Roof luggage rack for automobile

A technology for luggage racks and automobiles, which is applied to vehicle parts, additional accessories, transportation and packaging, etc. It can solve problems such as unreliable connection between crossbars and sidebars, inability to adjust the distance between front and rear crossbars, and inability to adjust luggage loads, etc., to achieve Improve the overall load-carrying performance, ample sidebar adaptation performance, and the effect of force balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

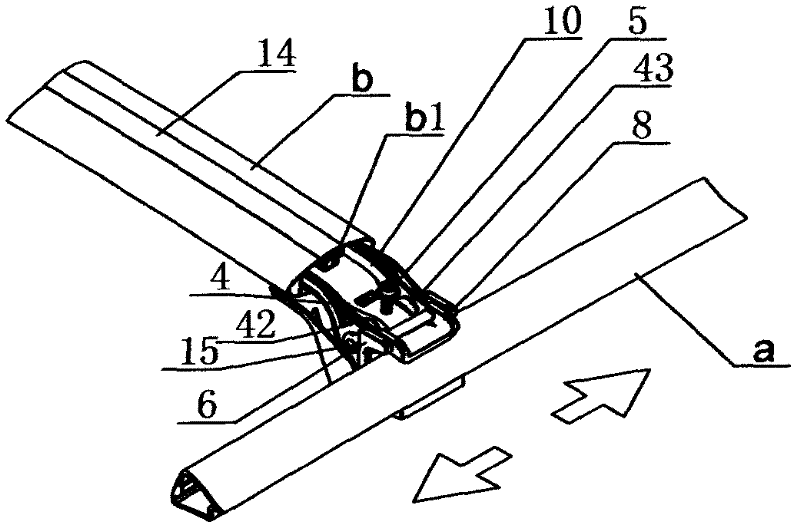

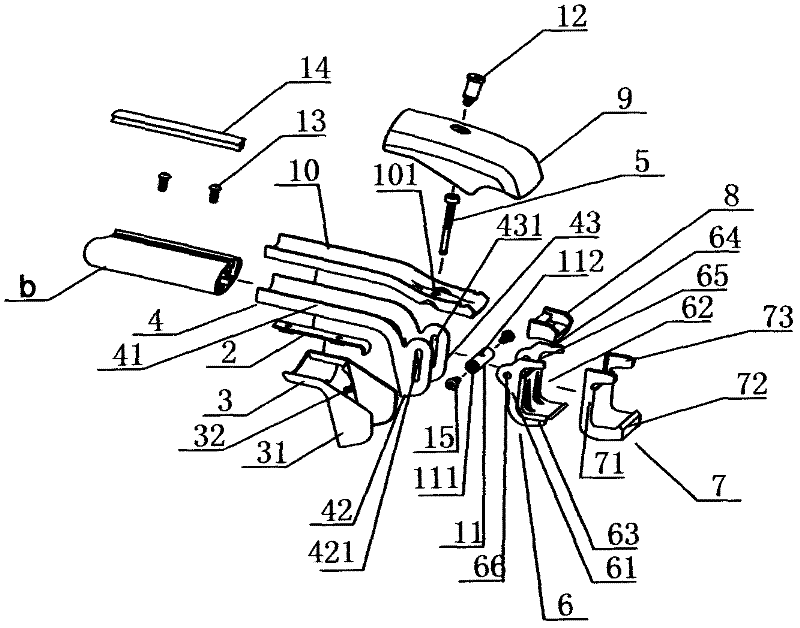

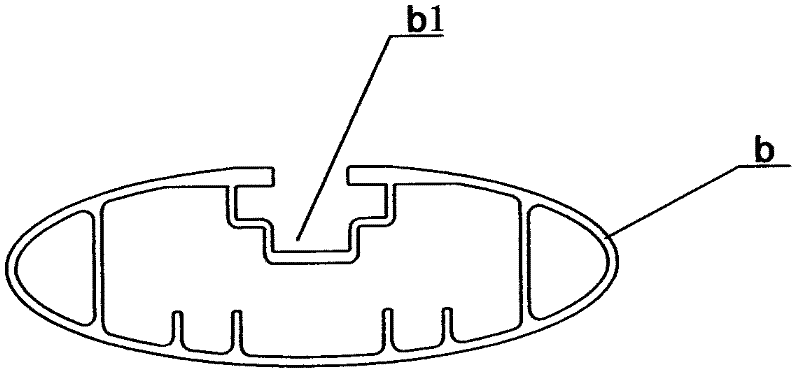

[0020] Such as figure 1 , 2 , shown in 4, the present invention is a kind of car roof luggage rack, comprises the two side bars a that are arranged on the two longitudinal sides of the car roof and two cross bars b that are arranged between the two side bars a, two cross bars b and A movable adjustment structure is provided between the rods a on both sides, and the movable adjustment structure includes a fixed bracket 4, a movable bracket 6 and a compression bracket 10, wherein one end of the fixed bracket 4 is sleeved and fixed in the lumen of the cross bar b, The other end of the fixed bracket 4 is pivotally connected to the movable bracket 6; one end of the movable bracket 6 is pivotally connected to the fixed bracket 4 through a screw sleeve 11 and two hexagon socket screws 15, and the other end of the movable bracket 6 is provided with a C-shaped groove connected with the side bar a 62;

[0021] Such as figure 2 , 6 As shown, the middle part of the screw sleeve 11 tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com