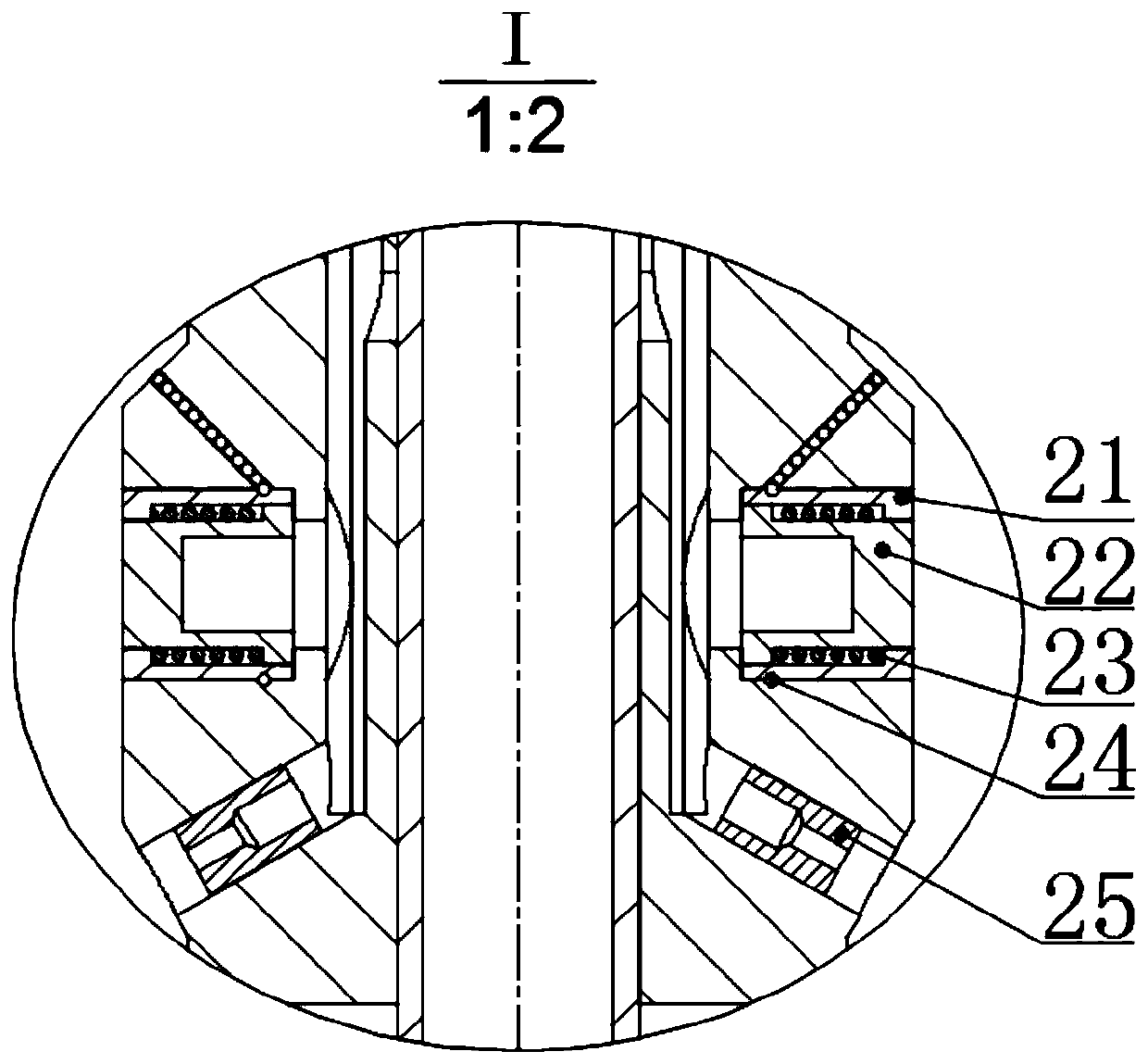

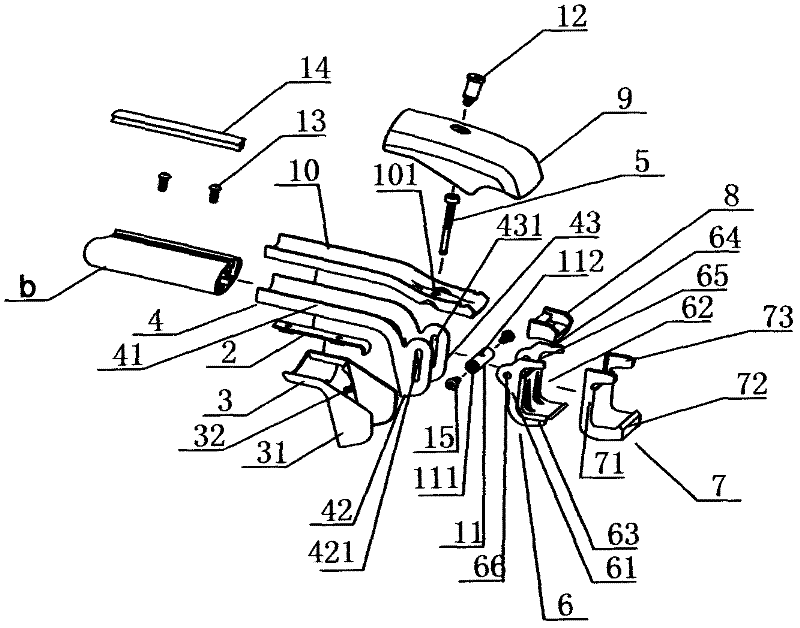

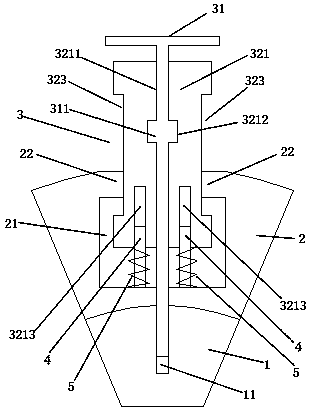

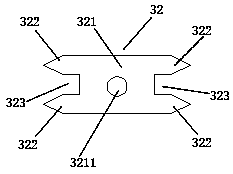

Mechanical rotary steering tool

ActiveCN110094161ASimple structureEasy to operateConstructionsDirectional drillingHorizontal wellsUpper joint

The invention discloses a mechanical rotary steering tool, which comprises an upper joint, a control unit, an execution unit, and a drill bit. According to the technical scheme, the end of a pin is mounted in the outer wall channel of an indexing mechanism, when pump pressure is increased, the indexing mechanism rotates and moves in the axial direction in the meantime to drive a mobile mandrel tomove along the axial direction, so that a radical passage hole at the lower end of the mobile mandrel communicates with a radical passage hole of a guide joint, and a high-pressure drilling fluid enters and pushes a telescopic arm to move outwards in the radial direction to realize a steering function; when the pump pressure is increased again, the limiting point of the cooperation between the indexing mechanism and the pin is switched, the indexing mechanism is reset, the mobile mandrel is reset under the action of the elastic force of a spring a, the drilling fluid is discharged from a bypass valve, and the telescopic arm is retracted under the action of the elastic force of a spring b to stop steering operation. According to the mechanical rotary steering tool, control of a wellbore trajectory and lowering of the cost of the rotary steering tool can be realized, and the mechanical rotary steering tool is suitable for using in structural wells such as horizontal wells and large displacement wells.

Owner:SICHUAN JUTINGZAO TECH CO LTD

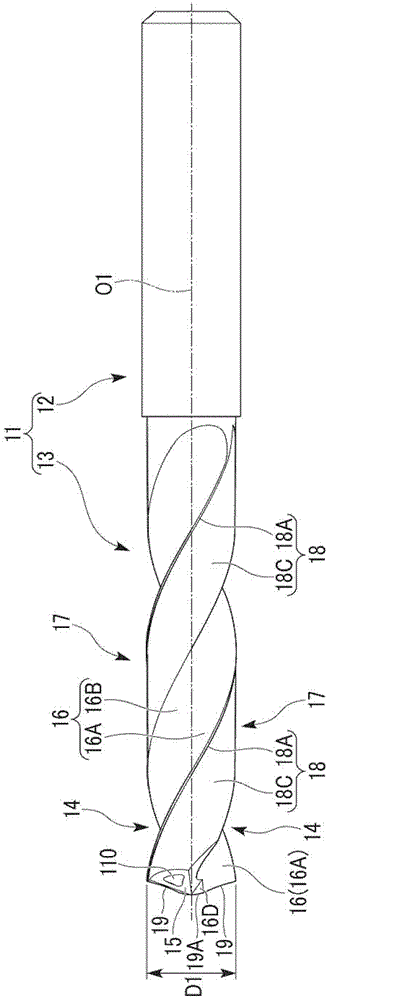

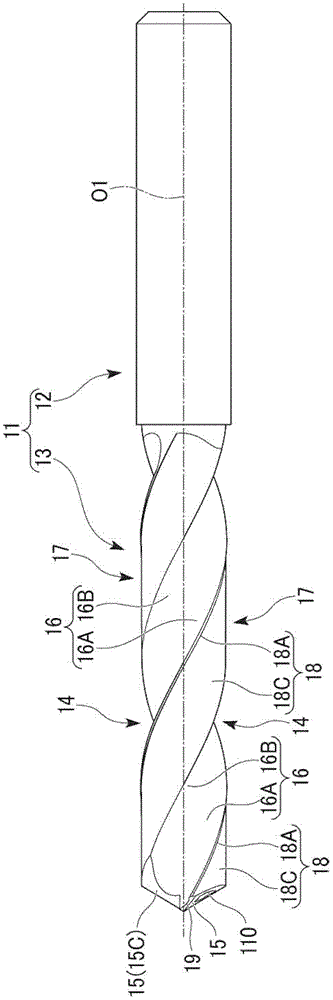

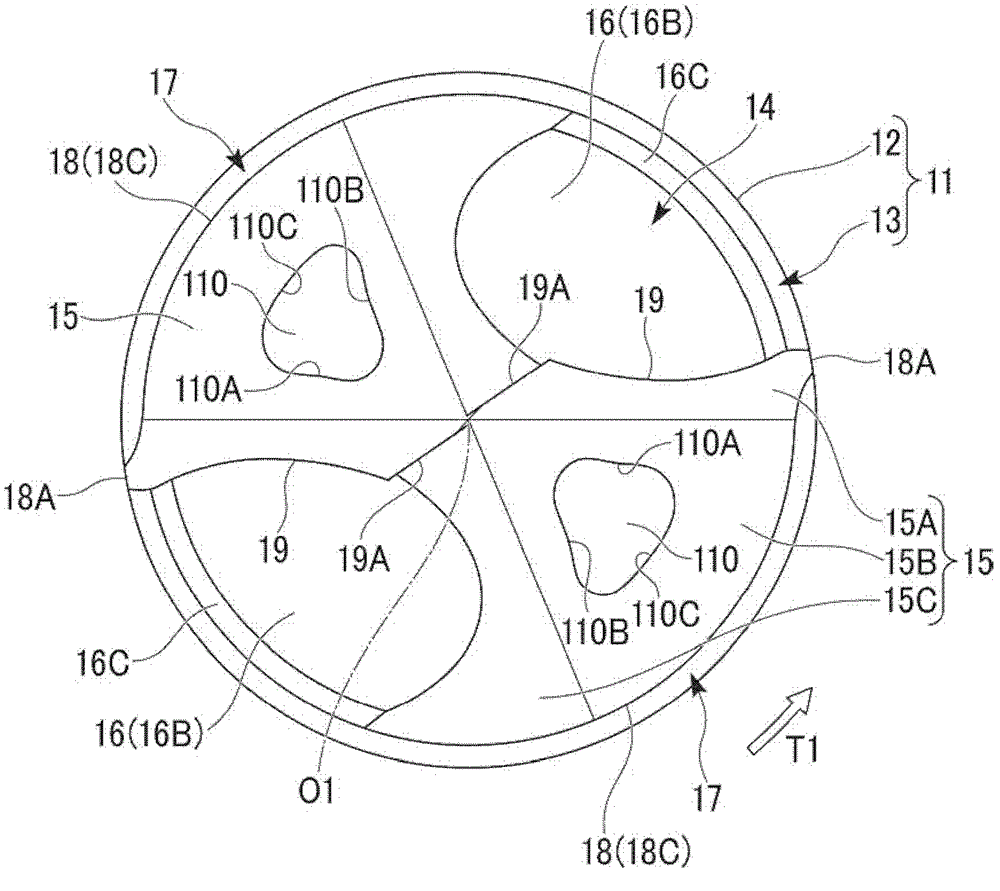

Drill with coolant holes

InactiveCN102802853AIncrease supplyUnbiased and uniform supplyTransportation and packagingWorkpiecesRidgeDrill bit

A drill provided with coolant holes, comprising: a drill body rotating about the axis thereof; cutting edge sections having top clearance surfaces; cutting debris discharge grooves each having a front groove-wall surface facing forward in the rotational direction of the drill body and also each having a rear groove-wall surface facing rearward in the rotational direction; cutting edges each formed at the ridge at which a front groove-wall surface and a top clearance surface intersect each other; land sections each formed between the cutting debris discharge grooves adjacent to each other in the rotational direction; and coolant holes formed by boring in the land sections and open in the top clearance surfaces. The coolant holes each include: a front hole-wall surface located ahead in the rotational direction and having a constant distance to the front groove-wall surface of a cutting debris discharge groove; a rear hole-wall surface located behind the rotational direction and having a constant distance to the rear groove-wall surface of a cutting debris discharge groove; and an outer peripheral hole-wall surface located on the outer peripheral side of the drill body and having a constant distance to the outer peripheral wall surface of a land section.

Owner:MITSUBISHI MATERIALS CORP

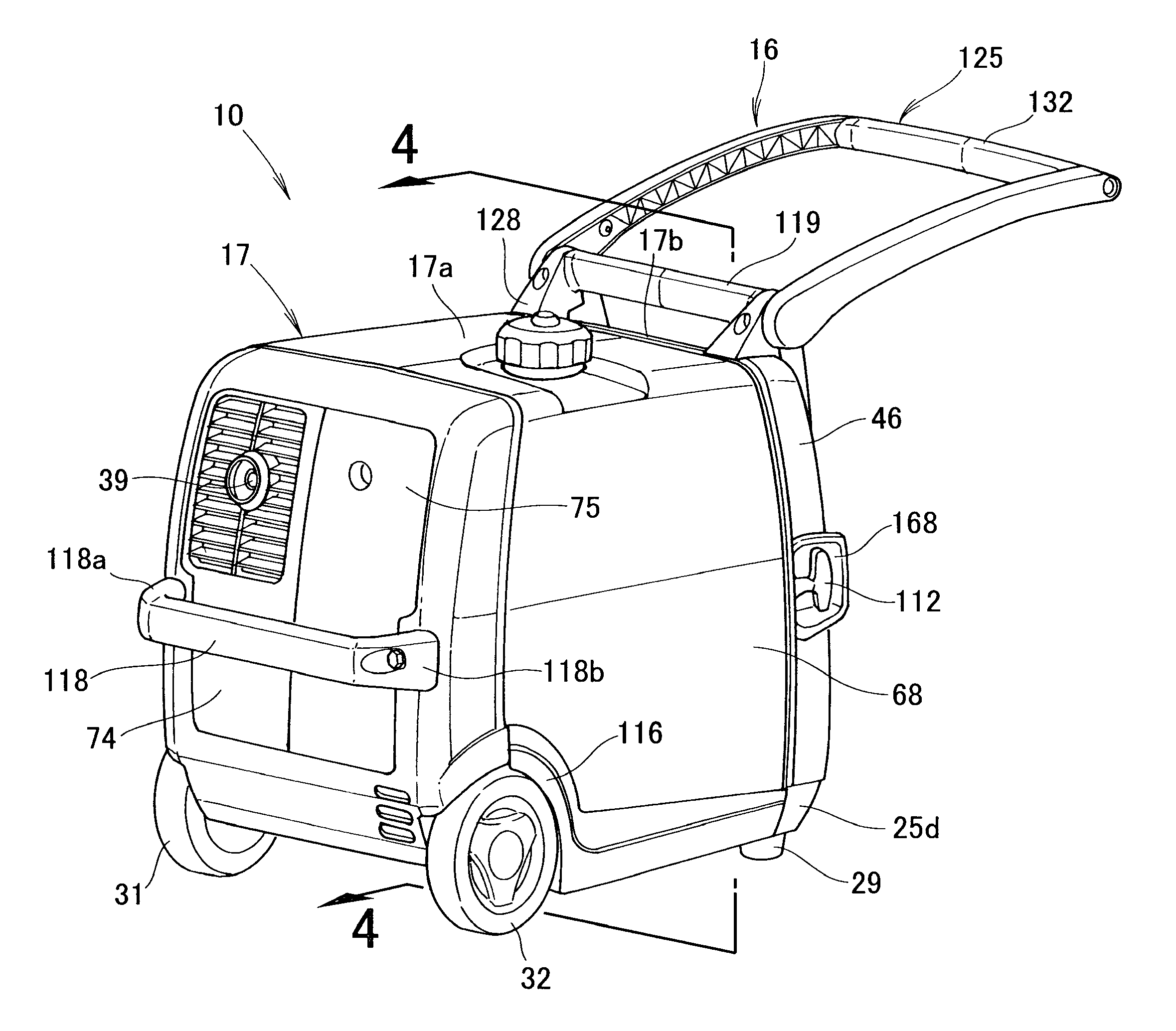

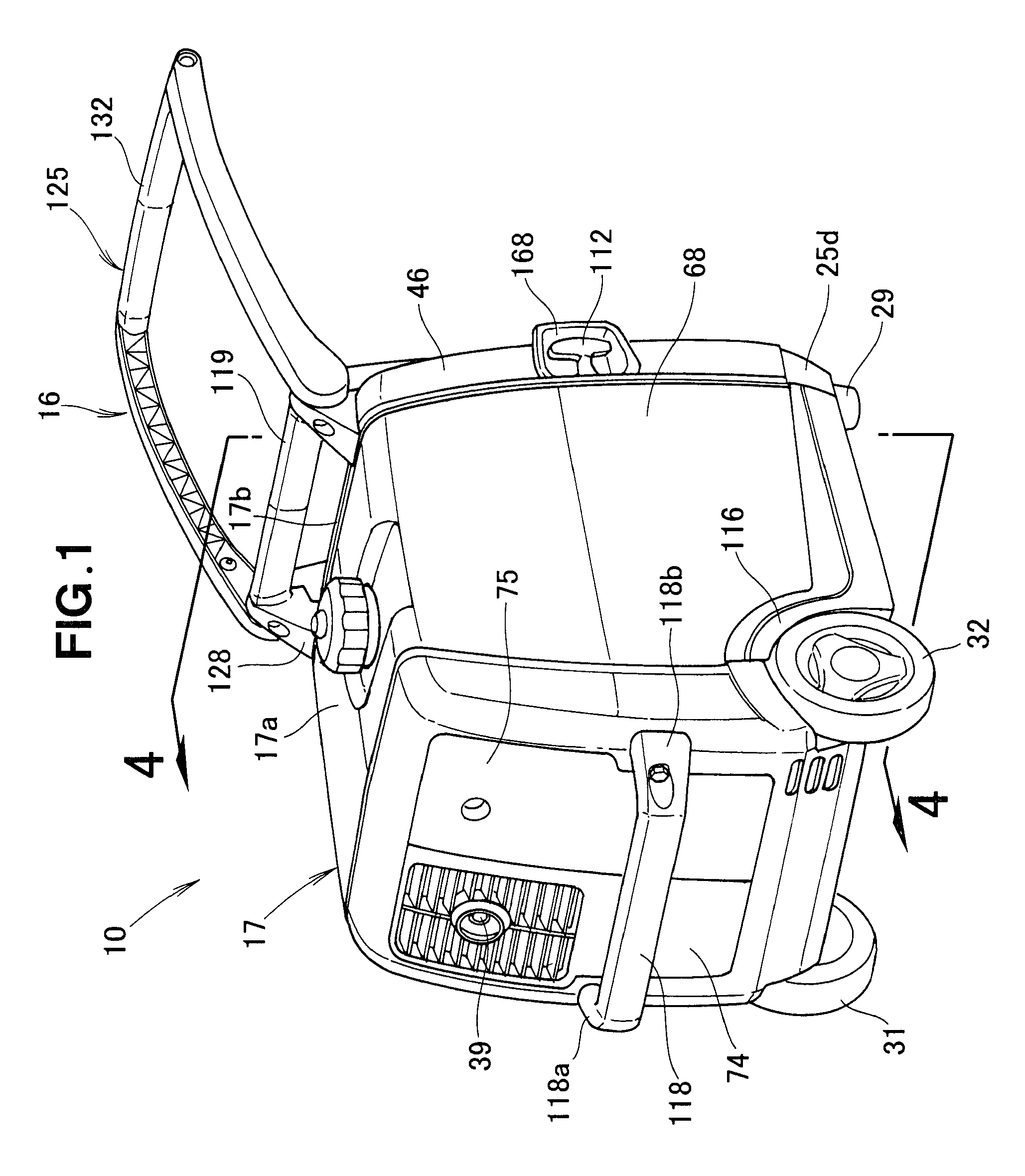

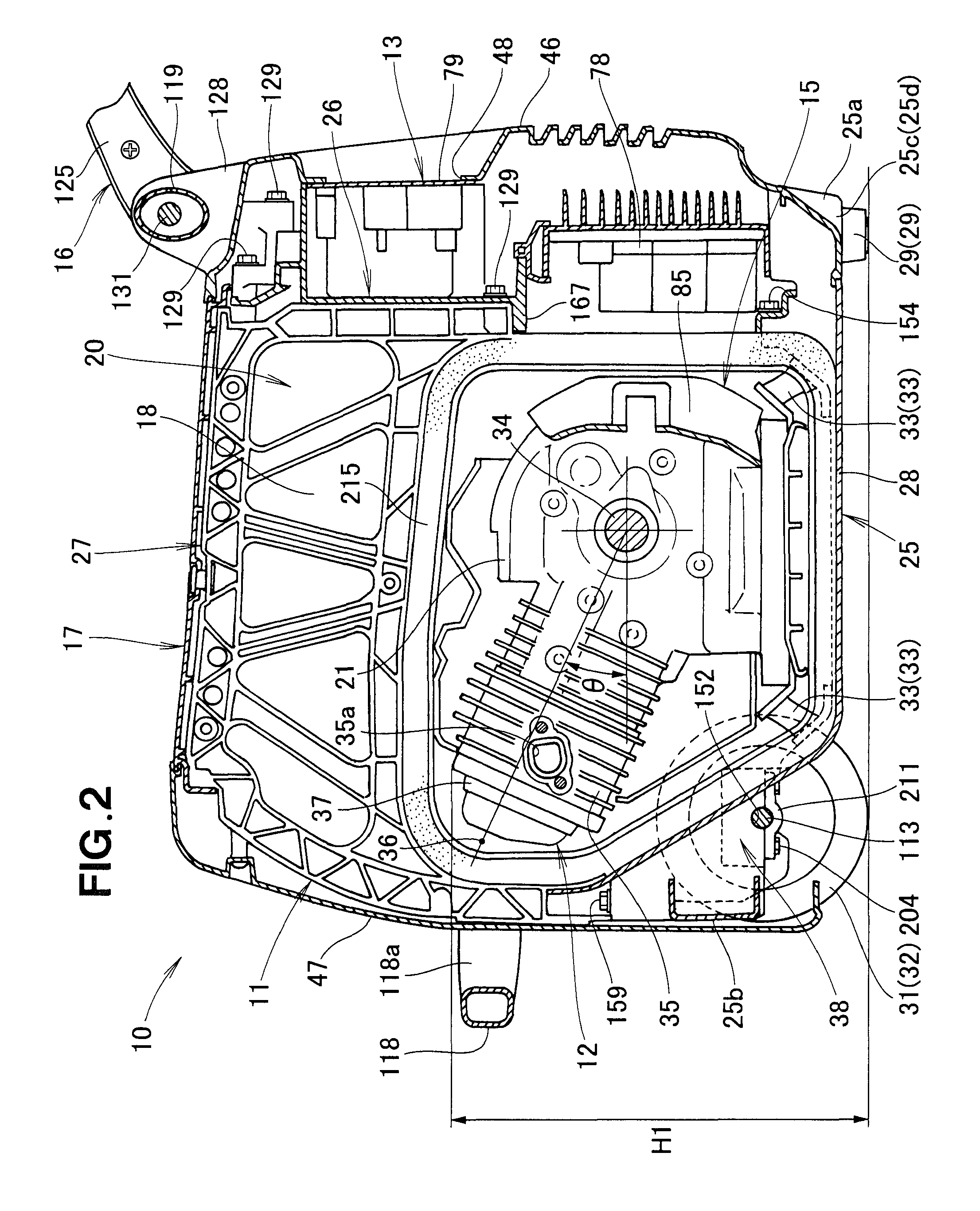

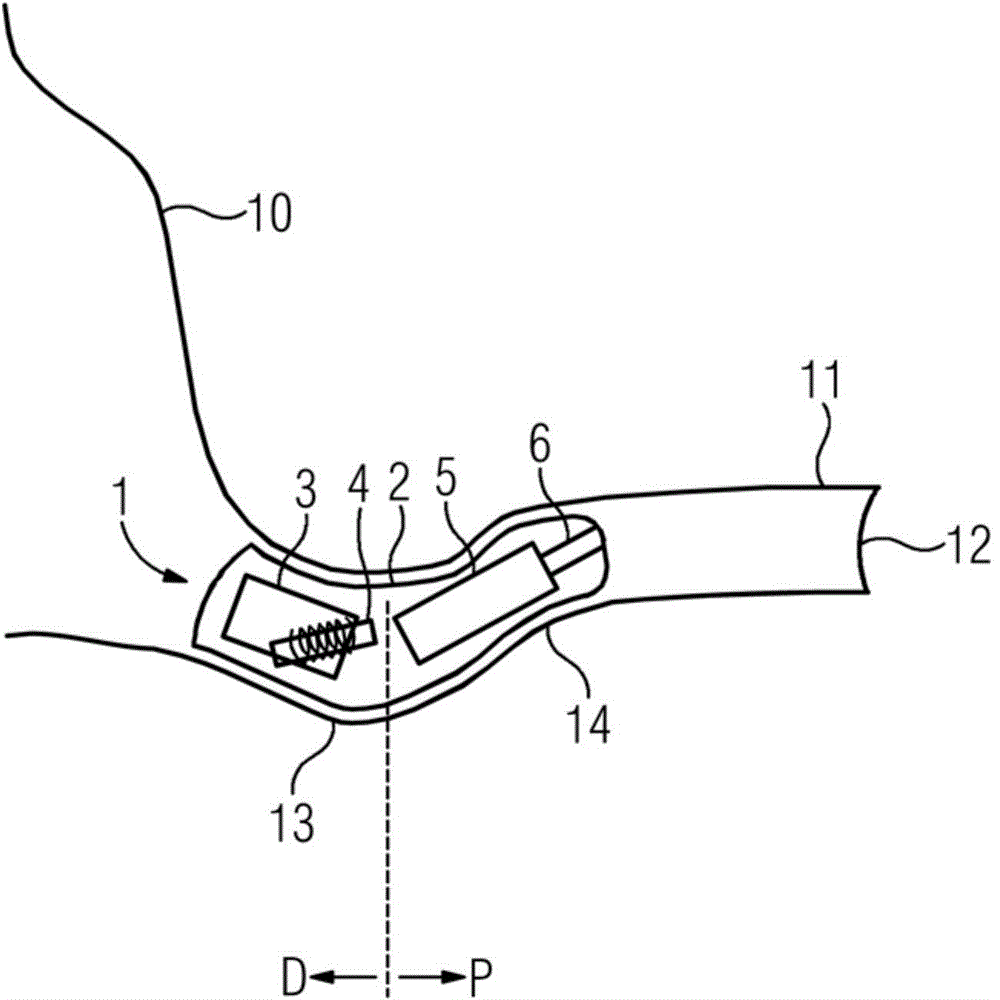

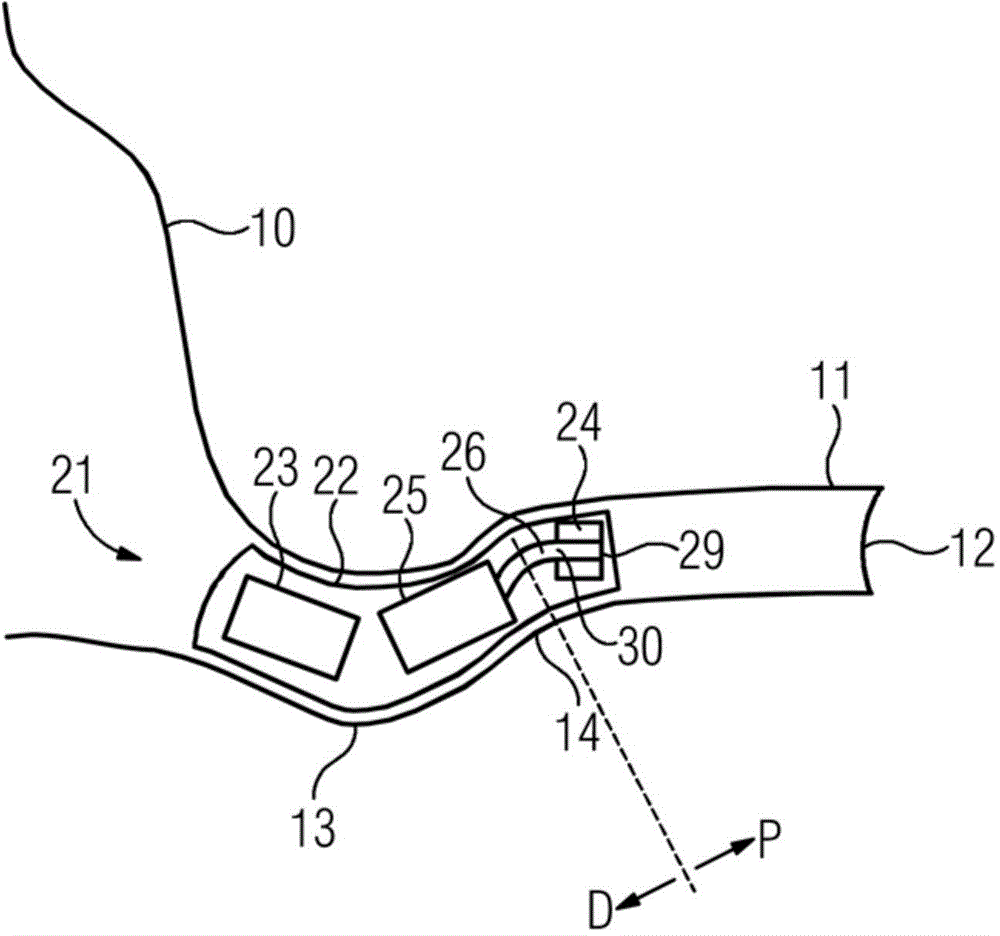

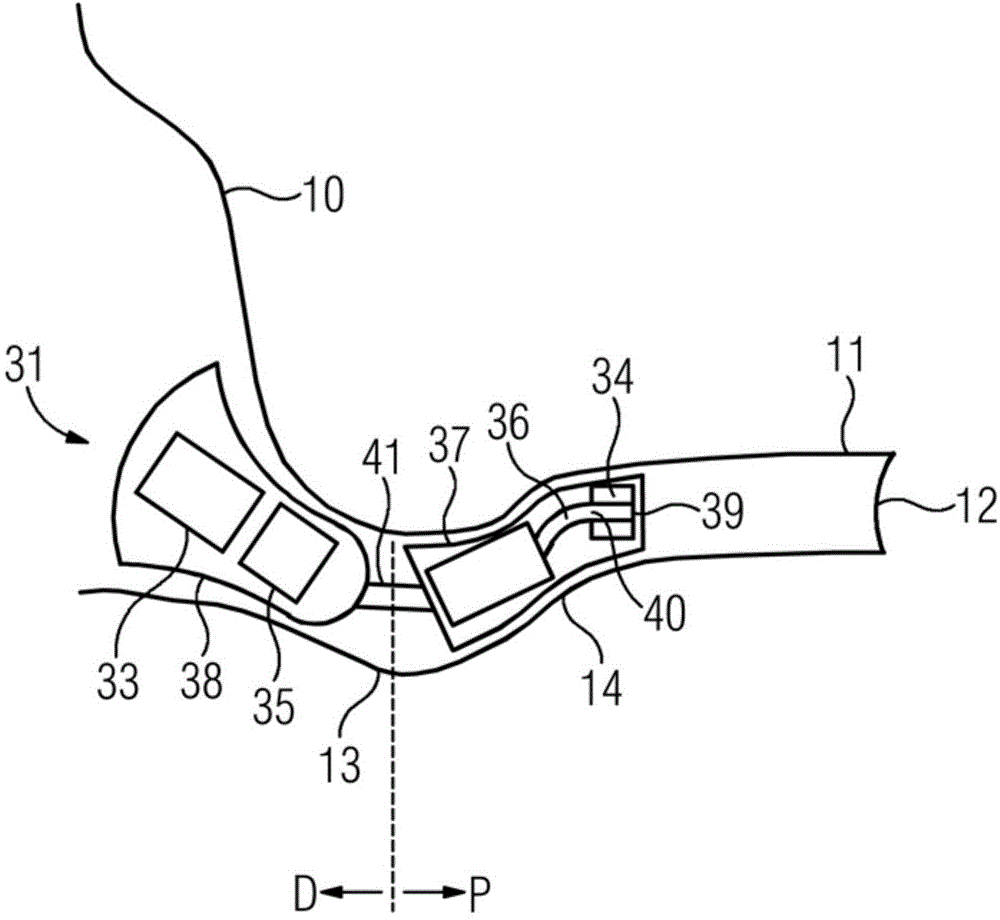

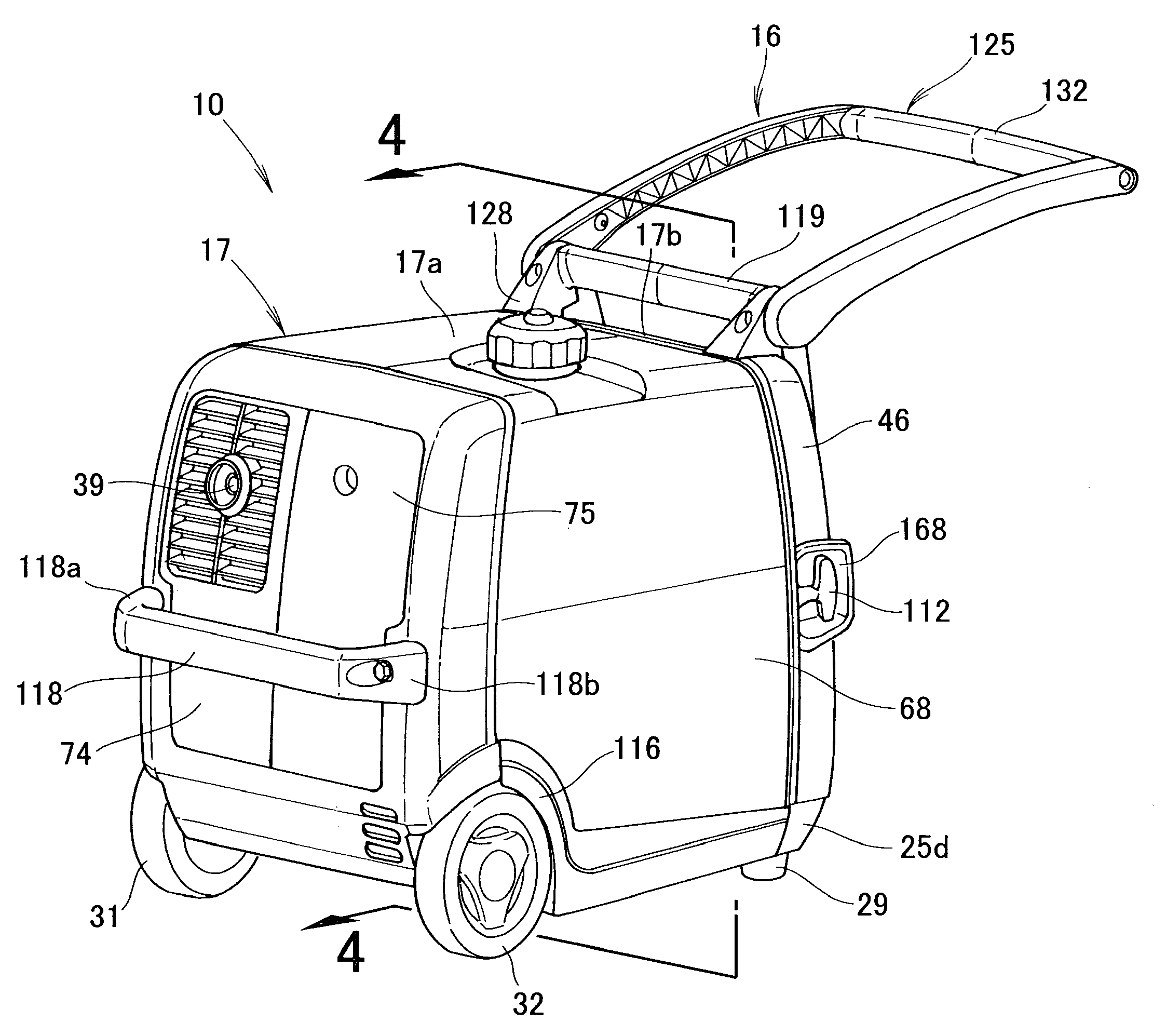

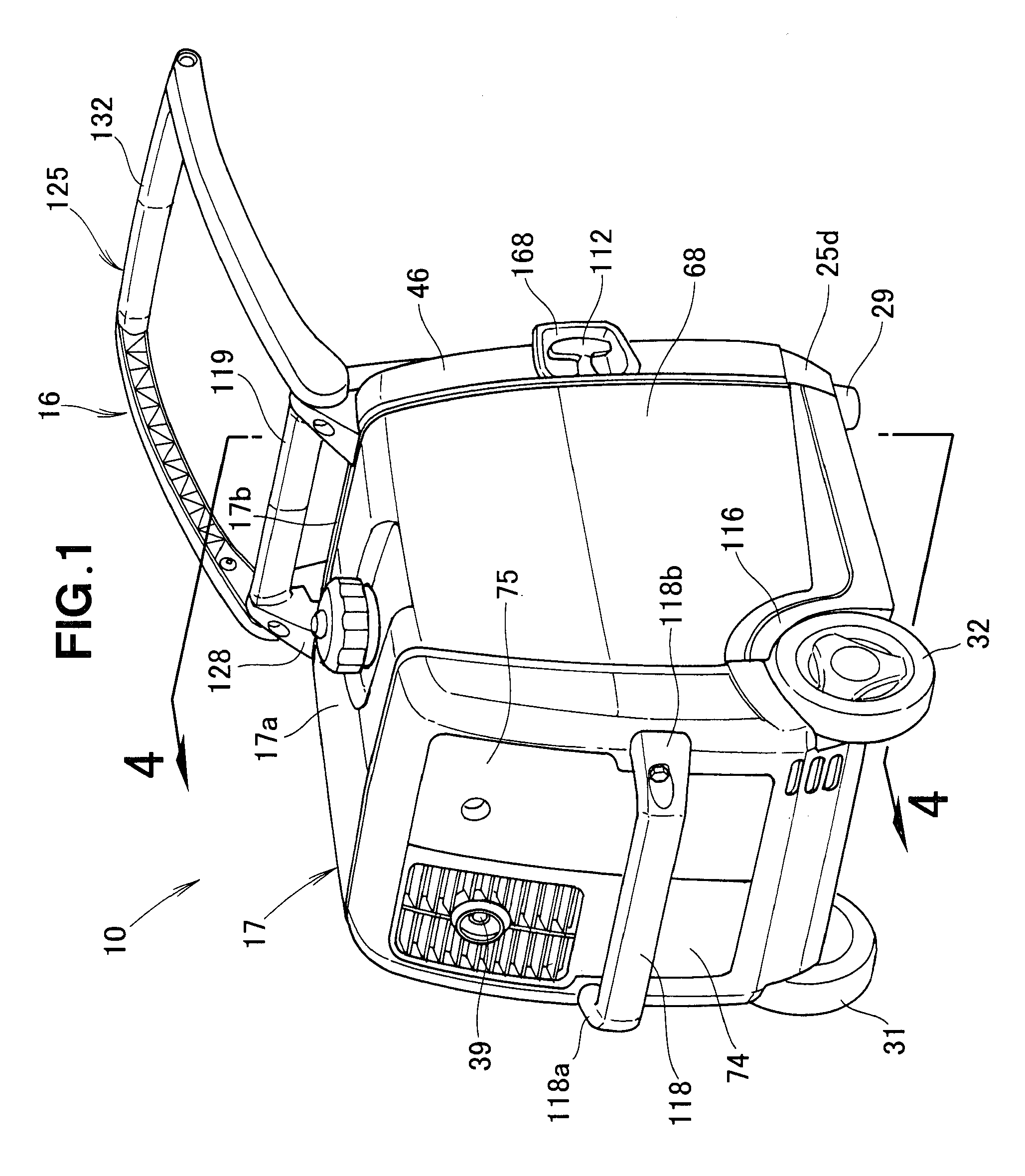

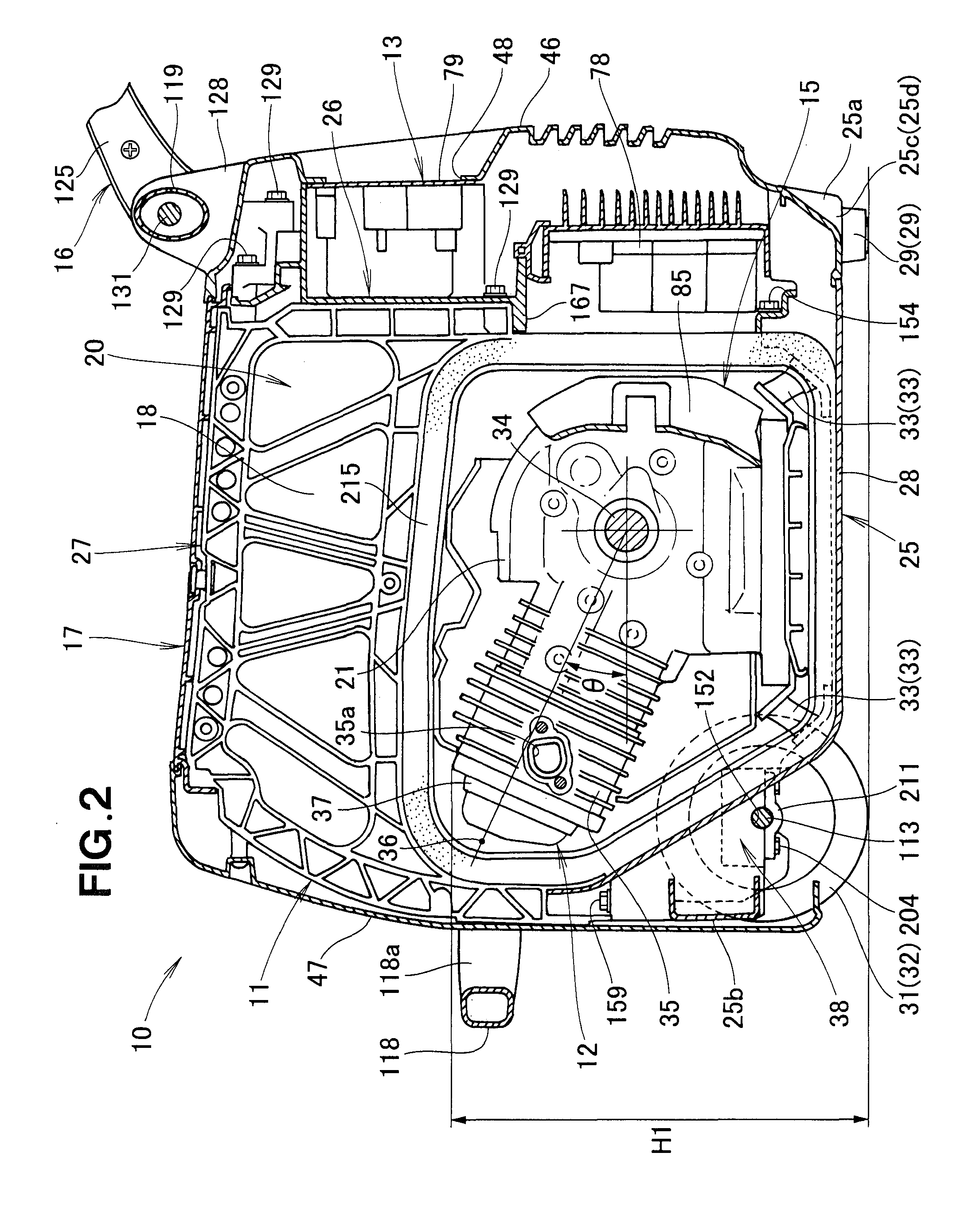

Engine generator

ActiveUS8328207B2Steady OrientationCarriage/perambulator with single axisMachines/enginesGravity centerEngine-generator

An engine generator movable on left and right wheels. The wheels are provided on a rear section of a bottom cover via an axle. A cylinder of an engine is disposed so as to incline upwards towards the direction of the axle. Inclining the cylinder lowers the center of gravity of the engine and disposes the axle positioned below the cylinder at a high position, thereby reducing the height of the engine generator. The orientation of the engine generator during travel is stabilized.

Owner:HONDA MOTOR CO LTD

Binaural Hearing Instrument And Earpiece

ActiveCN104066042AInterference Affects StabilitySteady improvement in qualityCompletely in canal hearing aidsEar supported setsEngineeringHeadphones

The invention relates to a binaural hearing instrument and an earpiece. The binaural hearing instrument and an earpiece for the binaural hearing instrument are enabled for broadband wireless data transmission to a further binaural hearing instrument. Wireless broadband binaural data transmission with high bandwidth and low resource requirement is afforded, while the devices can be manufactured easily and inexpensively. The hearing instrument has a housing, a signal processor, a receiver and an antenna for binaural data transmission. The housing can be worn at least partly in an auditory canal. A distal section houses the signal processor and the receiver. A proximal section adjacent to the eardrum and separated spatially from the proximal section houses the antenna. The antenna is disposed between the receiver and the sound outlet as far in the auditory canal as possible. The distance between the antennas of the two binaural hearing instruments is reduced by 1 to 2cm. regulated minimum distance is guaranteed between the antennas and the earpiece and th hybrid and compared with conventional positioning and the bit error rate is significantly improved.

Owner:SIVANTOS PTE LTD

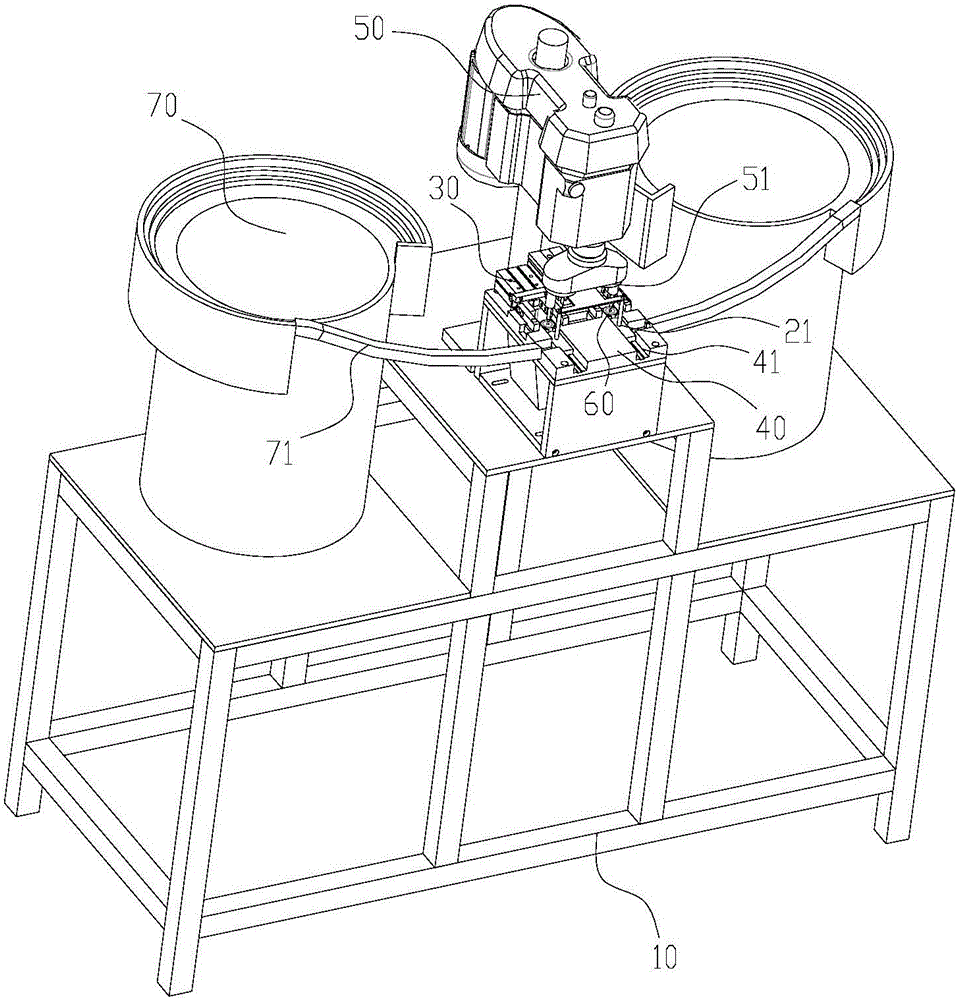

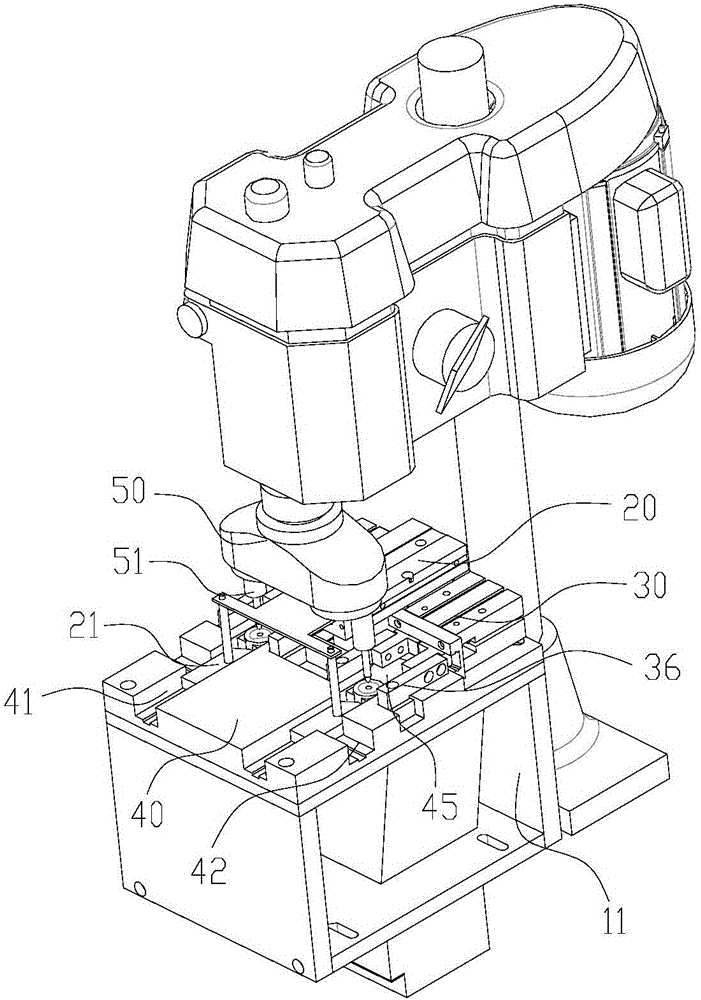

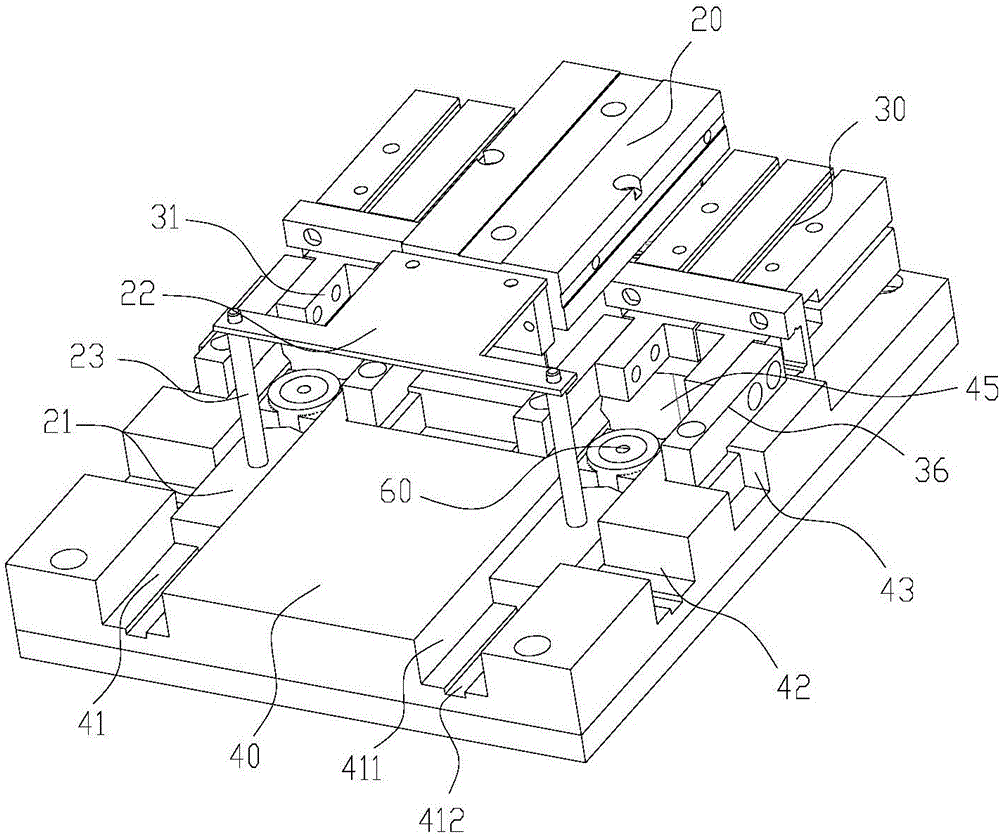

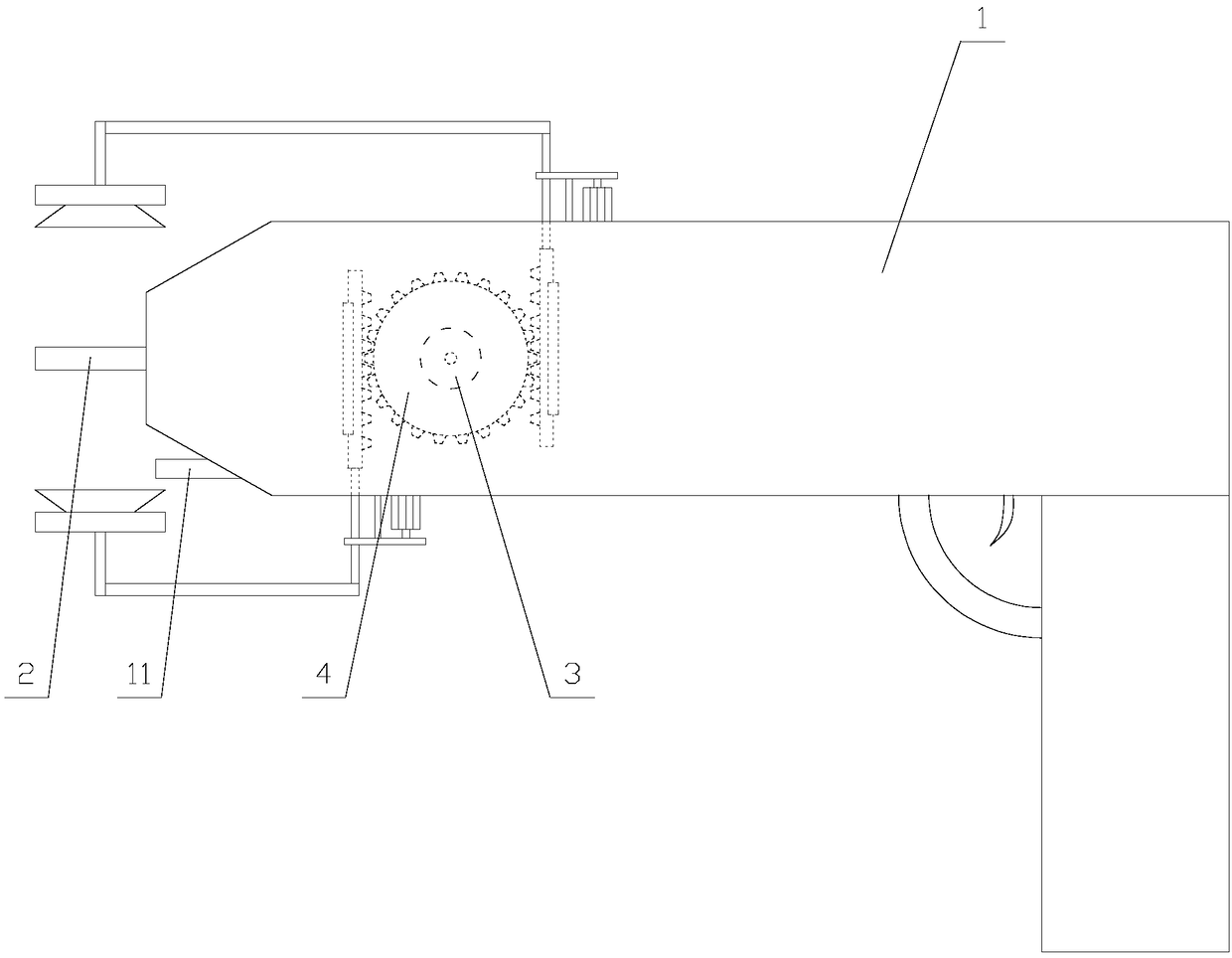

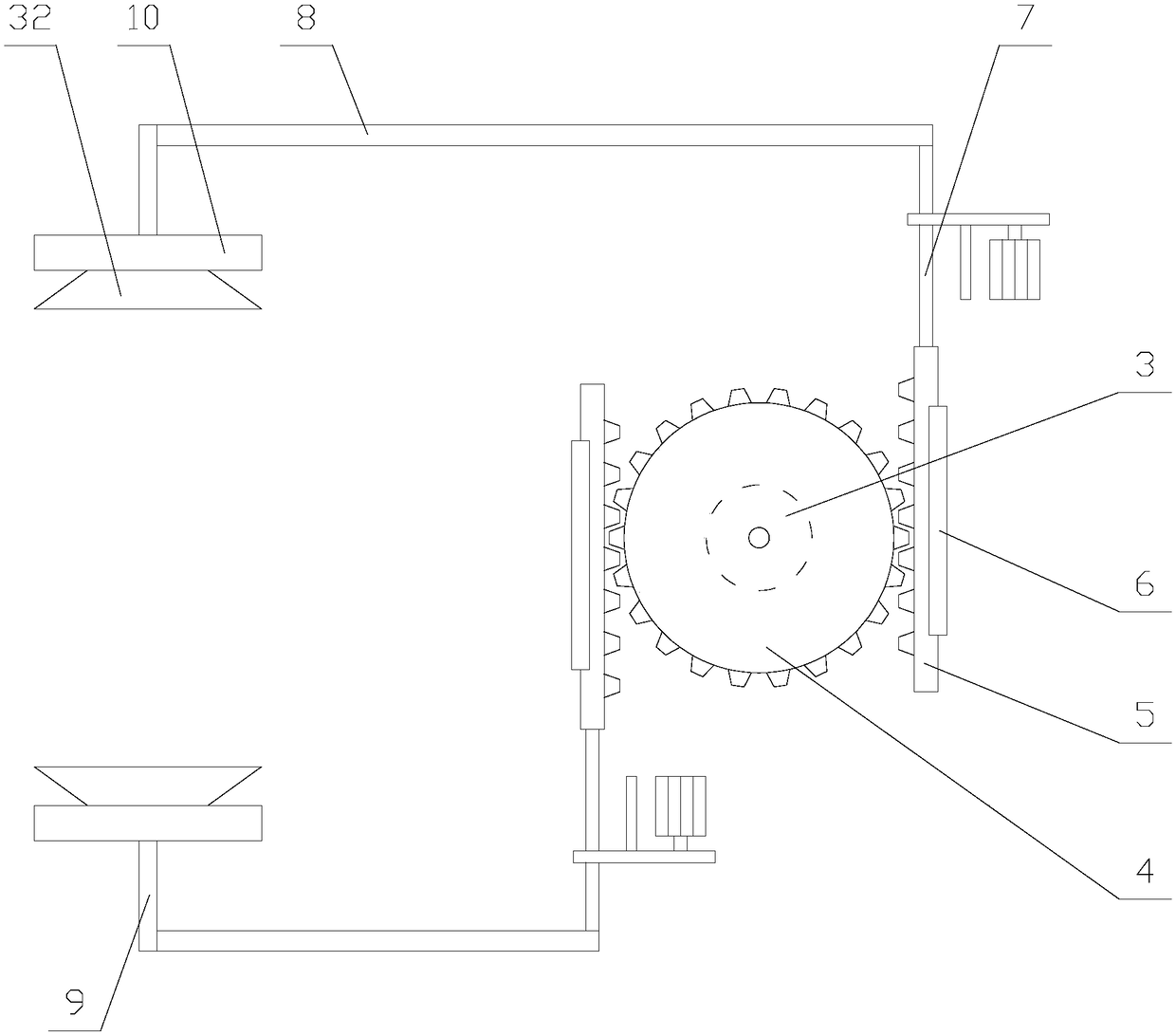

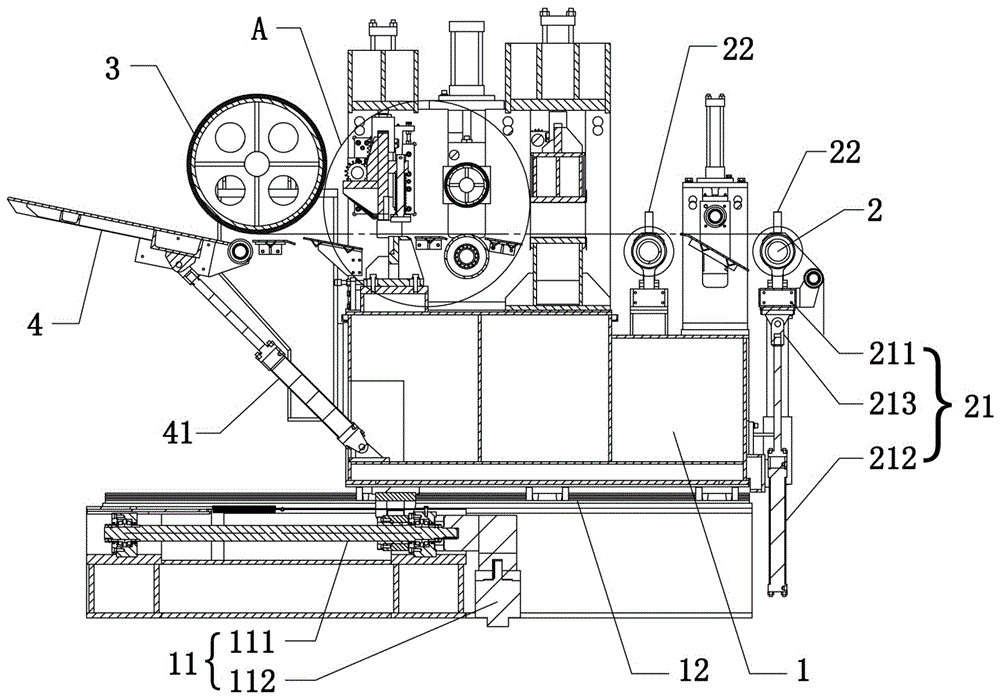

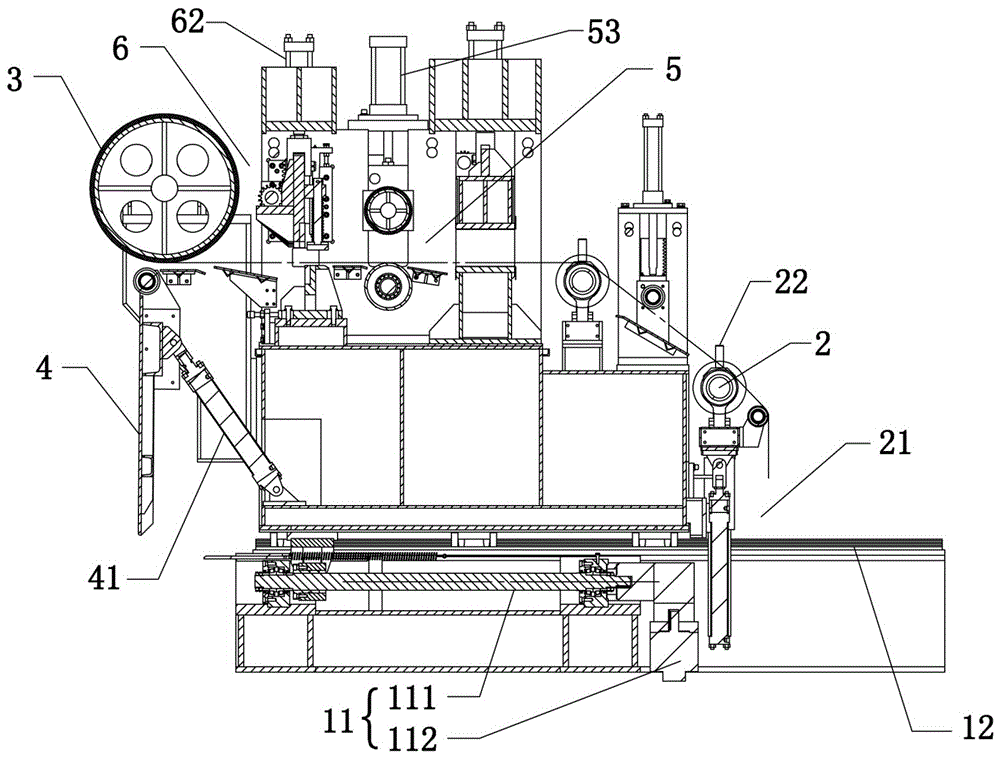

Automatic feeding tapping machine

ActiveCN105855646AGuaranteed coincidenceImprove machining accuracyThread cutting feeding devicesThread cutting machinesEngineeringDrill bit

The invention discloses an automatic feeding tapping machine which has the characteristics of being accurate in alignment and high in machining efficiency. The automatic feeding tapping machine comprises a machine frame, a headpiece and vibrating disks. A tapping drill is mounted on the headpiece. A positioning fixture is mounted on the machine frame. The positioning fixture comprises a bottom template, a push cylinder and a clamping cylinder. The bottom template is provided with guiding grooves and inlet grooves. Push plates are mounted on the push cylinder and are slidably arranged in the corresponding guiding grooves. Each vibrating disk is provided with a guide groove which communicates with the corresponding inlet groove. The clamping cylinder is provided with clamping seats. The clamping seats slide towards and draw close to the centers of the guiding grooves from the two sides. Workpieces are placed in the vibrating disks and slide along the guide grooves to be arranged to the inlet grooves. The push cylinder drives the push plates to slide along the guiding grooves and push the workpieces in the guiding grooves to slide. The sidewalls of the push plates close the inlet grooves until the workpieces are clamped by the clamping seats. The tapping drill moves along the axis and conducts tapping on the workpieces. After completion of tapping, the push plates push the workpieces to fall into a discharge port.

Owner:宁波三葵研磨材料有限公司

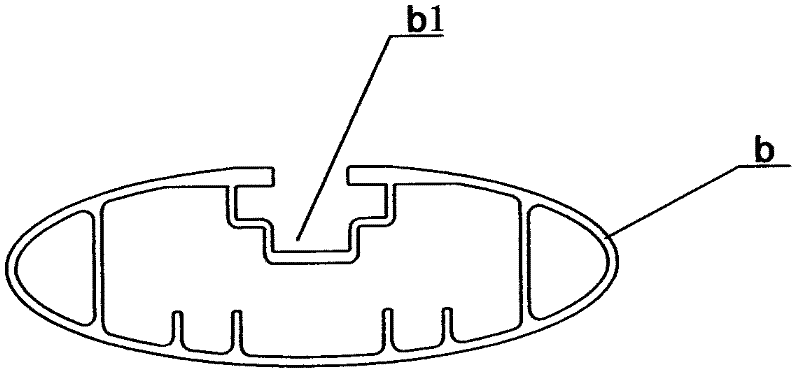

Roof luggage rack for automobile

ActiveCN102310814AImprove installation convenienceIncrease loading capacitySupplementary fittingsEngineeringLoad capacity

The invention relates to a roof luggage rack for an automobile, which comprises two side rods, two transverse rods, a fixed support frame, a movable support frame and a compressed support frame, wherein one end of the fixed support frame is sheathed and fixed in pipe cavities of the transverse rods, the other end of the fixed support frame is pivoted with the movable support frame, one end of themovable support frame is pivoted on the fixed support frame through a screw sleeve and two socket hexagon screws, the other end of the movable support frame is provided with a C-shaped groove connected with the side rods, a fastening screw hole is arranged in the middle of the screw sleeve in a way of transversely penetrating a sleeve body, a through hole is arranged in the compressed support frame, one end of the compressed support frame is sheathed and fixed in the pipe cavities of the transverse rods, and the other end of the compressed support frame is screwed into the fastening screw hole arranged in the middle part of the screw sleeve after passing through the through hole through a socket hexagon fastening bolt for tightly compressing the side rods. The lower part of the fixed support frame is sealed and decorated through a plastic lower case, the upper part of the compressed support frame is sealed and decorated through a plastic upper case. The extension and contraction of the transverse rods and the relative position of the transverse rods on the side rods can be regulated, and the vehicle load capacity is improved. The transverse rods can be conveniently taken down. An upper rubber pad and a lower rubber pad are adopted, and the buffer effect is realized.

Owner:广东君辉汽车用品有限公司

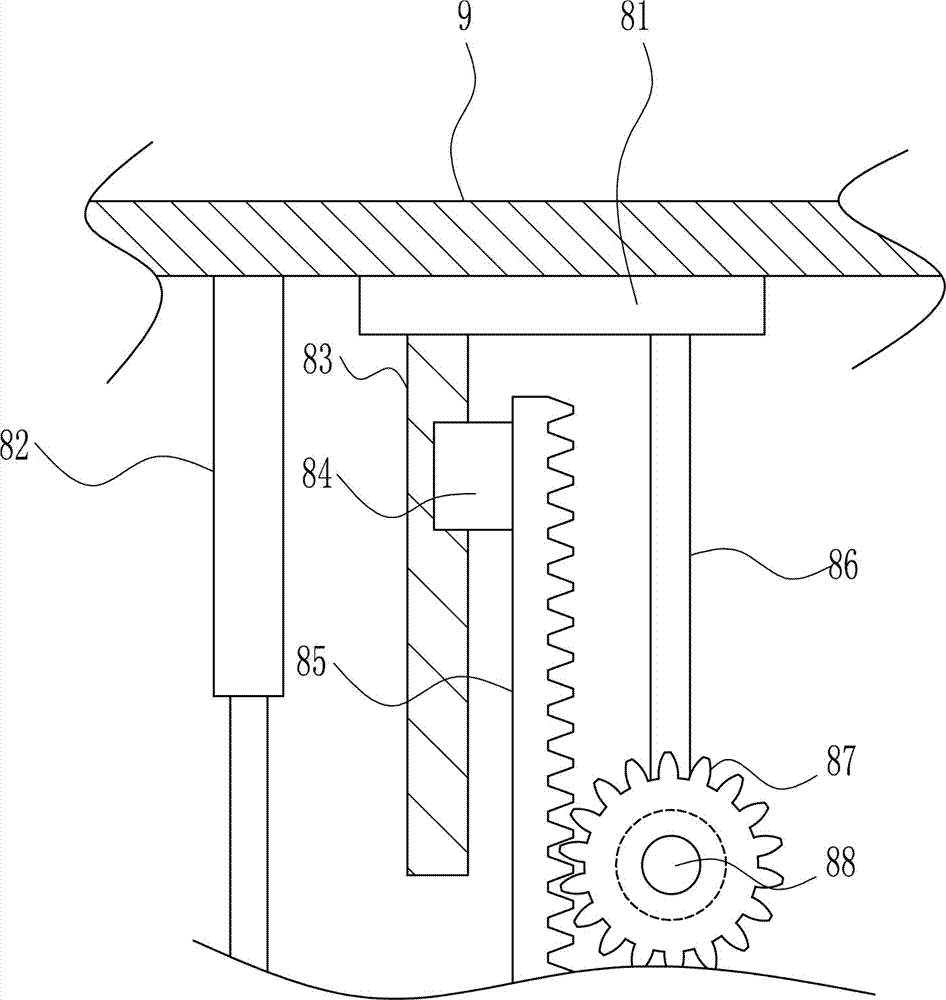

Stable and reliable clean type electric drill

ActiveCN108907288AImprove stabilityReduce shakingPortable power-driven toolsPortable drilling machinesElectric machineryScrap

The invention relates to a stable and reliable clean type electric drill. The stable and reliable clean type electric drill comprises a main body, a drill bit, a stabilizing mechanism and a collectingmechanism; the stabilizing mechanism comprises a stabilizing assembly and two clamping assemblies; the stabilizing assembly comprises a first motor, a gear and two stabilizing units; each stabilizingunit comprises a rack, a limiting groove, a first connection rod, a cross rod, a second connection rod and a connection block; the collecting mechanism comprises a collection tank and a telescopic assembly; the telescopic assembly comprises a drive unit, a positioning rod, a slide block, a fixed block, a telescopic frame, a connection board, two positioning blocks and two transmission blocks; anda PLC and a wireless signal receiving and dispatching module are arranged inside the main body. According to the stable and reliable clean type electric drill, stability of the main body is improvedthrough the stabilizing mechanism, shake of the electric drill during drilling is reduced, stability and practicability of the electric drill are higher, metal scraps are collected into the collectiontank through the collecting mechanism and are prevented from being scattered on the ground and hurting people, and accordingly safety and cleaning degree of the electric drill are improved.

Owner:SUZHOU SUPIN FURNITURE CO LTD

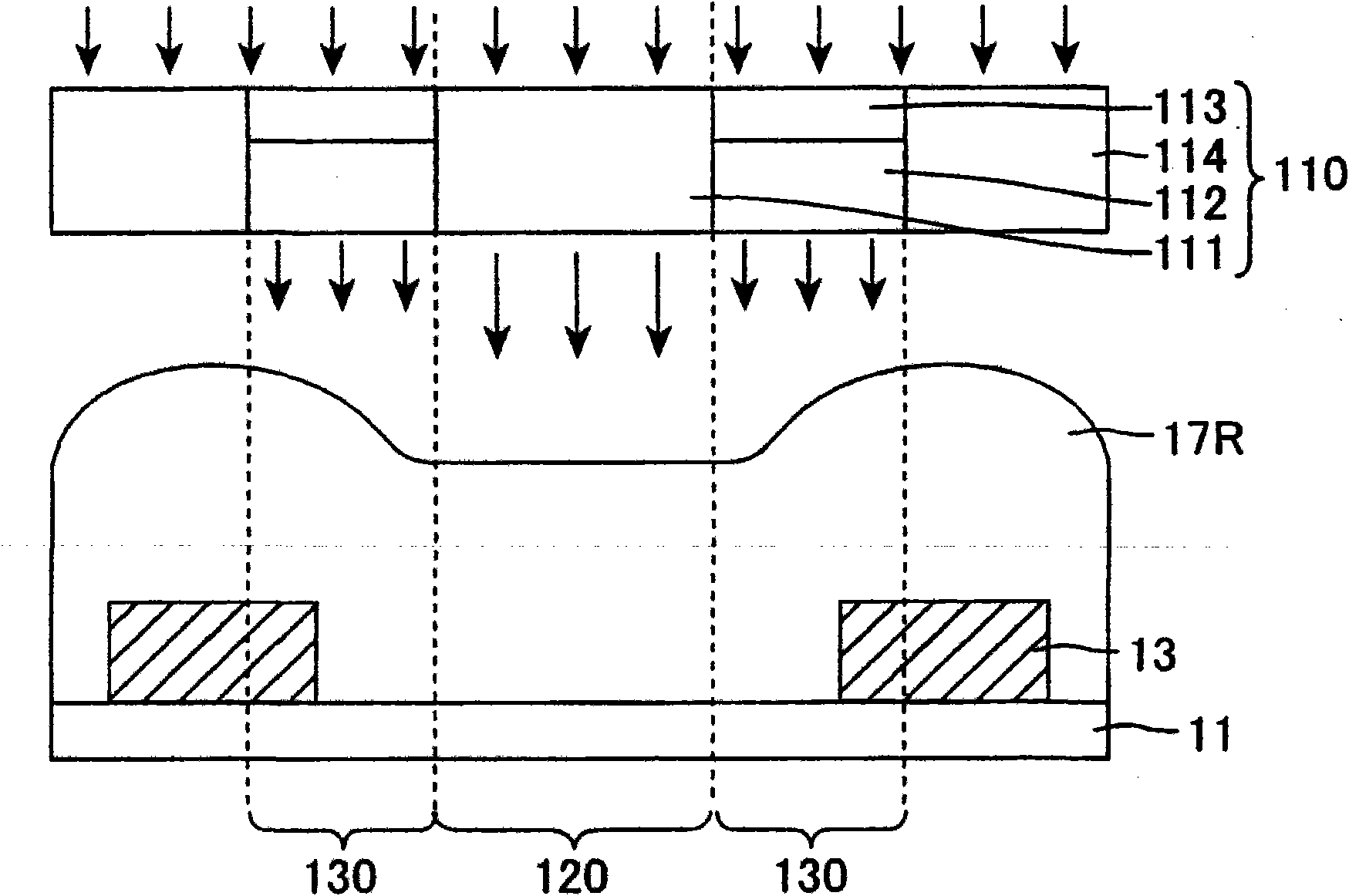

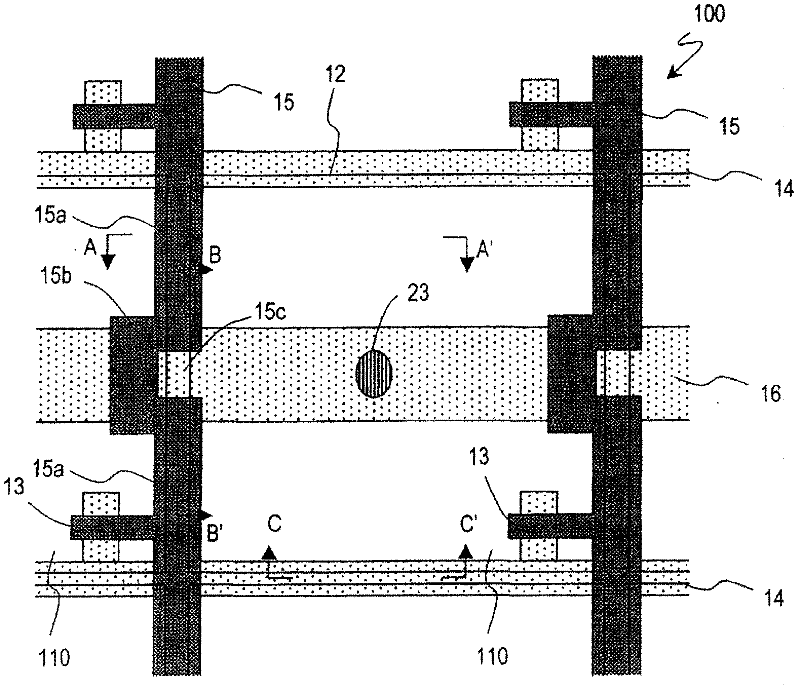

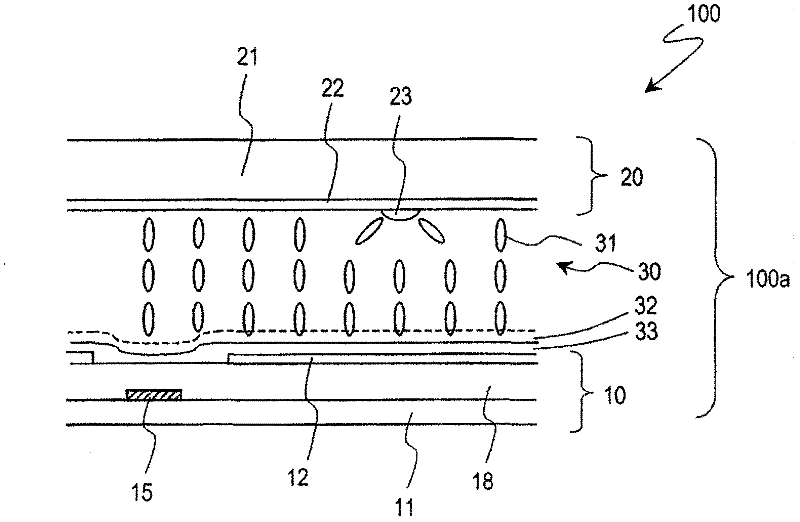

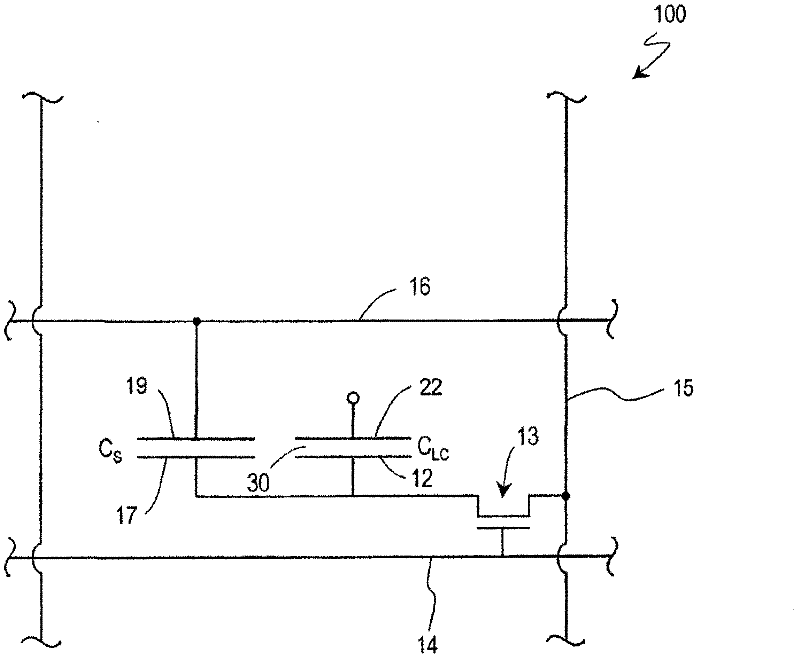

Liquid crystal display device and method for manufacturing liquid crystal display device

InactiveCN102209931AReduce disorientationReduce clutterNon-linear opticsVertical alignmentEngineering

High quality display is provided by reducing display nonuniformity in a liquid crystal display device. The liquid crystal display device is provided with: a TFT substrate (10) having a signal wiring line (15), which has a plurality of pixels (110) arranged in a first direction and a second direction, extends in the first direction, and supplies a TFT (13) with display signals, and a scanning wiring line (14), which extends in the second direction and supplies the TFT (13) with gate signals; a facing substrate (20) having counter electrodes; a vertically aligned liquid crystal layer (30) arranged between the substrates; and a vertical alignment film (33). The signal wiring line (15) and / or the scanning wiring line (14) has two linear sections (15a) which linearly extend in the first direction or the second direction on the boundary between adjacent two pixels, and a bent section (15b) which is arranged between the two linear sections and extends outside of the extending lines from the two linear sections. At the time of forming an alignment sustaining layer in the liquid crystal display device of a PSA system, liquid crystal molecules on the signal wiring line and / or the scanning wiring line can be aligned stably and in the more desirable direction.

Owner:SHARP KK

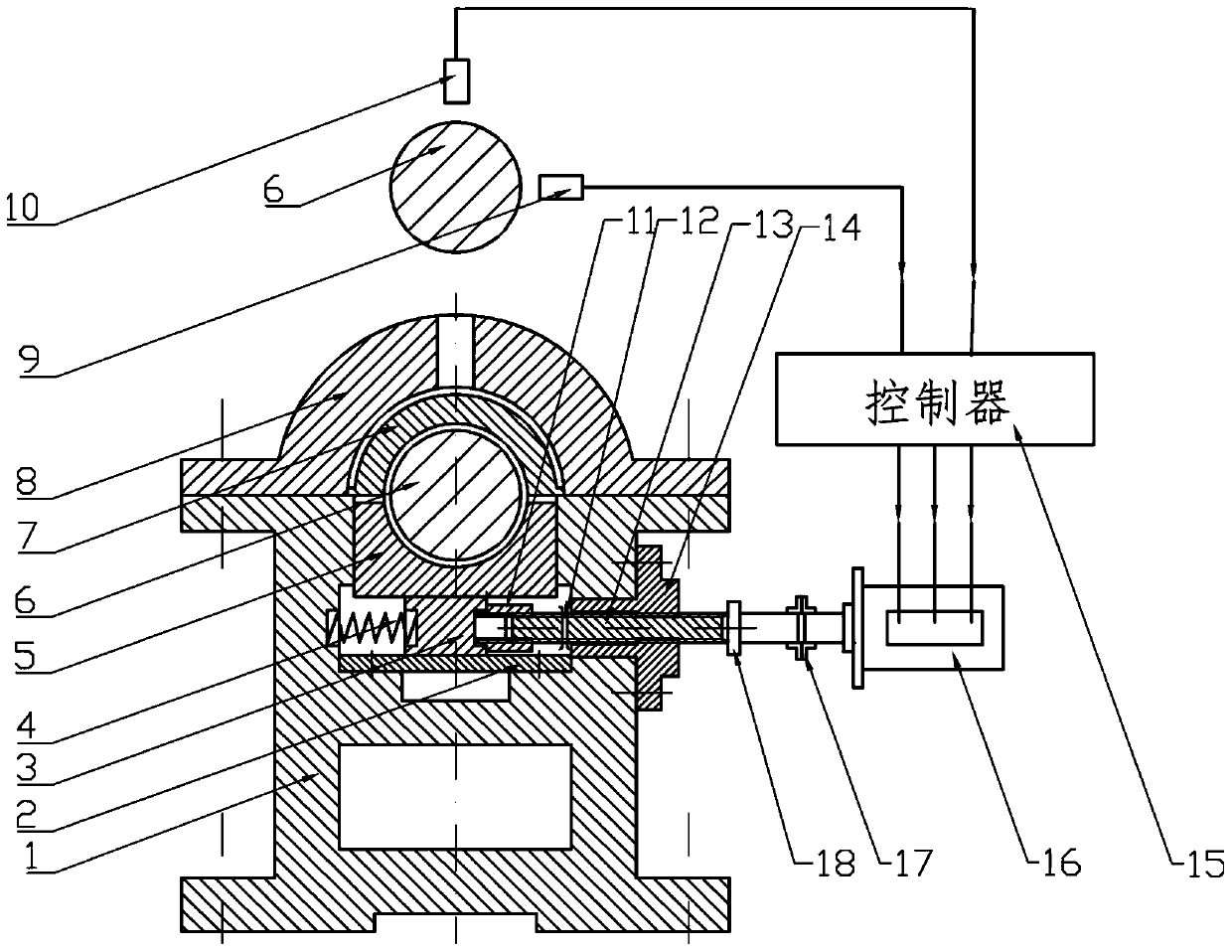

Intelligent support sliding bearing device with adjustable clearance and clearance adjustment method

ActiveCN111188833AImplementation limitOrientation stabilityShaftsRotary machine partsServoWhole systems

The invention discloses an intelligent support sliding bearing device with adjustable clearance and a clearance adjustment method. The intelligent support sliding bearing device comprises a support sliding bearing, an inclined block is arranged under the support sliding bearing, a guide rail is arranged under the inclined block, the bottom surface of the inclined block is matched with the guide rail in a sliding mode, the inclined block moves in the axial direction of the guide rail, the top surface of the inclined block is an inclined plane with a taper of 1 to 125, a pushing mechanism is arranged at one end of the inclined block, the other end of the inclined block is connected with a reset spring, and a vertical displacement sensor and a horizontal displacement sensor are respectively used for detecting the vertical radial displacement and the horizontal radial displacement of a rotor; the vertical displacement sensor and the horizontal displacement sensor are connected with the input end of a monitoring controller, and the output end of the controller is further connected with the control signal input end of a servo motor; when the rotor vibration is too large, signals collected by the sensors are sent to the controller, the controller controls the servo motor to make a certain action, and the clearance between the bearing and the shaft neck is changed, so that the elliptical bearing play a role, the rotor amplitude is reduced, and the whole system has a good effect of vibration reduction and suppression.

Owner:XI AN JIAOTONG UNIV

Engine generator

ActiveUS20090322046A1Steady OrientationCarriage/perambulator with single axisMachines/enginesGravity centerEngine-generator

An engine generator movable on left and right wheels. The wheels are provided on a rear section of a bottom cover via an axle. A cylinder of an engine is disposed so as to incline upwards towards the direction of the axle. Inclining the cylinder lowers the center of gravity of the engine and disposes the axle positioned below the cylinder at a high position, thereby reducing the height of the engine generator. The orientation of the engine generator during travel is stabilized.

Owner:HONDA MOTOR CO LTD

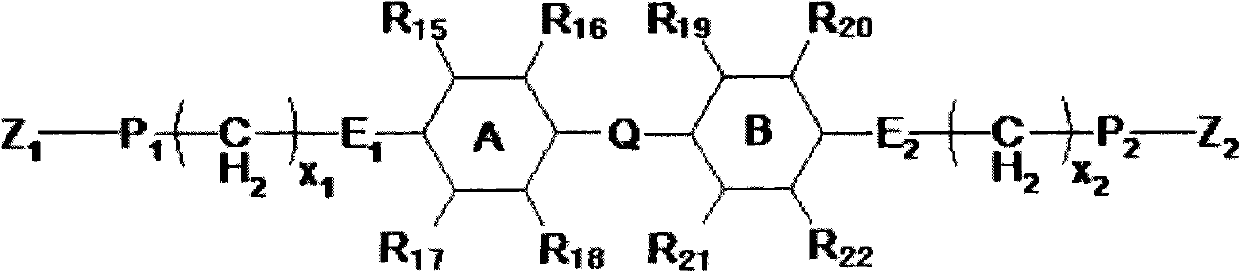

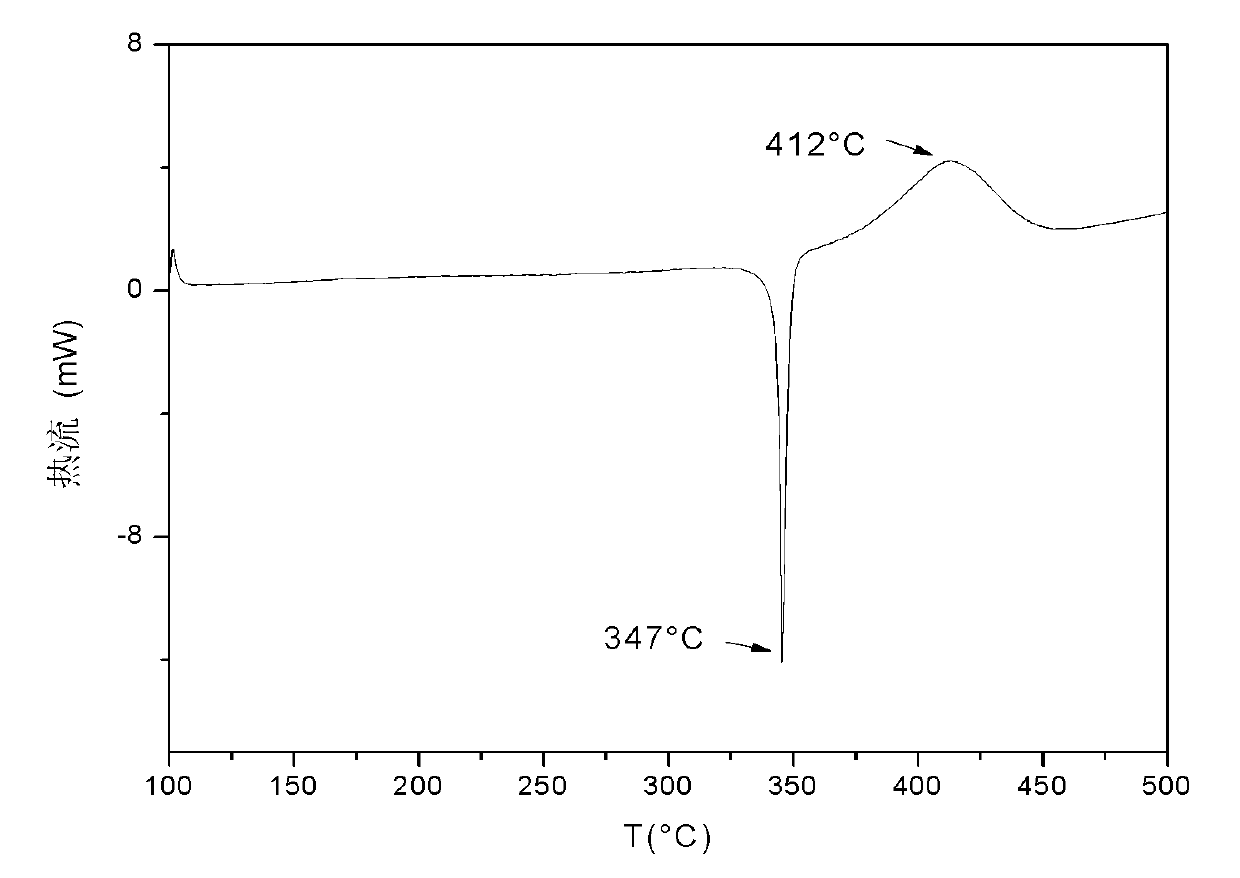

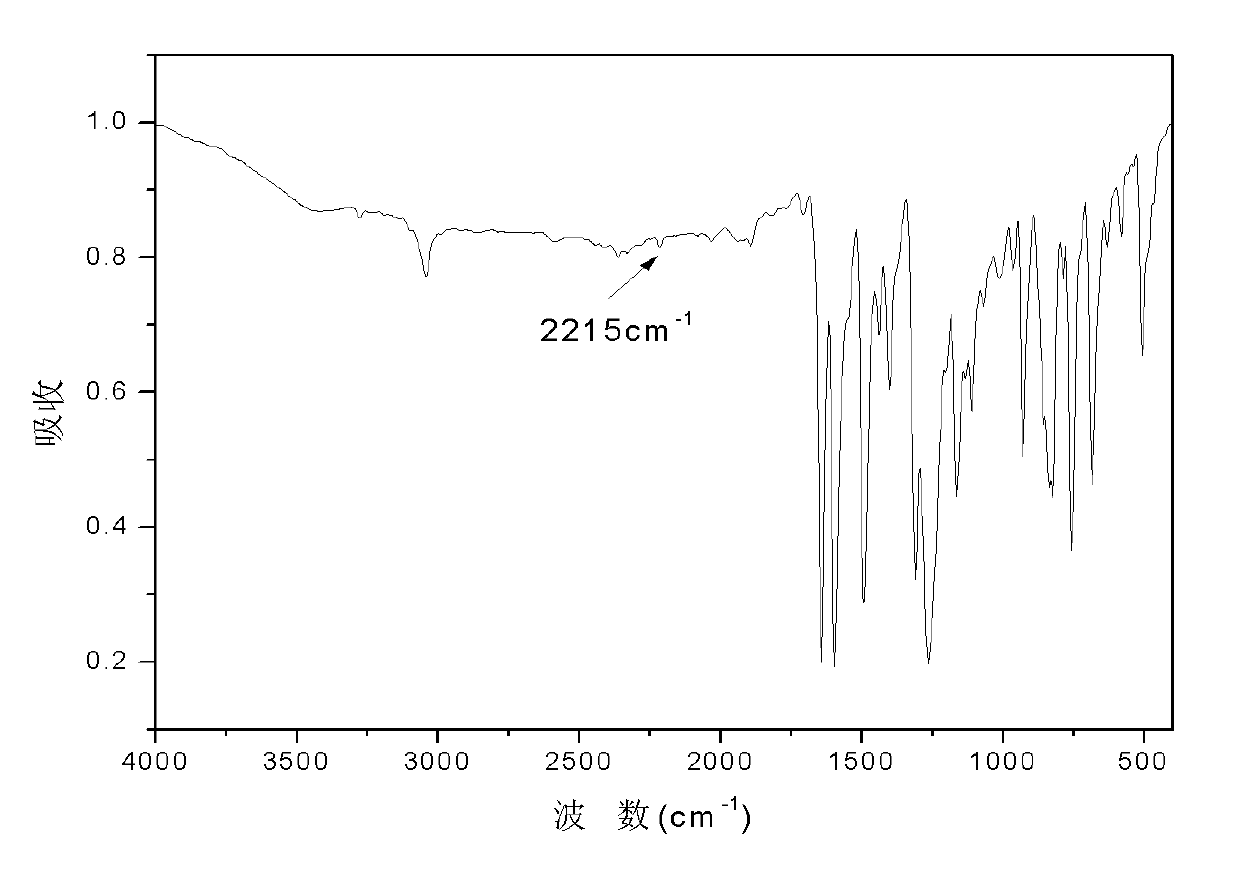

Liquid crystal low polymer, composition for synthesis, preparation method and liquid crystal material

InactiveCN102690181ASteady OrientationImprove heat stabilityLiquid crystal compositionsOrganic compound preparationCrystallographyOligomer

The invention provides a liquid crystal low polymer, a composition for synthesis, a preparation method and a liquid crystal material. The liquid crystal low polymer is disclosed as the following chemical formula, wherein the substituent group R is hydrogen or methyl group. The liquid crystal low polymer has the advantages of high glass transition temperature, favorable heat resistance and low viscosity, and has a self-crosslinkable group; and the liquid crystal low polymer also has thermal self-crosslinking property and high heat stability of the thermosetting material.

Owner:BOE TECH GRP CO LTD +1

Guiding transmission shaft structure with cutting knife

ActiveCN109178276AIngenious structural designEasy slide connectionPropulsive elementsDrive shaftFront and back ends

The invention discloses a guiding type transmission shaft structure with a cutting knife, which comprises a transmission shaft, a connecting ring, a cutting mechanism, a guiding column and a guiding elastic body. The threading block of the invention realizes the stable guiding function by cooperating and plugging the guide hole and the guide column in the mounting groove, and sleeves the guide elastic body on the guide column, so that the whole cutting knife can more stably carry out the telescopic floating; and the cutting knife of the invention utilizes the driving screw to carry out telescopic floating in the mounting groove of the connecting ring, and adjusts the proper cutting depth. The cutting knife of the invention has ingenious structure design, and the front and back ends of thetwo sides of the connecting block are respectively provided with a blade, so that the double-edged cutting of the two sides is realized, and the cutting efficiency is high; at the same time, a clamping sliding groove is respectively arranged between the blades on both sides of the threading block, which is convenient for sliding connection between the threading block and the mounting groove, realizes telescopic floating adjustment, and is more flexible in use.

Owner:东台市海一船用设备有限公司

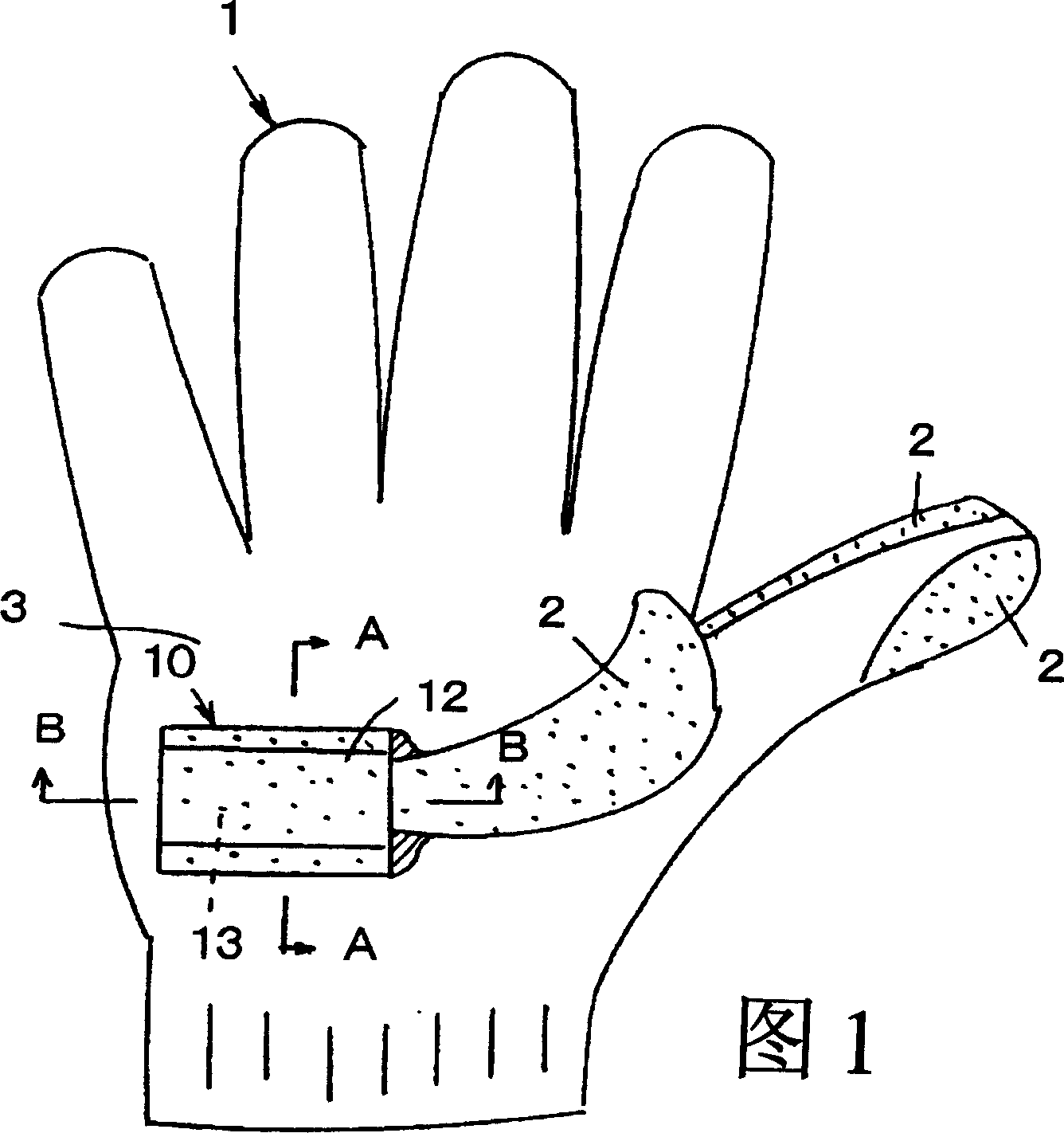

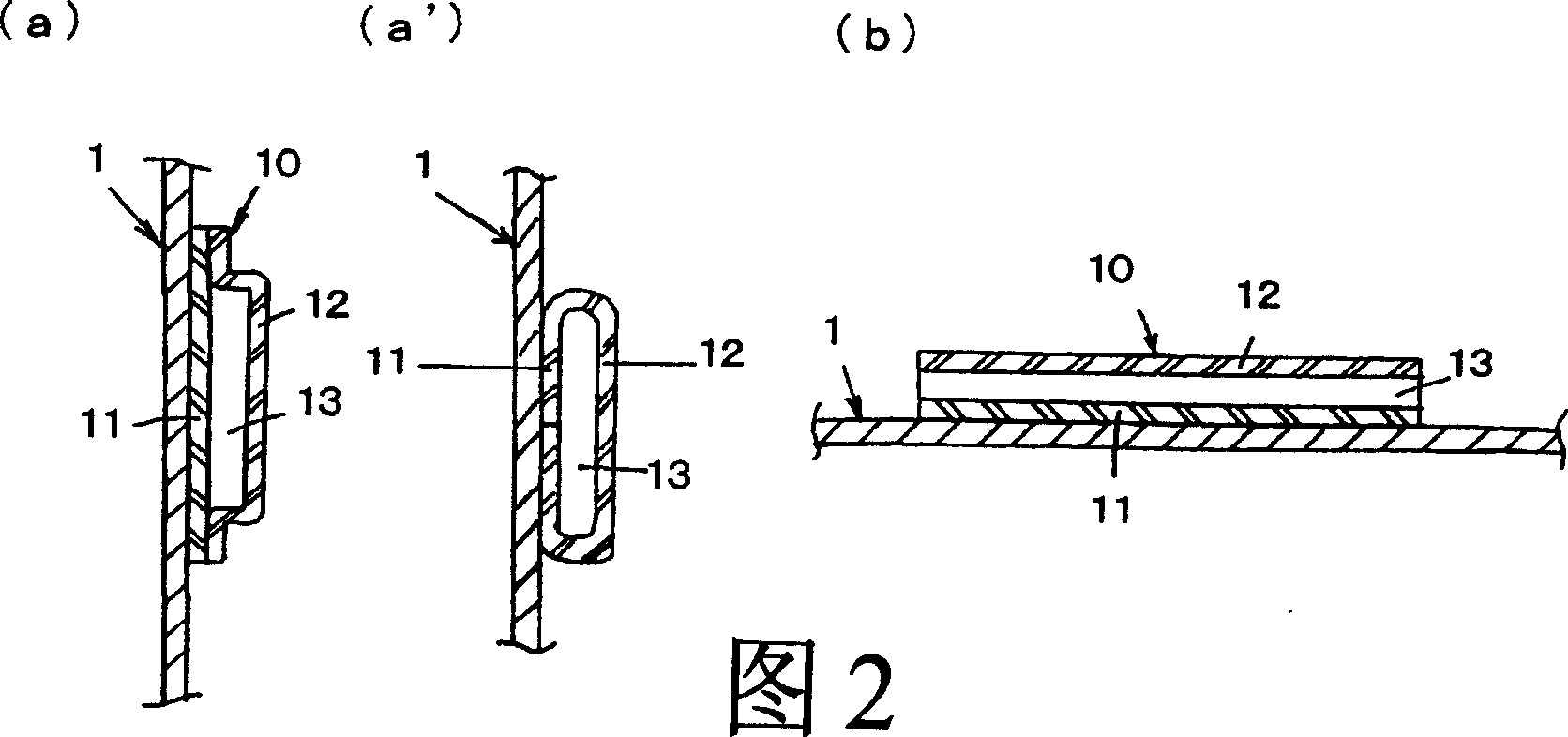

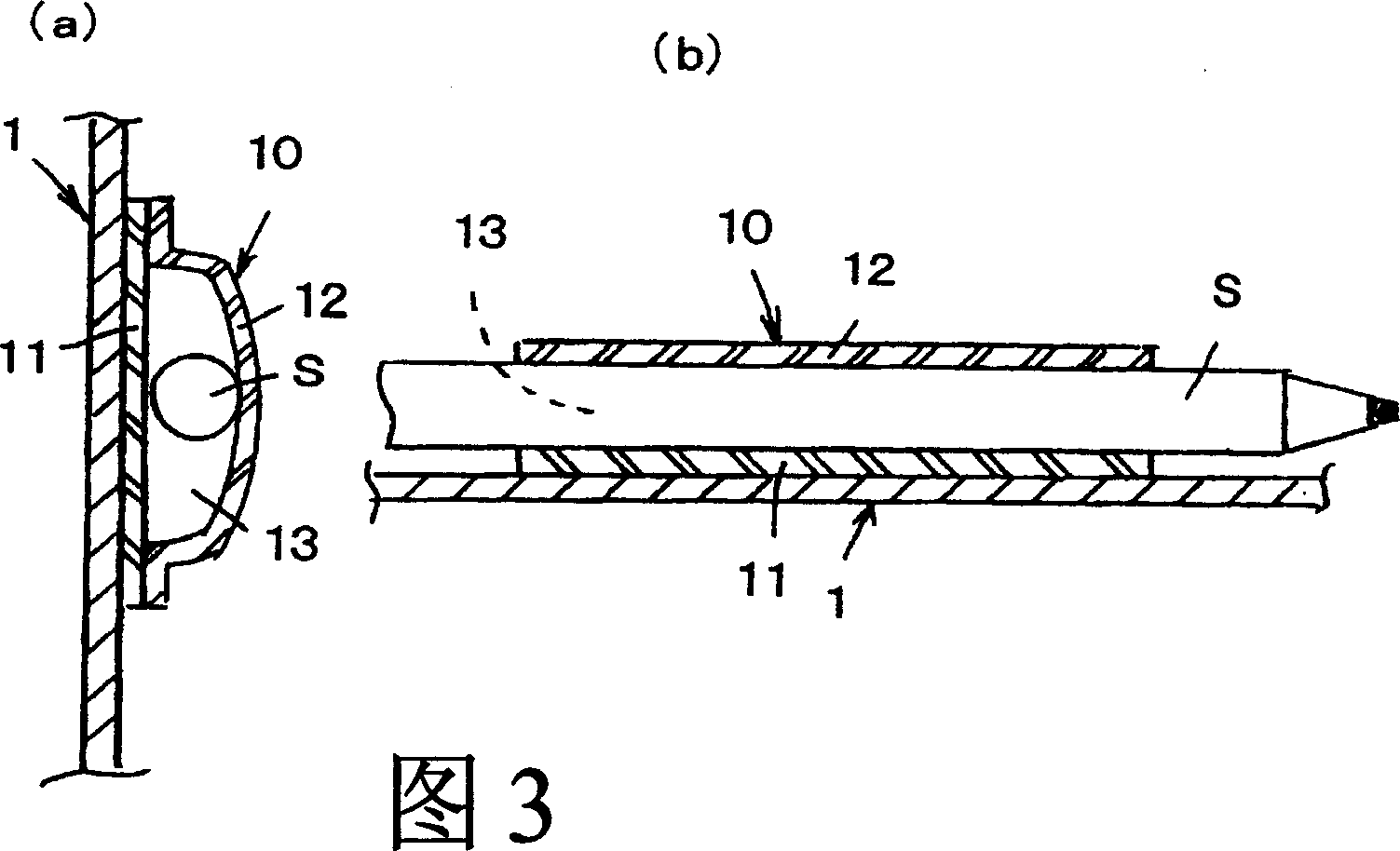

Operation gloves with reception part

To provide a working glove with a storage part so designed as to allow a working article such as a pencil or a cutter to be easily taken out or put in. The working glove with a storage part is structured as follows: forming a storage part 10 in which part or whole of the working article S such as a pencil, a cutter or a snip can be housed at a prescribed portion of a glove body 1; fixing a sheet-state reinforcing member 2 to at least the palm part 4 of the glove body 1 formed of sewn-up knit or the knitted glove body 1 to provide the storage part 10 where part or whole of the working article S such as a pencil, a cutter or a hand clip is detachably inserted to be held, at the back part 3 of the glove body 1. The storage part 10 is formed of material such as polyvinyl chloride or rubber rich in elasticity and having excellent slip-preventive effect.

Owner:赤木茂树

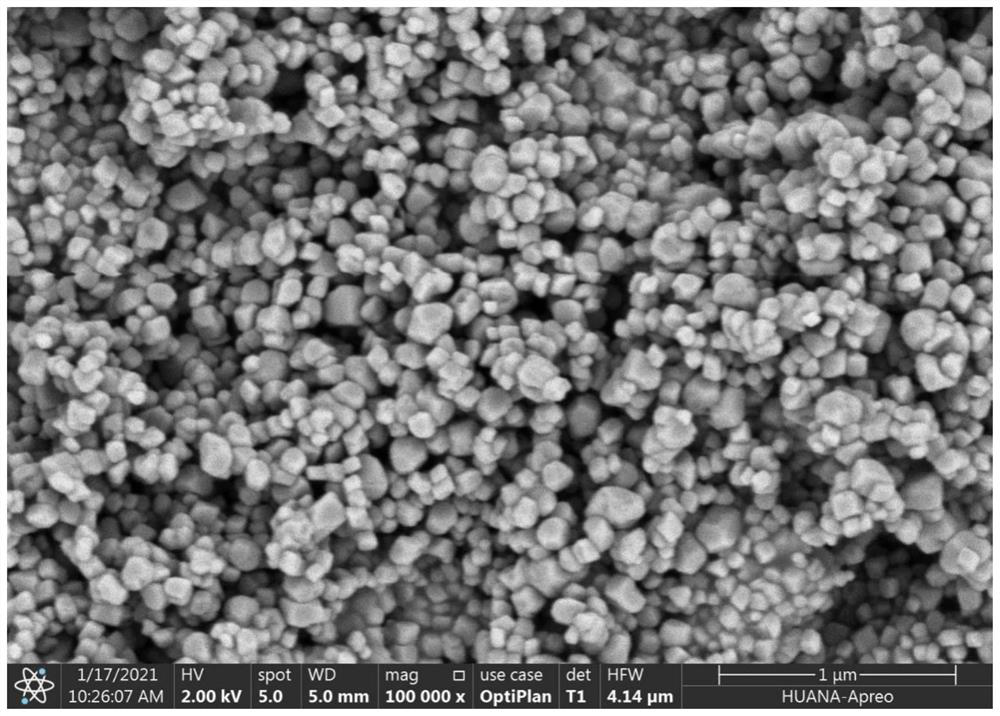

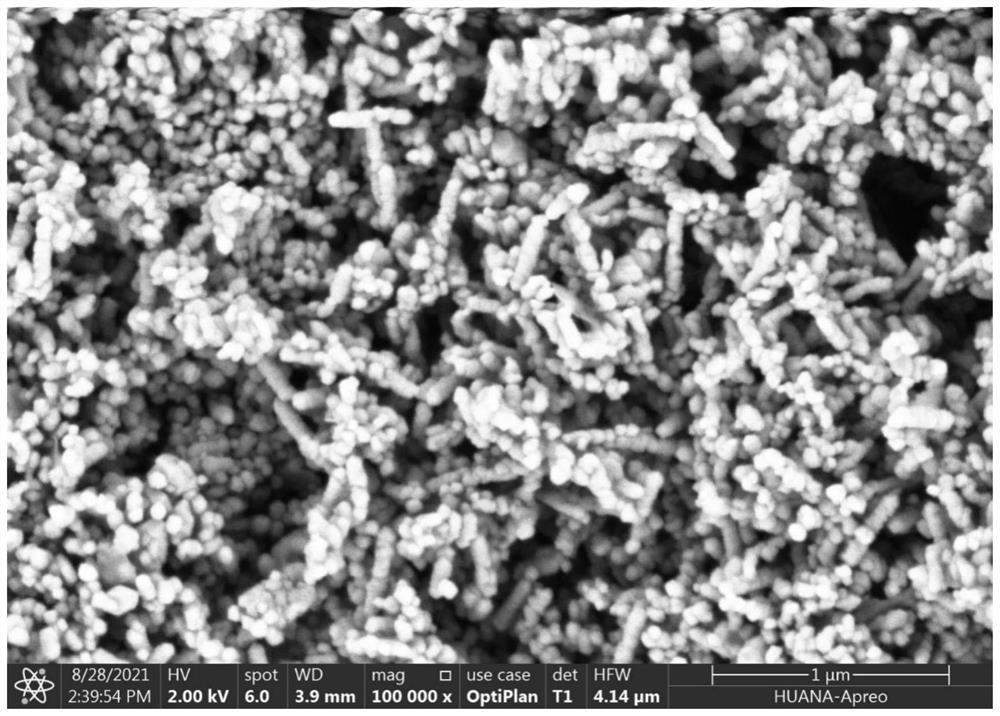

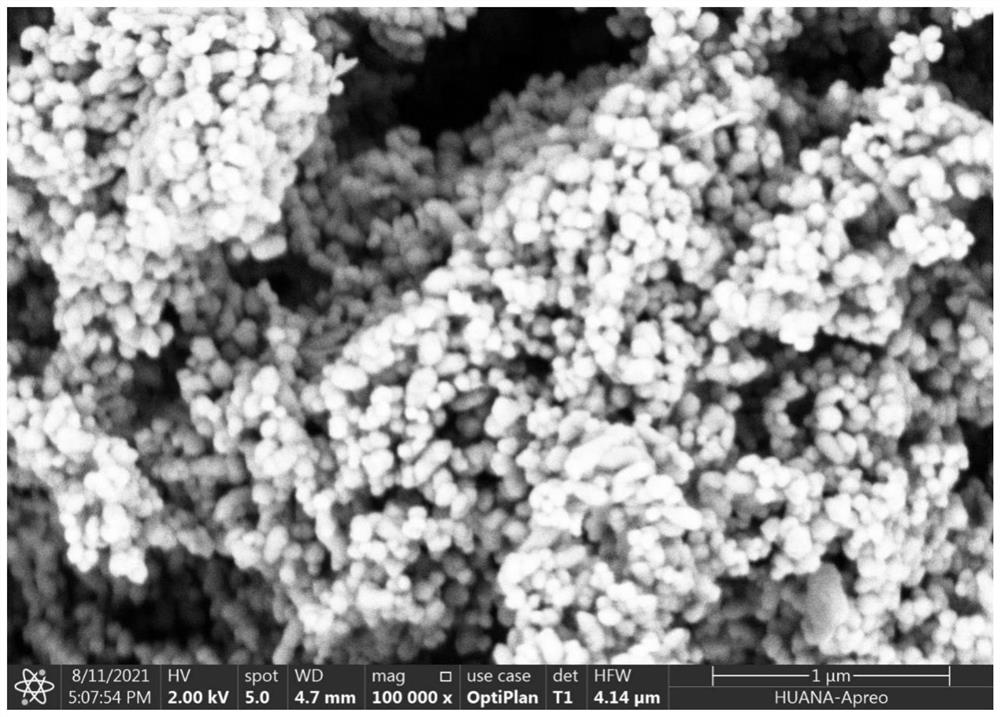

Preparation method of nano calcium carbonate for anti-sagging PVC plastifying paste

PendingCN113980491AImprove impact resistanceGood dispersionPigment treatment with macromolecular organic compoundsPigment physical treatmentActive agentAlkylphenol

The invention discloses a preparation method of nano calcium carbonate for anti-sagging PVC (polyvinyl chloride) plastifying paste. The method comprises the following steps of: pretreating suspension liquid by using a phosphoric acid compound; compounding the pretreated suspension liquid into a surfactant by using fatty acid saponification liquid, polyethylene glycol, fatty acid methyl ester sodium sulfonate and alkylphenol polyoxyethylene ether phosphate monoester to obtain a modified nano calcium carbonate suspension; and finally, carrying out filter pressing, drying and sieving to obtain the anti-sagging nano calcium carbonate for the PVC plastifying paste. According to the method, after the PVC accelerating paste is filled with the nano calcium carbonate, the nano calcium carbonate has relatively good sagging performance, flowability, viscoelasticity, dispersity, impact resistance and stability, and the nano calcium carbonate can be used as an excellent automobile chassis filler.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

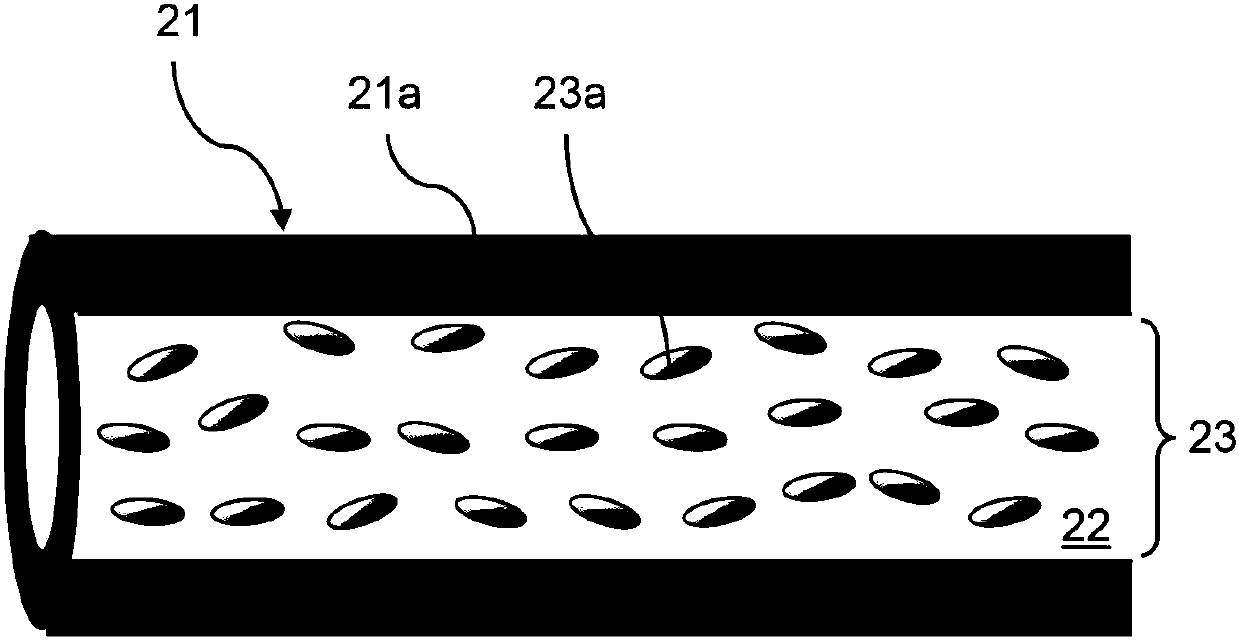

Method for manufacturing liquid crystal electro-optical module

ActiveCN108020960AImprove disclinationSteady OrientationNon-linear opticsCrystallographyOptical Module

The invention provides a method for manufacturing a liquid crystal electro-optical module. According to the method, liquid crystal alignment is performed in a non-contact manner to provide stable alignment of liquid crystal molecules sealed in the liquid crystal electro-optical module, so that the liquid crystal molecules have a pre-tilt angle defined in a steady state, and thus liquid crystal canbe prevented from defects caused by reverse tilt when an applied field tends to be dynamic. The method includes the steps of providing an optical unit including a hollow space; injecting a liquid crystal mixture into the hollow space; and applying a gradient field to the liquid crystal mixture, wherein the intensity of the gradient field shows a gradient distribution.

Owner:黄素真

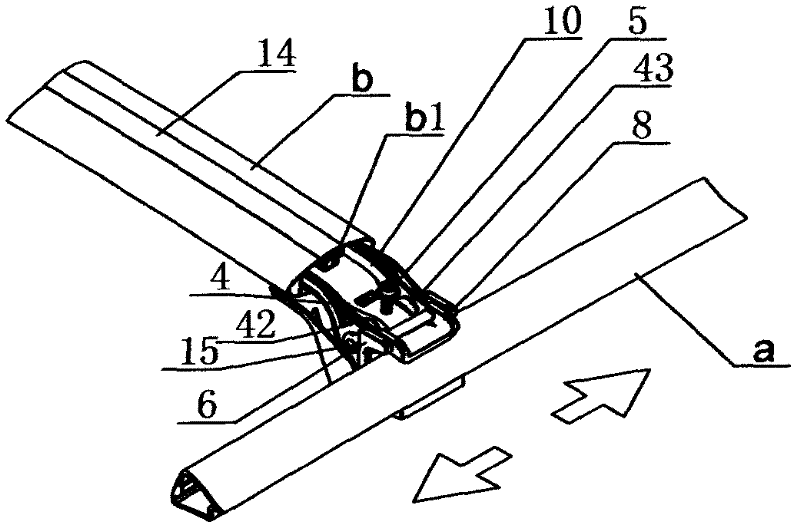

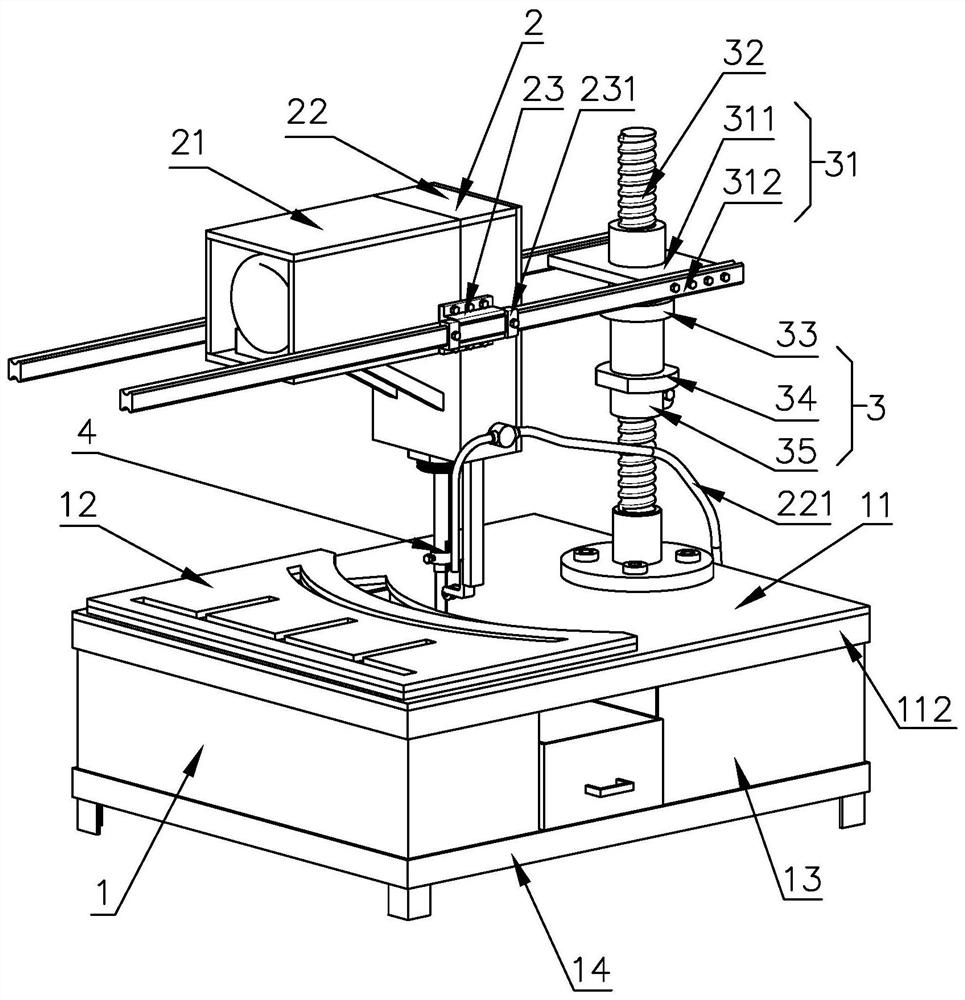

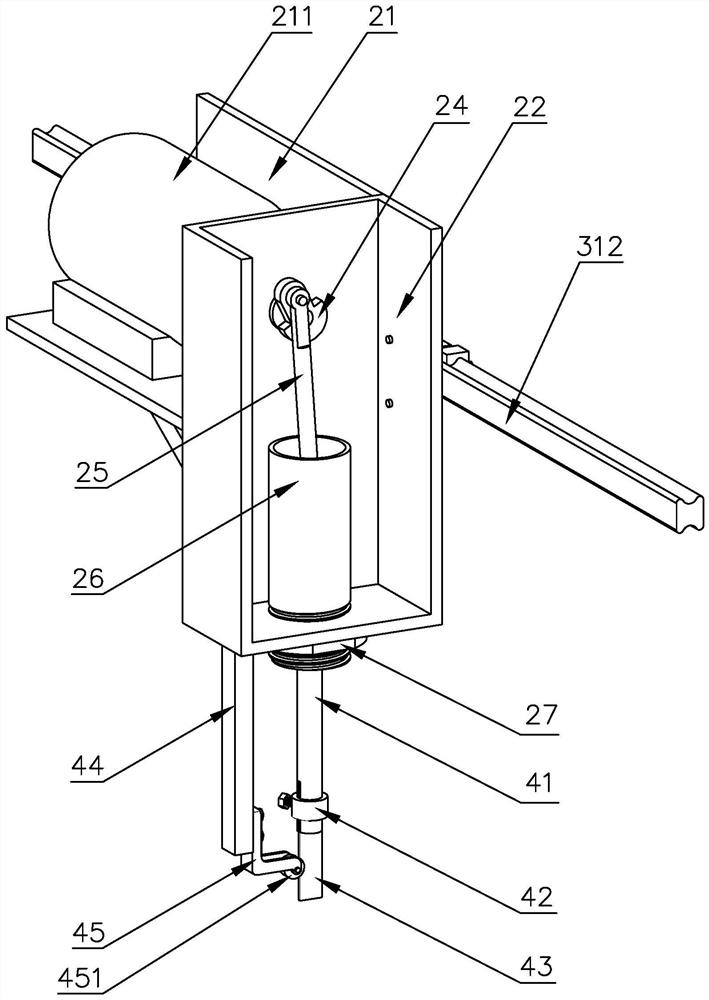

Arc-shaped cutting machine for paving marble slabs on roads

PendingCN112497528AStable cutterSteady OrientationWorking accessoriesStone-like material working toolsWire cuttingElectric machinery

The invention discloses an arc-shaped cutting machine for paving marble slabs on roads. The arc-shaped cutting machine comprises a base, a workbench, a power transmission mechanism, a stand column, acutting mechanism and a rotary supporting frame. The stand column is fixed to one end of the base, and the workbench is fixed at the other end of the base; one end of the rotary supporting frame is sleeved with the stand column through a shaft sleeve, the power transmission mechanism is fixed to the other end of the rotary supporting frame, the cutting mechanism is fixed to the bottom of the powertransmission mechanism, the power transmission mechanism comprises a power box and a transmission box, and a motor is mounted in the power box; a cam, a connecting rod, a guide sleeve and a U-shapedsleeve are arranged in the transmission box; the cutting mechanism comprises a knife rest, a cutter and a locking ring; the threaded end of the knife rest is connected into a center threaded hole at the bottom of the U-shaped sleeve through threads, and a cutter clamping groove is formed at the other end of the knife rest; the cutter is arranged in the cutter clamping groove; and the locking ringis sleeved with the cutter clamping groove and fixedly connected to one end of the knife rest. The arc-shaped cutting machine can stably conduct arc cutting on stones, meanwhile, the stones with different thicknesses can be cut, time and labor are saved, and the using requirement is met.

Owner:山东天智信息科技有限公司

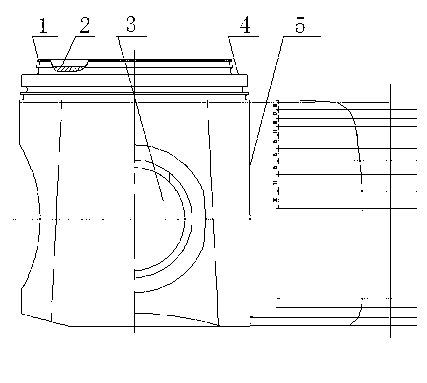

Piston skirt profile line structure

InactiveCN103016191AGuaranteed heat resistanceGuaranteed wear resistanceMachines/enginesPistonsLongest DiameterEllipse

The invention discloses a piston skirt profile line structure which comprises a sealing ring groove (1), an inner ring supporting surface (2), a piston pin hole (3), an outer ring supporting surface (4) and a middle-bulged varying ellipse profile line (5). The sealing ring groove (1) is arranged on a top skirt cylindrical fitting surface; the inner ring supporting surface (2) and the outer ring supporting surface (4) are arranged at the top of a piston skirt; the piston pin hole (3) is formed in the middle of the piston skirt; and the middle-bulged varying ellipse profile line (5) is arranged on the outer cylindrical surface of the piston skirt. The piston skirt profile line structure has the advantages that the excircle of a piston is designed into a special excircle (middle-bulged varying ellipse), so that a cross section perpendicular to the axis of the piston is an ellipse or a modified ellipse, the ellipticity changes in the axis direction according to certain rules, a convex ellipse of the piston shape is different from a common ellipse, the ellipse skirt adopts a structural mode of a convex reducing ellipse, the rules are that a long diameter becomes smaller, bigger and then smaller from the bottom end of the skirt part to the upper part and a short diameter becomes larger and smaller, and the gap between the piston and a cylinder is reduced.

Owner:DALIAN BINCHENG PISTON MFG

Numerical control tension adjusting device for panel production line

The invention discloses a numerical control tension adjusting device for a panel production line.The device comprises a movable base and a movable base horizontal movement mechanism, wherein the movable base is connected to a horizontal guide rail in a sliding mode, the horizontal guide rail extends in the conveying direction of a steel belt, and the movable base horizontal movement mechanism is used for driving the movable base to slide horizontally.A plurality of partition rollers for adjusting the tension of the steel belt are arranged on the movable base.A guide roller is arranged on the rear sides of the partition rollers and is close to a winding roller.When the radius of a steel belt roll on the winding roller is increased, the movable base moves backwards horizontally, and the interval between the guide roller and the steel belt roll on the winding roller is kept unchanged.

Owner:GUANGDONG DAQU MACHINE EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

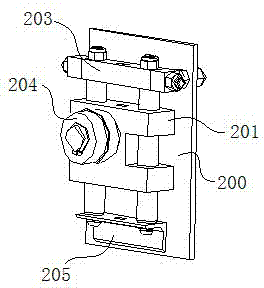

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com