Guiding transmission shaft structure with cutting knife

A drive shaft, oriented technology, applied in ship propulsion, ship parts, ships, etc., can solve the problems of affecting the normal operation of the propeller, the ship loses power, damage the propeller, etc., and achieves ingenious structural design, flexible use and high cutting efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

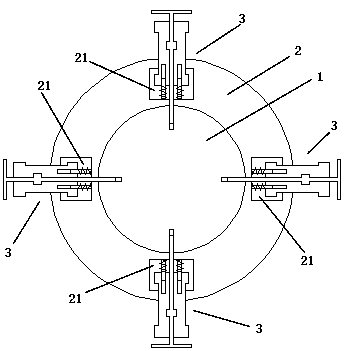

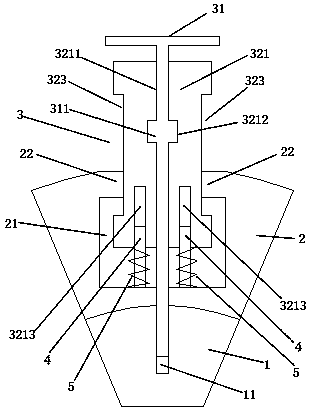

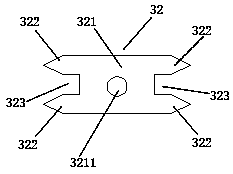

[0018] Such as Figures 1 to 4 As shown, a guide type transmission shaft structure with a cutter includes a transmission shaft 1, a connecting ring 2, a cutting mechanism 3, a guide column 4, and a guiding elastic body 5; the connecting ring 2 is fixedly sleeved on the transmission shaft 1 above; the outside of the connecting ring 2 is evenly provided with a plurality of installation grooves 21; the outside of the transmission shaft 1 is provided with a plurality of connecting threaded passages 11; the installation grooves around the outside of the connecting ring 2 21 corresponds to the position of the connecting threaded channel 11 around the outside of the transmission shaft 1; the mounting groove 21 and the connecting threaded channel 11 are communicated through the connecting groove; a cutting mechanism 3 is respectively installed in the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com