Method, device, and computer program for determining an offset angle in an electric machine

A technology of offset angle and voltage, which is applied in the direction of motor, motor control, AC motor control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

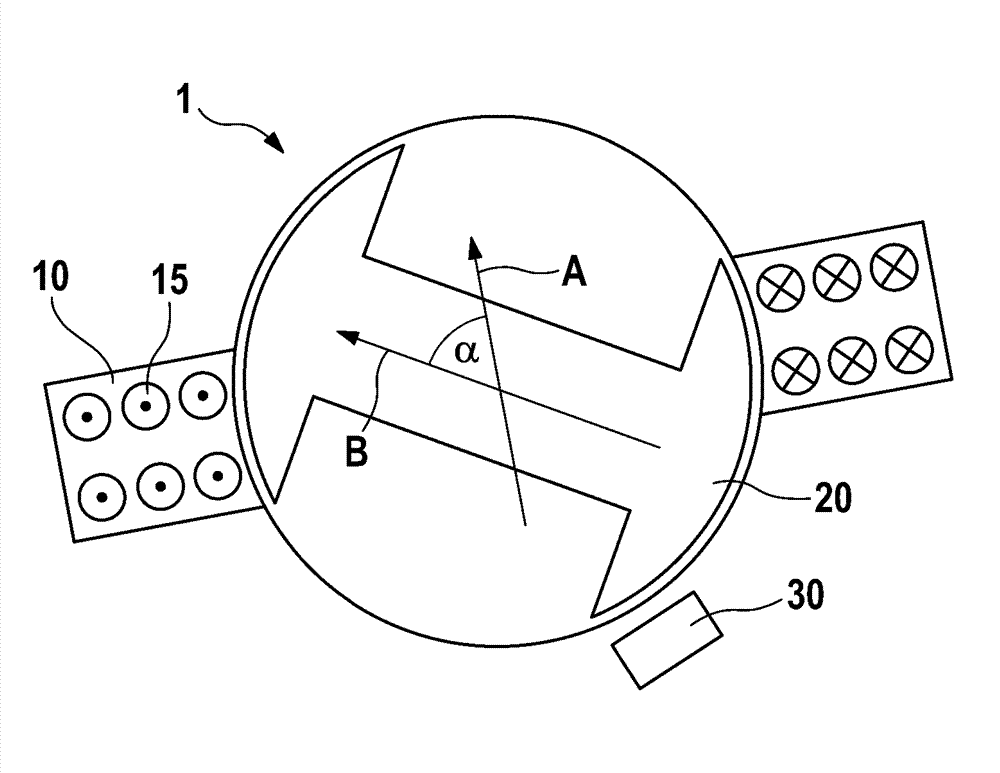

[0030] exist figure 1 An electrical machine 1 with a stator 10 having a stator winding 15 and a rotor 20 is shown in . The current flowing through the stator winding 15 exits the drawing in the winding section shown on the left and flows into the drawing in the winding section shown on the right. The resulting magnetic field has the direction of arrow A. For reasons of clarity, only a single stator winding 15 is shown, wherein usually the stator winding is arranged uniformly along the entire circumference of the stator. The rotor 20 is excited, for example by means of permanent magnets or a rotor winding (not shown), and has a magnetic field which is oriented in the longitudinal direction of the rotor, as indicated by arrow B. The force between the stator 10 and the rotor 20 is proportional to sin(α), where α is equal to the angle between the magnetic field A generated by the stator 10 and the magnetic field B generated by the rotor 20 .

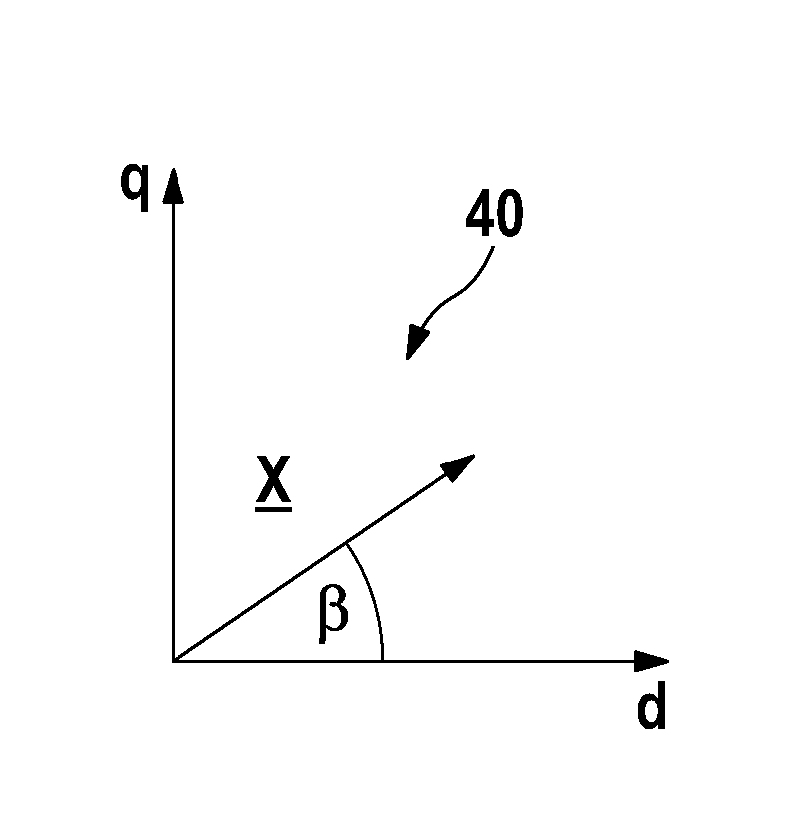

[0031]The current orientation of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com