Patents

Literature

54results about How to "Adjust the depth of cut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

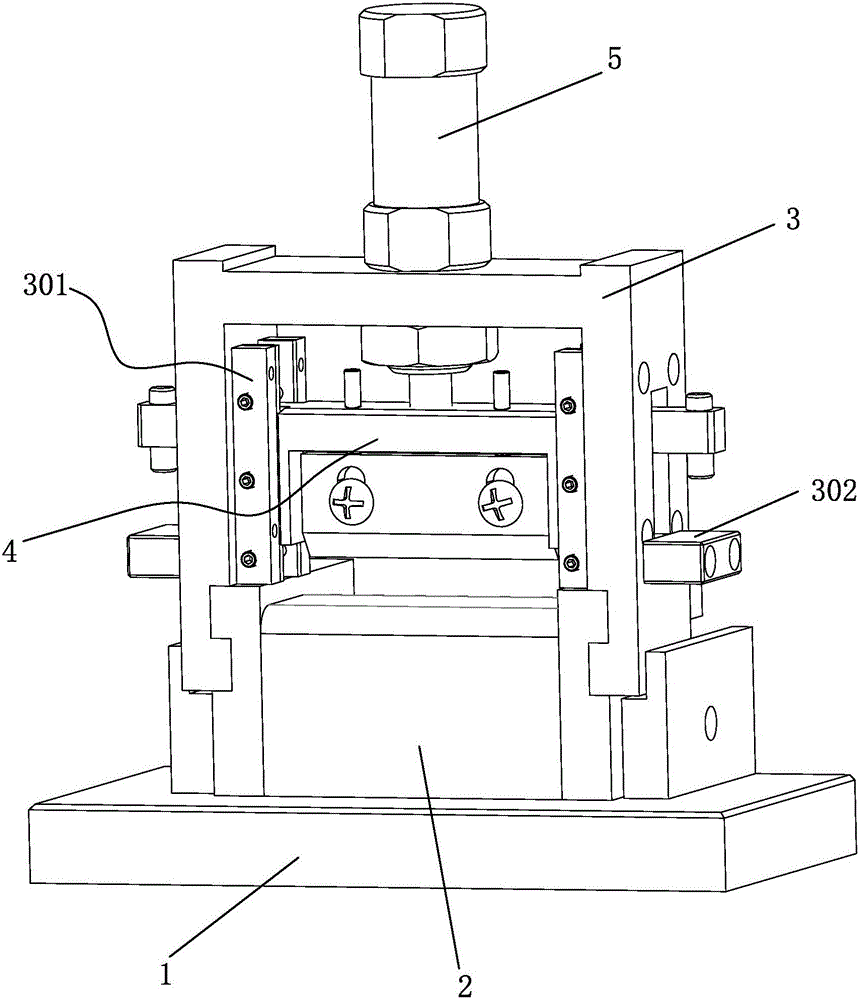

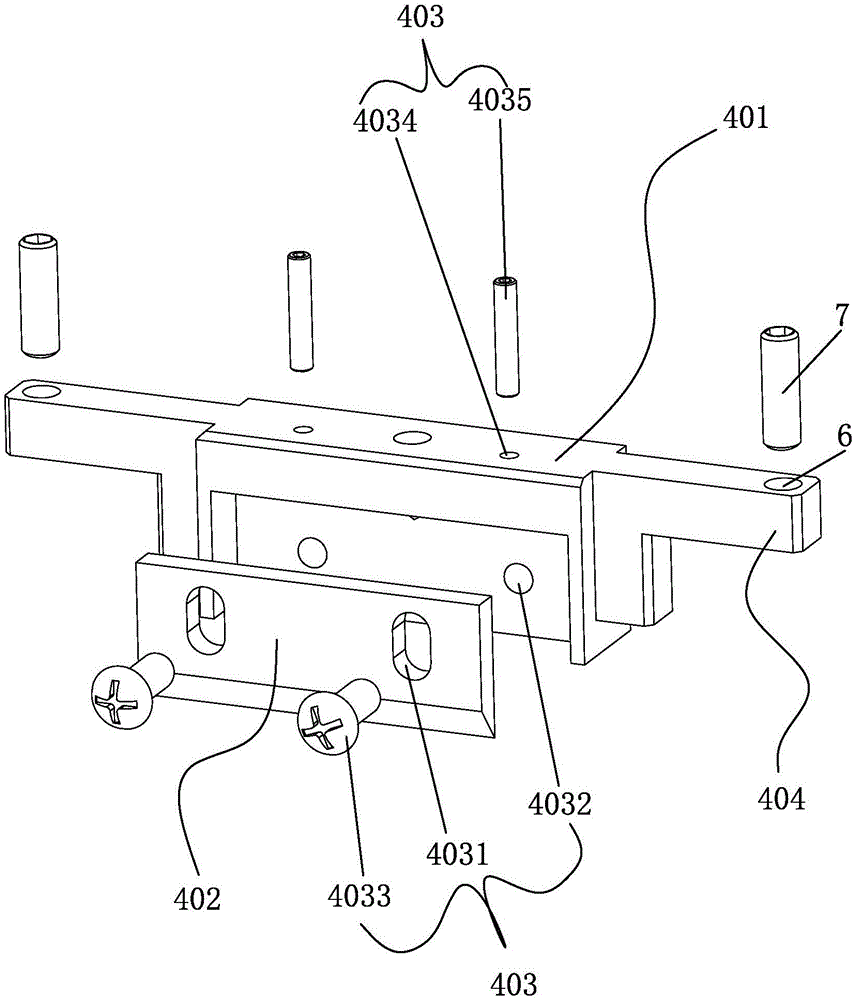

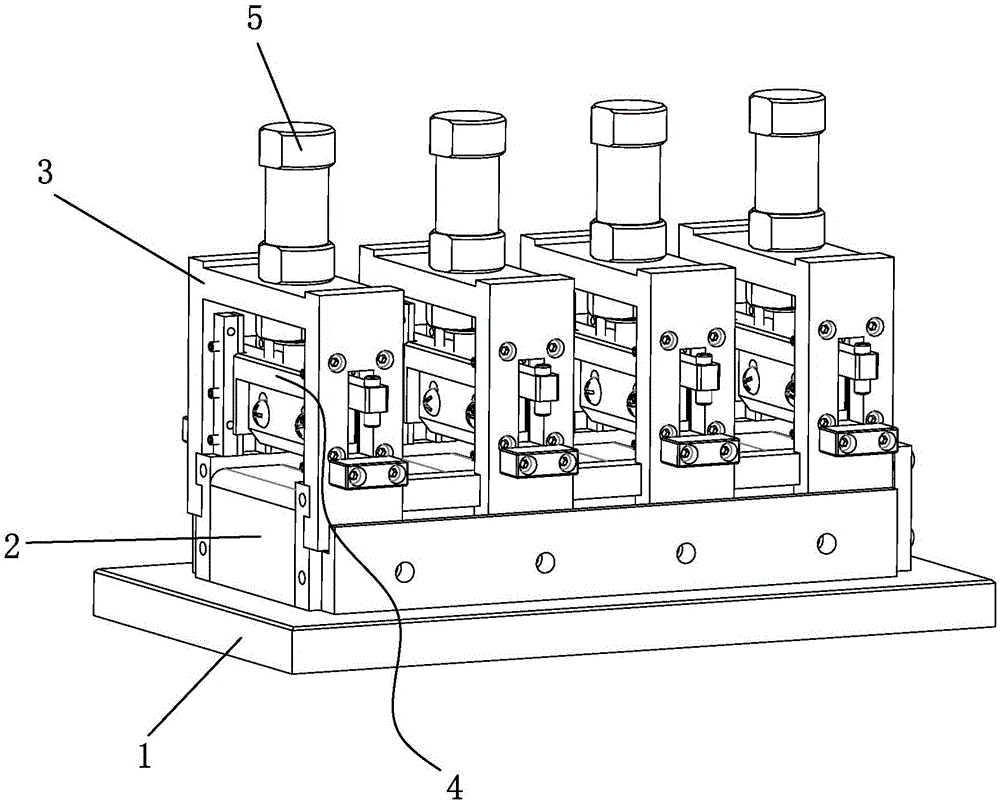

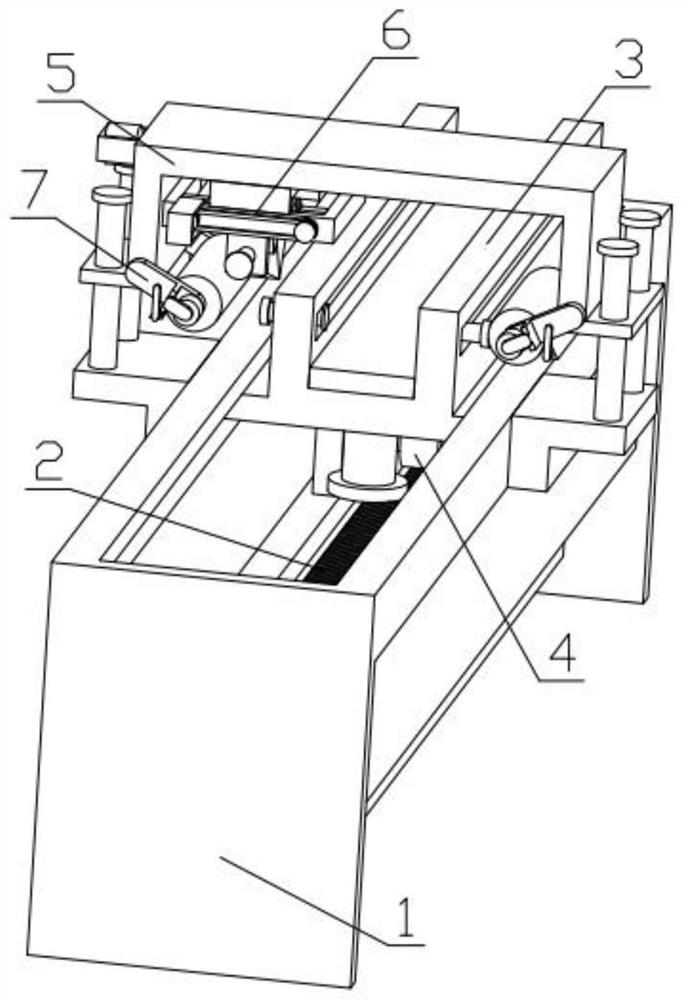

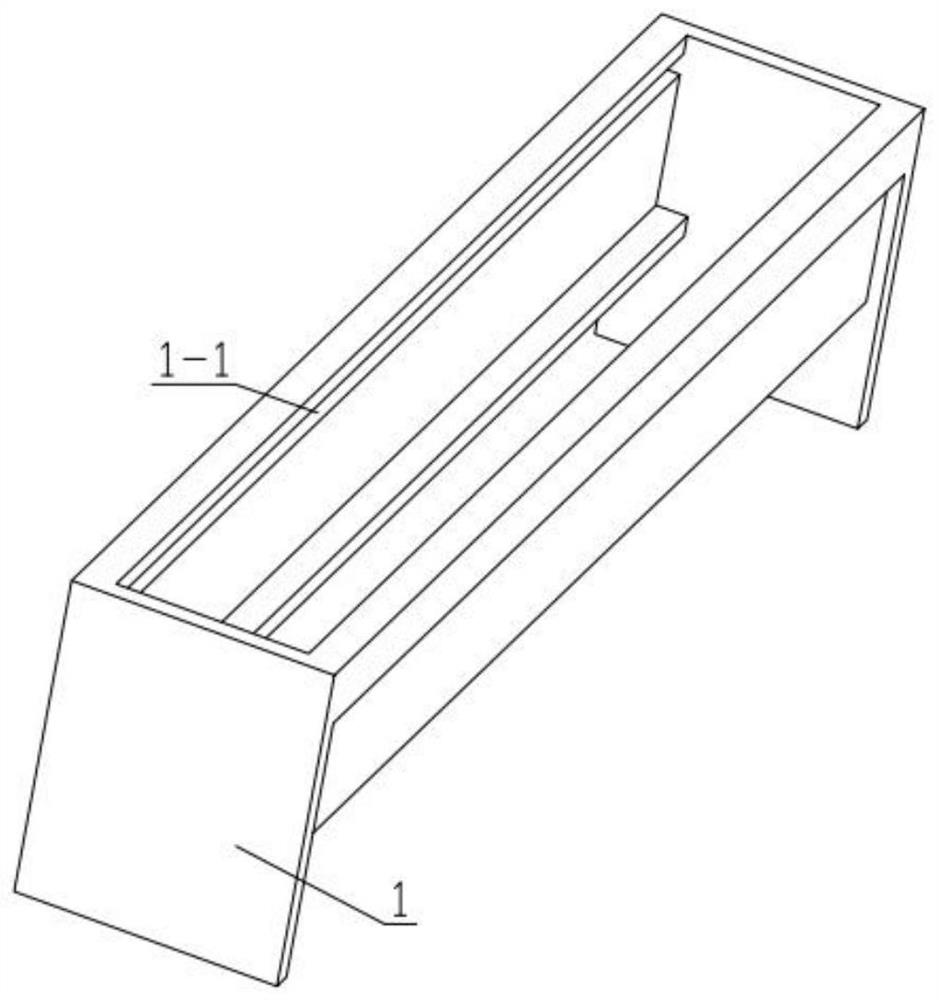

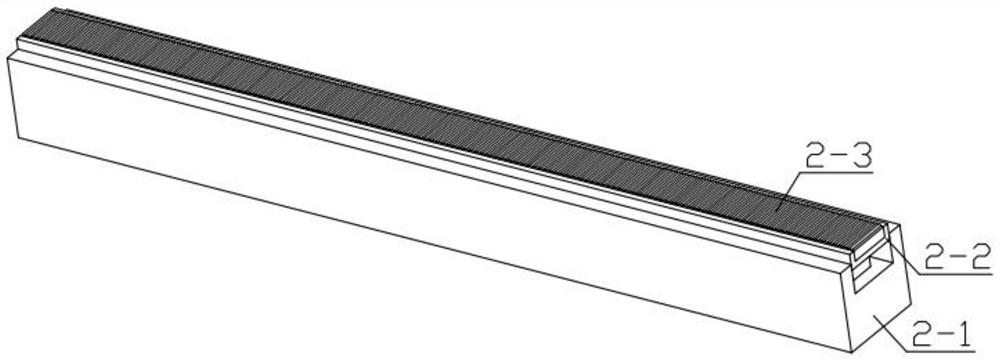

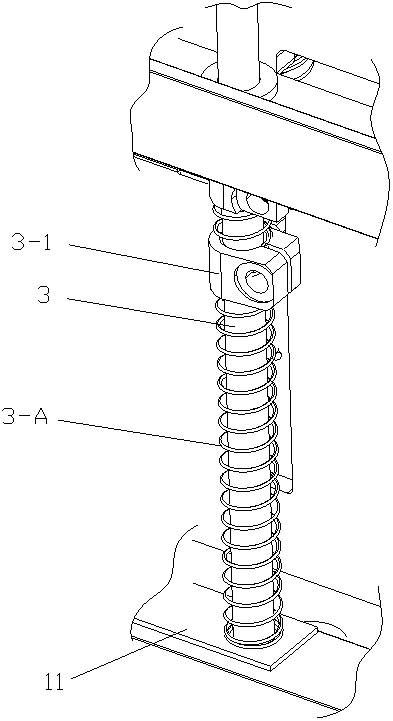

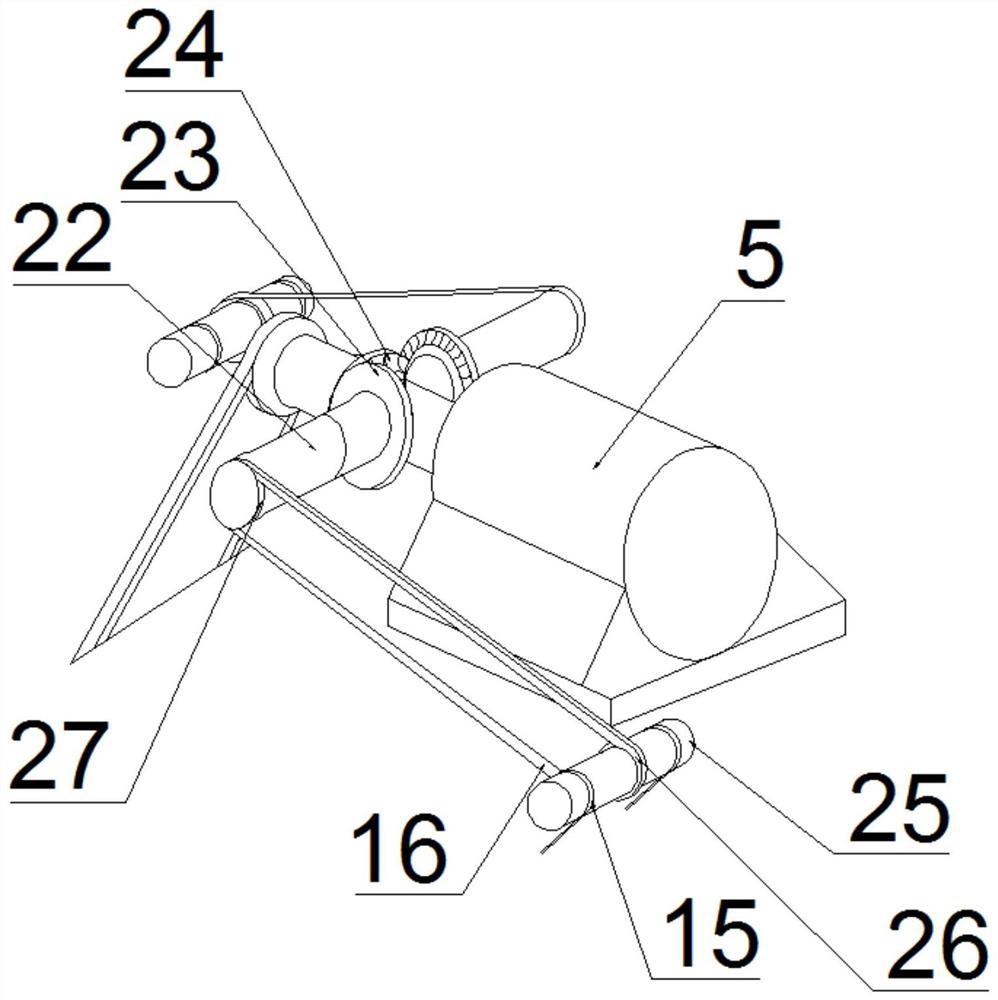

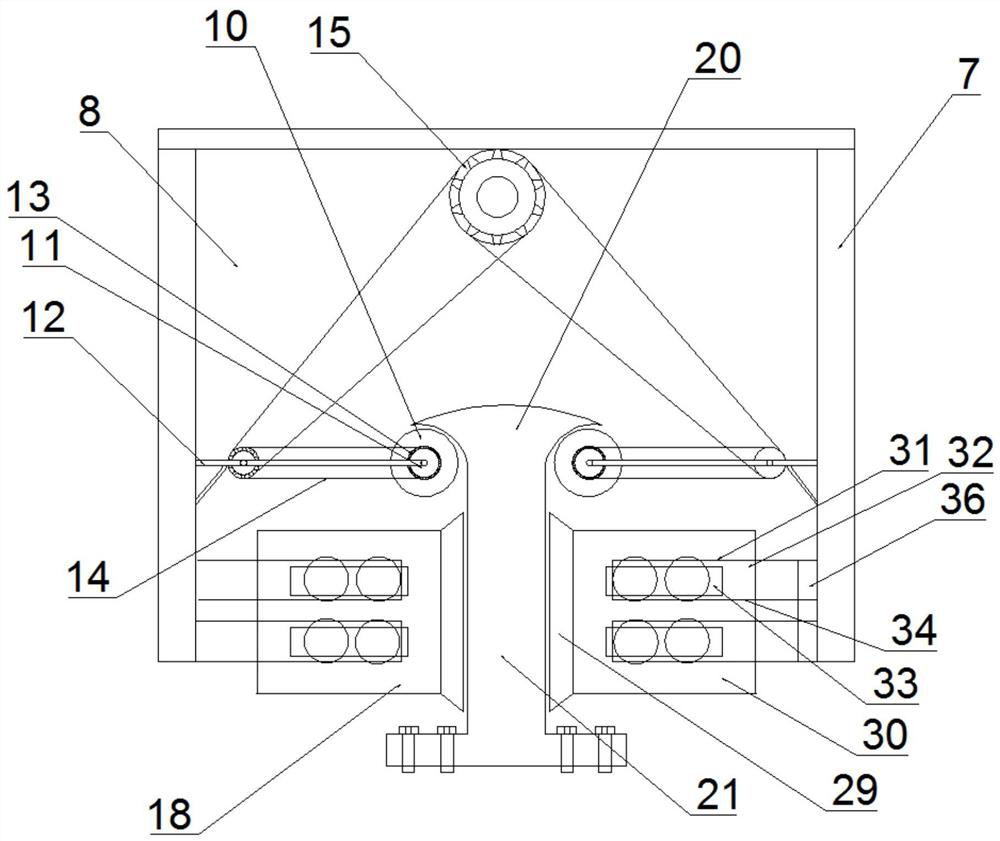

Wire shearing mechanism

The invention discloses a wire shearing mechanism. A cutter pad is arranged on a base, and a support is arranged on the cutter pad. A cutter assembly is slidably connected to the support, and the support is further provided with a driving device used for driving the cutter assembly to cut wires. The cutter assembly comprises a tool rest slidably connected with the support, a blade arranged on the tool rest and an adjusting structure for adjusting the wire cutting depth of the blade. According to the wire cutting mechanism, the cutting depth of the blade can be precisely adjusted so that wire rods can be cut off or pre-cut. During wire winding, all sets of wound wires are pre-cut by the wire cutting mechanism, the pre-cutting depth of the wire rods can be adjusted through the adjusting structure, and after wire winding of coils is completed, the ends of windings can be snapped along pre-cut positions with slight force. Accordingly, the wire cutting mechanism improves production efficiency, lowers the labor cost, guarantees uniform quality of all finished coil products, and has the characteristic of high yield.

Owner:宋红光

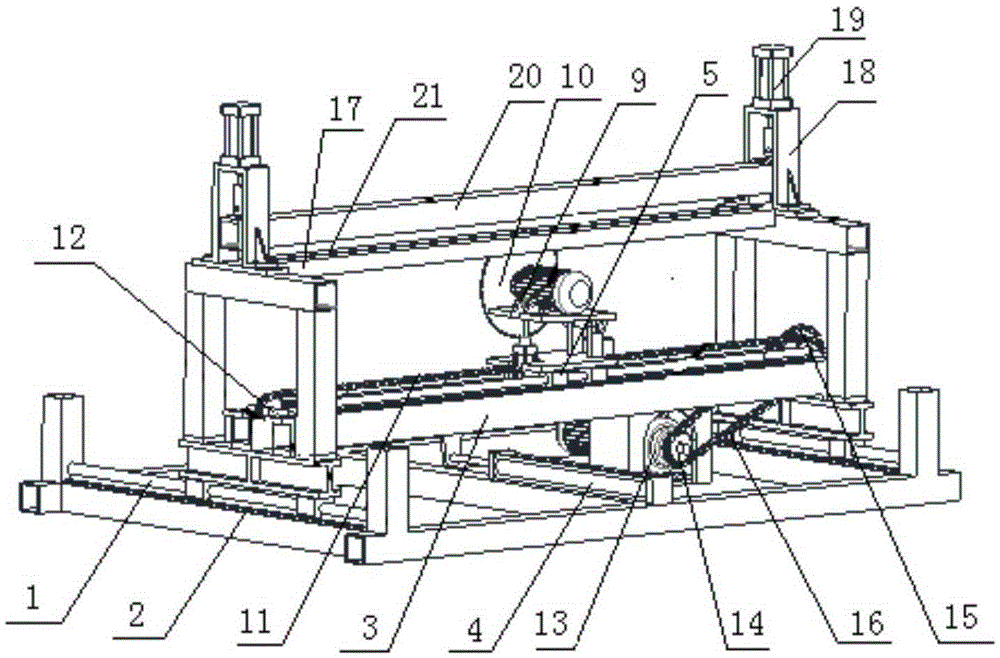

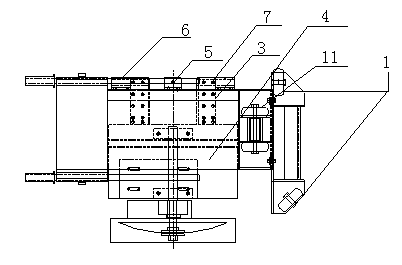

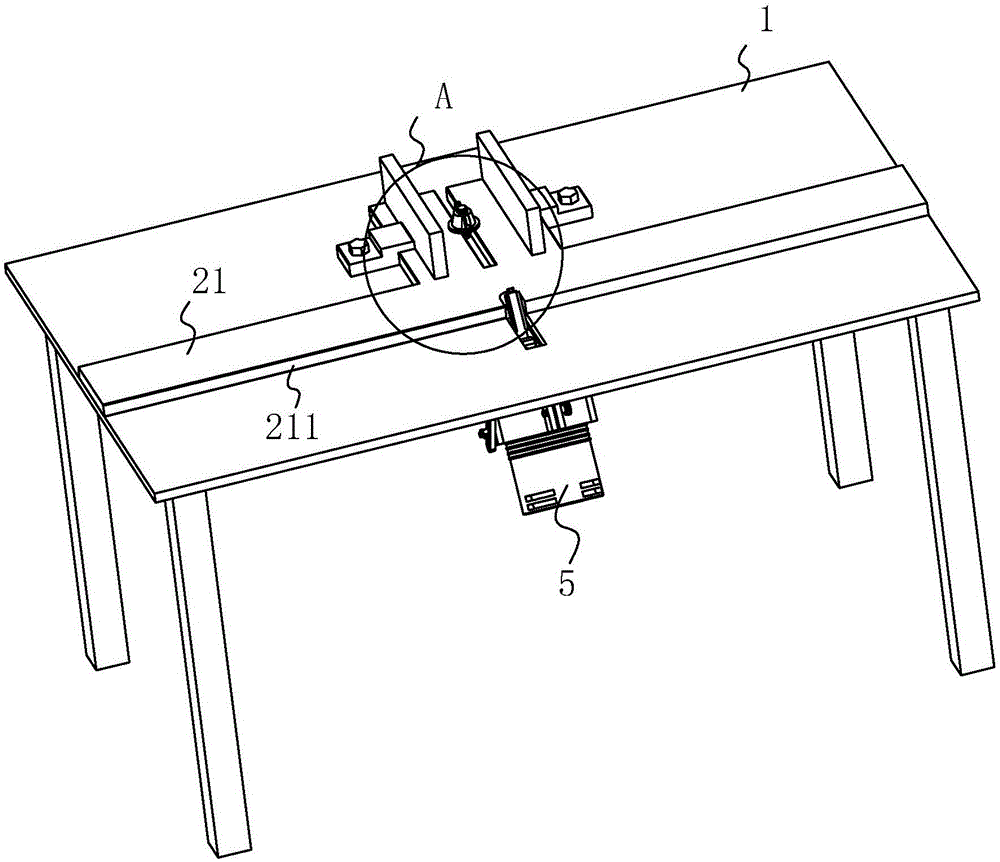

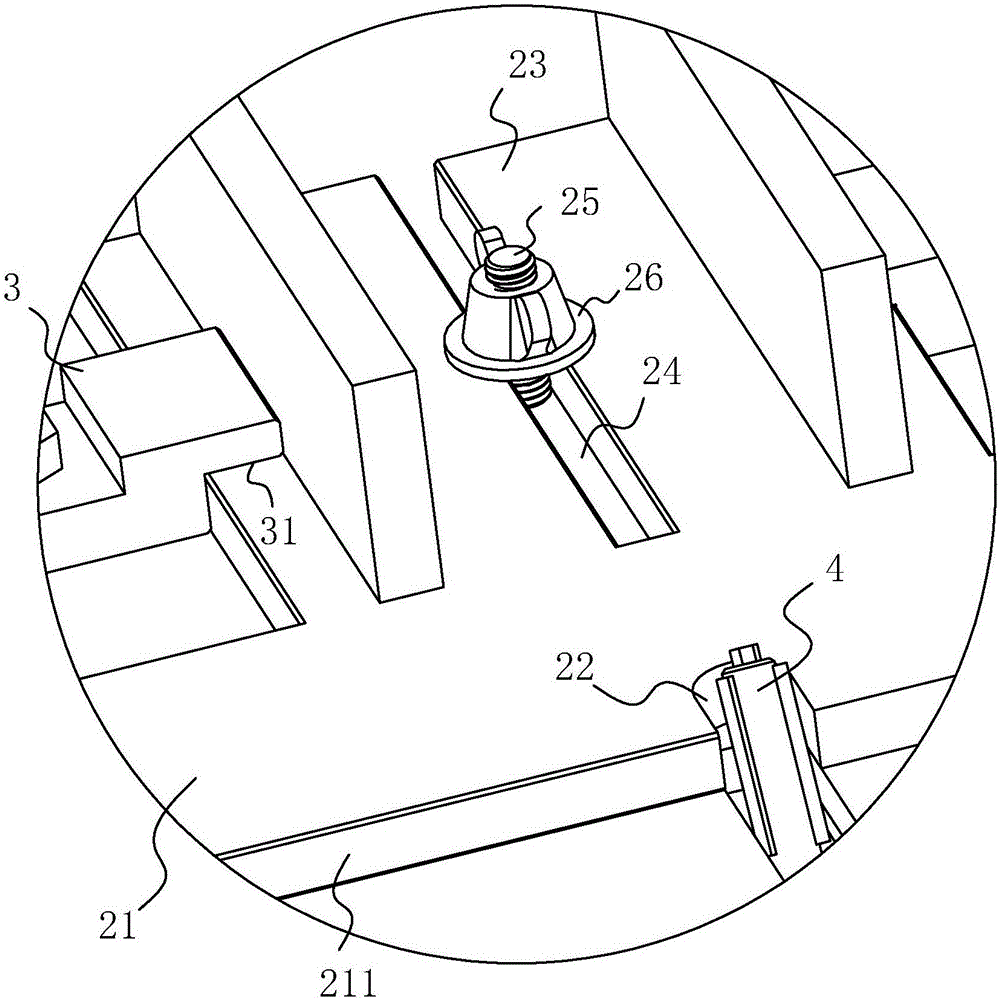

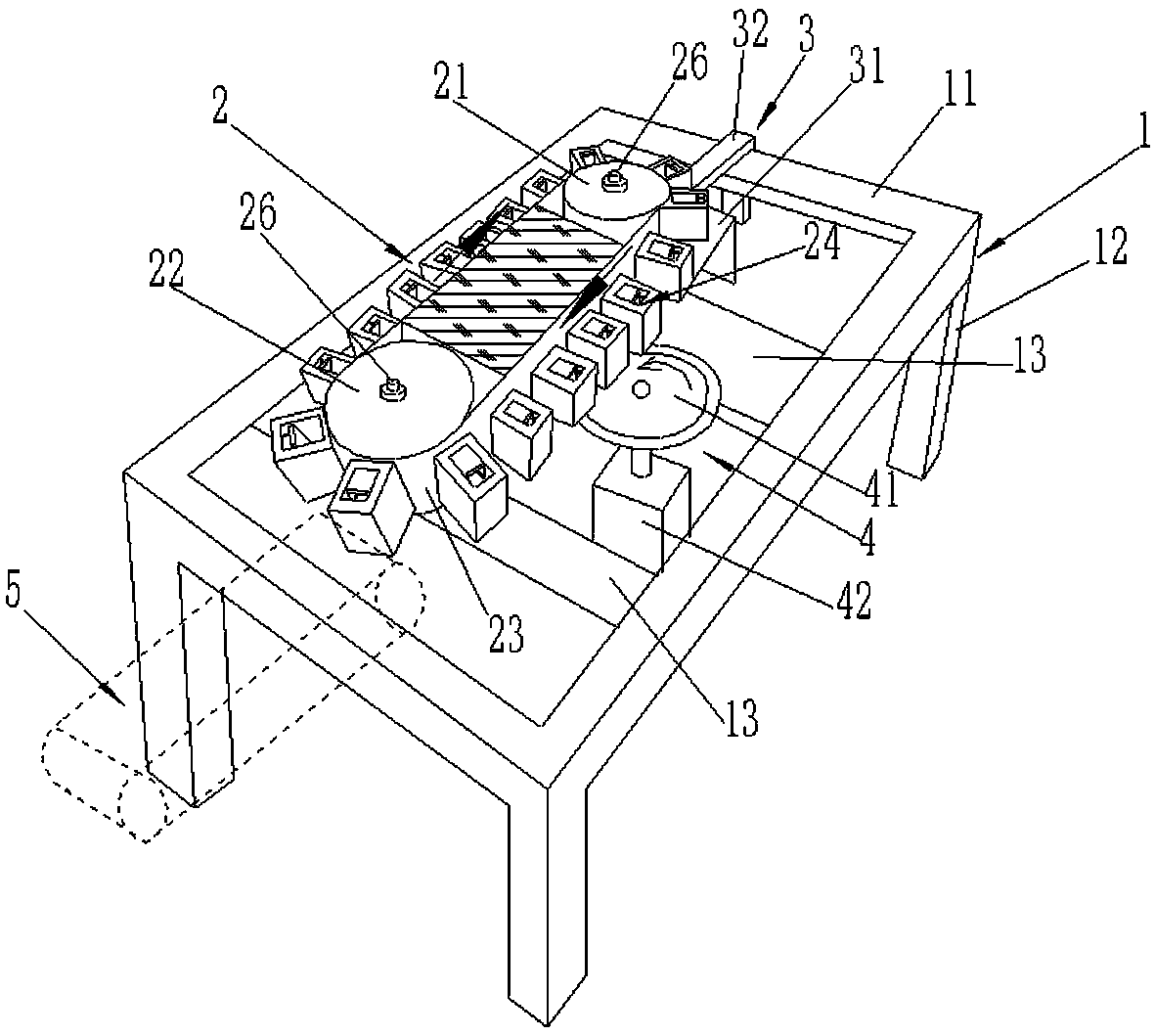

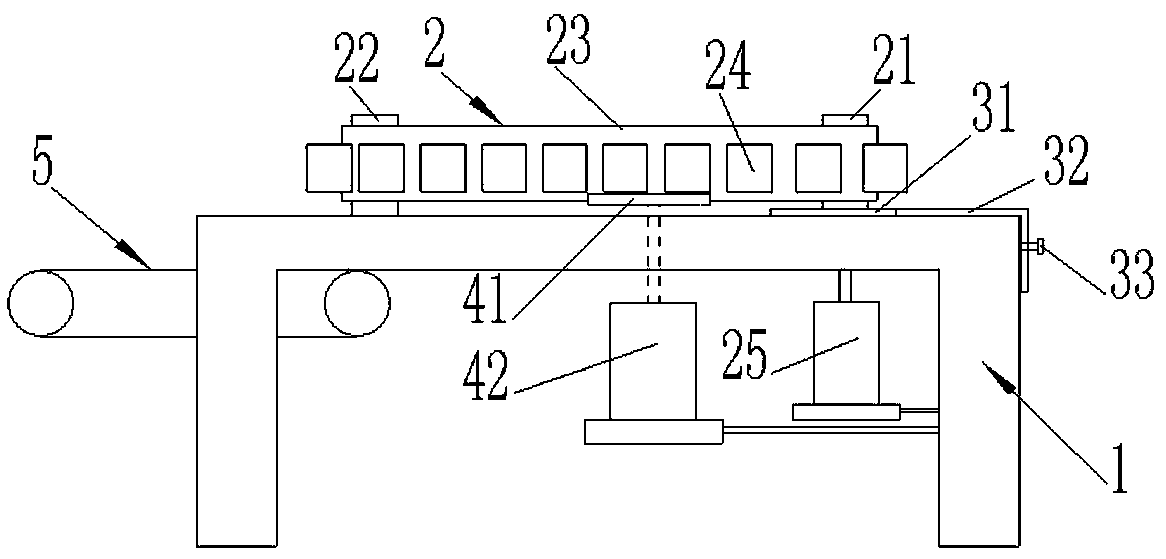

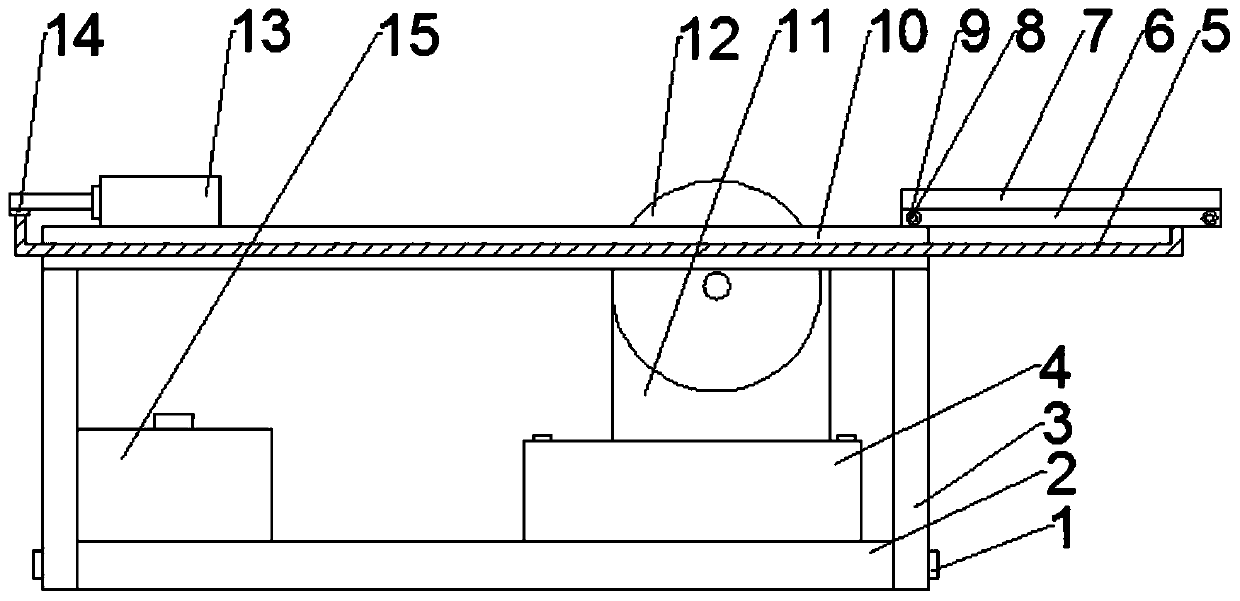

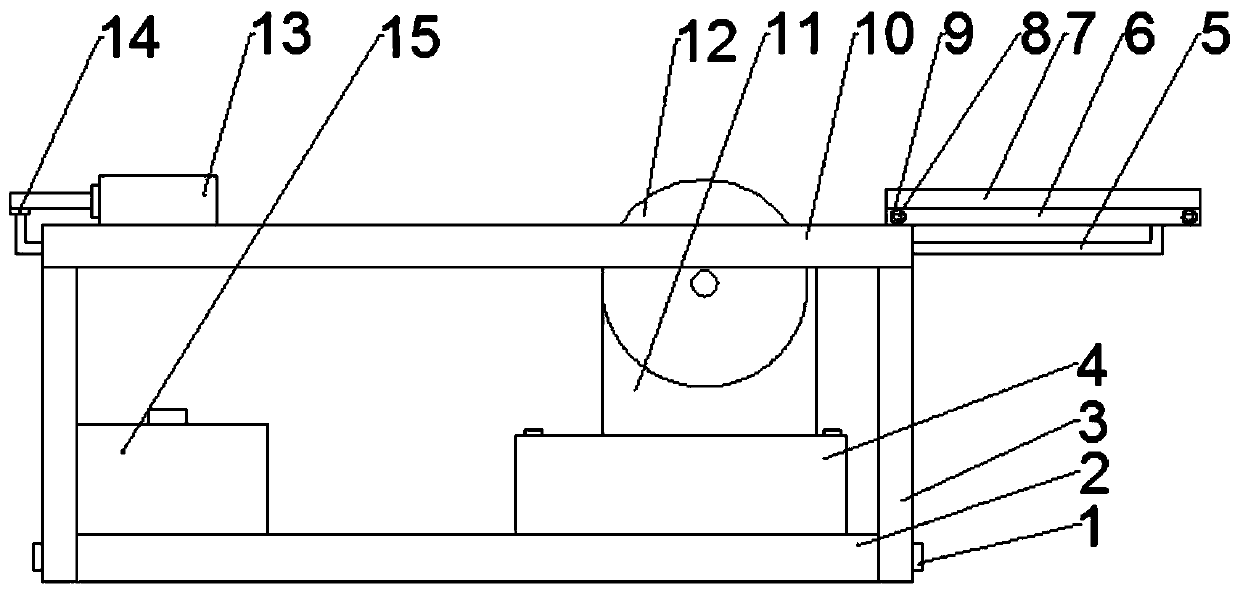

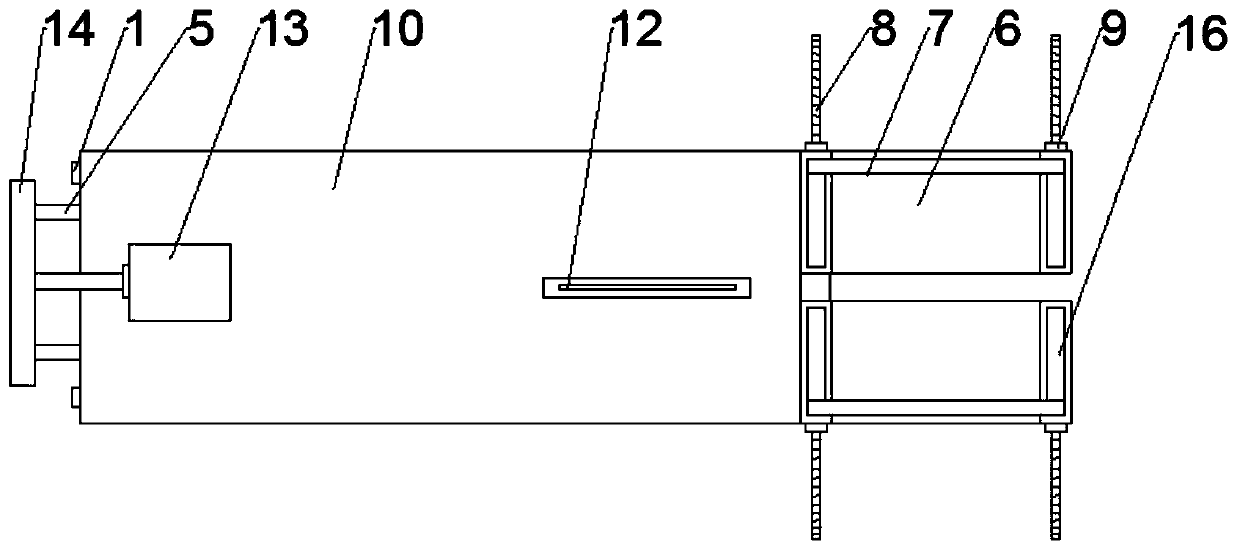

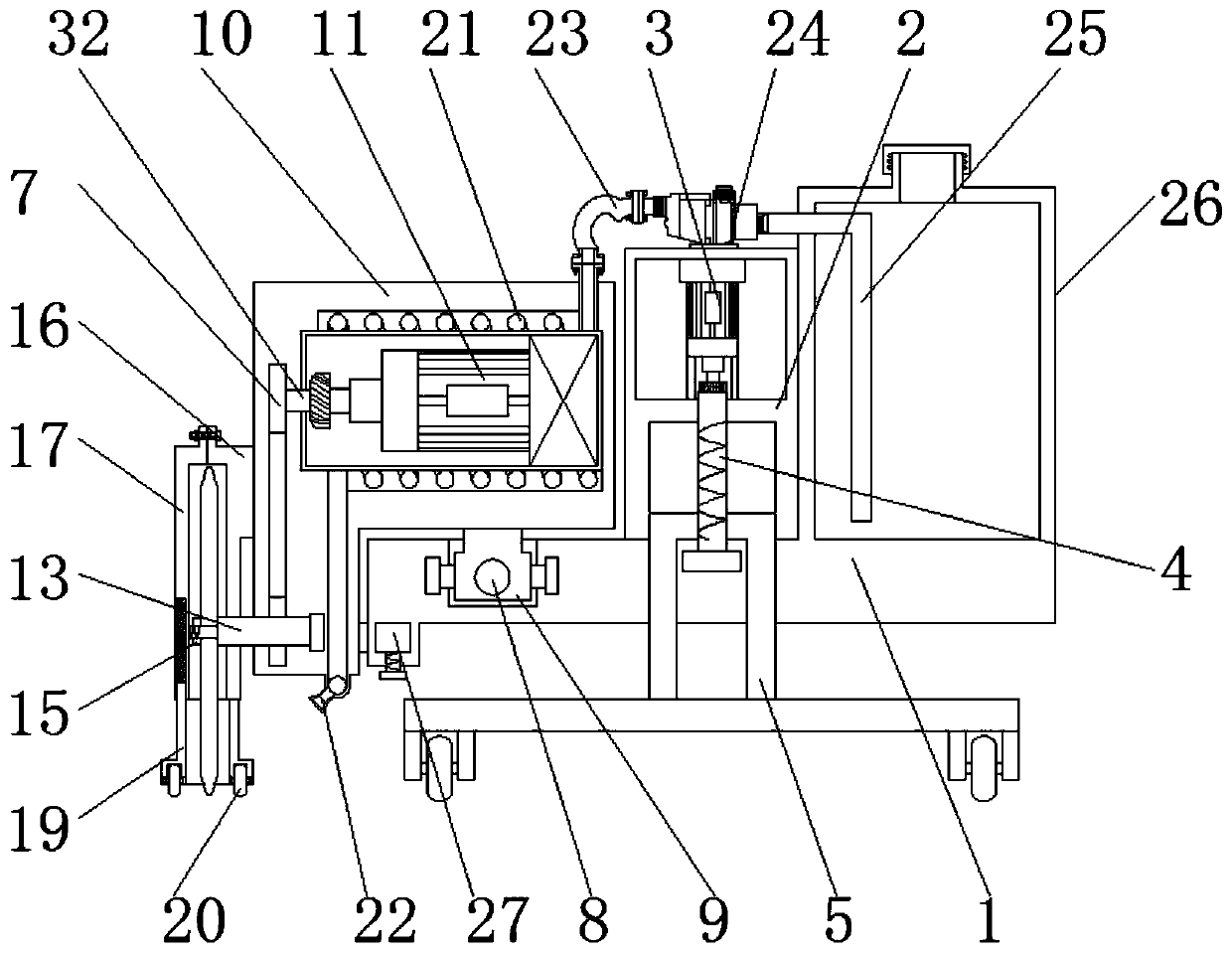

Cutting machine for PE building formwork production line

InactiveCN105150259AIncrease productivityAvoid damageMetal working apparatusReciprocating motionProduction line

The invention discloses a cutting machine for a PE building formwork production line. The cutting machine comprises a base. An installation base is arranged on the base in a sliding manner in the feeding direction. The base is provided with a return air cylinder used for pulling back the installation base to be reset. The installation base is provided with a cutting base which slides in the direction perpendicular to the feeding direction. The cutting base is provided with a cutting motor. An output shaft of the cutting motor is provided with a saw blade. The installation base is provided with a driving chain used for driving the cutting base to reciprocate. The two ends of the cutting base are each provided with a driving chain wheel for tensioning the driving chain. The cutting base is provided with a power device connected with one driving chain wheel. A lower pressing block perpendicular to the feeding direction is arranged on the installation base and located above the cutting base. The portions, on the two sides of the lower pressing block, of the installation base are provided with supports respectively. Two pressing plate air cylinders with adjustable stroke are vertically arranged on the supports downwards. An upper pressing block is erected between the ends of piston rods of the two pressing plate air cylinders. The cutting machine is applicable to the PE building formwork production line, and can achieve tracking cutting on plates in the plate feeding process.

Owner:JIANGSU UNIV OF SCI & TECH IND TECH RES INST OF ZHANGJIAGANG

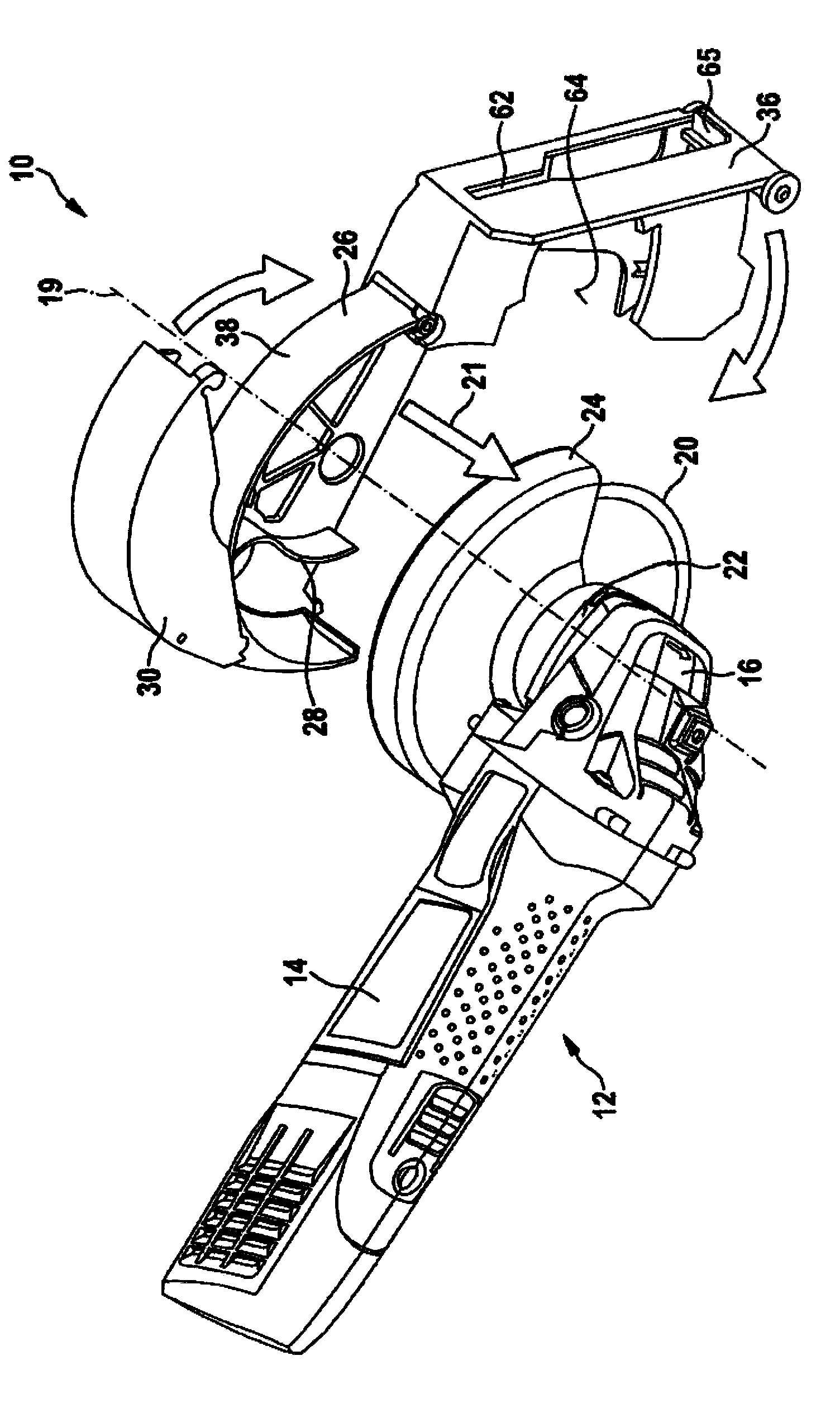

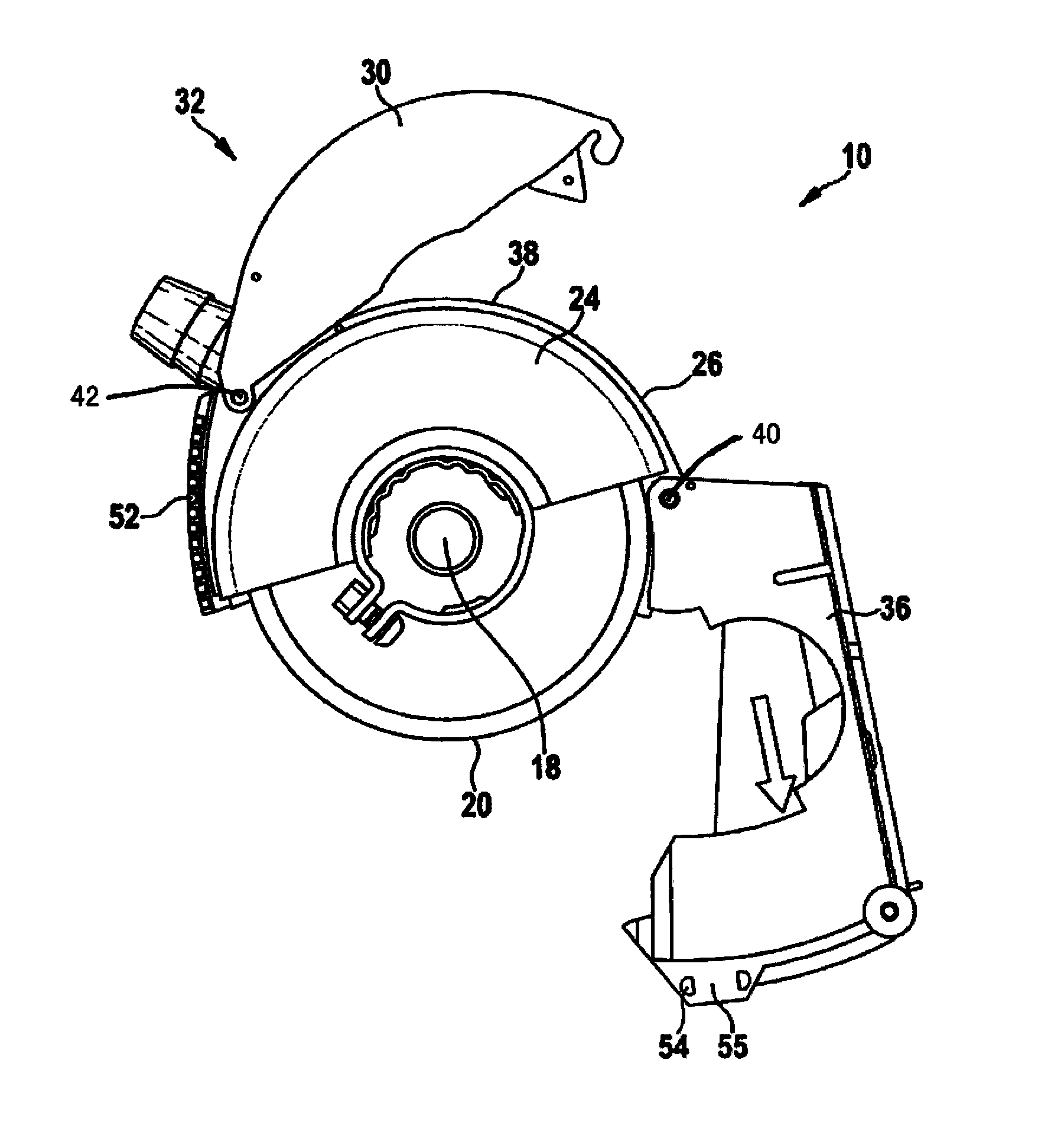

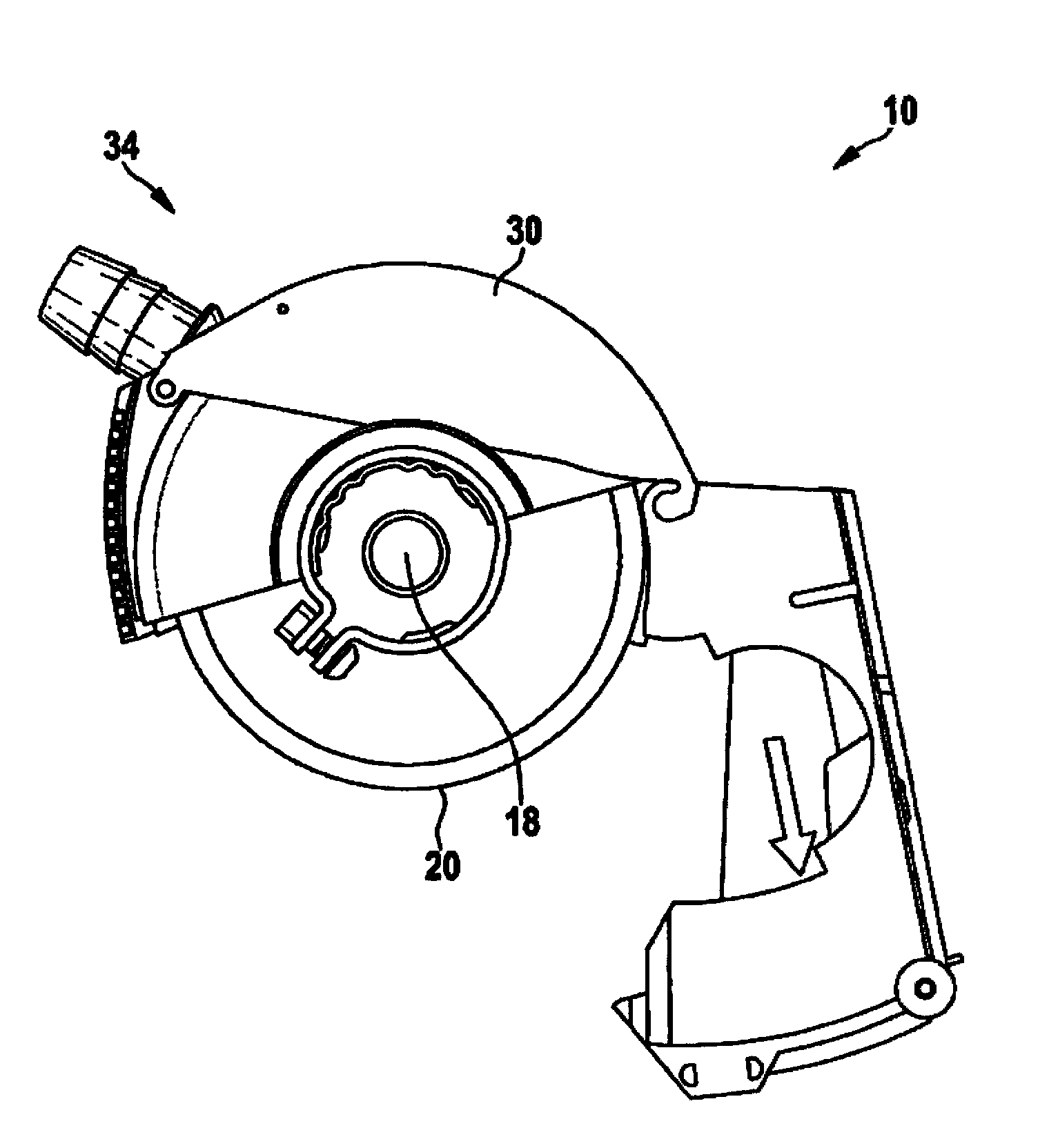

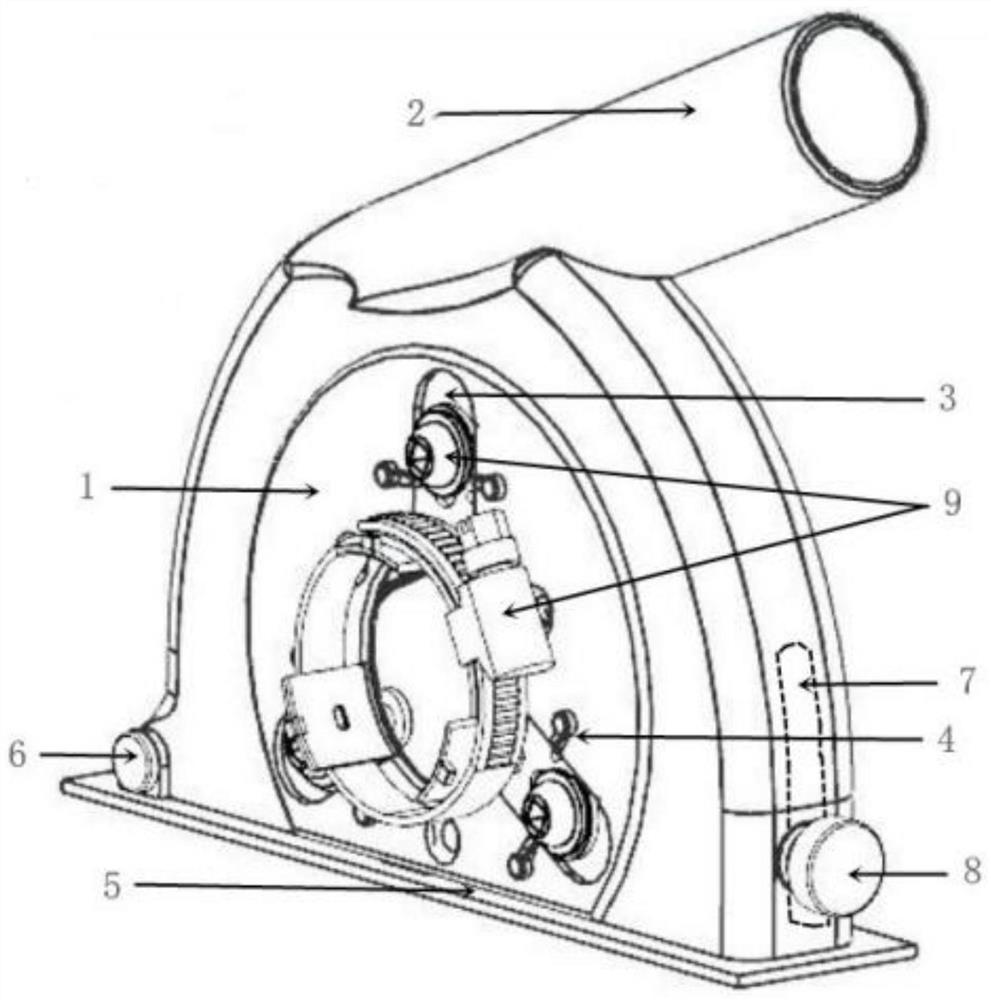

Cover device with dust suction device when used with electric tool

ActiveCN103372813AEasy to installSafe and reliable lockingPortable power-driven toolsGrinding/polishing safety devicesAngle grinderEngineering

The device (10) has a protective bonnet (24) i.e. angle grinder, comprising a receiving part (26) for receiving the protective bonnet. A closure part (30) is movably attached at the receiving part and movable between an open position and a closed position. The receiving part opens the closure part in an axial direction (19) over the protective bonnet of an electric power tool (12) relative to sharpening and / or separation tools (20) and is fastenable by closing / / locking of the closure part at the protective bonnet.

Owner:ROBERT BOSCH GMBH

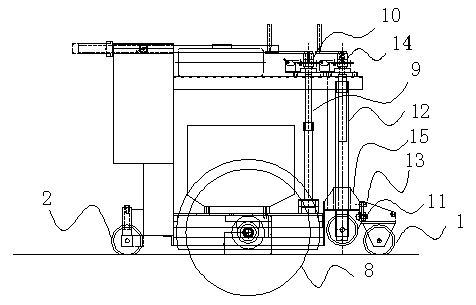

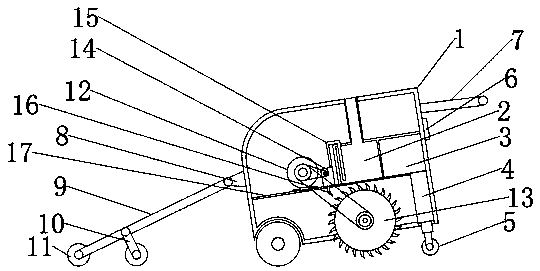

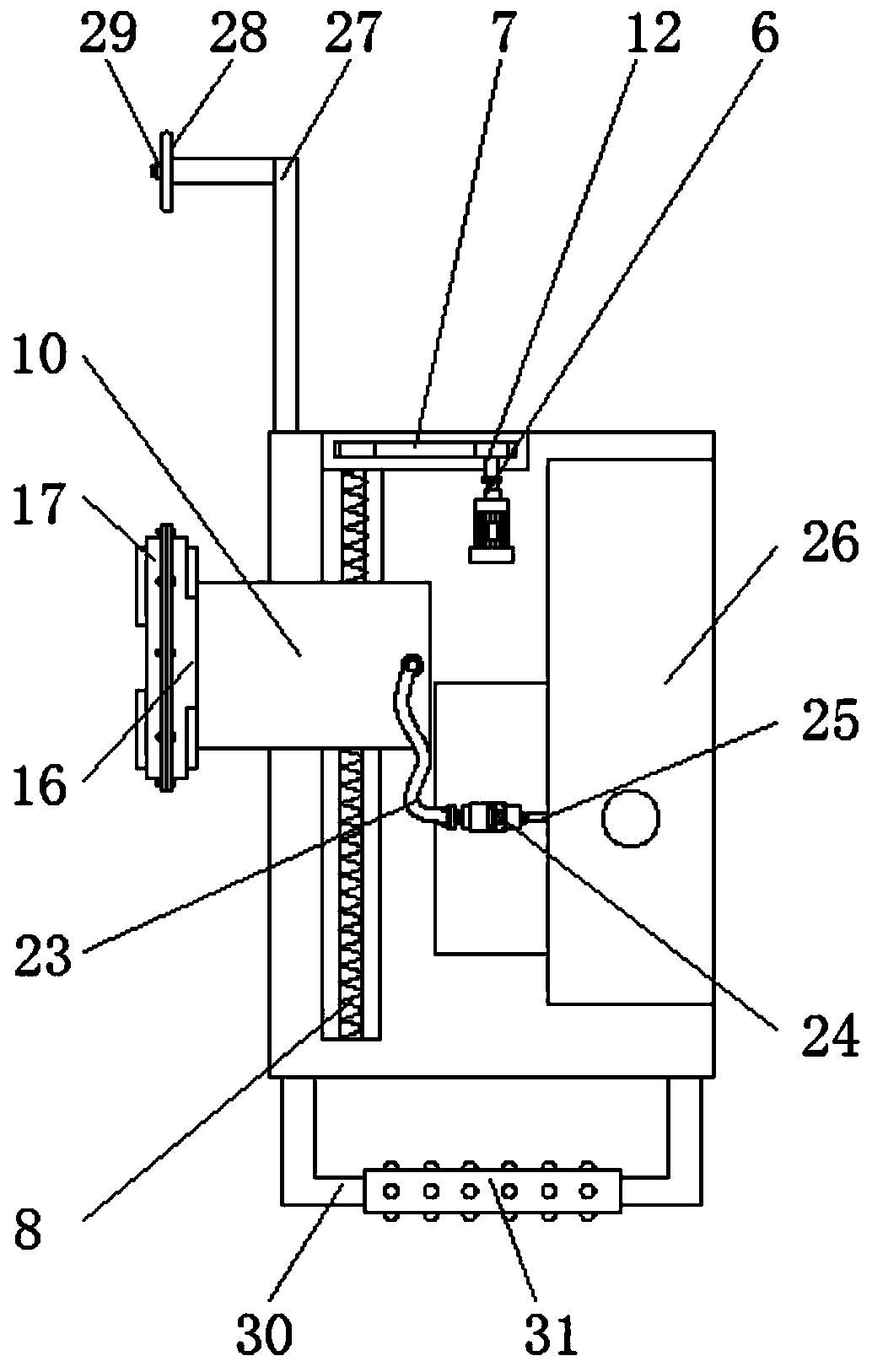

Road surface cutter capable of cutting circular spherical surface

The invention discloses a road surface cutter capable of cutting a circular spherical surface. The road surface cutter comprises a base, circular guide wheels and rear wheels capable of adjusting the direction of a central axis; the base comprises an adjusting surface and a working surface; a work circle center is arranged in the center of the outer edge of the adjusting surface; pin shafts are arranged at the two ends of the adjusting surface; a plurality rows of through holes are arranged on the adjusting surface in the width direction of the cutter; cutting discs are assembled at the bottom of the working surface by cutting shafts; the distance between the work circle center and the cutting disc can be adjusted by connecting different rows of through holes with the pin shafts; and the central axes of the circular guide wheels and the cutting discs are fixed and opposite to the work circle center of the adjusting surface of the base. According to the road surface cutter, circular surfaces can be cut by the cutter; radius of circular surfaces can be changed by adjusting the connection of the through holes and the pin shafts on the adjusting surface; the cutting depth and angle can be changed by moving a first adjusting rocking bar up and down; working modes of cutting straight lines and cutting circular surfaces can be switched by moving a second adjusting rocking bar up and down; and the straight line cutting depth also can be adjusted at a straight line cutting mode.

Owner:TONGLING LONGSHUN ENVIRONMENTAL PROTECTION EQUIP

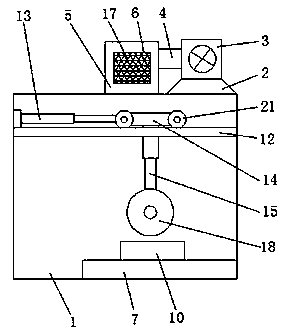

High-efficiency building timber cutting device

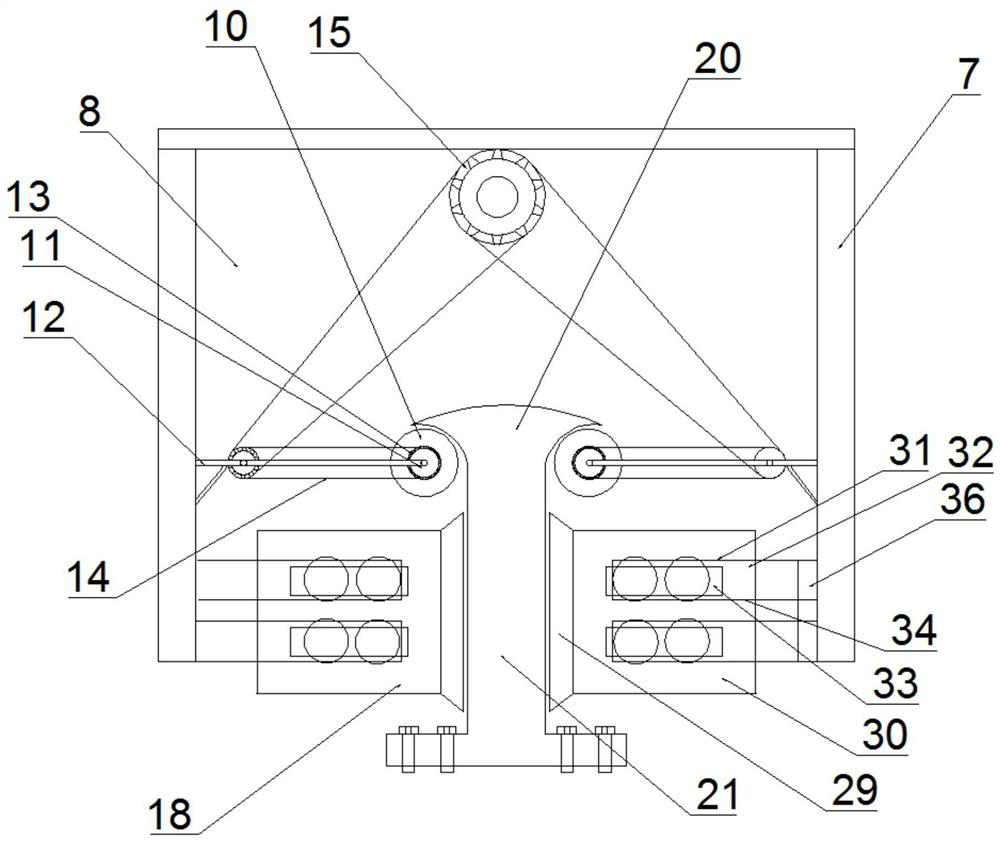

The invention discloses a high-efficiency building timber cutting device, and relates to the technical field of timber cutting equipment. The high-efficiency building timber cutting device comprises a case body, a top case is fixedly connected with the top of the inner wall of the case body, a bottom case is fixedly connected with the bottom of the right side of the case body, and a placing table is slidably connected between the two sides of the inner wall of the case body; and a movable device is arranged in the top case, a connecting plate is fixedly connected with the bottom of the movable device, the bottom of the connecting plate penetrates through the top case and extends to the bottom of the top case, and a motor case is fixedly connected with the bottom of the connecting plate. According to the timber cutting device with an adjusting function, the problem that existing timber cutting equipment cannot be adjusted according to a needed cutting length is solved, the timber cutting device can be adjusted effectively, the situation that the needed precision of timber cutting is achieved is ensured, the cutting depth of timber can be adjusted, different cutting requirements can be met, timber with a variety of diameters can also be cut simultaneously, and thus the cutting efficiency of the timber is enhanced.

Owner:陈功鸿

Cable stripping machine

ActiveCN112260150AAdjust the depth of cutNot destroyedBasic electric elementsApparatus for removing/armouring cablesStructural engineeringKnife blades

The invention discloses a cable stripping machine, which comprises: a clamping assembly provided with an inlet end and an outlet end, wherein a guide part is arranged at the inlet end of the clampingassembly, and the thickness of the guide part is gradually increased from the inlet end to the outlet end to form a guide slope; and a stripping assembly, which is arranged at the outlet end of the clamping assembly, and comprises a plurality of cutting tools, wherein each cutting tool is telescopic so as to adjust the cable cutting depth. According to the cable stripping machine, the length of the cutting tools can be adjusted according to different sheath thicknesses of cut cables, so that the cutting depth is adjusted, and the cable stripping machine can cut the sheaths of the cables with different radiuses and different thicknesses; and each blade can be independently adjusted, so that the thicknesses of different sheaths at different positions on the same cable can be cut.

Owner:ZHEJIANG SHIP ELECTRONICS TECH

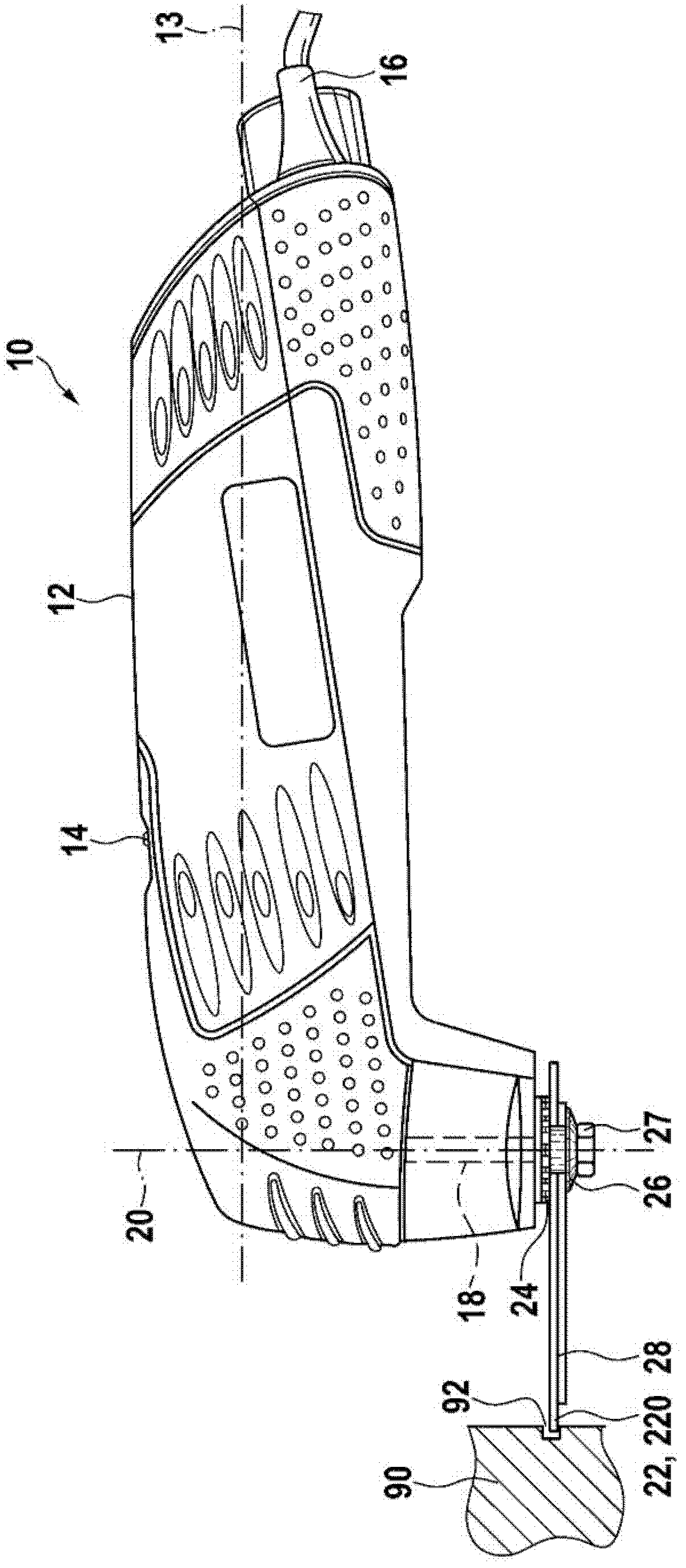

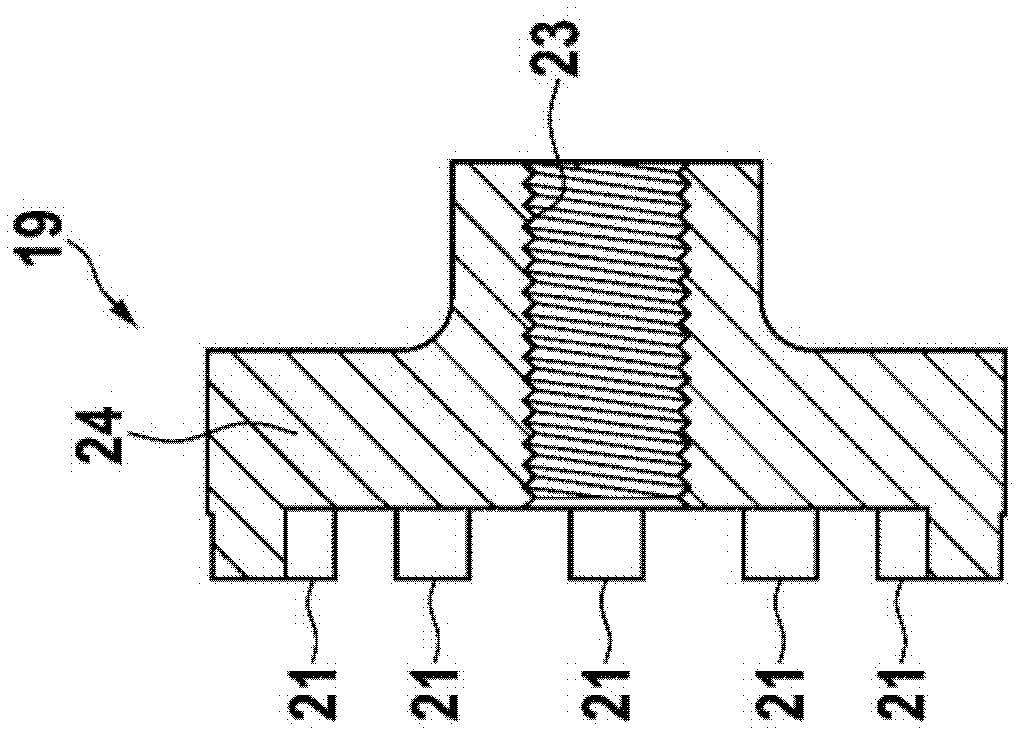

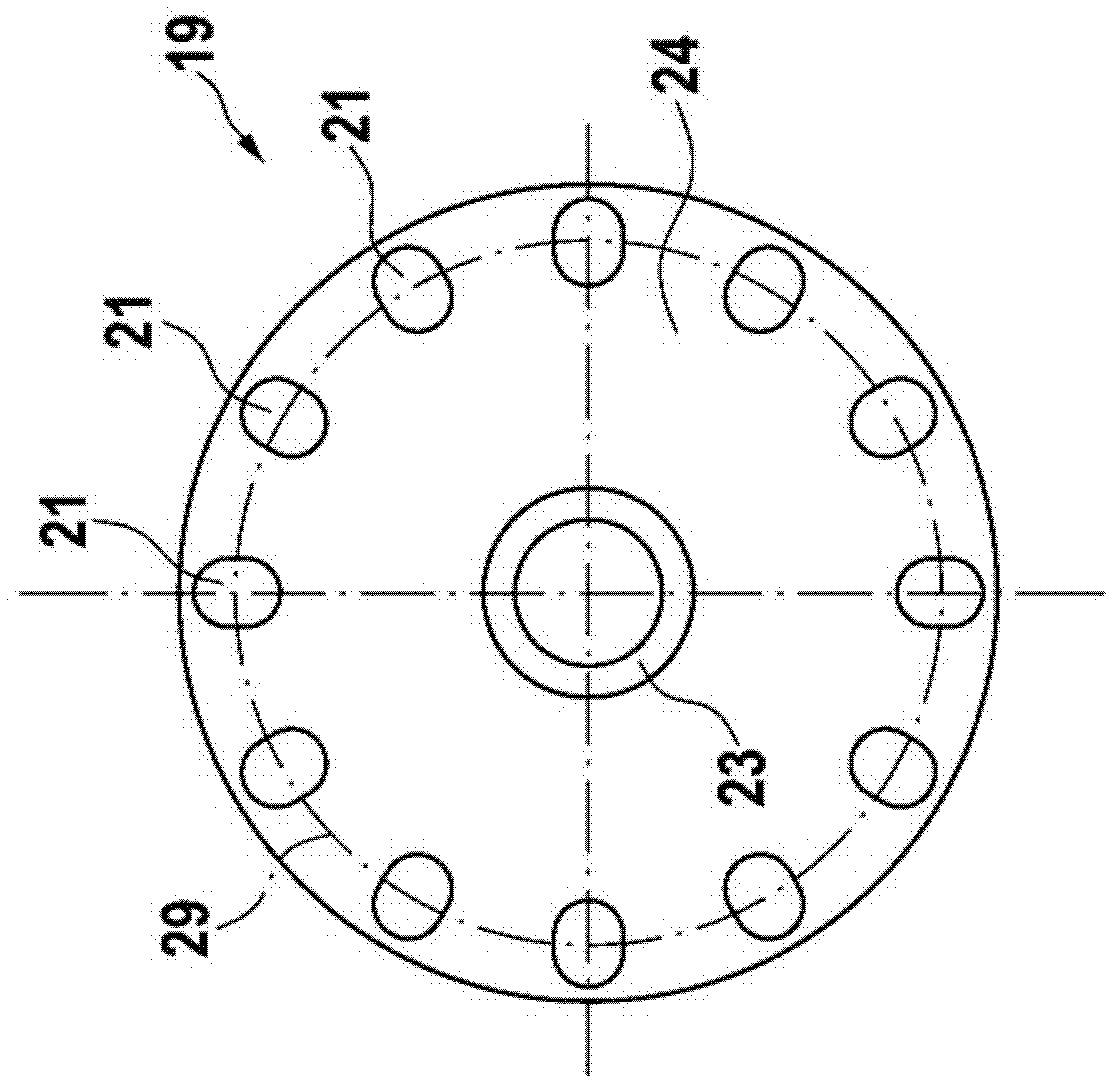

Stop device for a portable machine tool

InactiveCN102548720AImprove protectionReduce riskPortable power driven sawsPower driven reciprocating sawsHand heldStops device

The invention relates to a stop device, particularly a depth stop (280), for a rotationally driven, particularly oscillatingly driven, chipping or cutting, round and / or angular disc shaped tool (22, 220) of a portable machine tool, particularly a saw blade, by means of which a cut (92) can be produced in a workpiece (90) in a chipping manner, comprising a disc-like means that is arranged axially adjacent to the tool (22, 220), preferably axially supported thereon, and exposes opposite the outer edge thereof (290) a certain part of the tool (22) for penetration into the cut (92) by a defined degree and prevents further penetration into the cut (92) beyond the defined degree, as soon as the edge (290) is supported on the tool (90). According to the invention, the disc-shaped tool (22, 220) is crucible-shaped and the stop device, particularly the depth stop (280), is also similarly designed so as to be precisely crucible-shaped, wherein the depth stop (280) enters a concave crucible-shaped region of the tool (22, 220) and / or vice versa, it receives the tool (22, 220) in an axially supporting manner in the concave crucible-shaped region thereof.

Owner:ROBERT BOSCH GMBH

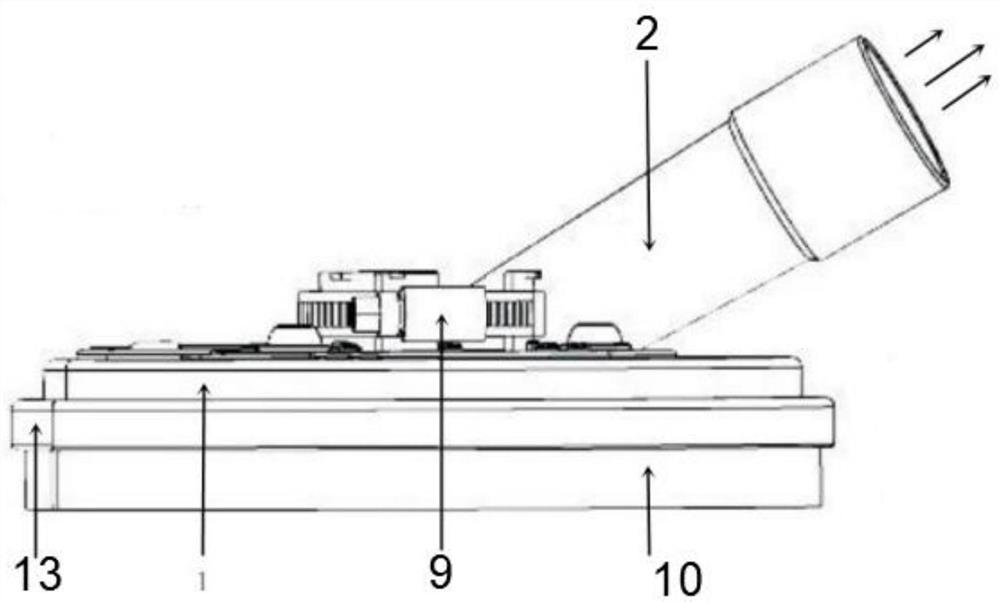

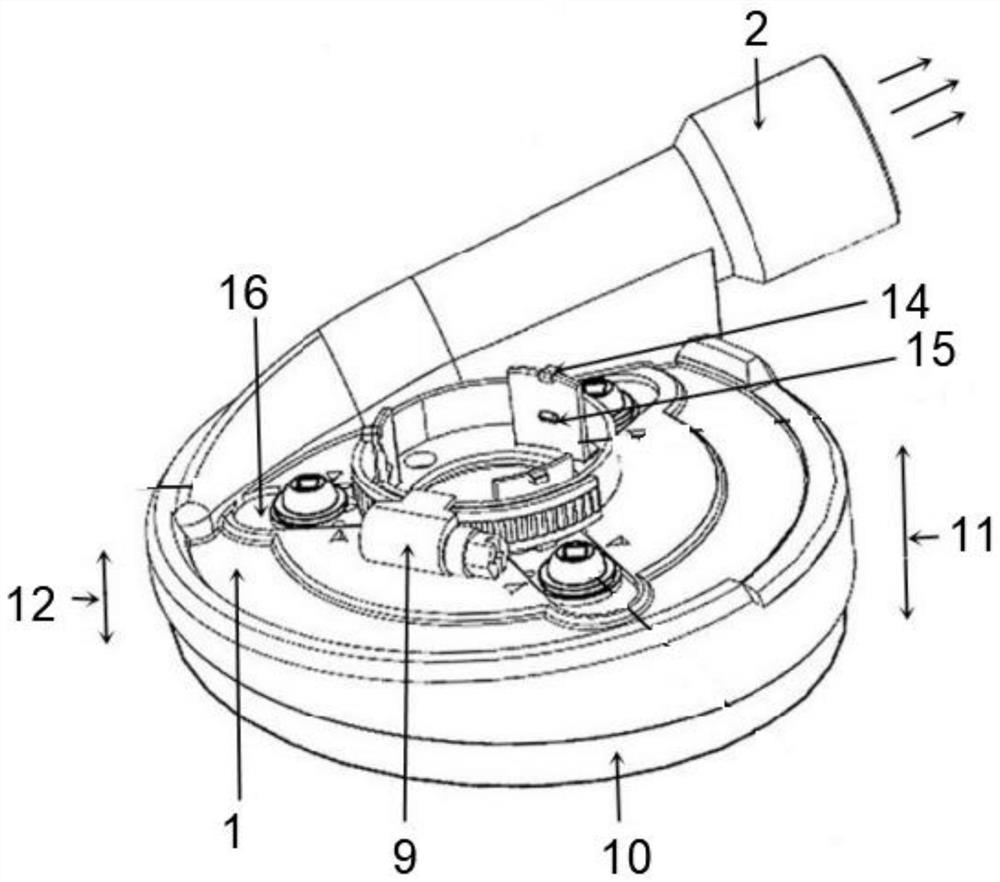

Angle grinder dust cover

PendingCN112223119AEasy to polishEasy to prevent dustPortable grinding machinesGrinding/polishing safety devicesAngle grinderEngineering

The invention discloses an angle grinder dust cover which comprises a dust cover body, a fixed piece fixed to the dust cover body through fasteners and a dust outlet pipe communicating with the dust cover body. The dust outlet pipe is arranged in the cutting direction, a mounting hole is formed in the dust cover body, and the position, outside the mounting hole, of the dust cover body is fixedly connected with the fixed piece through the fasteners. Each fastener comprises an L-shaped supporting frame, and each L-shaped supporting frame comprises a horizontal section movably connected into a supporting frame sliding groove and a vertical section perpendicular to the horizontal section. The angle grinder dust cover is installed on an angle grinder and can adjust the supporting frames to reach the corresponding clamping inner diameter according to the outer diameter of the head of the angle grinder without being limited by various outer diameters of the head of the angle grinder, a cutting cover can adjust the cutting depth of the angle grinder, further a grinding cover can grind internal corners, and after the angle grinder dust cover is connected with a dust collector, the dust canbe completely absorbed without leakage.

Owner:上海波邦电控科技发展有限公司

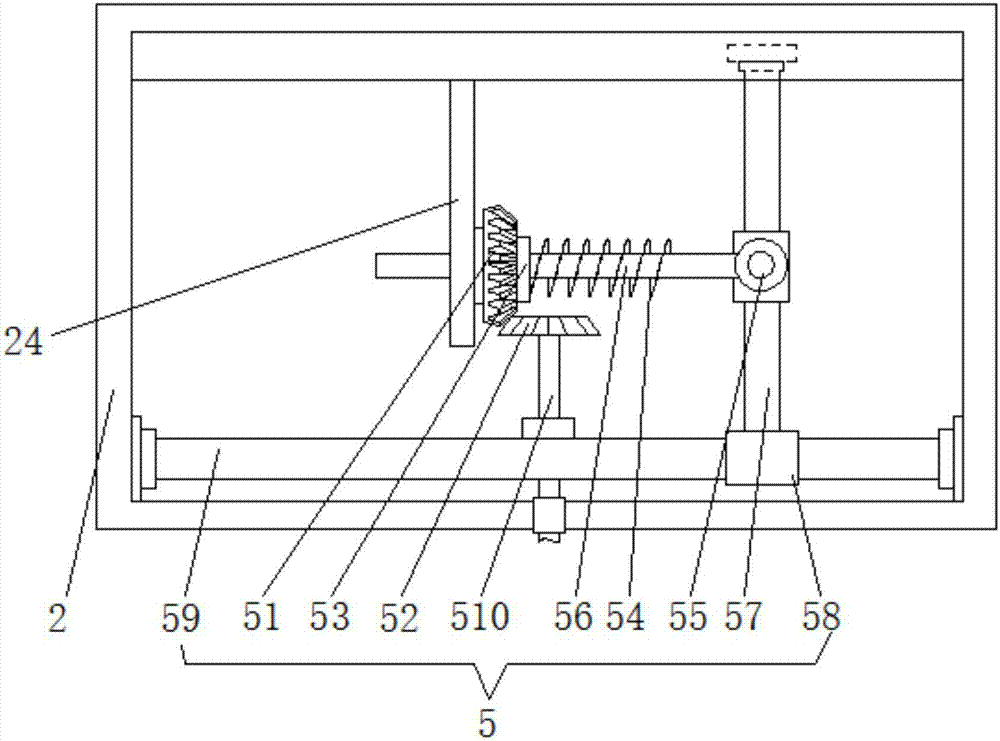

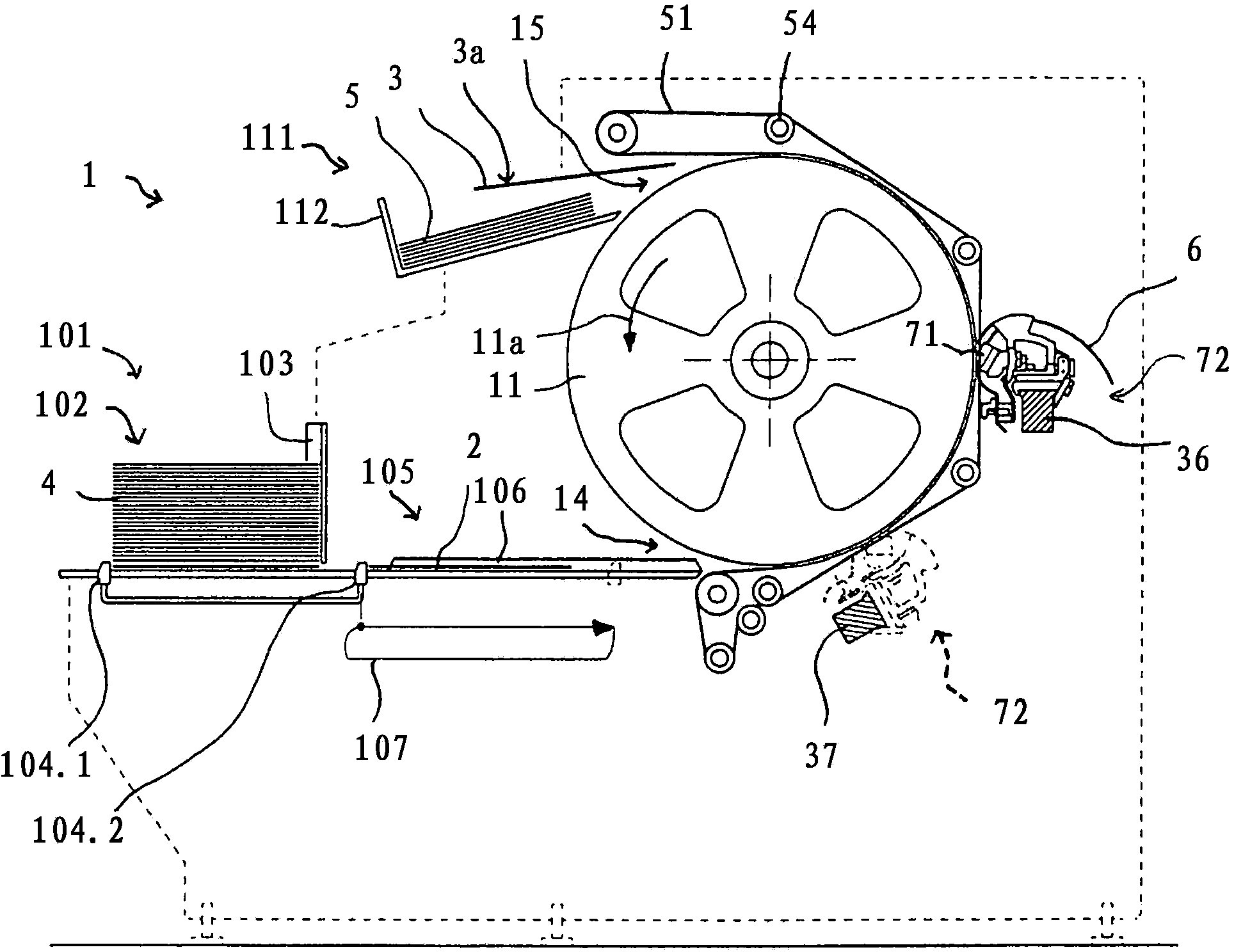

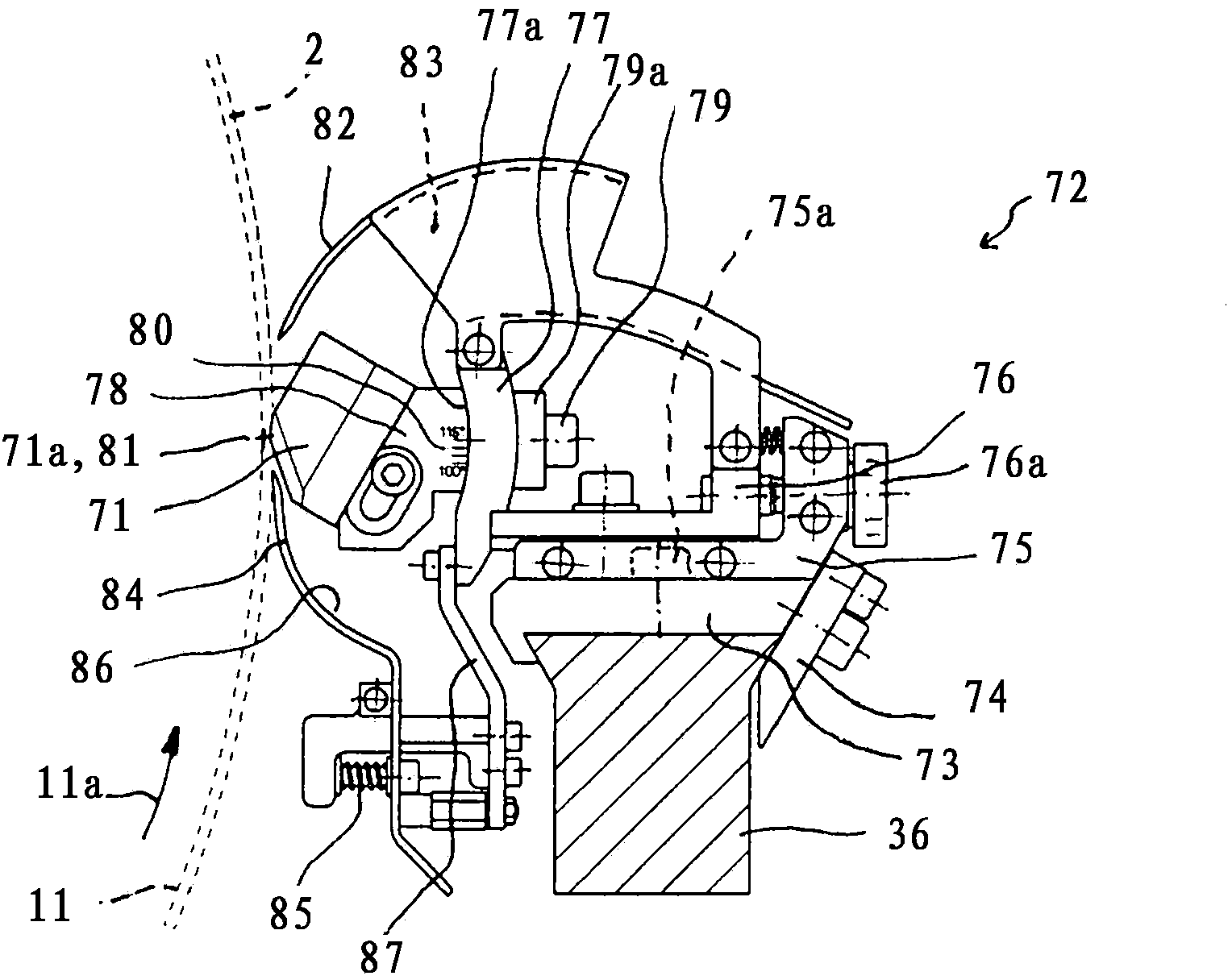

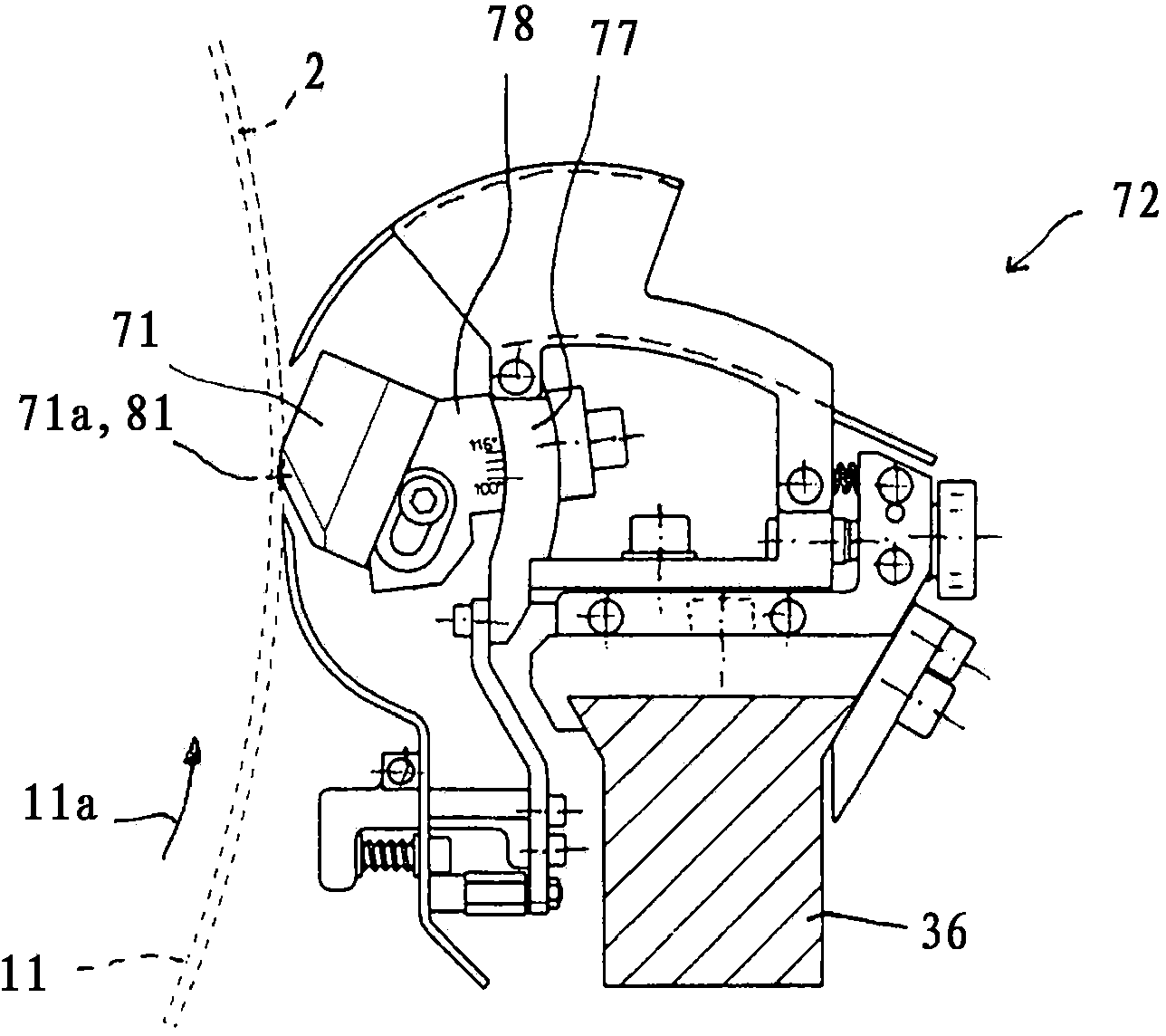

Device for making a groove in cardboard blanks

ActiveCN103802365ASimple pivotEasy to adjustBoxes/cartons making machineryPaper-makingCardboardCircular segment

The groove forming device (1) has the rollers (54) that are circulated with an endless belt (51) and spaced to each other. An inlet (14) and an outlet (15) are partially formed on the transport drum (11), and the cardboard blanks (2) are effectively conveyed to the drum. The grooves cutting tool (72) is positioned on the circumference of the drum and provided with a knife receptacle for securing a knife. A sheet guide in the knife receptacle in the grooves cutting tool is adjusted. The center of curvature of the sheet guide is laid in the region of the drum casing.

Owner:KOLBUS

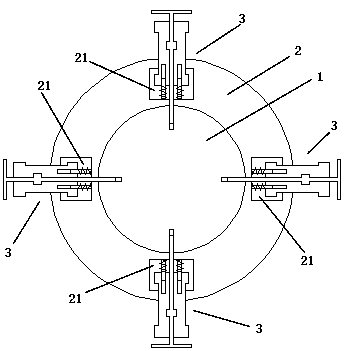

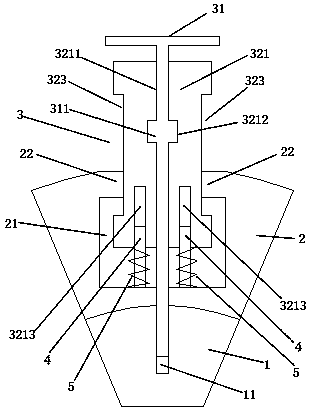

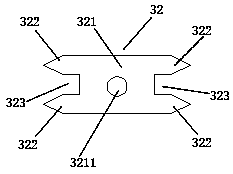

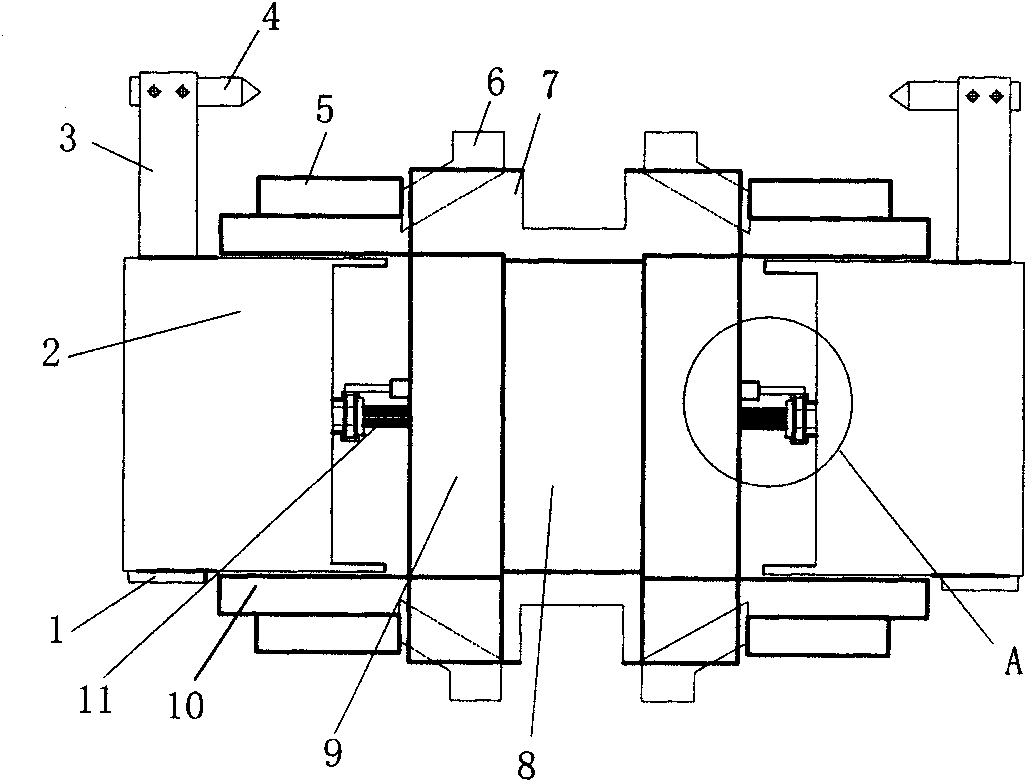

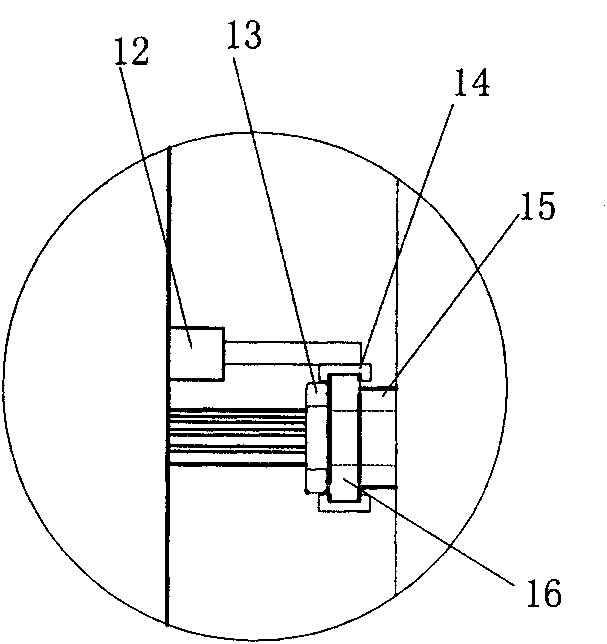

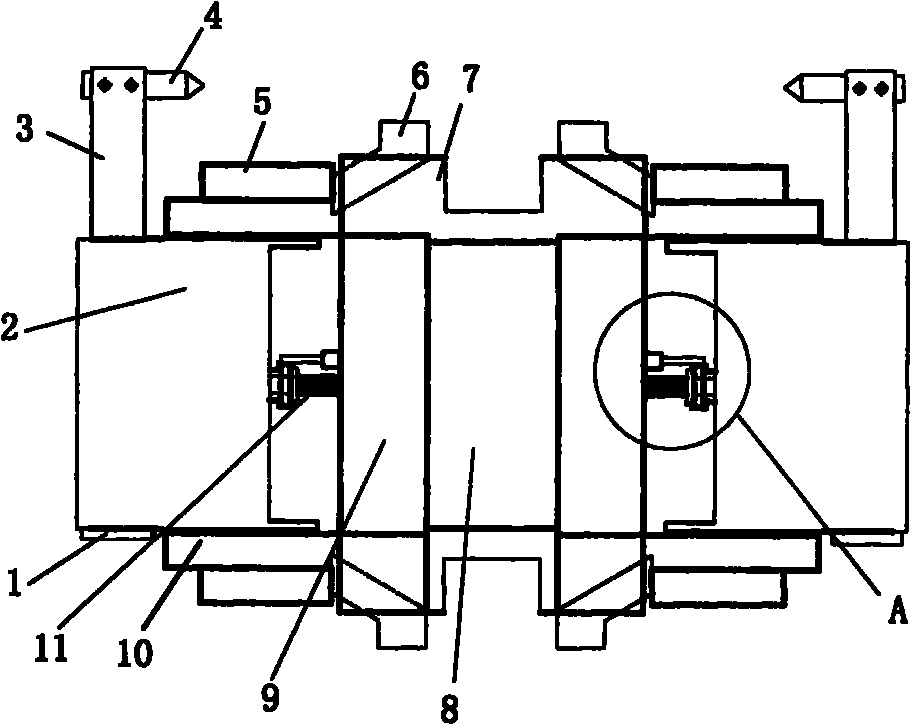

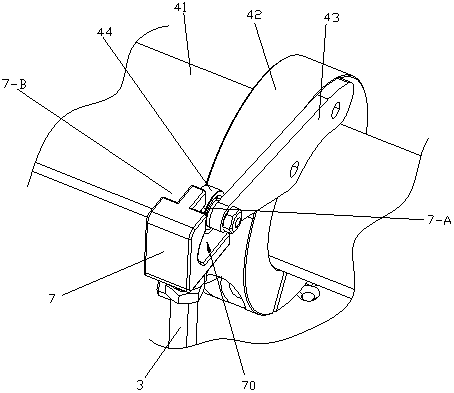

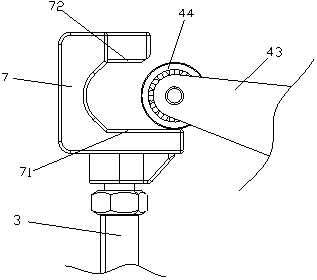

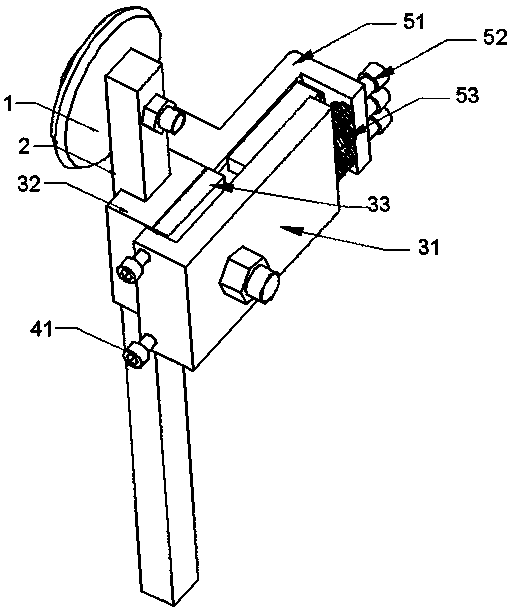

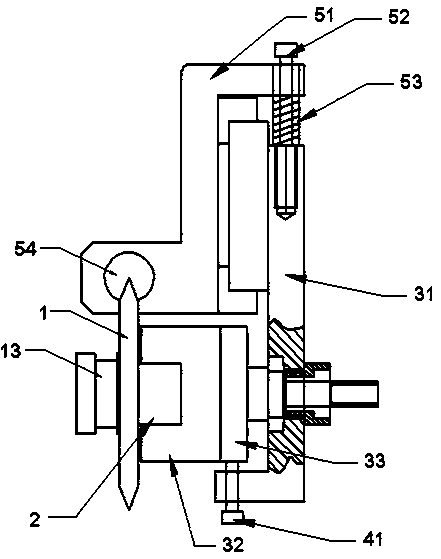

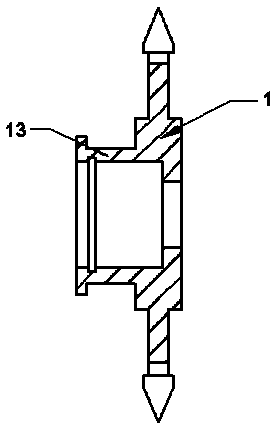

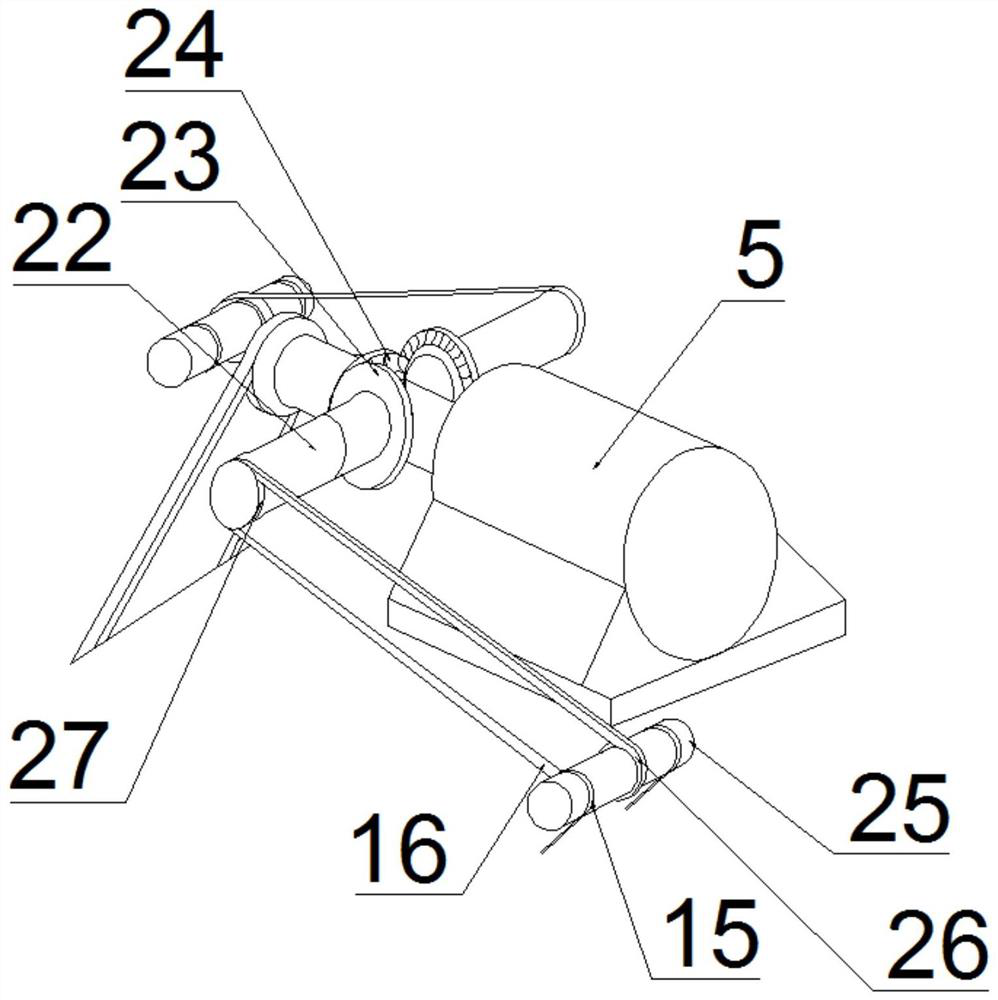

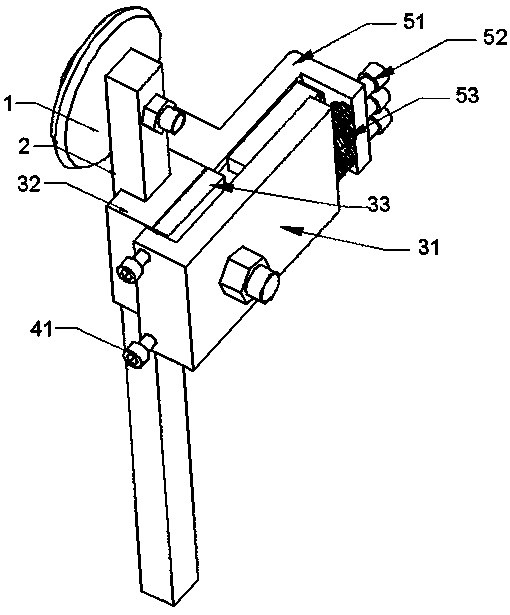

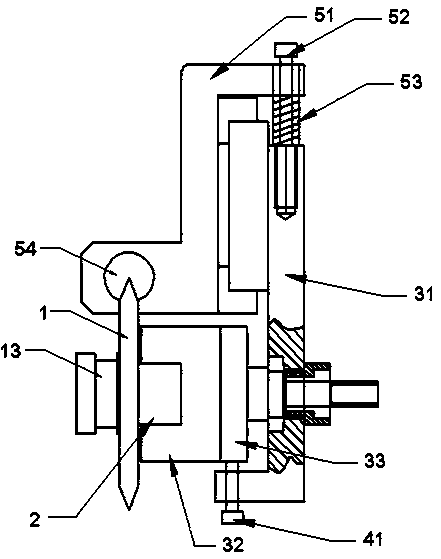

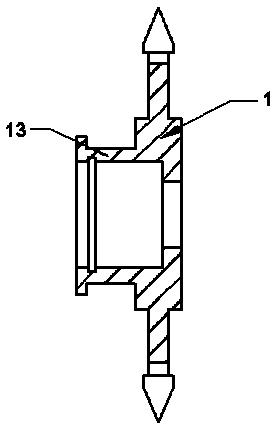

Guiding transmission shaft structure with cutting knife

ActiveCN109178276AIngenious structural designEasy slide connectionPropulsive elementsDrive shaftFront and back ends

The invention discloses a guiding type transmission shaft structure with a cutting knife, which comprises a transmission shaft, a connecting ring, a cutting mechanism, a guiding column and a guiding elastic body. The threading block of the invention realizes the stable guiding function by cooperating and plugging the guide hole and the guide column in the mounting groove, and sleeves the guide elastic body on the guide column, so that the whole cutting knife can more stably carry out the telescopic floating; and the cutting knife of the invention utilizes the driving screw to carry out telescopic floating in the mounting groove of the connecting ring, and adjusts the proper cutting depth. The cutting knife of the invention has ingenious structure design, and the front and back ends of thetwo sides of the connecting block are respectively provided with a blade, so that the double-edged cutting of the two sides is realized, and the cutting efficiency is high; at the same time, a clamping sliding groove is respectively arranged between the blades on both sides of the threading block, which is convenient for sliding connection between the threading block and the mounting groove, realizes telescopic floating adjustment, and is more flexible in use.

Owner:东台市海一船用设备有限公司

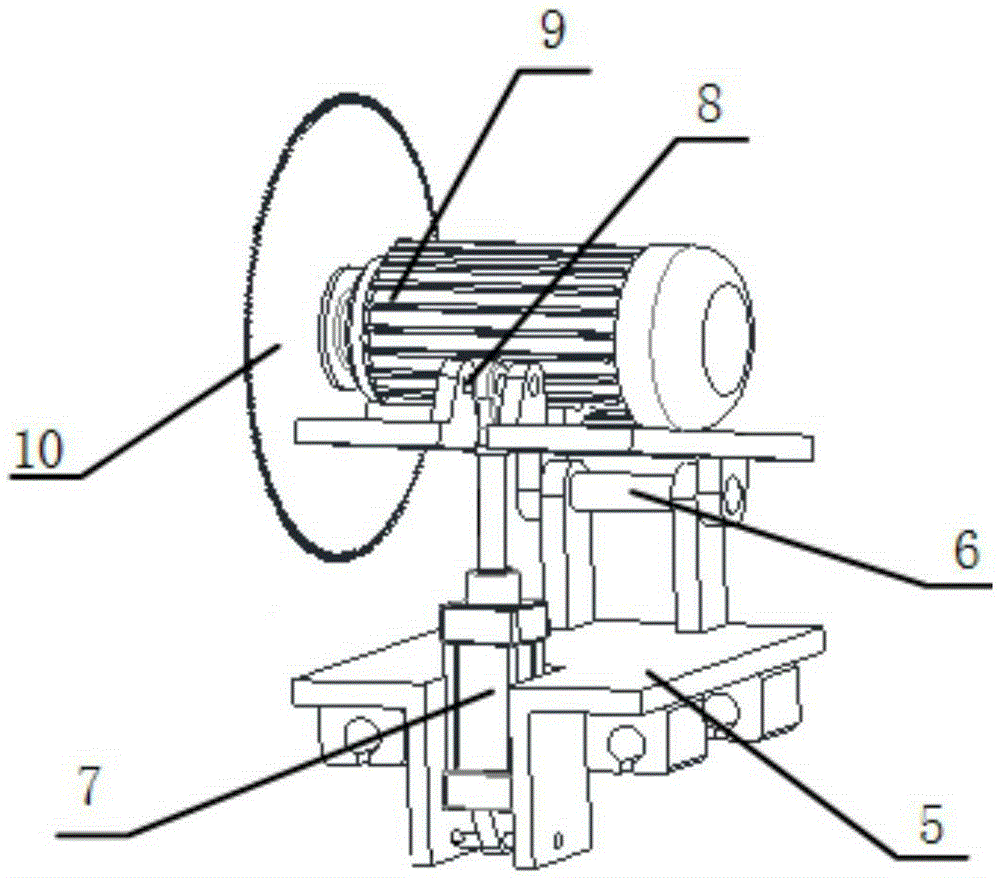

Efficient valve body processing equipment

The invention discloses efficient valve body processing equipment, comprising a stand (10), a motor (8), linear electric motors (1) and a feed slide bar (3), wherein the stand (10) is a tubular cylinder body, both ends of the tubular cylinder body are connected with screw nuts (5), and the middle of the tubular cylinder body is provided with two annular bosses (7); the annular boss is provided with a slide block mechanism; the motor (8) forms a transmission connection with two speed reducers (9); the inner chambers at both ends of the cylinder body are slide holes, and a main shaft (2) is arranged in each slide hole; each main shaft forms transmission connection with a spline (11) of the speed reducer; the end of each main shaft (2) is radially fixed with the liner electric motor (1); the output shaft of the linear electric motor (1) is connected with the feed slide bar (3); and a turning tool (4) is fixed on the feed slide bar (3). The invention greatly improves the labor efficiency, reduces the processing cost of the valve body, and greatly improves the processing safety. The yield of the valve body is greatly improved.

Owner:铜陵市力通机械制造有限公司

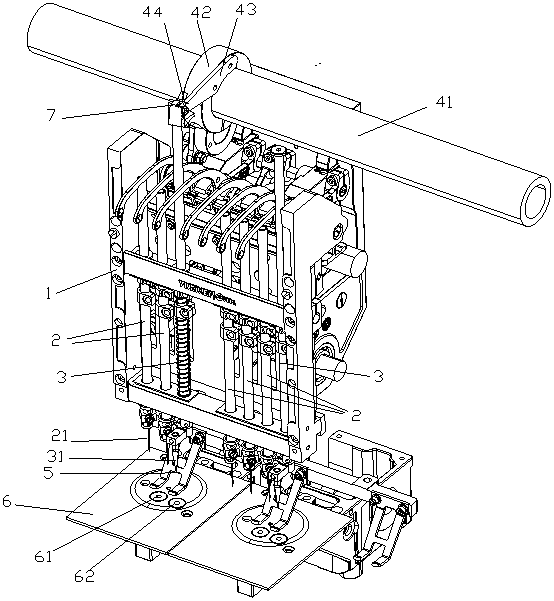

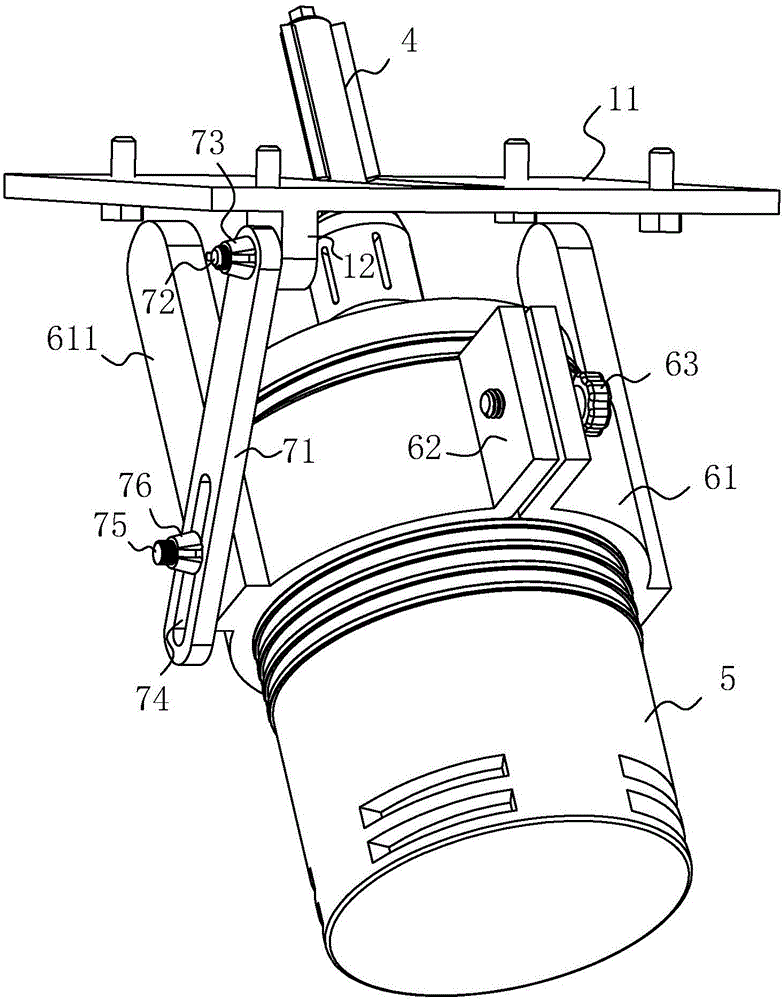

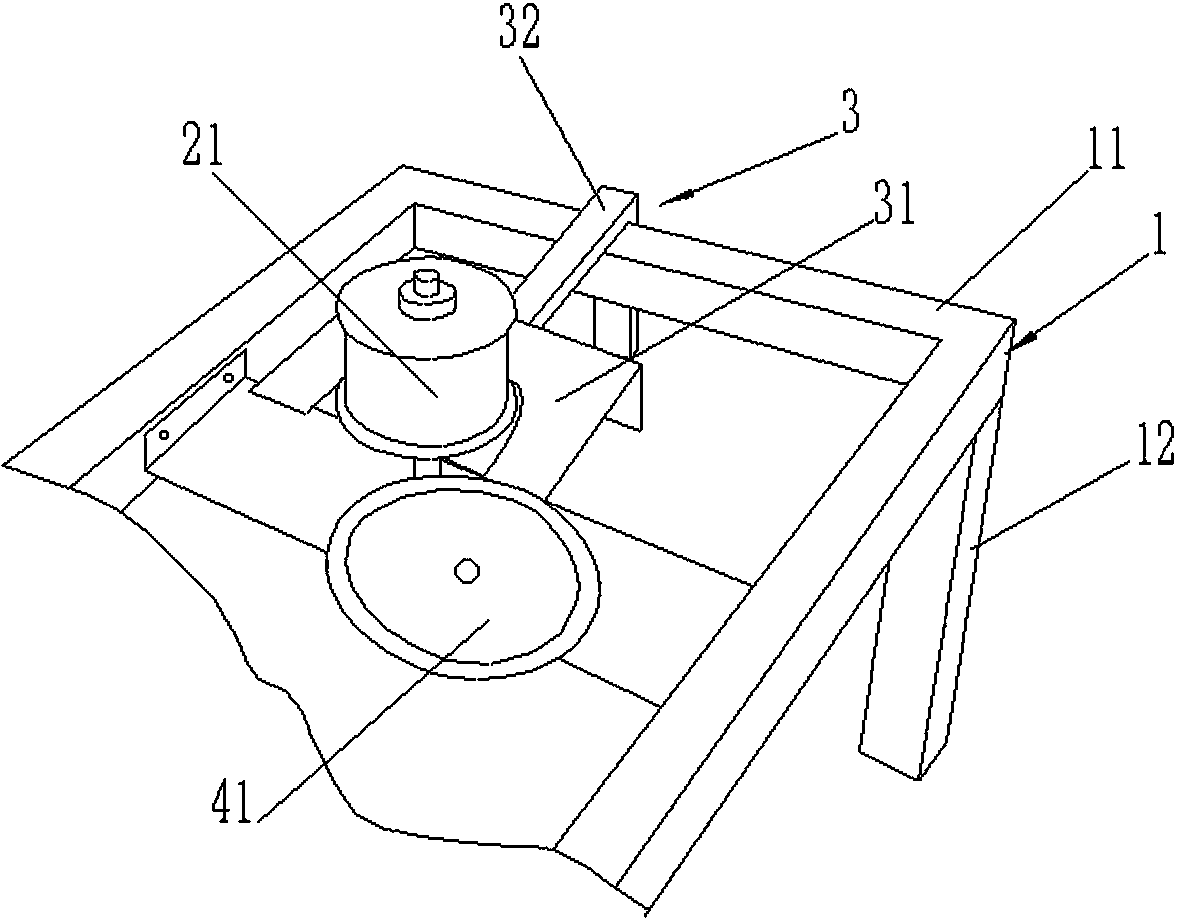

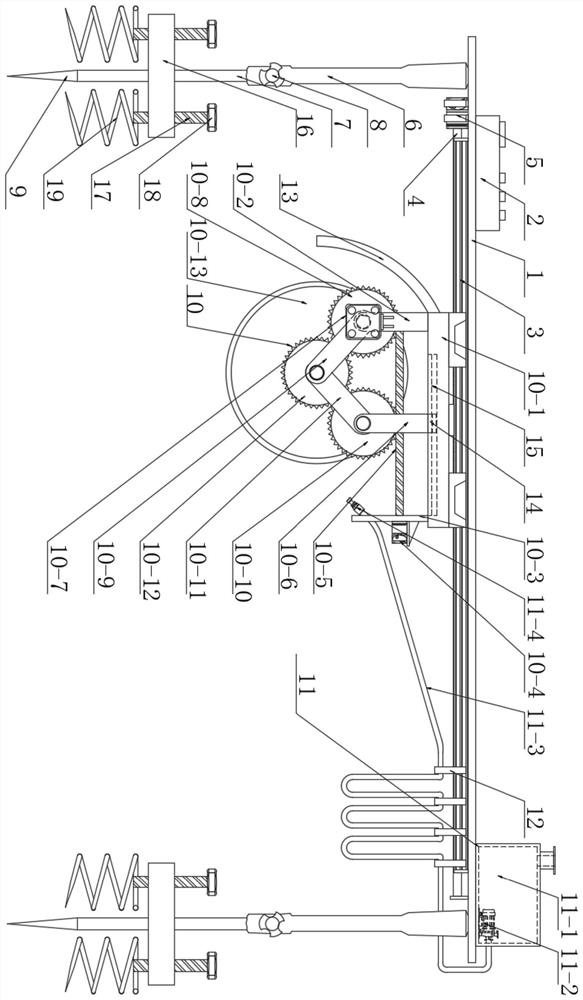

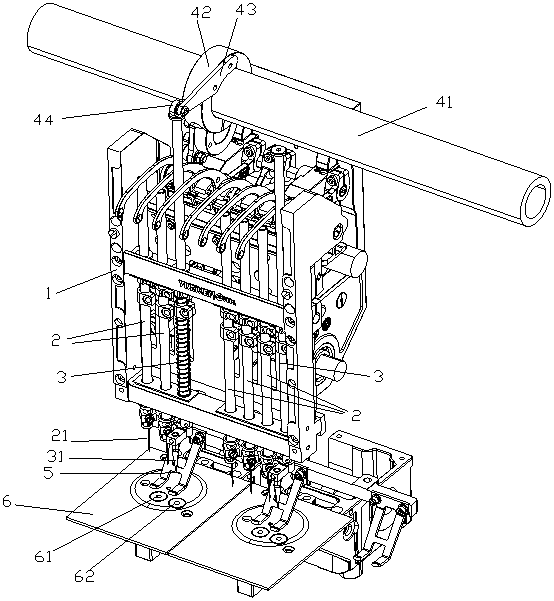

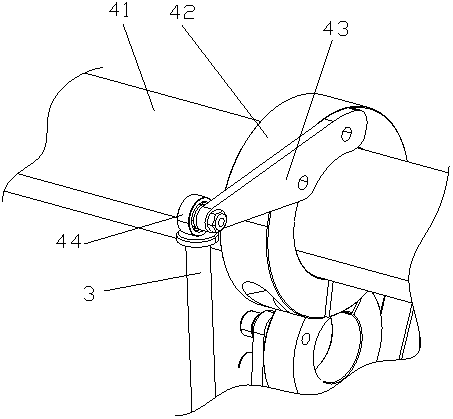

Independent hole carving system used for embroidery machine

The invention discloses an independent hole carving system for an embroidery machine. The independent hole carving system comprises a needle bar frame and a plurality of needle bars installed on the needle bar frame, wherein the needle bar frame can horizontally move left and right. The independent hole carving system further comprises a hole carving driving system which is not connected with anyneedle bar, the needle bar frame can horizontally move left and right, a hole carving knife is assembled at the bottom end of any one of the needle bars, a driven part is assembled at the top end of each needle bar, the needle bars with the driven parts can move to a driving position of the hole carving driving system, and the hole carving driving system can act on the driven parts and drive the needle bars to move downwards to the maximum stroke and then drives the needle bars to completely reset or semi-reset. The independent hole carving system has the beneficial effects that the needle bars can be randomly selected to assemble the hole carving knifes for hole carving, and hole carving and multi-color embroidery are both considered.

Owner:浙江镨美科智能刺绣设备有限公司

Medical instrument case part inclined side cutting device

ActiveCN106826999AReduce the difficulty of manual cuttingSimple structureMetal working apparatusEngineeringOblique cutting

The invention discloses a medical instrument case part inclined side cutting device. The medical instrument case part inclined side cutting device aims at solving the shortcoming of high polishing difficulty and high machine tool processing cost during inclined side cutting of case parts in existing medical case production processes. According to the technical scheme, the medical instrument case part inclined side cutting device comprises a frame, a guide mechanism, a driving device and a cutting tool bit, wherein the guide mechanism comprises a vertical guide face and can guide a case part to slide; the driving device is arranged on the frame; the cutting tool bit is driven by the driving device to rotate and arranged in an inclined mode and can penetrate the guide surface to for an inclined cut surface which is protruded from the guide surface. The medical instrument case part inclined side cutting device has the advantages of being simple in operation, low in cost and capable of facilitating inclined side cutting of the case parts.

Owner:深圳市佳鑫一帆科技有限公司

Cutting and adjusting device

ActiveCN110814787AIncrease automation and adjustabilityCompact structureLarge fixed membersMilling equipment detailsStructural engineeringMilling cutter

The invention belongs to the technical field of a word bending machine and provides a cutting and adjusting device. The cutting and adjusting device comprises a milling cutter and a square rail cutterrod rotatably connected with the milling cutter; the square rail cutter rod is in sliding connection with an adjusting base; and a perpendicularity adjusting mechanism for adjusting the perpendicularity of the square rail cutter rod as well as a depth adjusting mechanism for adjusting the distance between the square rail cutter rod and a plate are arranged on the adjusting base. Through the perpendicularity adjusting mechanism, the perpendicularity of the square rail cutter rod can be adjusted, so that the perpendicularity of the milling cutter is adjusted; and on the basis that the perpendicularity is adjusted and through the depth adjusting mechanism, the distance between the square rail cutter rod and the plate can be adjusted, so that the distance between the milling cutter and the plate is adjusted, the technical effect of adjusting the cutting depth and perpendicularity of the milling cutter is achieved, and the high efficiency and the adjustability of plate cutting are improved.

Owner:潍坊达创数控设备有限公司

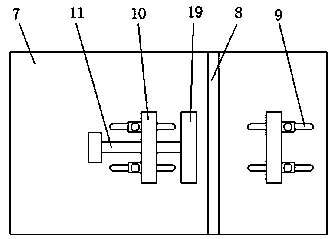

Mechanical machining device

InactiveCN112024968AAchieve fixed positionTo achieve the purpose of fixed positionShearing machinesCleaning using toolsEngineeringMachining

The invention relates to an elevator accessory machining device, in particular to a mechanical machining device which comprises a base frame, a displacement plate assembly, a rack fixing assembly, anadjustable displacement assembly, a height adjusting mechanism, an adjustable cutting mechanism and scrap clearing mechanisms. The displacement plate assembly is fixedly installed on the base frame. The rack fixing assembly is installed on the base frame in a sliding manner. The adjustable displacement assembly is fixedly installed on the rack fixing assembly. The height adjusting mechanism is fixedly installed on the base frame. The adjustable cutting mechanism is installed on the height adjusting mechanism in a sliding manner. The scrap clearing mechanisms are fixedly installed at the two ends of the height adjusting mechanism correspondingly. The mechanical machining device has a function of carrying out adjusting according to different specifications of machined racks, meanwhile, the device also has a function of adjusting the opening diameter of a cutter, production cost increase caused by cutter replacing is avoided, the device further has a scrap clearing function, and the situation that scraps enter the device, and are generated is prevented.

Owner:邵阳县振华机械锻造配件有限责任公司

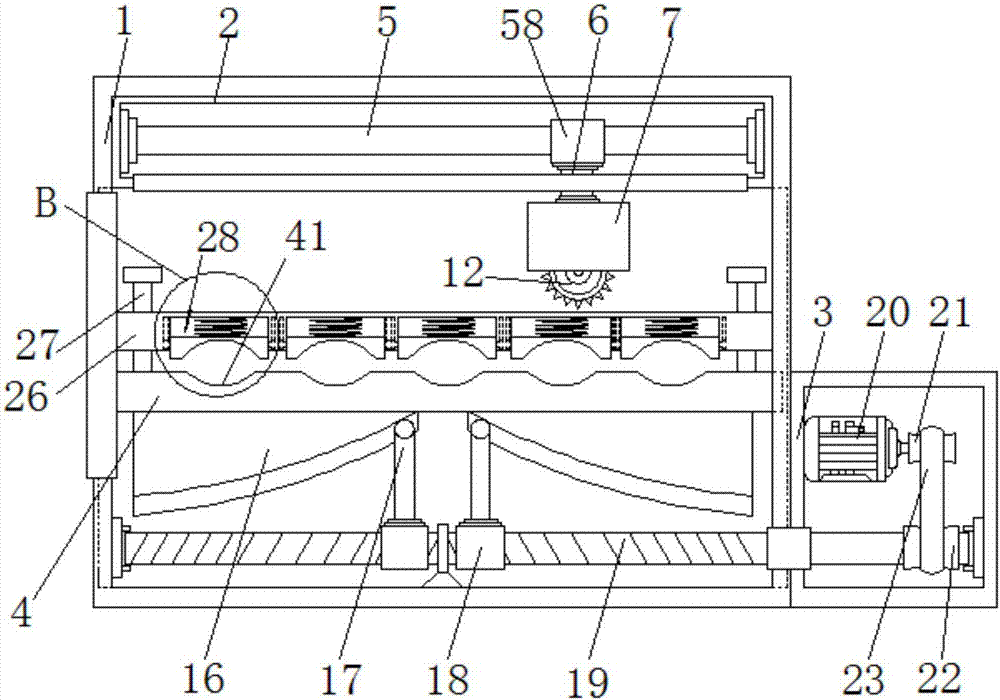

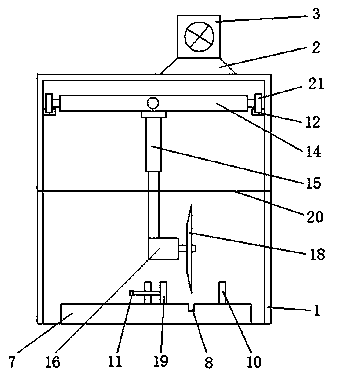

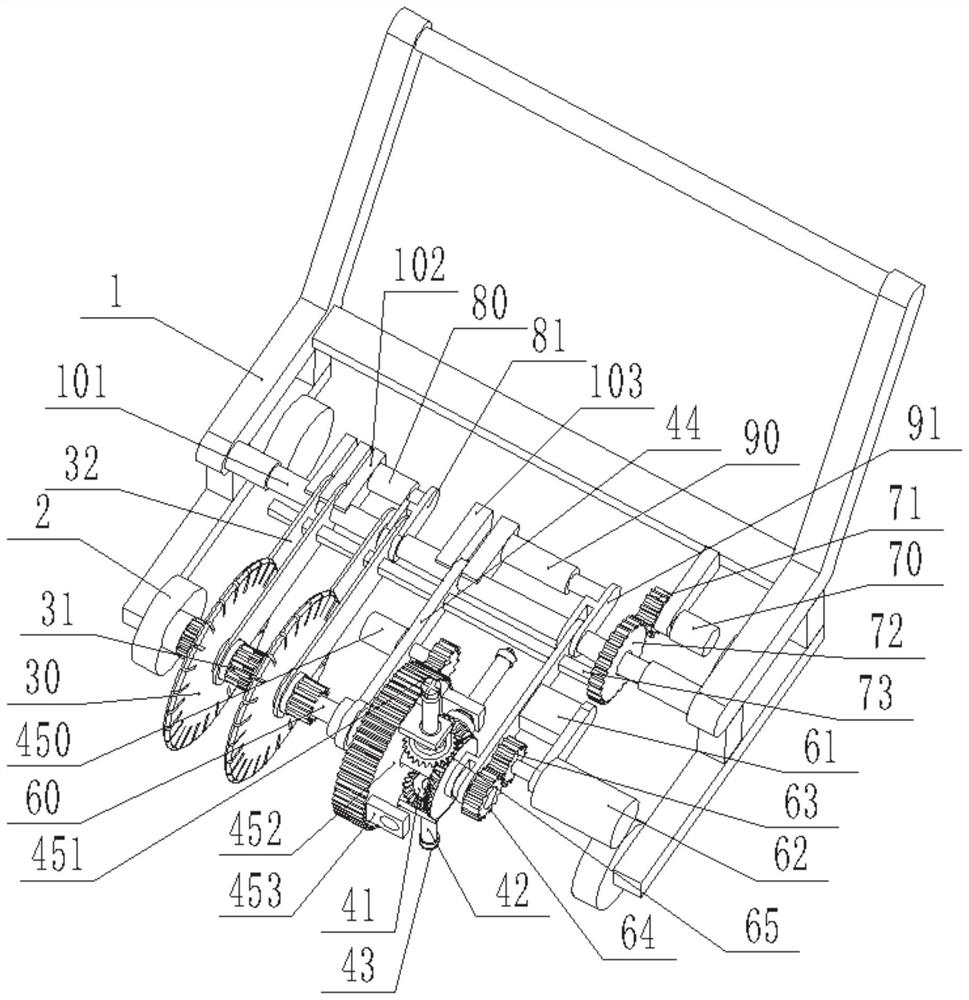

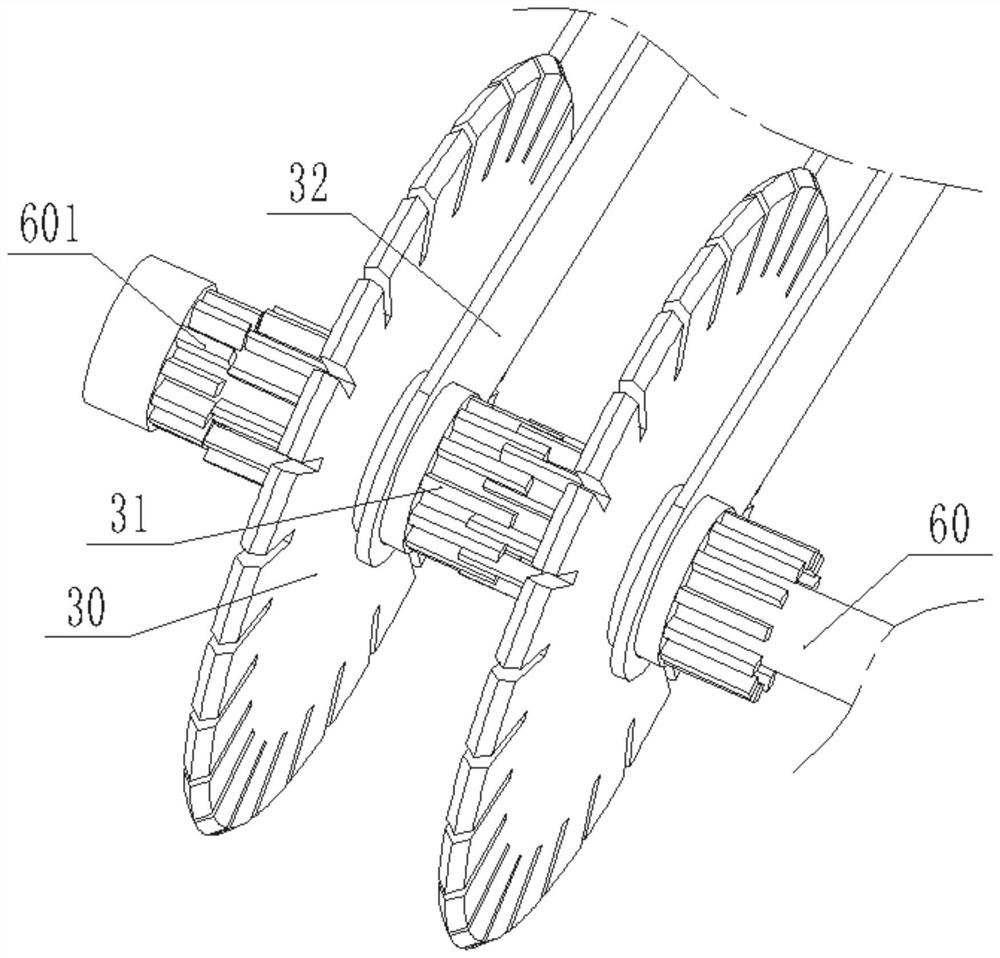

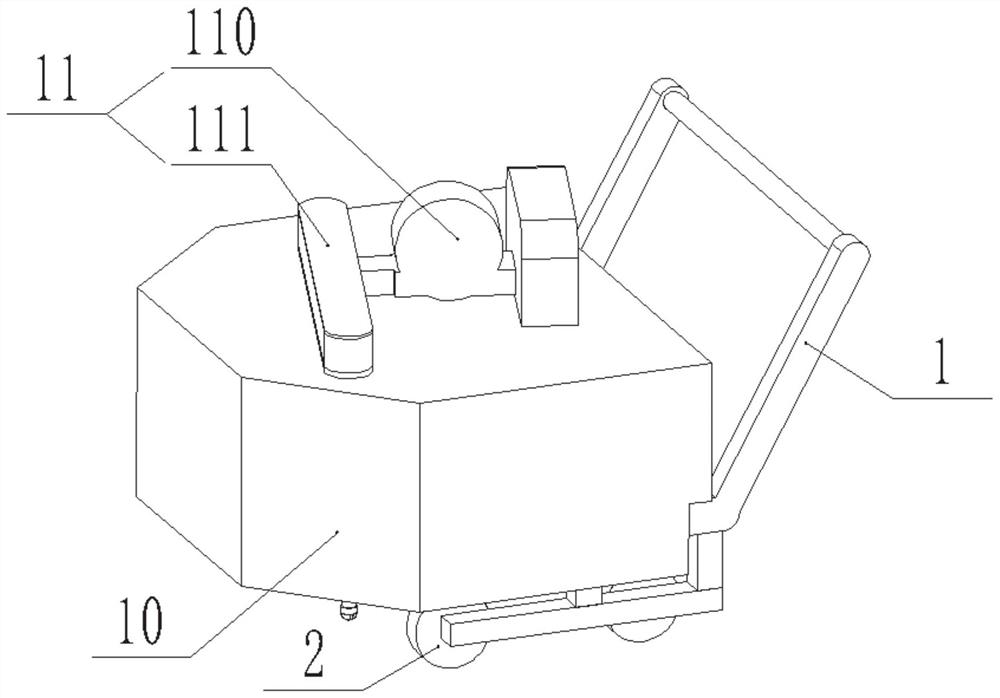

Needle mushroom root cutting device

PendingCN109434900ASimple and efficient operationImprove work efficiencyMetal working apparatusMushroomEngineering

The invention relates to a needle mushroom root cutting device. The needle mushroom root cutting device comprises a machine frame, a transmission mechanism and a cutting mechanism, wherein the transmission mechanism and the cutting mechanism are arranged on the machine frame; the machine frame comprises a horizontal outer frame, stand columns which are vertically fixed at the lower ends of the four corners of the outer frame and two supporting plates which are horizontally fixed in the outer frame; the transmission mechanism comprises a driving belt wheel, a driven belt wheel, a conveying belt, a plurality of clamps and a first driving motor, the driving belt wheel and the driven belt wheel are horizontally arranged on the two supporting plates correspondingly, the conveying belt is woundaround the peripheries of the driving belt wheel and the driven belt wheel, the plurality of clamps are fixed on the outer surface of the conveying belt at intervals, and the first driving motor drives the driving belt wheel to rotate; and the driving belt wheel and the driven belt wheel are connected to the two supporting plates through vertical shafts in a rotating mode correspondingly, the clamps are detachably provided with the needle mushroom in a clamped mode, moreover, the root of the needle mushroom penetrates out of the lower portions of the clamps, the cutting mechanism is located onone side below the conveying mechanism, the conveying mechanism conveys the clamps provided with the needle mushroom in a clamped mode to one side of the cutting mechanism, the cutting mechanism comprises a horizontal circular blade and a second driving motor for driving the circular blade to rotate, and a cutting edge of the circular blade is used for cutting the root of the needle mushroom below the clamps.

Owner:福建梧峰农林发展有限公司

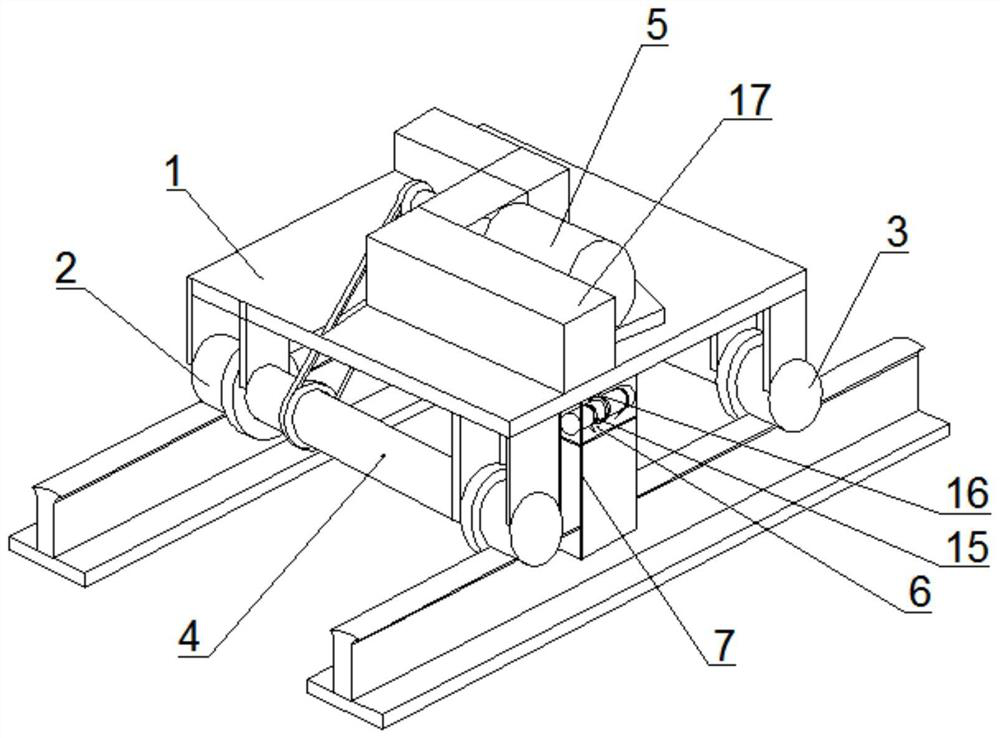

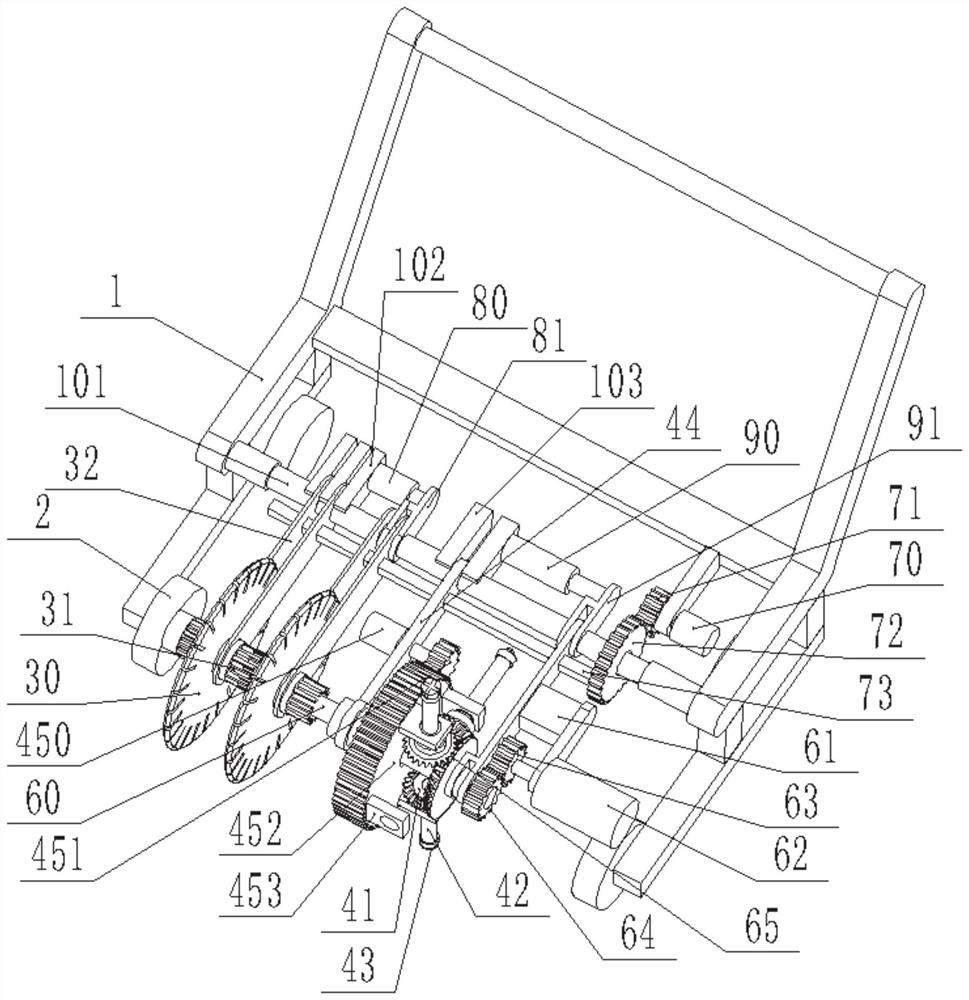

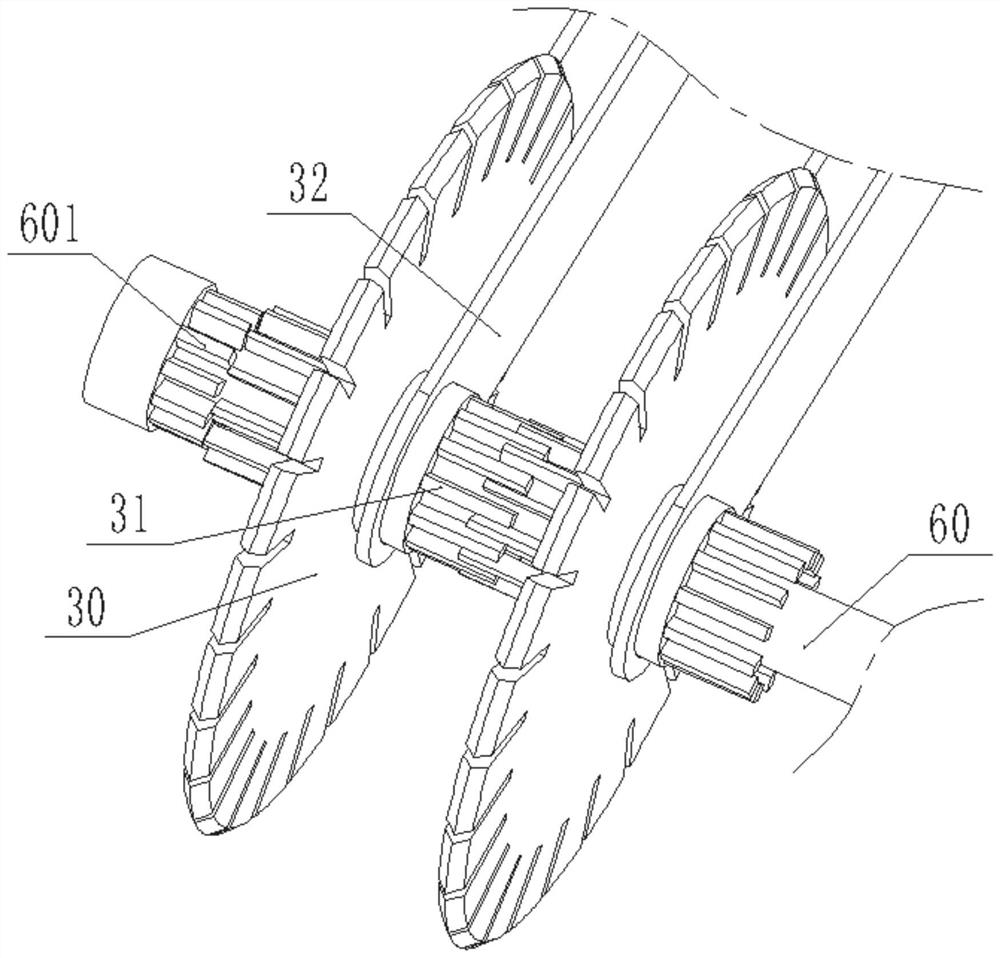

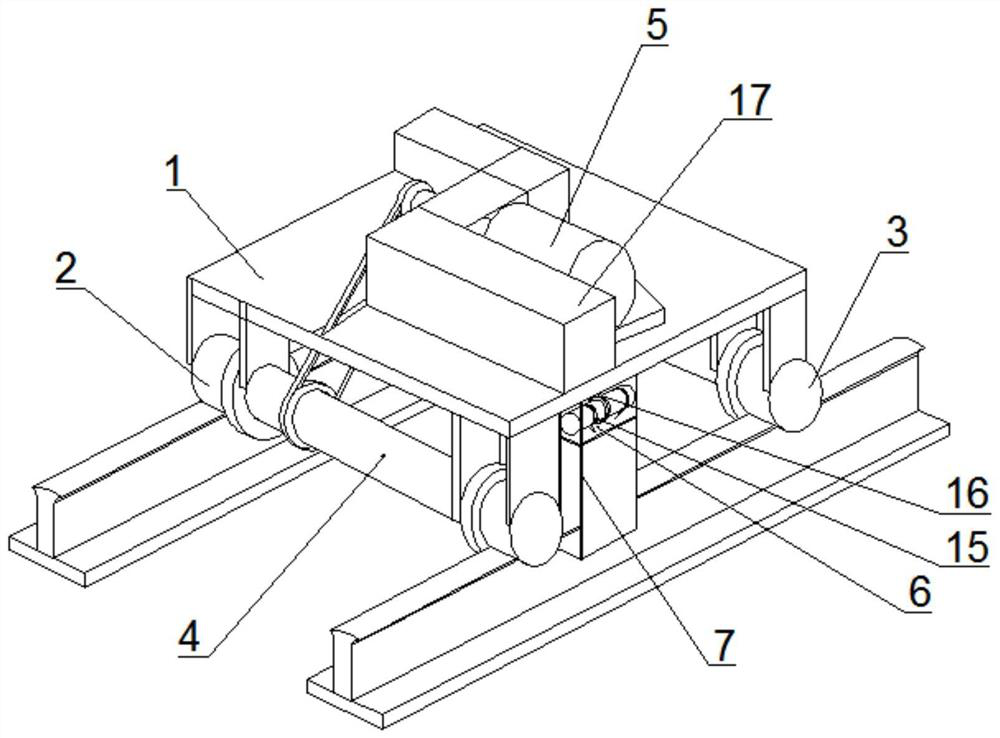

Double-rail rust removing and grinding device and using method thereof

ActiveCN111893818ALong post-maintenance periodReduce maintenance costsRailway track constructionDrive shaftElectric machinery

The invention discloses a double-rail rust removing and grinding device, which comprises a device base, wherein a front rail wheel and a rear rail wheel are symmetrically installed at the lower ends of the two sides of the device base, the rail wheels are mounted on a transmission shaft, a driving motor is mounted at the upper end of the device base, a shaft of the driving motor is rotationally connected to the front rail wheel, a grinding device is mounted between the front rail wheel and the rear rail wheel; a grinding frame is installed on the two sides of the lower end of the device base,a first grinding mechanism and a second grinding mechanism are mounted on the grinding frame, and the second grinding mechanism is arranged at the rear end of the first grinding mechanism. According to the double-rail rust removing and grinding device provided by the invention, by means of the double-rail rust removing and grinding device, rust on the rails is removed at a time, repeated rust removing is avoided, it is guaranteed that the later maintenance time period of the rails is prolonged after rust removing, the maintenance cost is reduced, and meanwhile, the influence on rail transportation caused by repeated maintenance is avoided.

Owner:株洲伟雄工程机械有限公司

Road cutting machine for municipal building construction

ActiveCN113882231AGuaranteed neatnessImprove work efficiencyRoads maintainenceMaintainance and safety accessoriesGear wheelBall screw

The invention discloses a road cutting machine for municipal building construction, and relates to the technical field of building construction equipment. The cooling mechanism is arranged on the right side of the supporting plate; the middle part of the top surface of the adjusting plate is fixedly connected with a nut in the ball screw pair; the adjusting seat is rotationally arranged on the threaded rod in a sleeving manner through threads, and the upper side face of the adjusting seat abuts against the bottom face of the adjusting plate; the middle of the first gear is fixedly connected with an output shaft of a third motor. The second gear is rotationally arranged on the rear side wall of the adjusting base through a rotating shaft and a bearing. The middle part of the third gear fixedly sleeves the rotating shaft at the connecting part of the first connecting strip and the second connecting strip, and the two sides of the third gear are respectively meshed with the first gear and the second gear; the cutting blade is fixedly arranged at the rear end of the rotating shaft in the middle of the third gear; the road surface is cut in an automatic cutting mode, the cutting depth of the cutting blade can be adjusted, meanwhile, the regularity of cutting joints is guaranteed, and the working efficiency is improved.

Owner:JINLING INST OF TECH

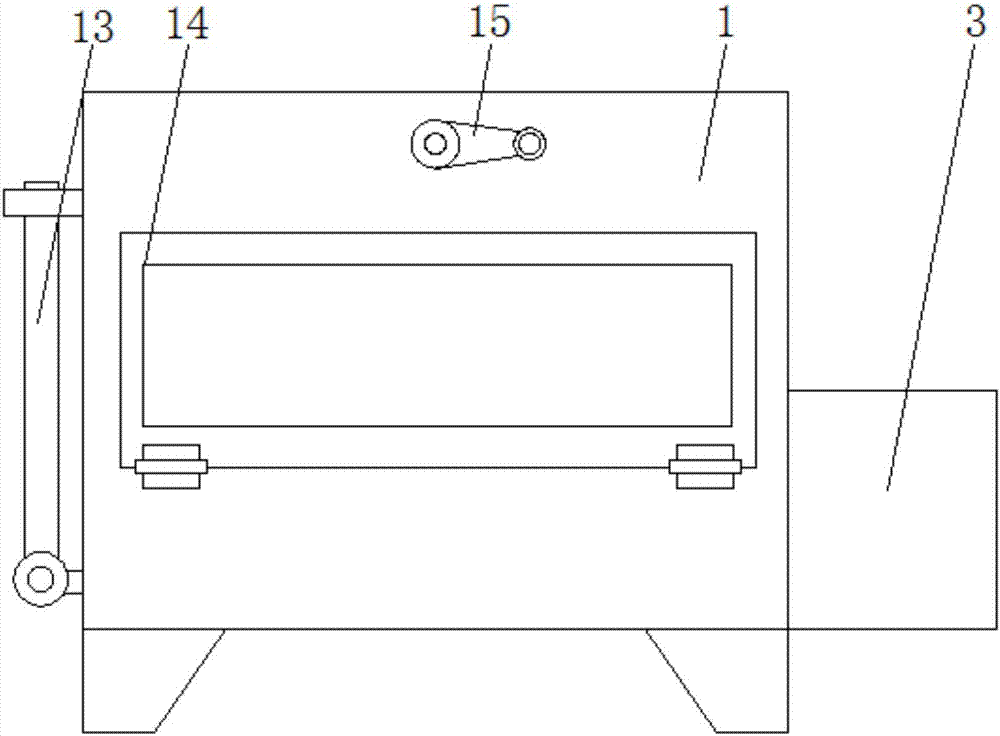

Road surface cutting machine with convenient cutting depth adjustment

InactiveCN110644341AImprove work efficiencyGuaranteed cutting qualityRoads maintainenceStructural engineeringWater tanks

The invention provides a road surface cutting machine with convenient cutting depth adjustment, and relates to the technical field of construction engineering machinery. The road surface cutting machine with convenient cutting depth adjustment comprises a machine body, a transverse plate is installed in the machine body, a water tank is fixedly installed at the top of the transverse plate, a hydraulic box is fixedly installed on the right side of the water tank, and a water pump is fixedly installed on the left side of the water tank. According to the road surface cutting machine with convenient cutting depth adjustment, the cutting depth is adjusted to a required numerical value on a control panel, a control system on the control panel adjusts the pressure of the hydraulic box according to the input numerical value to control the length of a telescopic column, so that the distance from a cutting wheel to the ground is controlled, the purpose of controlling the cutting depth is achieved. Compared with a traditional cutting machine, according to the road surface cutting machine with convenient cutting depth adjustment, the cutting depth can be accurately grasped through the controlpanel, so that the disadvantage that the cutting depth is controlled by depending on the feeling of an operator or by measuring the groove depth after cutting in the traditional cutting machine is overcome, and the work efficiency is improved.

Owner:张红英

Cutting device for packaging box

InactiveCN109093695AAdjust the depth of cutPrevent tamperingMetal working apparatusEngineeringExhaust pipe

The invention relates to a cutting device for a packaging box. The cutting device comprises a cabinet. The top of the cabinet is fixedly connected with a dust collection cover. An exhaust fan is mounted at the top of the dust collection cover, and communicates with an inner cavity of the cabinet through the dust collection cover. One side of the exhaust fan is connected with an exhaust pipe, and one end of the exhaust pipe is connected with a dust collection box. Exhaust outlets are formed in the two sides of the dust collection box correspondingly, and the bottom of the inner cavity of the cabinet is fixedly connected with a bottom plate. A groove is formed in the top of the bottom plate, and strip-shaped wire holes are symmetrically formed in the two sides of the groove. The cutting device is simple in structure and convenient to operate, and chippings or flying dust generated during sheet cutting in the cabinet can be sucked away to avoid the situation that the chippings or the flying dust is sucked by workers into lung cavities and consequently harms body health of the workers; the chippings or the flying dust discharged by the exhaust fan can be filtered and collected to avoidthe situation that the chippings or the flying dust is discharged into air and consequently pollutes the environment; and the positions of sheets with different sizes can be fixed, the sheets are prevented from moving during cutting, and thus the influences on the product quality are avoided.

Owner:苏州凤羽包装材料有限公司

Aerated brick cutting device

InactiveCN110815600ANo scrappingNo deviationWorking accessoriesStone-like material working toolsBrickElectric machinery

The invention discloses an aerated brick cutting device and belongs to the technical field of aerated brick processing. The aerated brick cutting device comprises a base. A motor and bracket are arranged on the base, the bracket is fixedly connected to the base, the top end of the bracket is fixedly connected to a cutting table, a groove is formed in the cutting table, an output shaft of the motoris fixedly connected to a round cutting knife, the cutting knife penetrates the groove and is in clearance fit to the groove, a conveying mechanism is arranged on the side, parallel to the axis of the cutting knife, of the cutting table, the conveying mechanism comprises two conveying tables arranged in a spaced manner, the lower surfaces of the two conveying tables are slidably connected to theupper surface of the cutting table, fixing assemblies for fixing aerated bricks are arranged on the two conveying tables, the lower surfaces of the two conveying tables are fixedly connected to slidebars, the slide bars penetrate the cutting table and are slidably connected to the cutting table, the other end of the cutting table is fixedly connected to an air cylinder, and a telescopic rod of the air cylinder is fixedly connected to the slide bar. Deviation of the aerated brick cut by the aerated brick cutting device according to the scheme can be avoided effectively, and meanwhile, the aerated brick cutting device cuts the aerated brick quite precisely.

Owner:贵州彬腾越新型建材有限公司

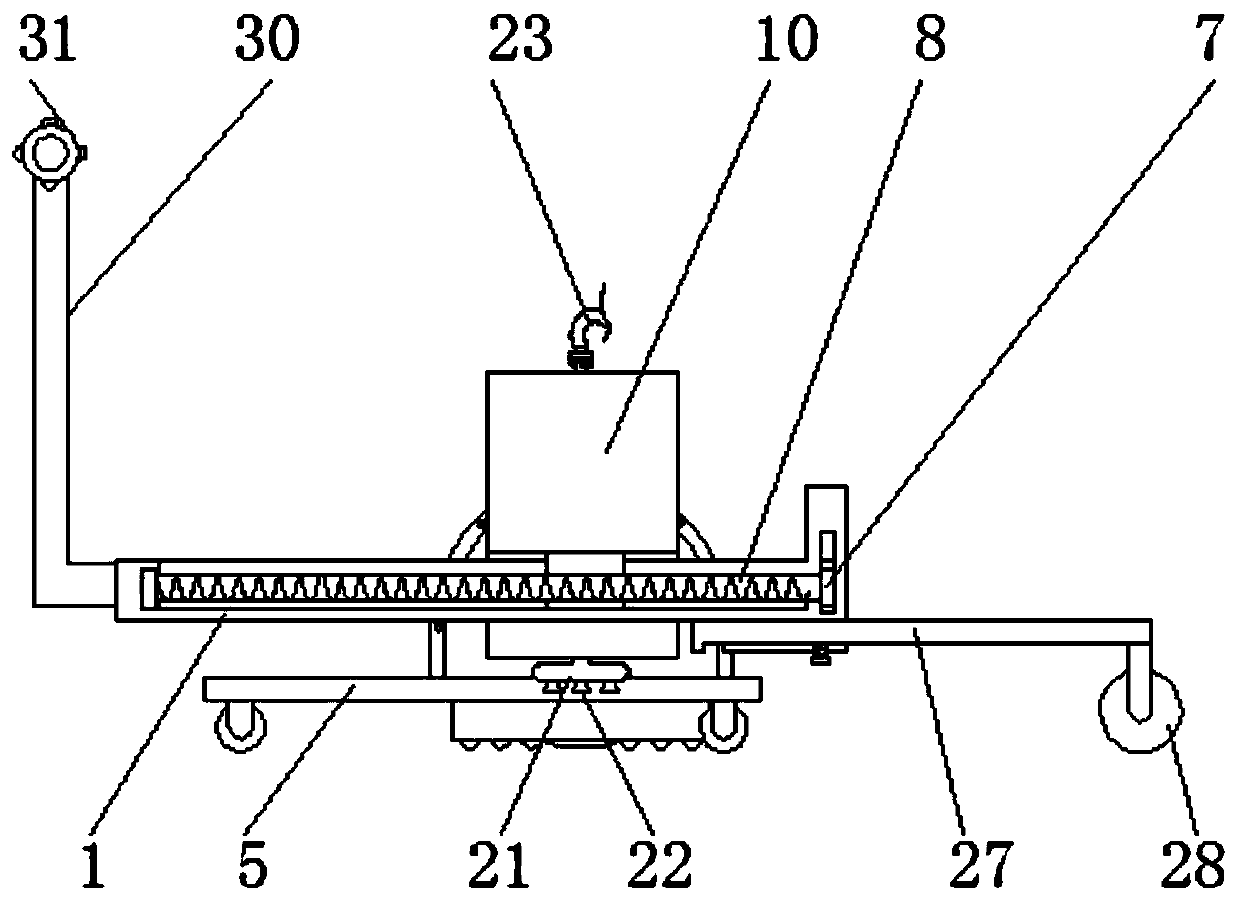

A road repair cutting machine

The invention discloses a road surface repair cutting machine, which comprises a push frame body, a roller, a cutting mechanism, a drilling mechanism, a rotating drive mechanism, and a drive switching mechanism, and a plurality of the roller wheels are installed at the bottom of the push frame body; The cutting mechanism includes a saw blade, a first spline tooth, and a mounting frame; the first spline teeth are installed on both sides of the saw blade; the drive switching mechanism includes a main shaft, a driving bevel gear, a first rotary drive Components, the first linear movement drive component, the first rotation drive component includes a driving gear, a driven gear, a rotating motor, and a moving frame. The invention integrates two operations of cutting and drilling, and has strong functionality, and the cutting and drilling operations use the same power source, which saves energy and reduces costs, and at the same time realizes the adjustment of the cutting depth of the cutting mechanism and the drilling depth of the drilling mechanism , Improve the scope of work.

Owner:湖南汉坤实业有限公司

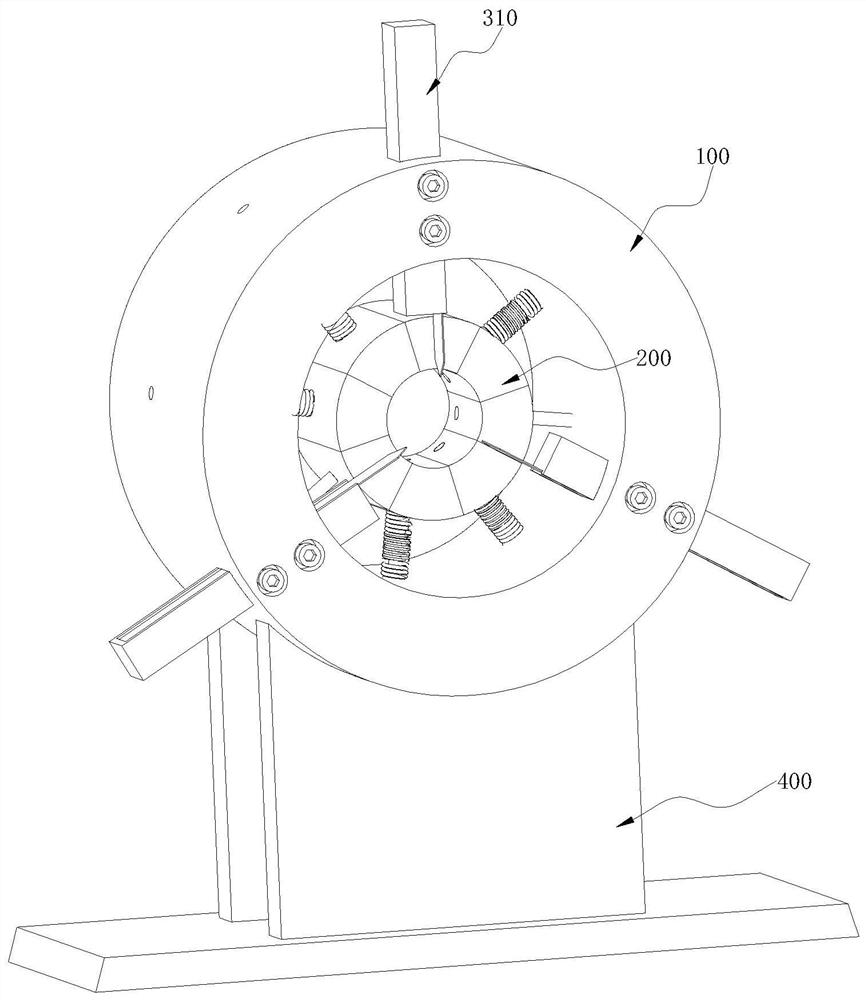

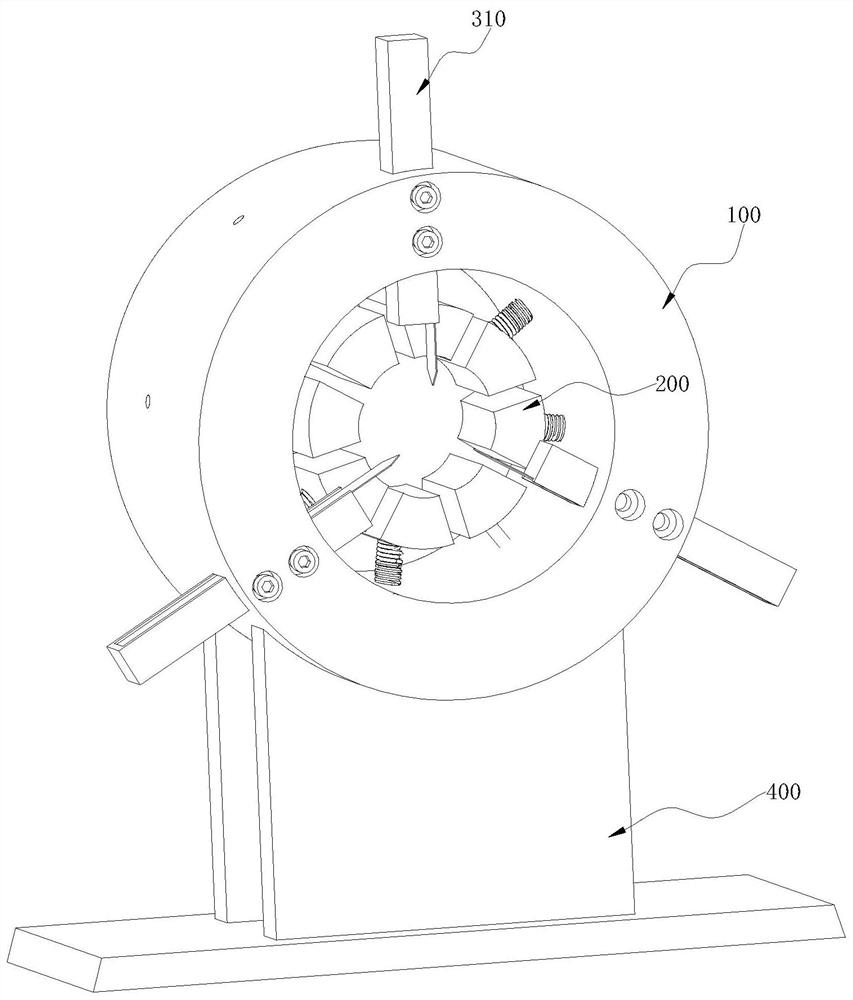

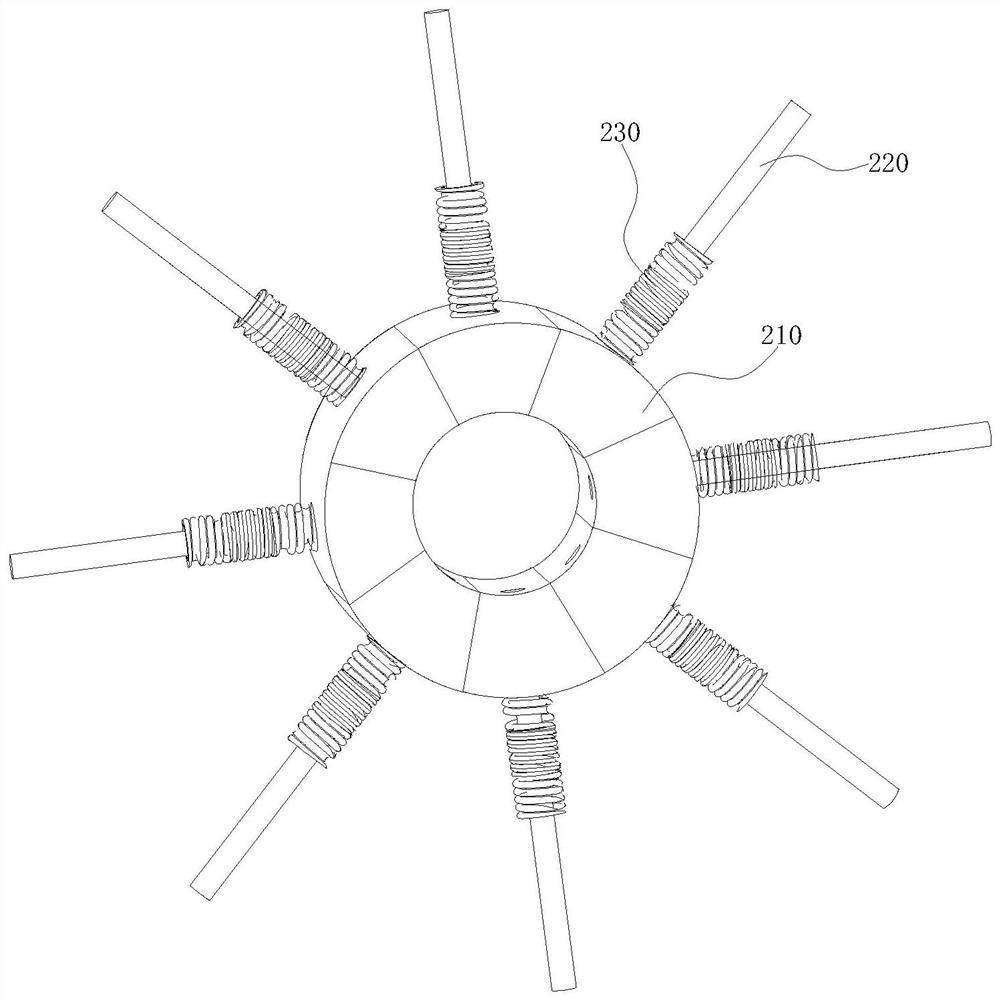

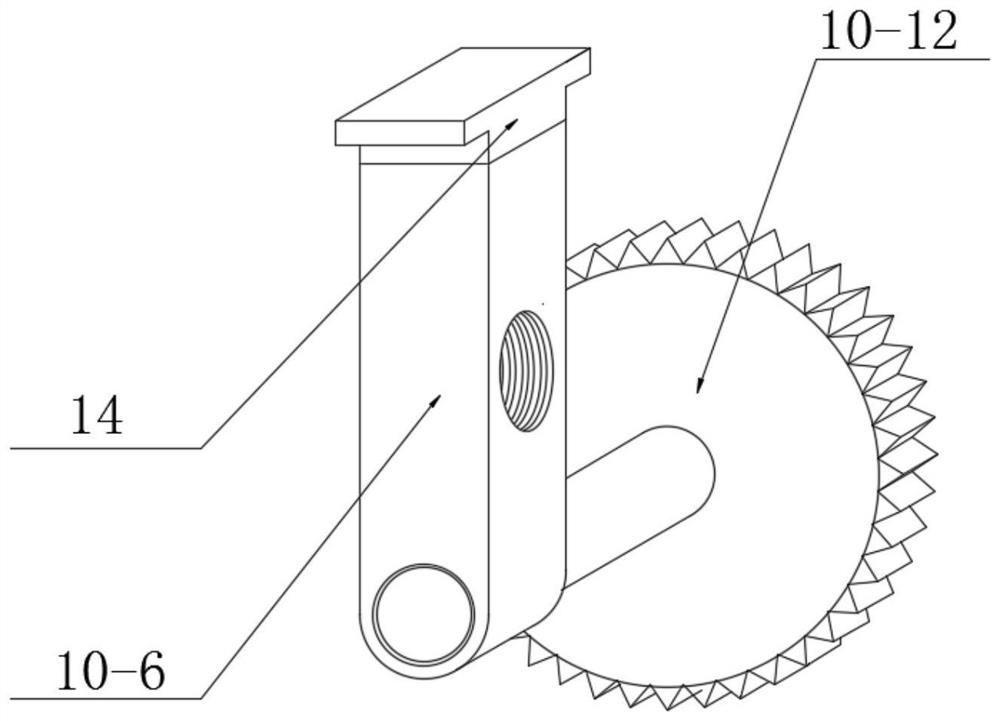

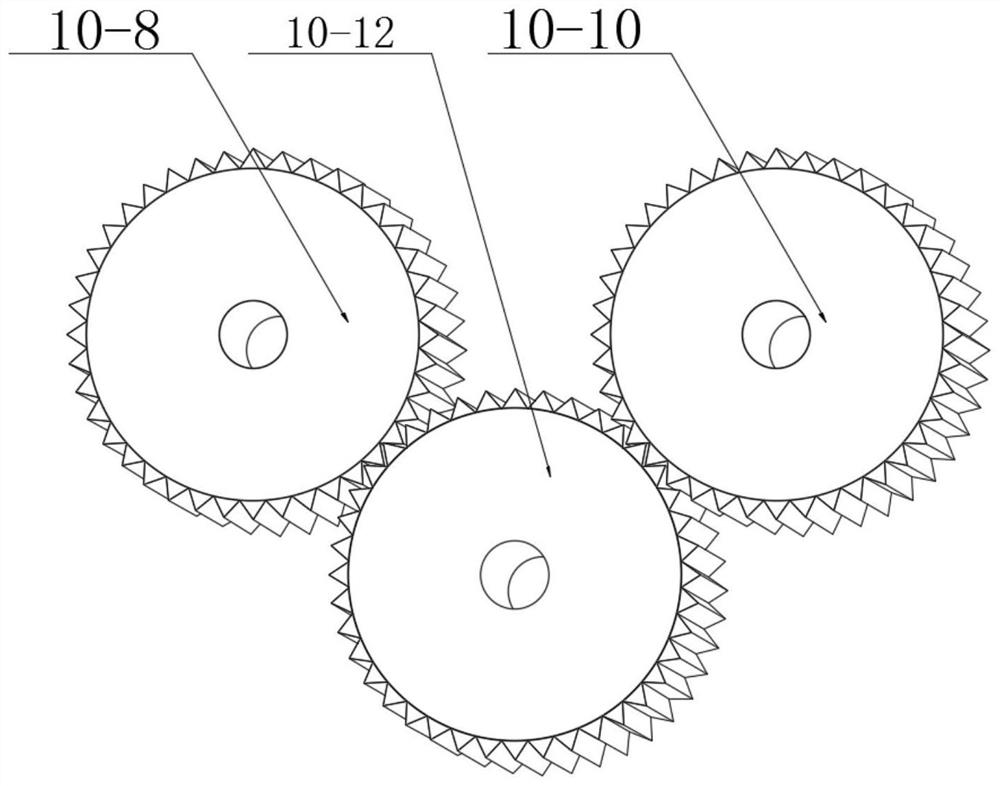

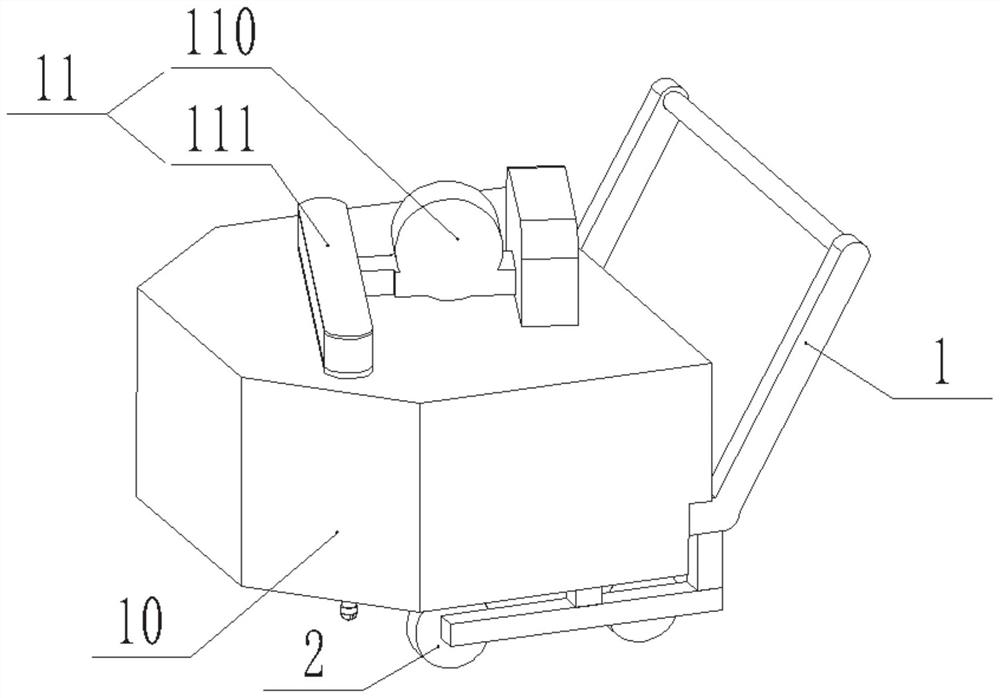

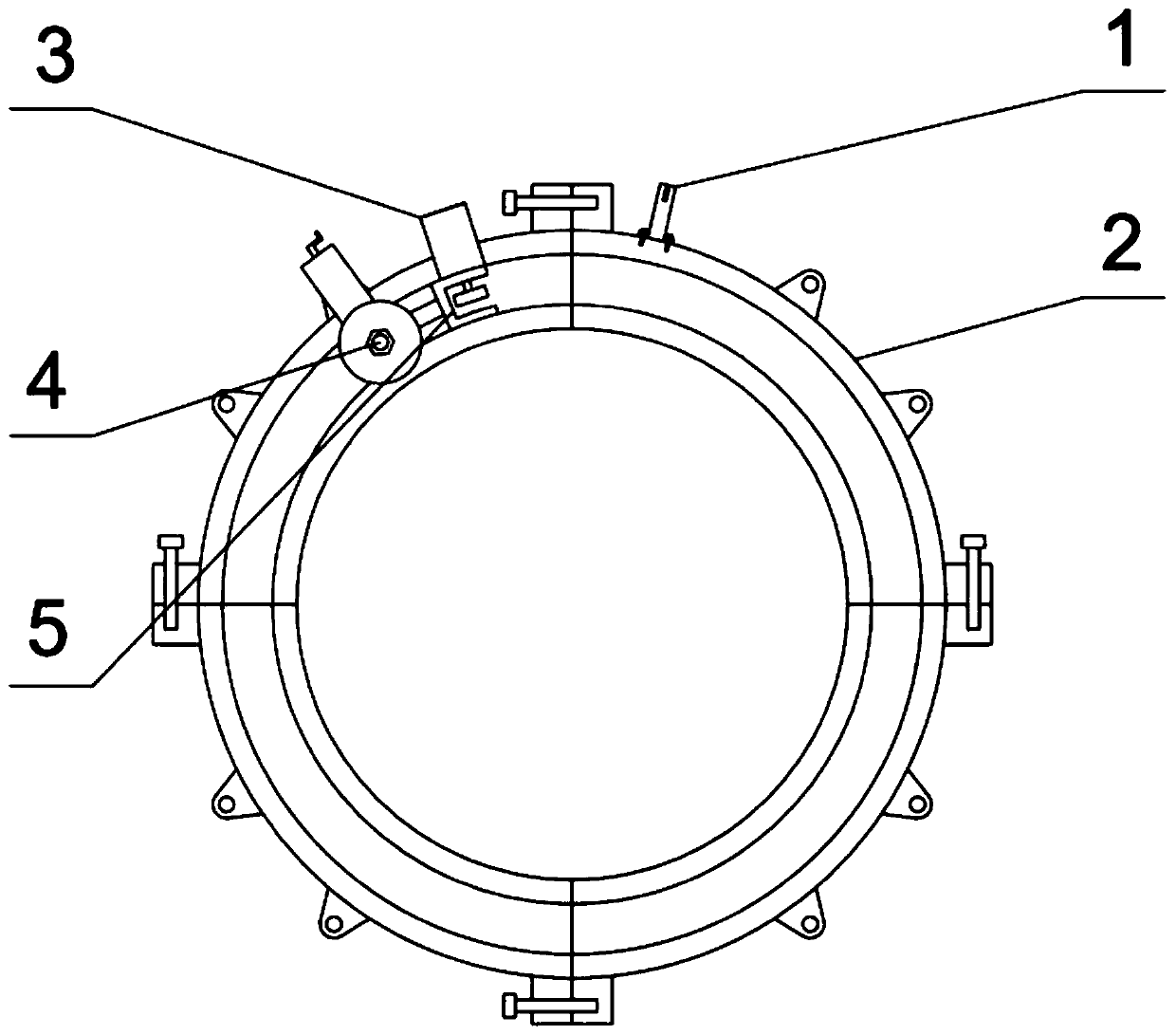

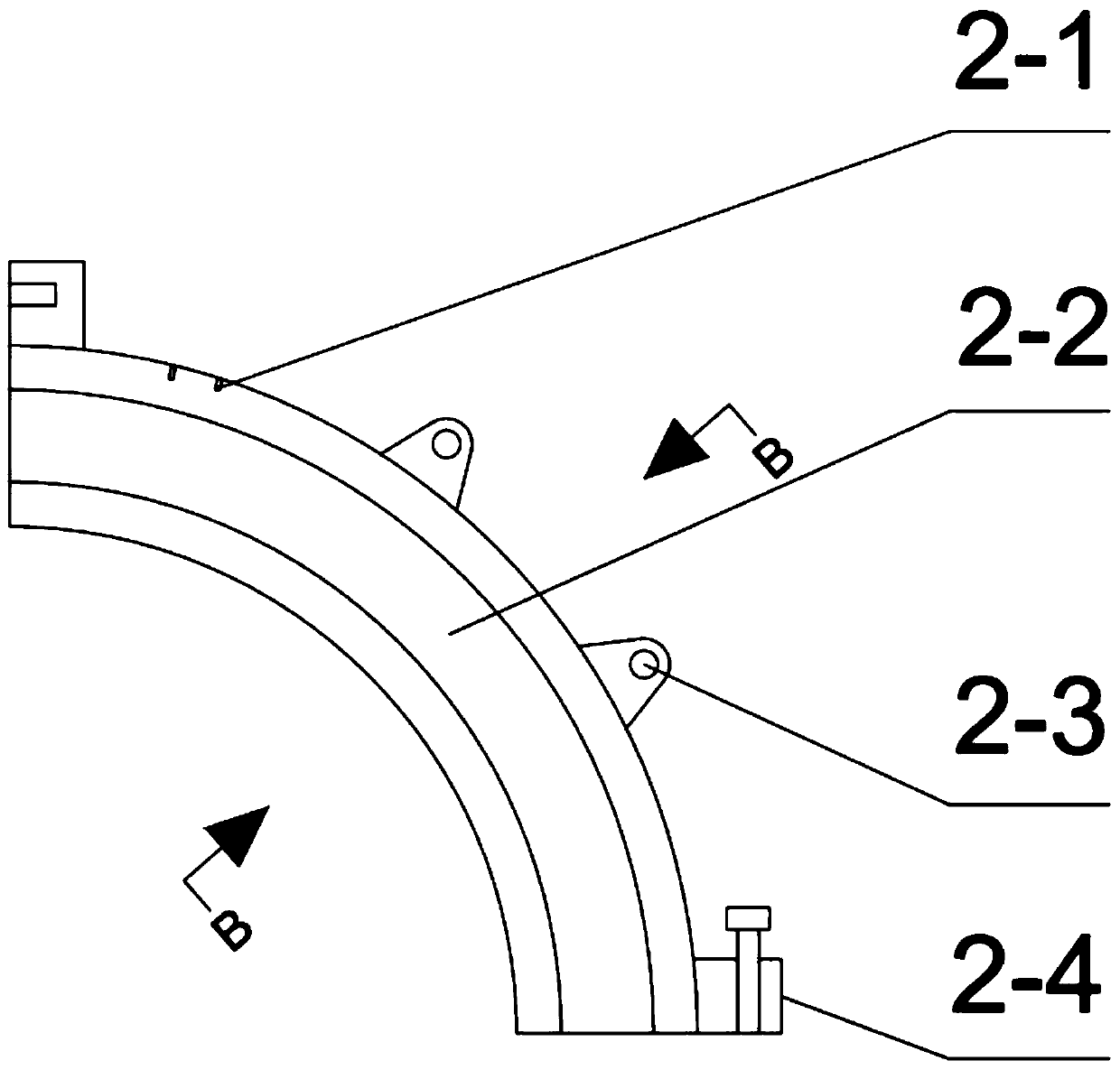

A multifunctional heating pipeline rotary cutting device

The invention relates to a cutting device, in particular to a multi-functional heating pipeline rotary cutting device. The multi-functional heating pipeline rotary cutting device can cut a heating pipe through a cutting disc and can rotate around and cut the heating pipe, and the cutting depth can be regulated through bolts in step by step. A retaining frame is fixed to the upper portion of the right side of one of fixing frames through a screw; the four fixing frames are mutually fixed through screws; a gear motor is fixed to a connecting frame through screws; a cutting device body is fixed to one end of the connecting frame through screws; and the connecting frame is located in sliding grooves of the fixing frames.

Owner:嘉兴晟源工业设计有限公司

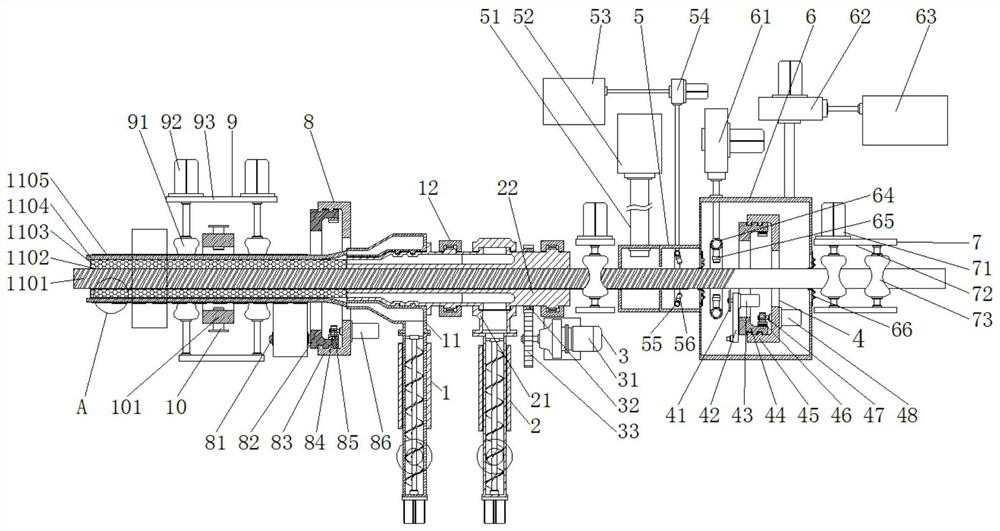

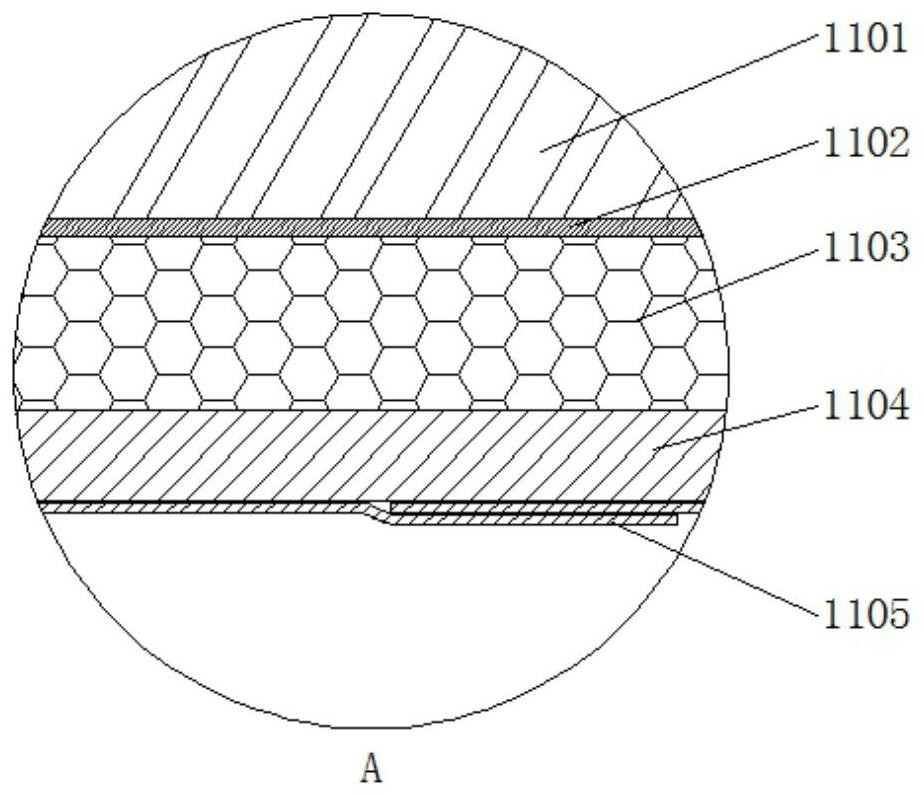

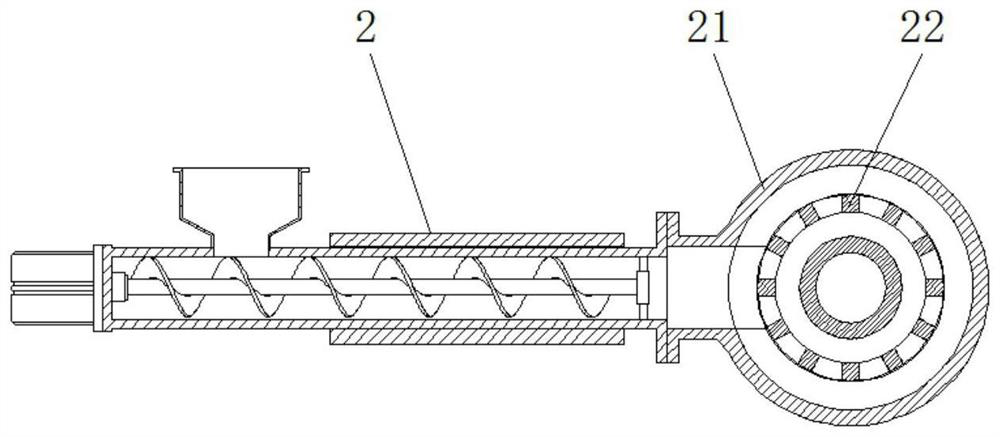

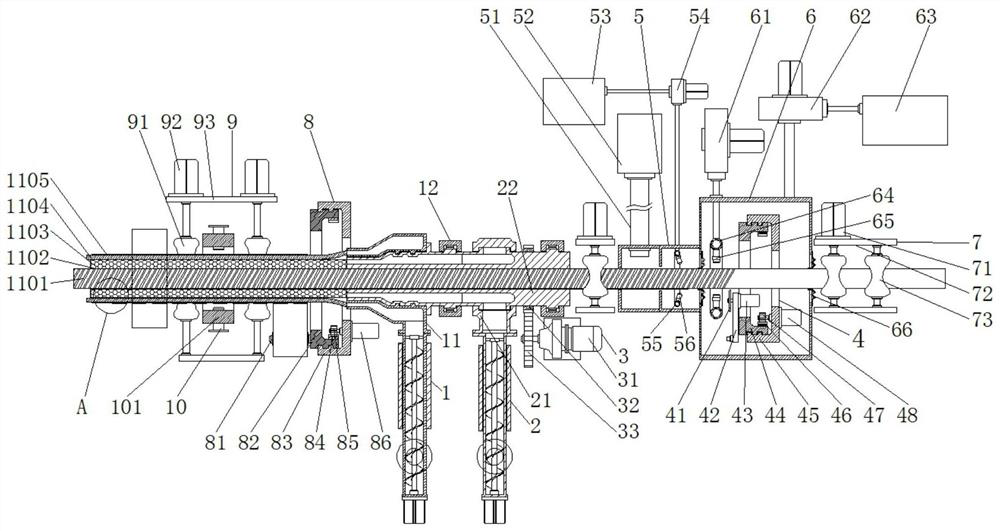

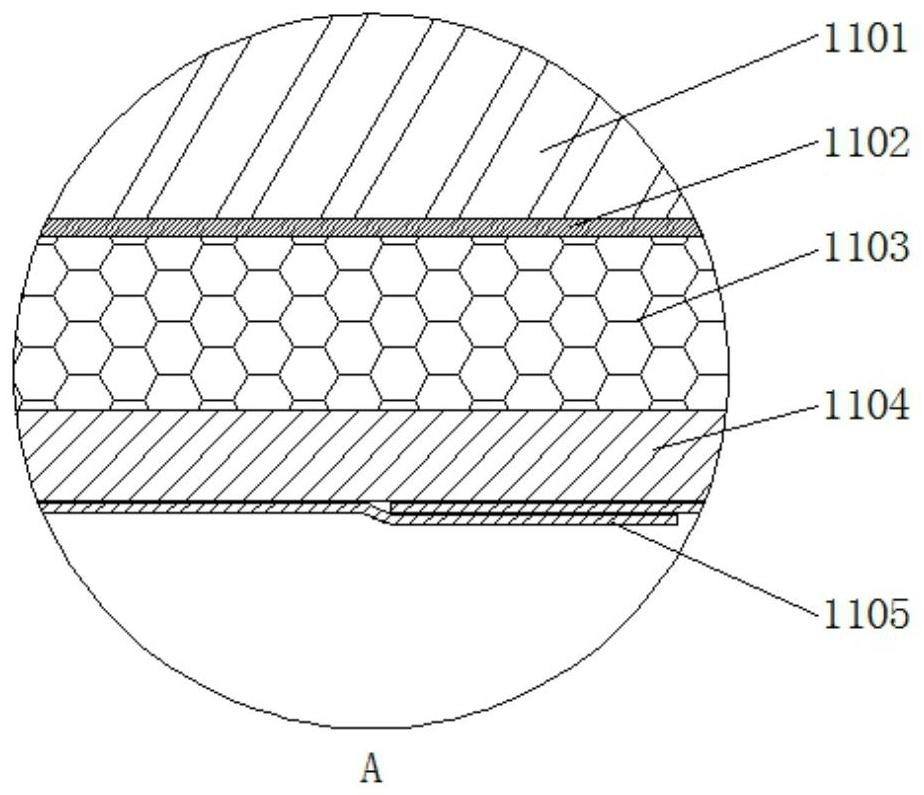

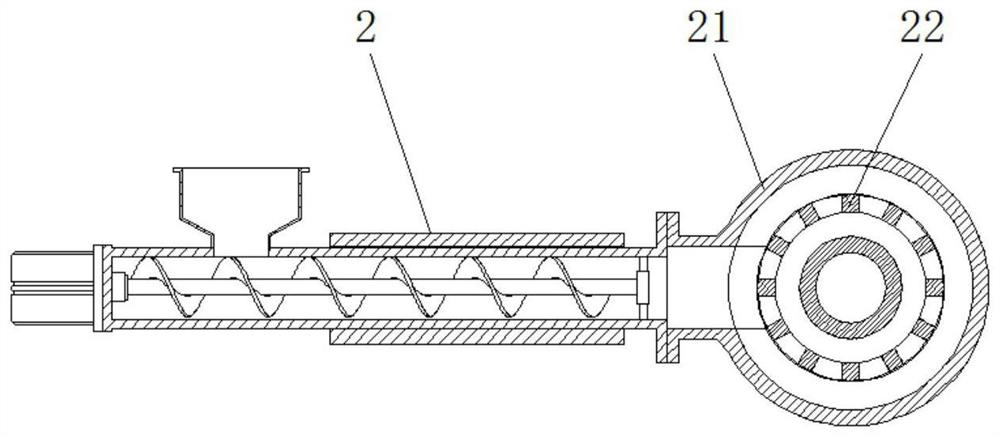

Polyurethane thermal insulation composite tube and forming device thereof

ActiveCN113513638AImprove integrityBond evenly and firmlyThermal insulationPipe protection by thermal insulationPolymer scienceInsulation layer

The invention relates to the technical field of polyurethane thermal insulation materials, in particular to a polyurethane thermal insulation composite tube. The polyurethane thermal insulation composite tube comprises an inner tube, wherein the outer wall of the inner tube is evenly covered with an anti-corrosion layer; the inner tube is sleeved with an outer tube; a polyurethane insulation coating is filled between the anti-corrosion layer on the outer tube and the anti-corrosion layer on the inner tube; the outer tube is wrapped with a thermal insulation layer. A forming device of the polyurethane thermal insulation composite tube comprises a foaming extrusion machine head, wherein a round hole matched with the diameter of an inner tube is formed in the middle of the foaming extrusion machine head, the foaming extrusion machine head is rotationally sleeved with an outer tube extrusion machine head, and a spraying box is arranged at one side of the tail end of the foaming extrusion machine head. By means of the matching structure of the foaming extrusion machine head and the outer tube extrusion machine head, the inner tube can penetrate through, meanwhile, wrapping and covering of the outer tube and filling of the polyurethane insulation coating are conducted, the inner tube, the polyurethane insulation coating and the outer tube are synchronously formed in a section of area, higher efficiency is achieved, and the integrity of the tube is higher after the tube is formed.

Owner:浙江天诚绝热科技股份有限公司

Pavement joint cutting machine capable of avoiding cutting dead angle

ActiveCN110820508AAvoid cutting cornersAdjustable cutting depthRoads maintainenceElectric machineryEngineering

The invention discloses a pavement joint cutting machine capable of avoiding the cutting dead angle. The pavement joint cutting machine comprises a connecting frame and a water tank, wherein a first connecting box is connected to the center part of the upper surface of the connecting frame through welding, and a bottom frame is movably connected to the outer side of the middle part of a first connecting rod; the front side of the first connecting box is provided with a second servo motor which is connected to the upper surface of the connecting frame through welding, the front side of a thirdconnecting rod is fixedly connected with a connecting device, and a second connecting rod is located on the left side of the interior of the connecting frame; and the upper part of a first connectingblock penetrates through the connecting frame, the upper part of the interior of a connecting cavity is fixedly connected with a first motor, and the left side of a sixth connecting rod is fixedly connected with the connecting device. According to the pavement joint cutting machine capable of avoiding the cutting dead angle, the cutting dead angle can be prevented, the device does not need to be rotated when a joint is cut, the cutting depth can be adjusted, the durability of the device is high, and the dustproof effect is good.

Owner:嘉兴华飞鹏科技有限公司

Forming device for polyurethane thermal insulation composite pipe

ActiveCN113513638BImprove integrityBond evenly and firmlyThermal insulationPipe protection by thermal insulationPolymer scienceInsulation layer

The invention relates to the technical field of polyurethane thermal insulation materials, in particular to polyurethane thermal insulation composite pipes, including an inner pipe, the outer wall of the inner pipe is evenly covered with an anti-corrosion layer, and an outer pipe is provided on the outer wall of the inner pipe, and the anti-corrosion layer on the outer pipe and the inner pipe The polyurethane insulation layer is filled in between, and the outer pipe is covered with a heat insulation layer. The molding device of the polyurethane insulation composite pipe includes a foaming extrusion head, and the middle of the foaming extrusion head is provided with an inner pipe. Round holes with matching diameters, and an outer tube extruder head is set on the outer rotating sleeve of the foam extruder head, and a spray box is arranged on the tail end side of the foam extruder head. The present invention can realize the wrapping and covering of the outer pipe and the filling of the polyurethane insulation layer while the inner pipe passes through the matching structure of the foam extrusion head and the outer pipe extrusion head, so that the inner pipe, the polyurethane insulation layer and the The outer tube is formed synchronously in a certain area, which is more efficient and makes the integrity of the tube higher after forming.

Owner:浙江天诚绝热科技股份有限公司

Independent hole carving system

PendingCN111118767ASolve the disadvantage of only monochrome embroideryFlexible useAutomatic machinesSurgeryBiomedical engineering

The invention discloses an independent hole carving system. The independent hole carving system comprises a needle rod frame and a plurality of needle rods mounted on the needle rod frame; the needlerod frame can perform translation left and right; the bottom end of any one needle rod is assembled with a hole carving knife, and a hole carving driving system is arranged and is not connected with any of the needle rods; the hole carving driving system can drive each needle rod which moves to the corresponding driving position to move downwards for the highest stroke; and each needle rod is provided with a reset part for driving the needle rod to perform upward movement reset. The independent hole carving system has the beneficial effects that the needle rod can be optionally selected to beassembled with the hole carving knife for carrying out hole carving, and hole carving and multi-color embroidery can be both performed.

Owner:浙江镨美科智能刺绣设备有限公司

A kind of multifunctional pavement cutting equipment

The invention discloses a multifunctional road surface cutting device, which comprises a push frame body, a roller, a cutting mechanism, a drilling mechanism, a rotation drive mechanism, and a drive switching mechanism, and a plurality of rollers are installed at the bottom of the push frame body; The cutting mechanism includes a saw blade, a first spline tooth, and a mounting frame; the first spline teeth are installed on both sides of the saw blade; the drive switching mechanism includes a main shaft, a driving bevel gear, a first rotary A drive assembly, a first linear movement drive assembly, the first rotation drive assembly includes a driving gear, a driven gear, a rotating motor, and a moving frame. The invention integrates two operations of cutting and drilling, has strong functionality, and the same power source is used for cutting and drilling operations, which saves energy and reduces costs, and at the same time realizes the adjustment of the cutting depth of the cutting mechanism and the drilling depth of the drilling mechanism , Improve the scope of work.

Owner:湖南汉坤实业有限公司

A cutting adjustment device

ActiveCN110814787BAdjust the depth of cutImprove automationLarge fixed membersMilling equipment detailsMilling cutterStructural engineering

The invention belongs to the technical field of a word bending machine and provides a cutting and adjusting device. The cutting and adjusting device comprises a milling cutter and a square rail cutterrod rotatably connected with the milling cutter; the square rail cutter rod is in sliding connection with an adjusting base; and a perpendicularity adjusting mechanism for adjusting the perpendicularity of the square rail cutter rod as well as a depth adjusting mechanism for adjusting the distance between the square rail cutter rod and a plate are arranged on the adjusting base. Through the perpendicularity adjusting mechanism, the perpendicularity of the square rail cutter rod can be adjusted, so that the perpendicularity of the milling cutter is adjusted; and on the basis that the perpendicularity is adjusted and through the depth adjusting mechanism, the distance between the square rail cutter rod and the plate can be adjusted, so that the distance between the milling cutter and the plate is adjusted, the technical effect of adjusting the cutting depth and perpendicularity of the milling cutter is achieved, and the high efficiency and the adjustability of plate cutting are improved.

Owner:潍坊达创数控设备有限公司

A dual-track derusting and grinding device and its application method

ActiveCN111893818BLong post-maintenance periodReduce maintenance costsRailway track constructionDrive shaftElectric machinery

The invention discloses a double-track derusting and polishing device, which comprises a device base. Front track wheels and rear track wheels are symmetrically installed on the lower ends of both sides of the device base. The track wheels are installed on a transmission shaft. A driving motor is installed, the shaft of the driving motor is connected to the front track wheel in rotation, a grinding device is installed between the front track wheel and the rear track wheel, and the grinding frame is installed on both sides of the lower end of the device base, A first grinding mechanism and a second grinding mechanism are installed on the grinding frame, and the second grinding mechanism is arranged at the rear end of the first grinding mechanism. The rust removal and grinding device completes the problem of one-time removal of rust on the track, avoiding repeated rust removal, and at the same time ensuring that the post-maintenance period of the track after rust removal is longer, reducing maintenance costs, and avoiding multiple times The maintenance caused the impact on rail transportation.

Owner:株洲伟雄工程机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com