Vacuum cleaner

A vacuum cleaner, vacuum cleaner technology, applied in the direction of vacuum cleaners, household appliances, cleaning equipment, etc., to achieve the effects of easy installation, preventing vibration, and eliminating trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Reference will now be made in detail below to embodiments of the present invention with reference to the accompanying drawings.

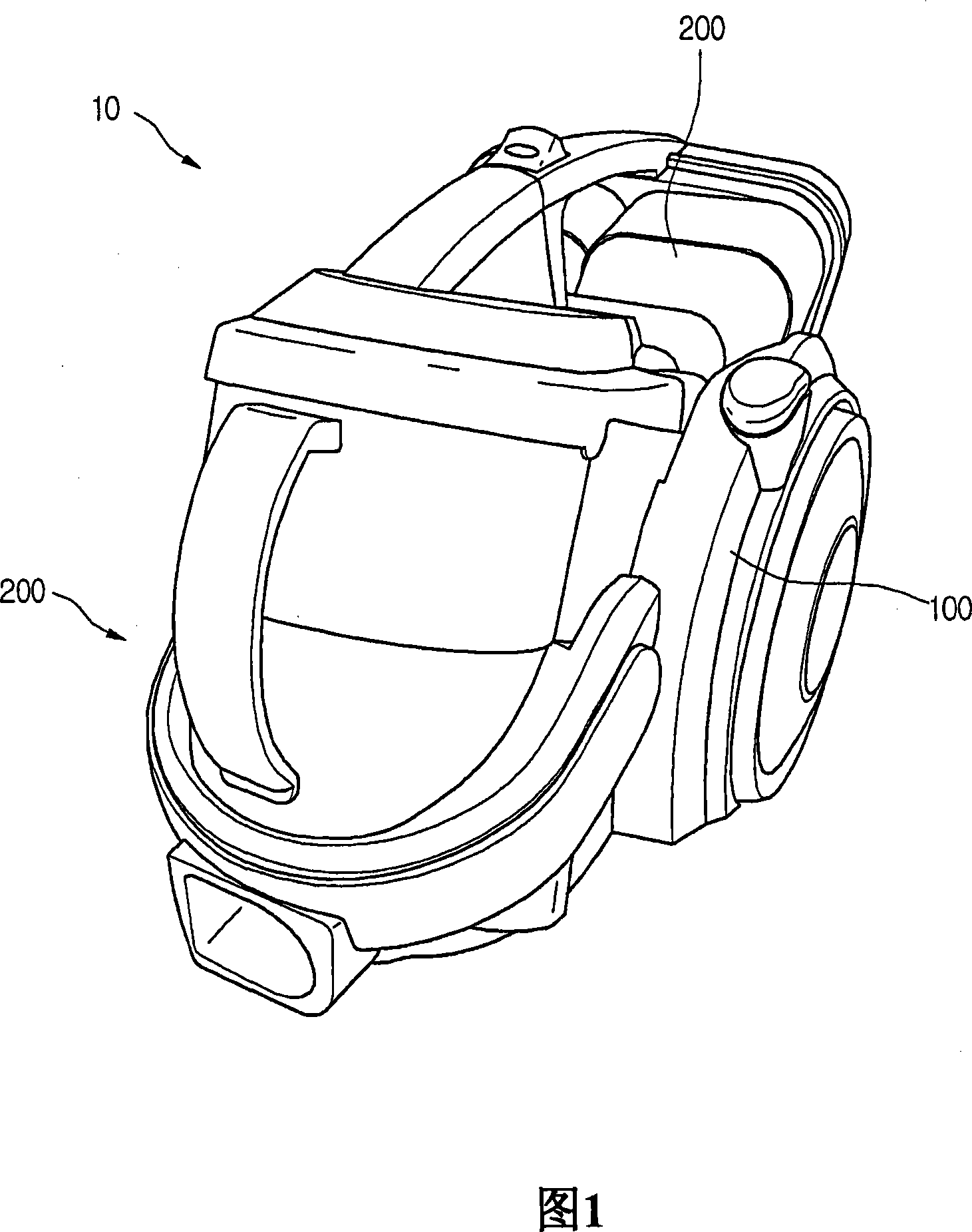

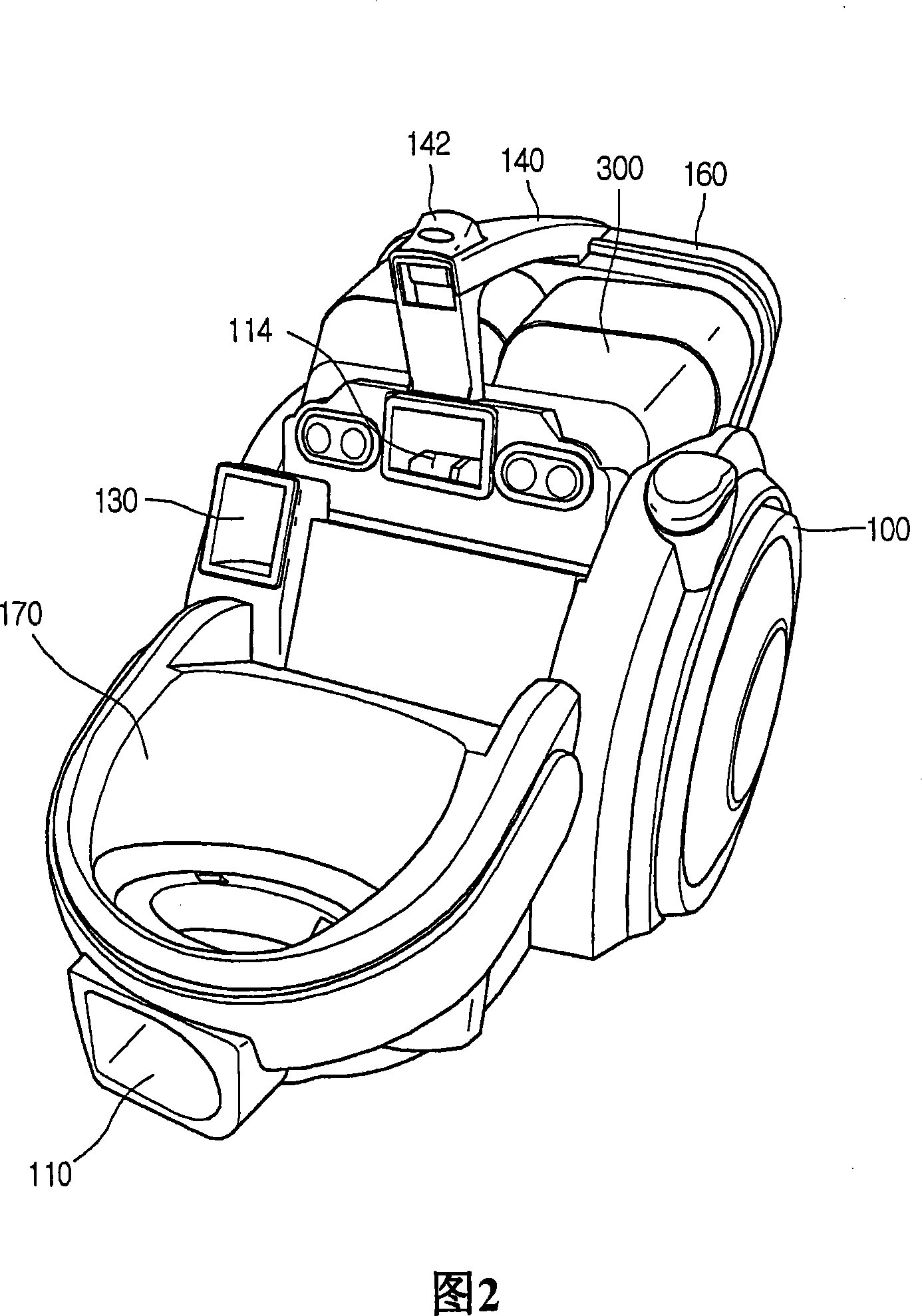

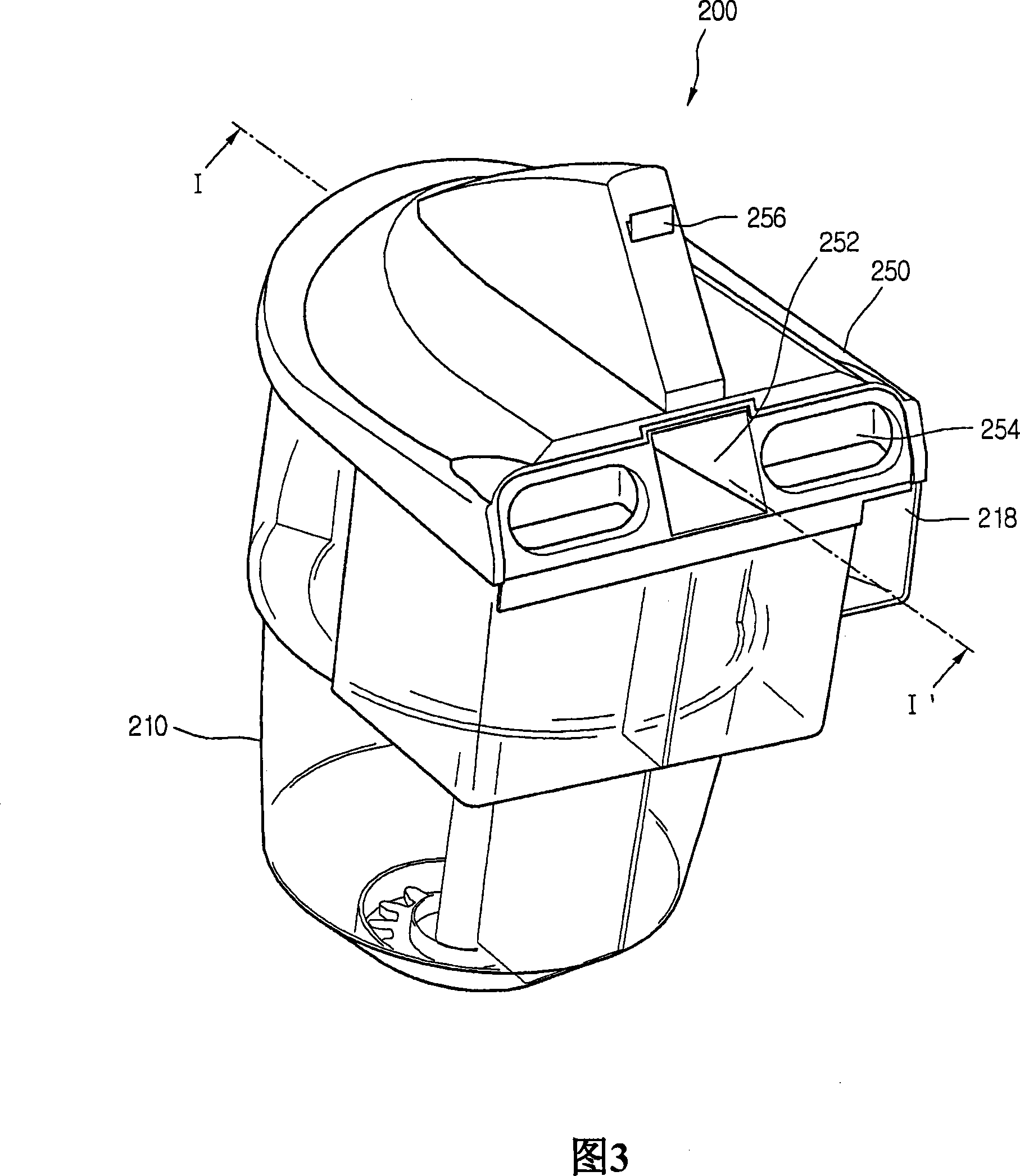

[0045] 1 is a perspective view of a vacuum cleaner according to a preferred embodiment of the present invention, FIG. 2 is a perspective view showing a state in which a dust collector is separated from the vacuum cleaner, and FIG. 3 is a perspective view of a dust collector according to a preferred embodiment of the present invention. picture.

[0046] Referring to FIGS. 1 to 3, a vacuum cleaner 10 according to the present invention includes: a cleaner body 100 having a suction motor (not shown) that generates suction power inside; Dust included.

[0047] Further, although not shown, a suction nozzle sucking air containing dust and a connection pipe connecting the suction nozzle to the cleaner main body 100 are included.

[0048] Because it is the same as the prior art, the detailed description of the basic composition of the suction nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com