Cutting and adjusting device

A technology of adjusting device and adjusting seat, which is applied to the details of milling machine equipment, large fixed members, metal processing machinery parts, etc., can solve the problems of inability to adjust the verticality of the milling cutter, complicated assembly, inconvenient installation and disassembly, etc., to achieve improved automation and Adjustability, improved adjustment speed and stability, ease of maintenance and replacement of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be described in detail below in conjunction with embodiments. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

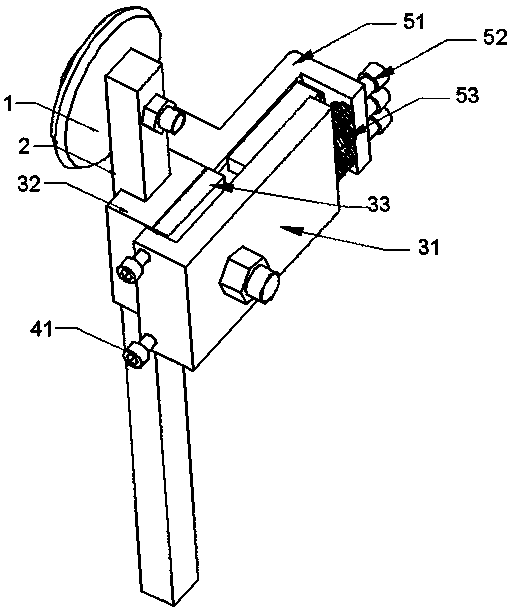

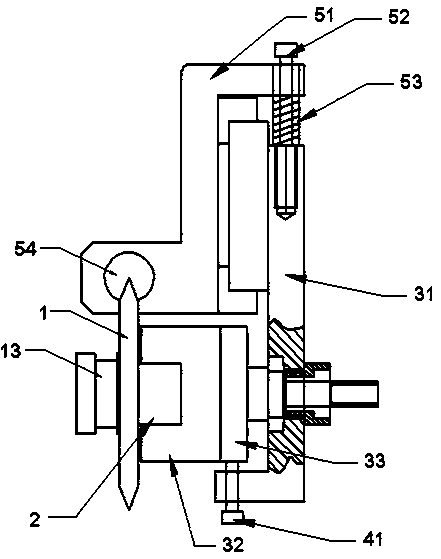

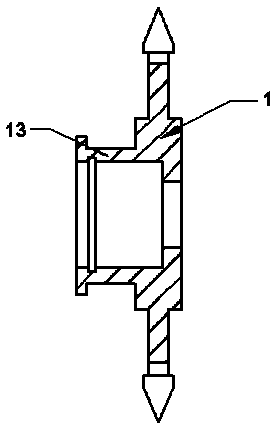

[0031] like Figure 1-Figure 3 As shown, a cutting adjustment device includes a milling cutter 1 and a square rail cutter bar 2 rotatably connected to the milling cutter 1. The square rail cutter bar 2 is slidably connected to an adjustment seat 3, and the adjustment seat 3 is provided with a square rail for adjusting The vertical adjustment mechanism 4 for the verticality of the cutter bar 2, and the depth adjustment mechanism 5 for adjusting the distance between the square rail cutter bar 2 and the plate, through the setting of the vertical adjustment mechanism 4, the square rail cutter bar 2 can be adjusted relative to the adjustment seat 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com