Patents

Literature

62results about How to "Efficient shearing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

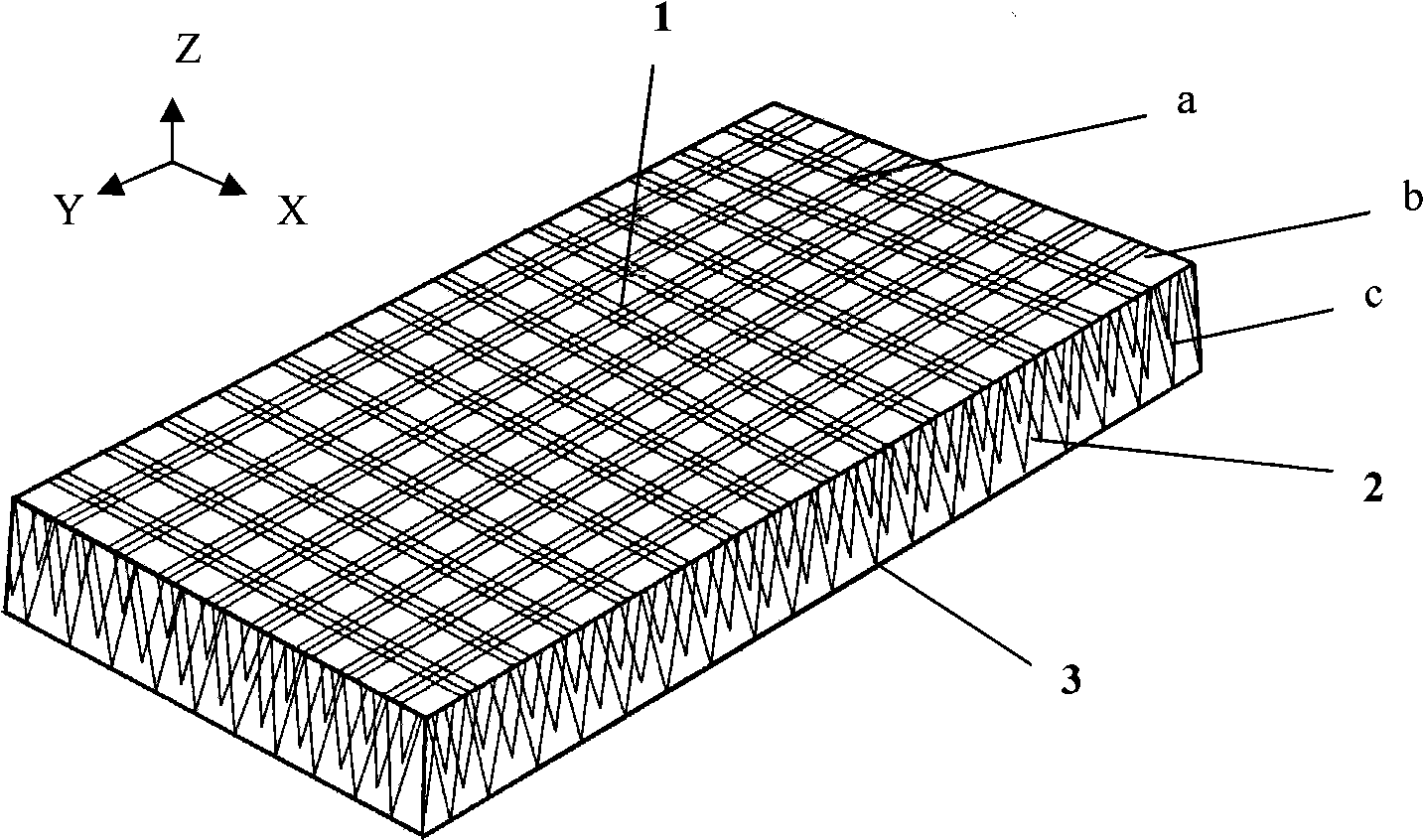

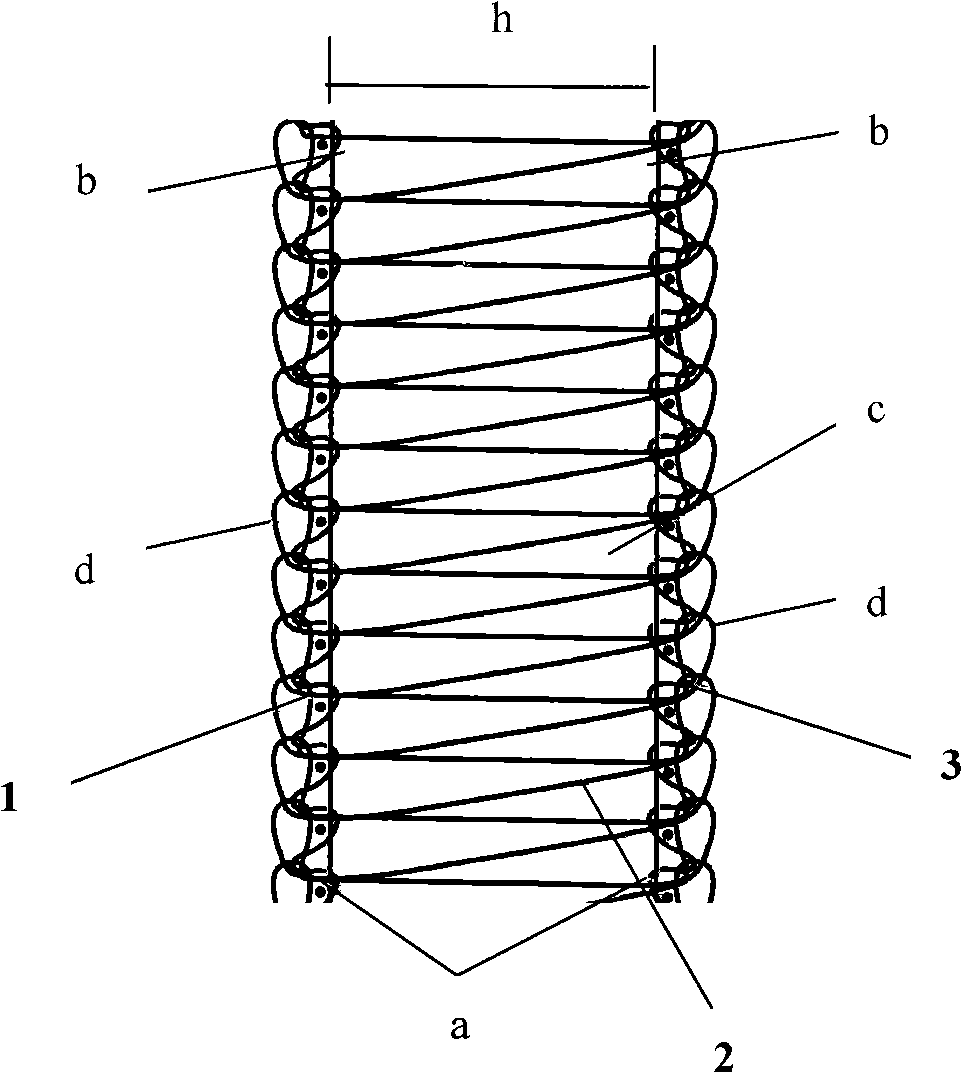

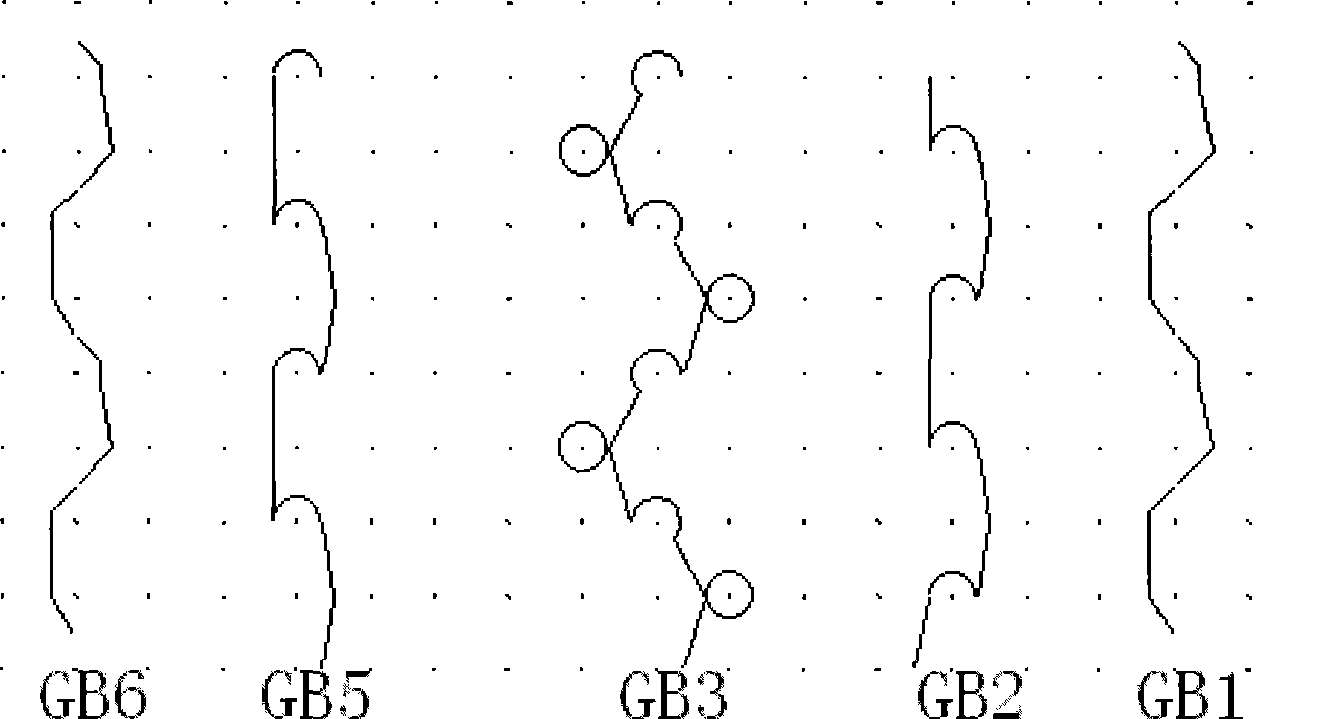

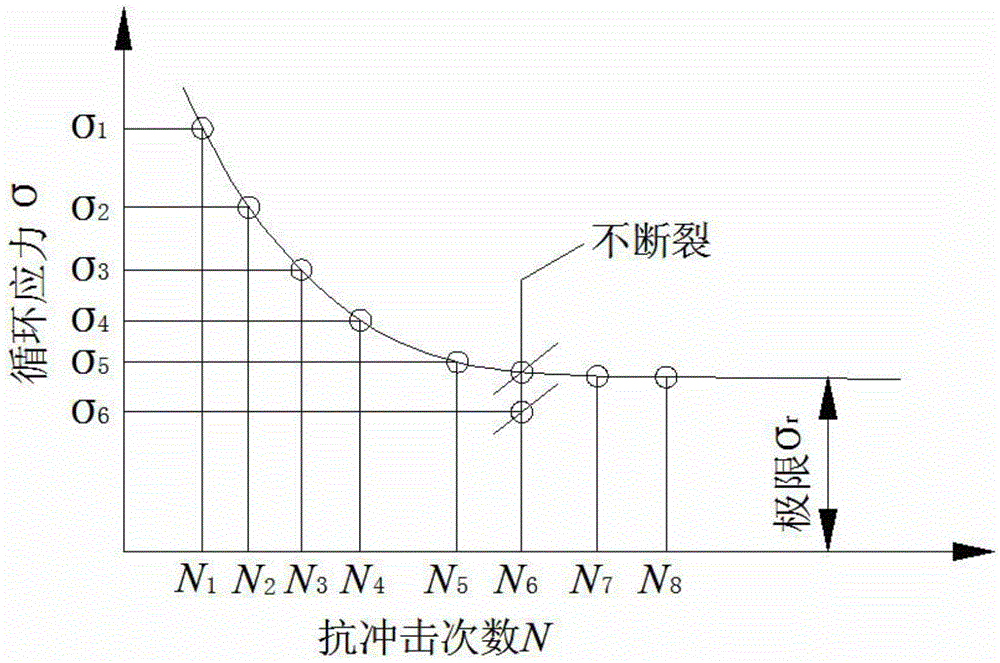

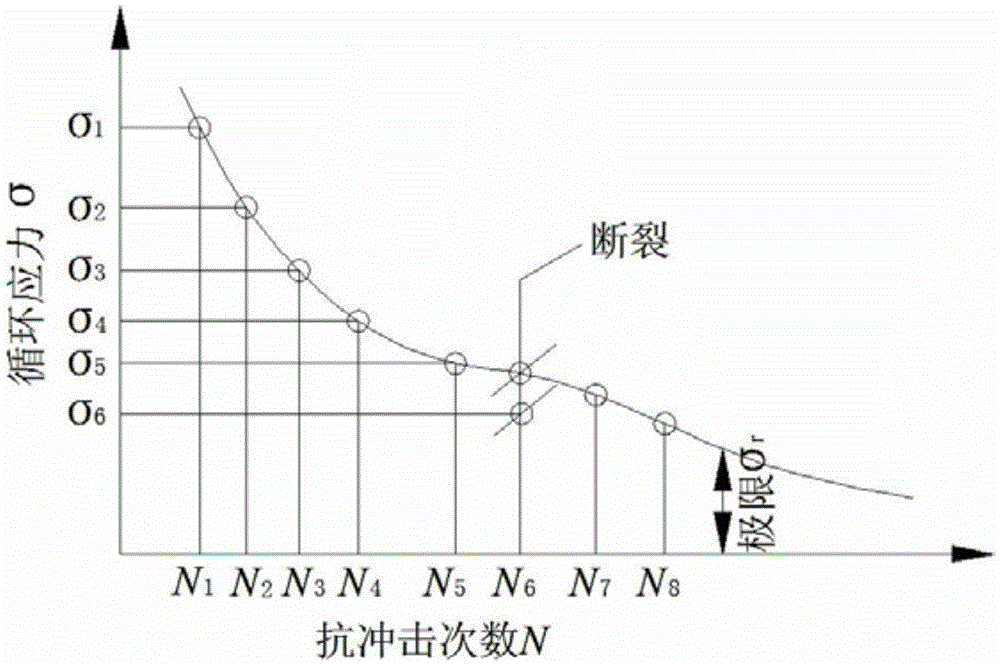

Production method for three-dimensional reinforced warp knitted spaced fabric

The invention relates to a manufacture method for three-dimensional reinforced warp knitted spaced fabric, and the warp knitted spaced fabric is produced on a modified double tricot raschel machine with full weft insertion devices. A main body of adopted raw materials is tows of high-performance fiber such as fiber glass, carbon fiber, aramid fiber, ultra high modulus polyethylene and the like. The manufacture method comprises the following steps: introducing high-performance fiber inserted weft yarns on the whole width of the machine in the X-axis direction through two weft insertion devices arranged on the front and the back of the machine; introducing high-performance fiber inserted warp yarns in the Y direction through guide bars; binding and fixing the inserted warp yarns and the inserted weft yarns through chain stitch or tricot stitch of common or high strength synthetic fiber filament yarns; adopting the high-performance fiber on upper and lower surface layer connecting yarns, ensuring the distance of 5 to 6 cm between the two surface layers, and providing reinforcing fiber in the Z-axis direction; and designing raw materials, densities, arrangement modes and interlayer thickness of the inserted warp and weft yarns of the surface layers and interlayer connecting yarns according to the requirements to form three-dimensional mesh structures with different mesh sizes and specifications. The manufacture method is characterized in that the high-performance fiber is extended and arranged in three-dimensional directions so as to overcome the defects and disadvantages of the prior spaced fabric taken as a reinforced material, and the manufacture method provides an ideal three-dimensional reinforced fabric for production of composite boards with good tensile, bending, shearing and compression properties and shock resistance.

Owner:JIANGNAN UNIV

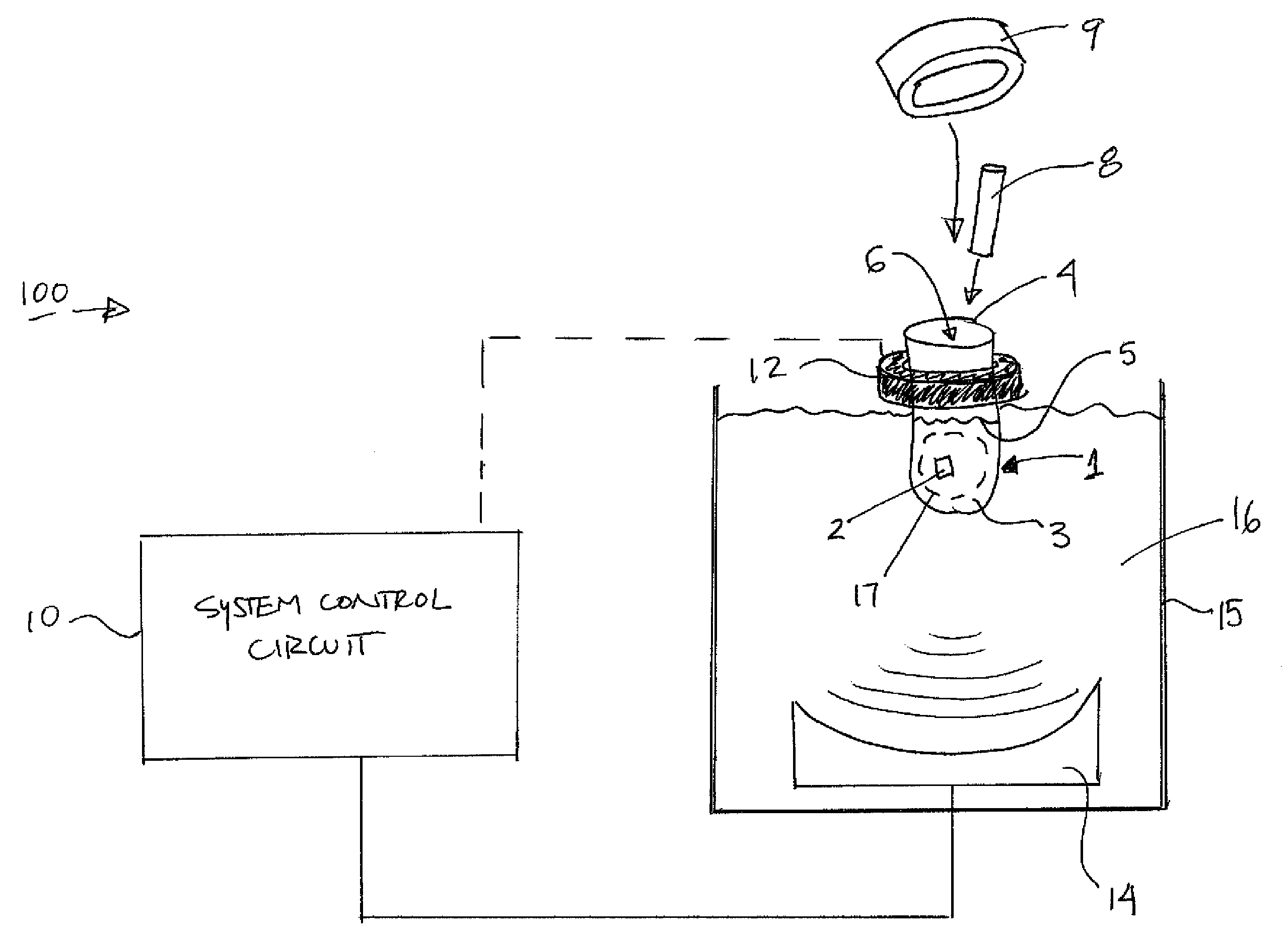

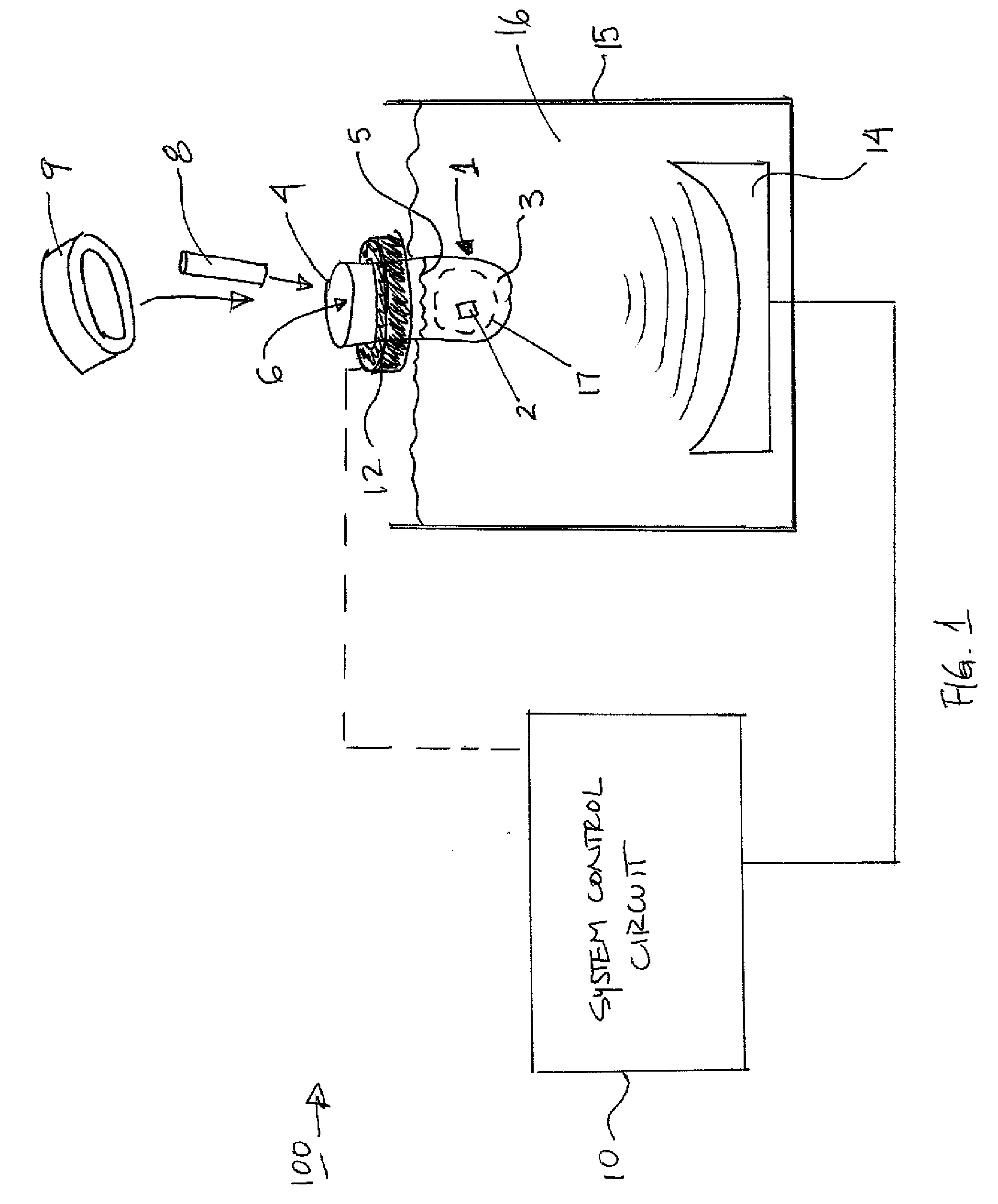

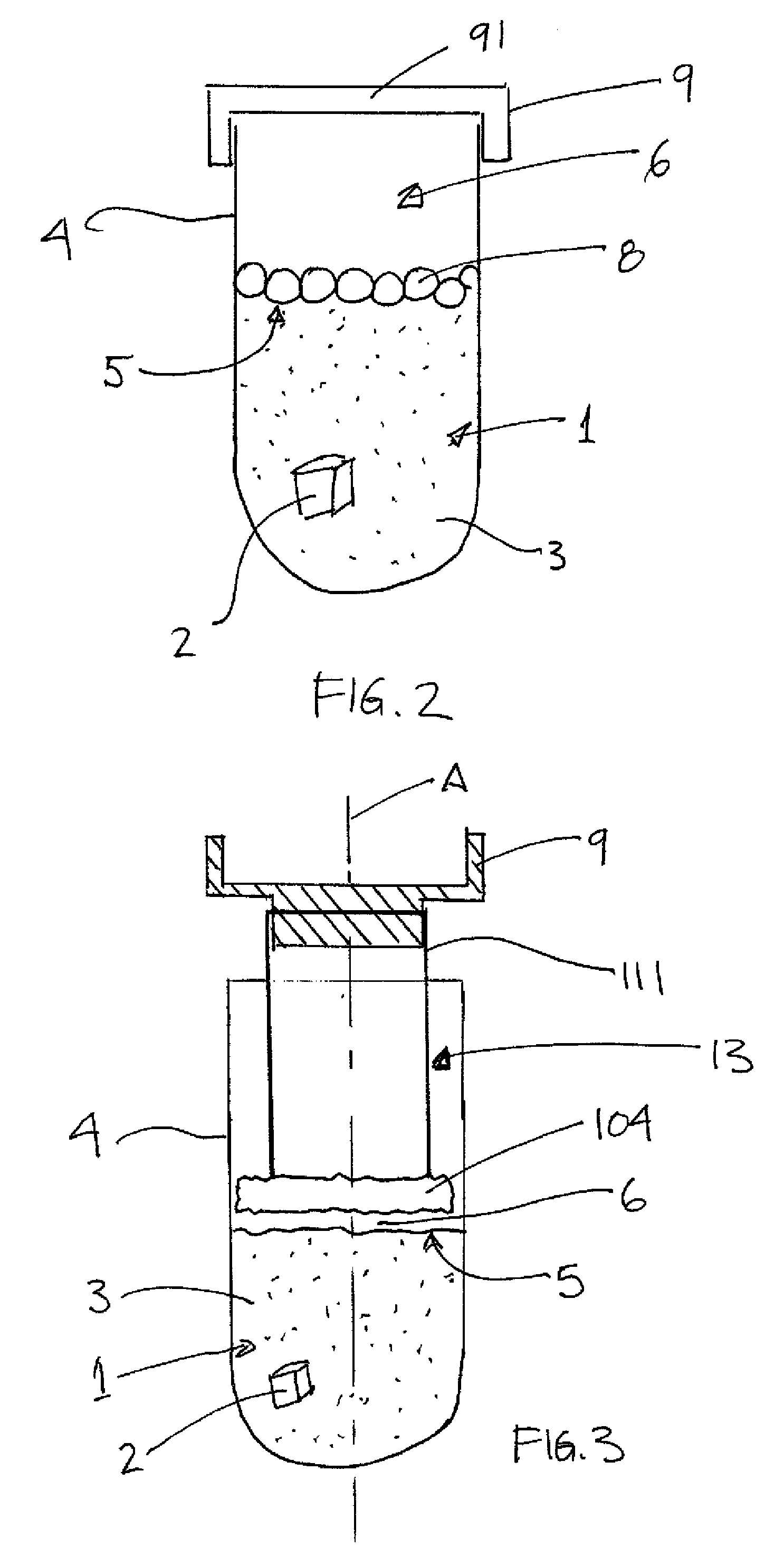

Method and apparatus for treatment enhancement in acoustic processing of samples

ActiveUS20090317884A1Reduce sound energySlow and incomplete processing of sampleBioreactor/fermenter combinationsShaking/oscillating/vibrating mixersAcoustic energyProduct gas

Method and apparatus for controlling acoustic treatment of a sample including a liquid. A processing volume in which the sample is acoustically treated may be controlled, e.g., by positioning a suitable element so as to reduce and / or eliminate a headspace at a sample / gas interface. An interaction between the acoustic energy and the sample may be controlled, e.g., by using an energy director positioned at least partially in the sample that helps to reduce splashing or other sample ejection that would otherwise occur.

Owner:COVARIS INC

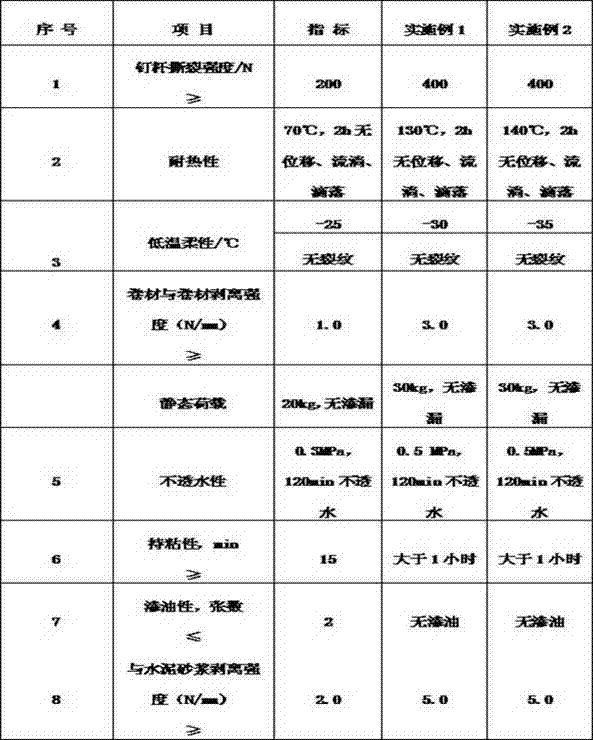

Self-adhesion waterproof rolls used for road bridge and preparation method thereof

ActiveCN103160241AGood high and low temperature resistanceImprove impermeabilityBallastwayFilm/foil adhesivesSelf-healingCooking & baking

The invention relates to self-adhesion waterproof rolls used for a road bridge. The self-adhesion waterproof rolls used for the road bridge comprises, by weight, 40-60 parts of asphalt No.90, 10-20 parts of softening oil, 3-10 parts of styrene-butadiene-styrene block copolymer, 2-5 parts of butadiene styrene rubber, 3-8 parts of reclaimed polypropylene, 0.5-3 parts of high temperature modifier, 5-15 parts of rubber powder and 25-40 parts of stuffing. The self-adhesion waterproof rolls used for the road bridge has excellent high-and-low temperature resistance performance, is imperious, impact-proof, anti-shearing and large in bonding strength, and has self-healing creep performance. Fire baking is not required in construction, cold construction is adopted, the construction method is simple, and the construction efficiency is high.

Owner:新疆德生建科防水材料科技有限公司

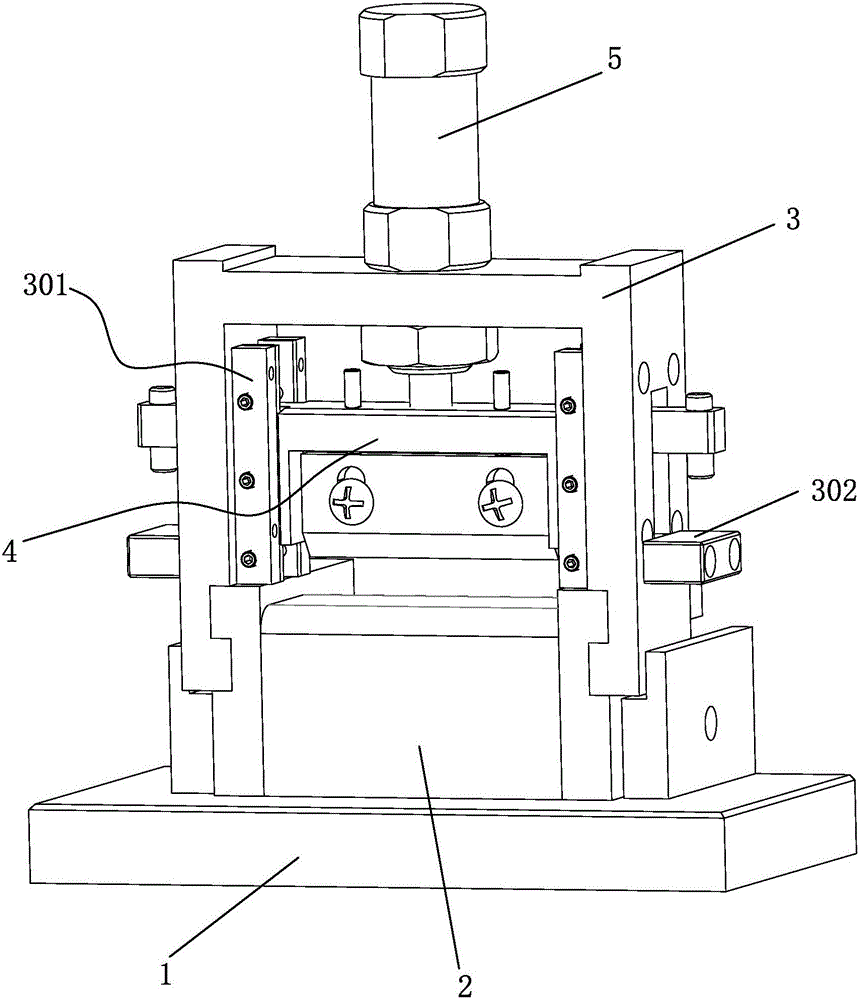

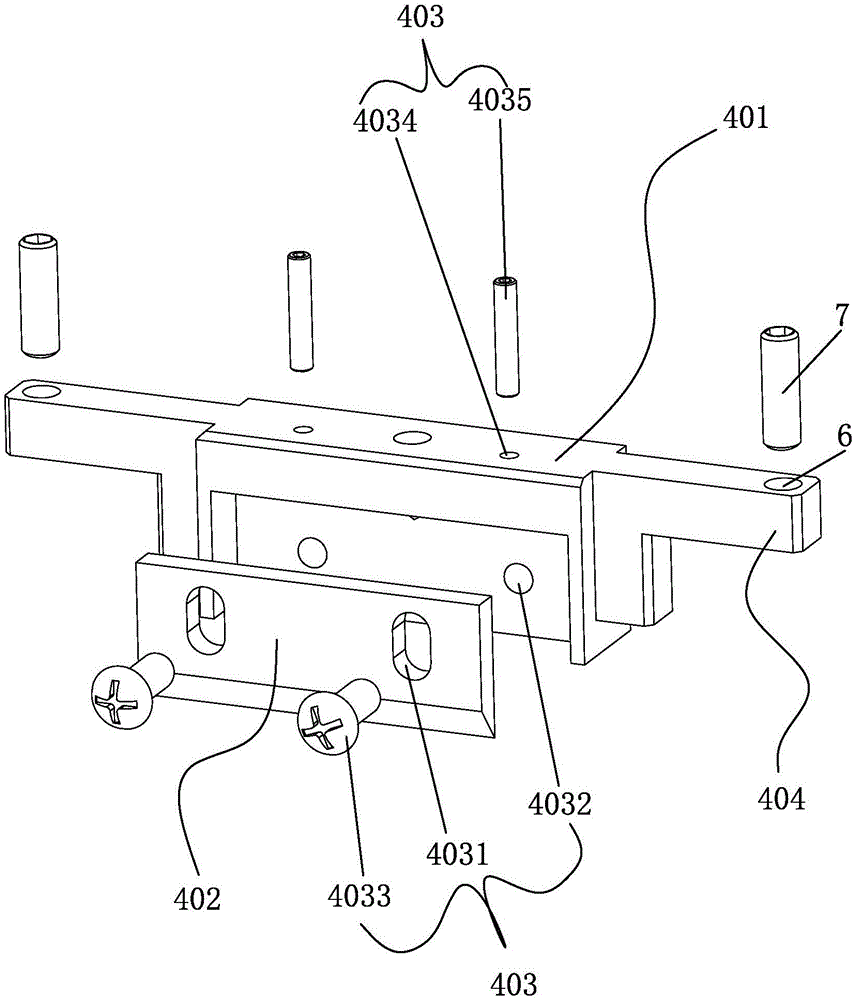

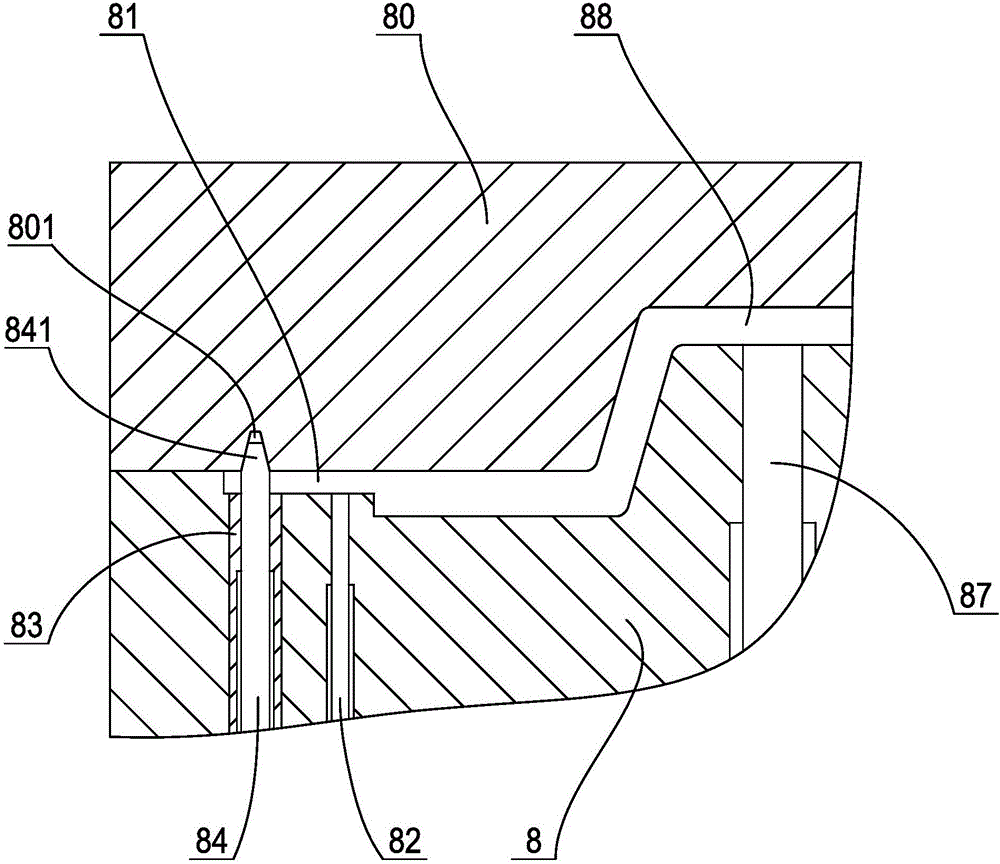

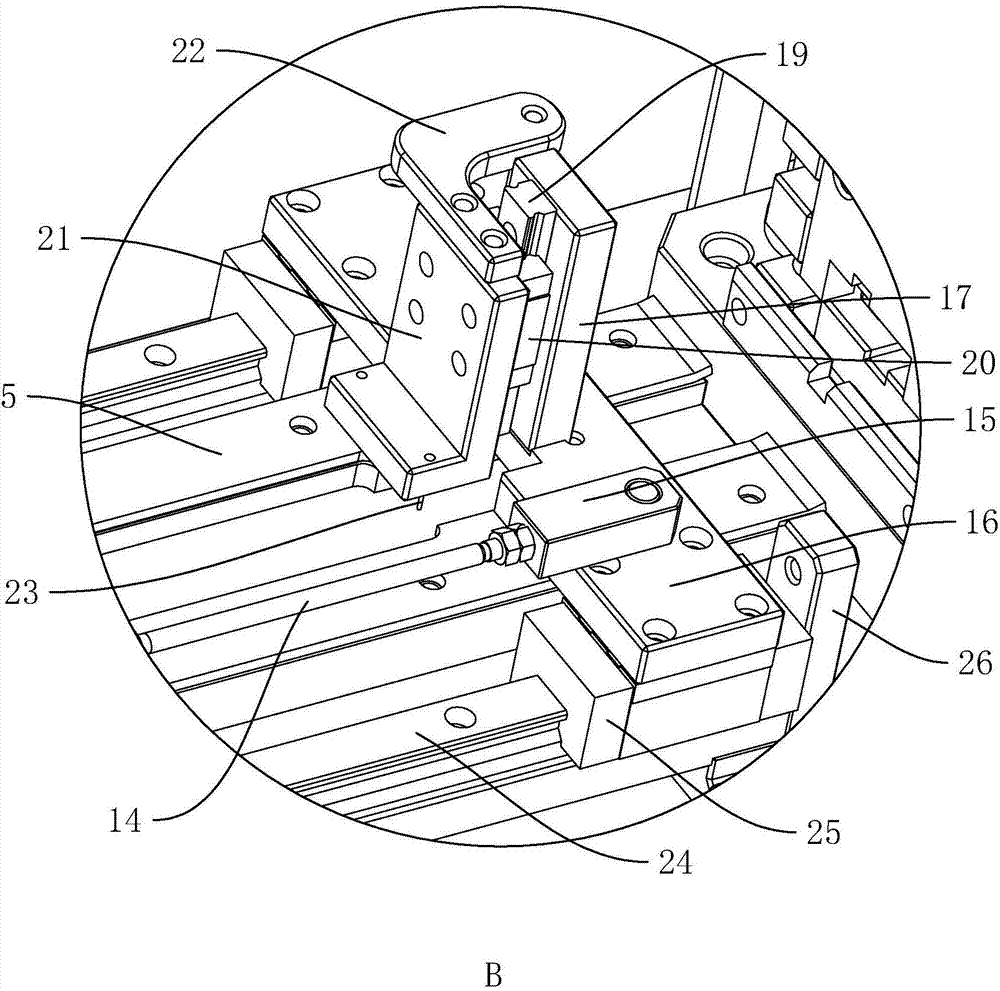

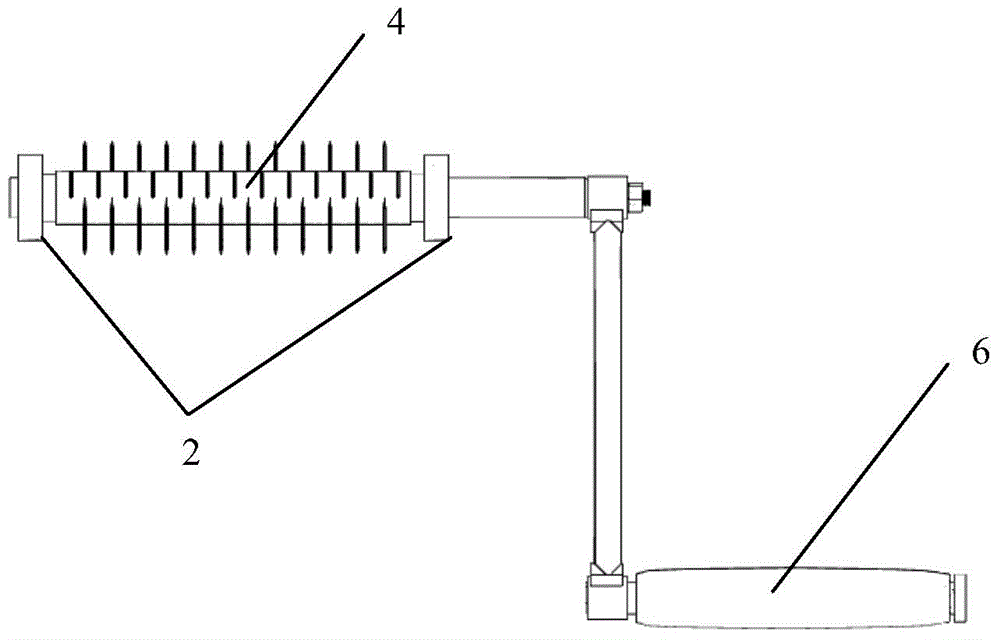

Wire shearing mechanism

The invention discloses a wire shearing mechanism. A cutter pad is arranged on a base, and a support is arranged on the cutter pad. A cutter assembly is slidably connected to the support, and the support is further provided with a driving device used for driving the cutter assembly to cut wires. The cutter assembly comprises a tool rest slidably connected with the support, a blade arranged on the tool rest and an adjusting structure for adjusting the wire cutting depth of the blade. According to the wire cutting mechanism, the cutting depth of the blade can be precisely adjusted so that wire rods can be cut off or pre-cut. During wire winding, all sets of wound wires are pre-cut by the wire cutting mechanism, the pre-cutting depth of the wire rods can be adjusted through the adjusting structure, and after wire winding of coils is completed, the ends of windings can be snapped along pre-cut positions with slight force. Accordingly, the wire cutting mechanism improves production efficiency, lowers the labor cost, guarantees uniform quality of all finished coil products, and has the characteristic of high yield.

Owner:宋红光

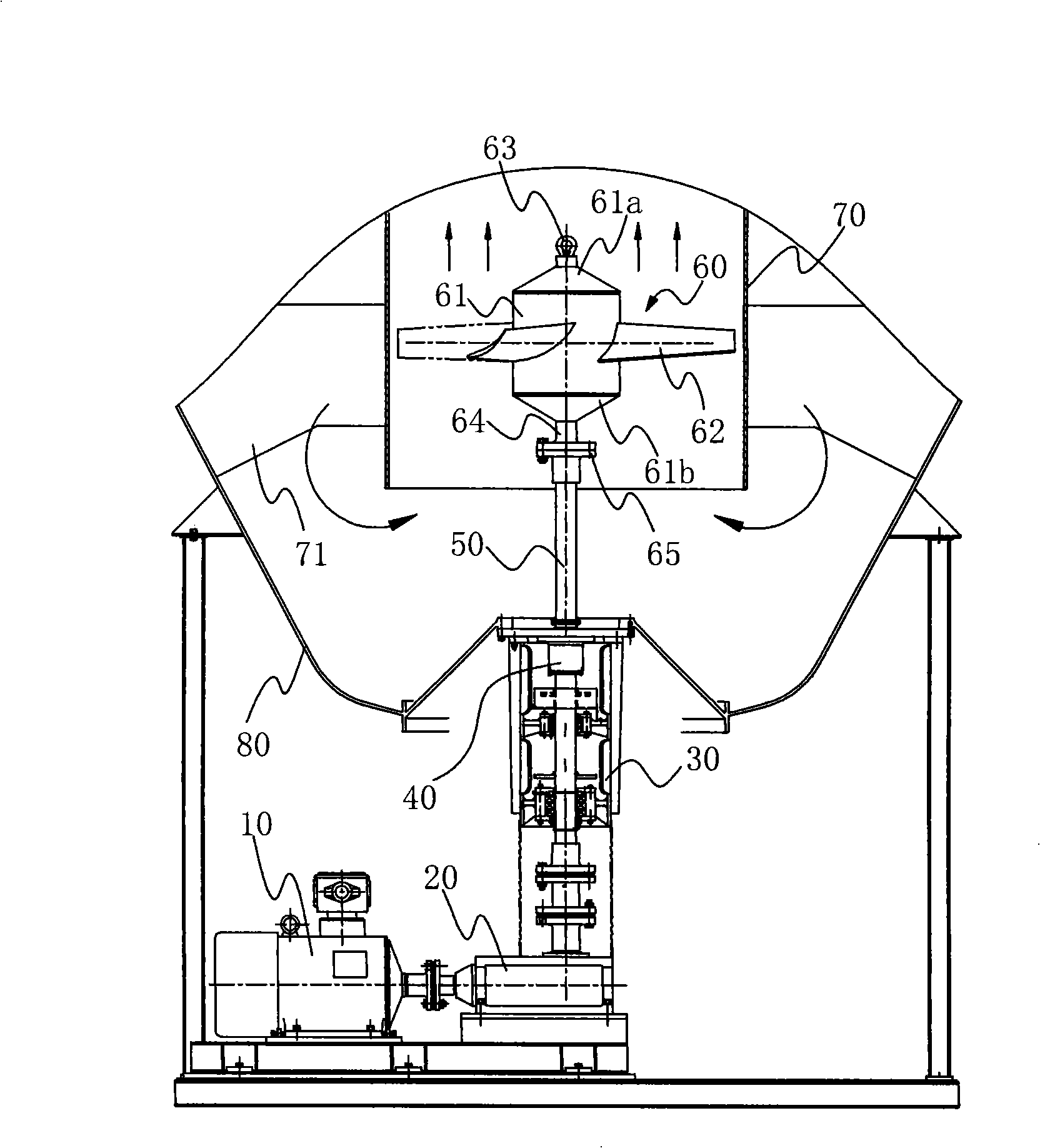

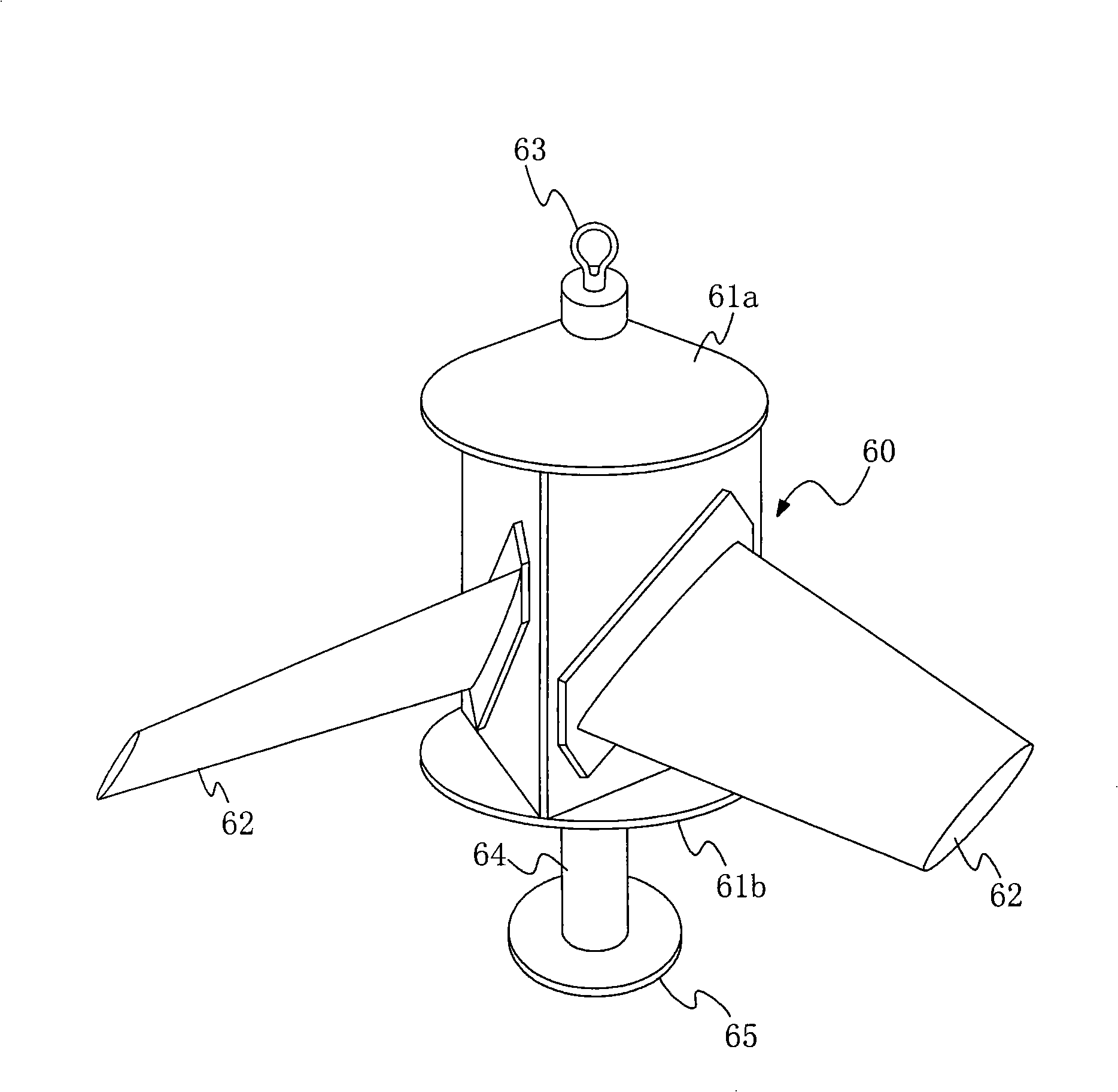

Reaction kettle bottom agitation system

ActiveCN101310843AShorten the lengthEasy to operateRotary stirring mixersChemical/physical/physico-chemical stationary reactorsChemical industryPharmaceutical industry

The invention discloses a stirring system at the bottom of a reaction kettle, which can be widely applied to the processes of shearing, emulsification and homogenizing in media of petroleum trade, chemical industry, pharmaceuticals industry, food service industry, etc. The reaction kettle is internally provided with an air guide sleeve the upper end and the lower end of which are both open. The lower part of a stirring device in the air guide sleeve is provided with a transmission device which is fixed at the bottom of the reaction kettle. Cartridge and combined mechanical seals are arranged between the bottoms of the transmission device and the reaction kettle, and the transmission device is connected with a power output shaft of a speed reducer while a power input shaft of the speed reducer is connected with a motor. With the respect to the problem of the over-length of stirring shafts in the general jacking structure adopted, the stirring system of the invention can greatly shorten the length of the stirring shaft and ensure the stable operation and that a rotating shaft bears small subsidiary stress, thus providing comparatively favorable application environment for sealing.

Owner:合肥华升泵阀股份有限公司

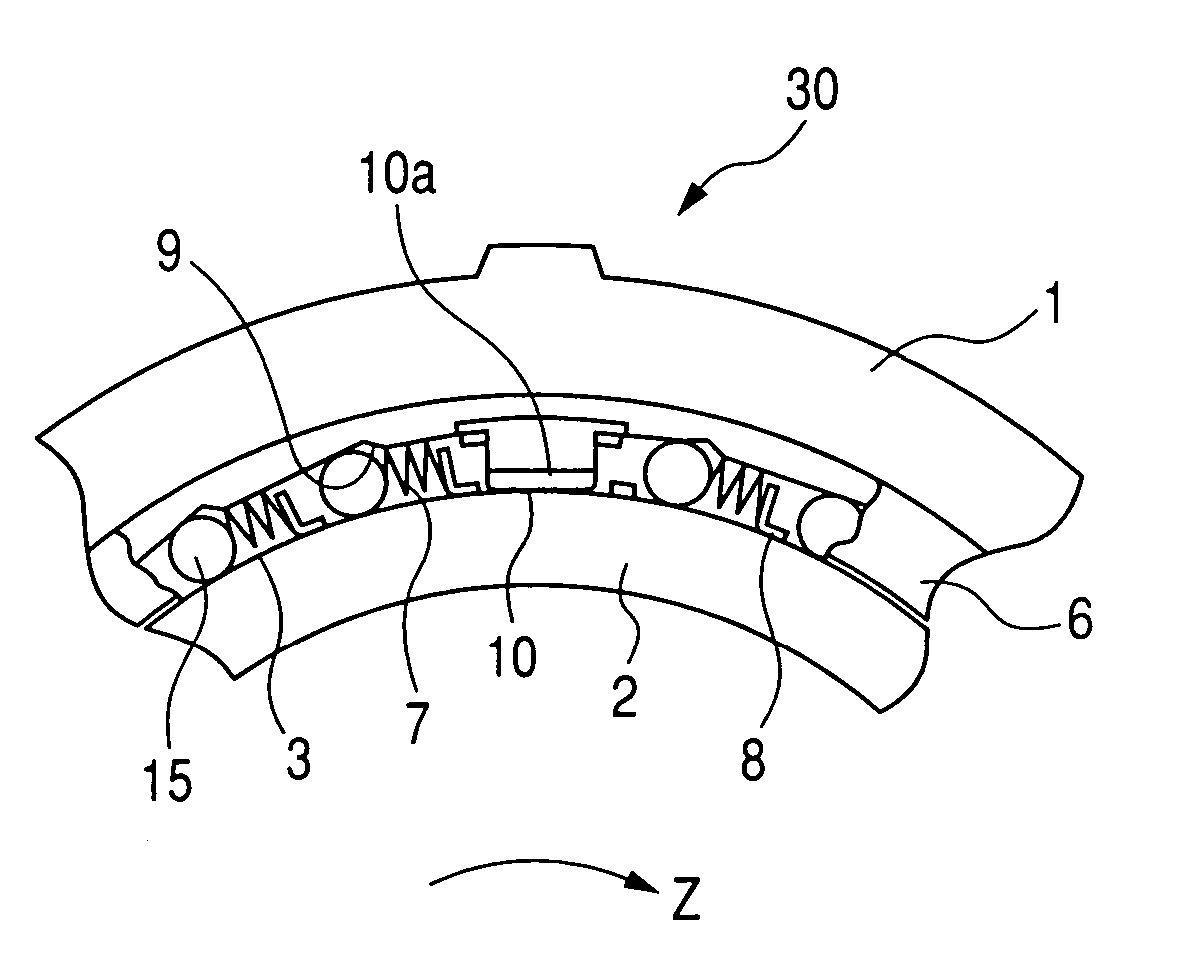

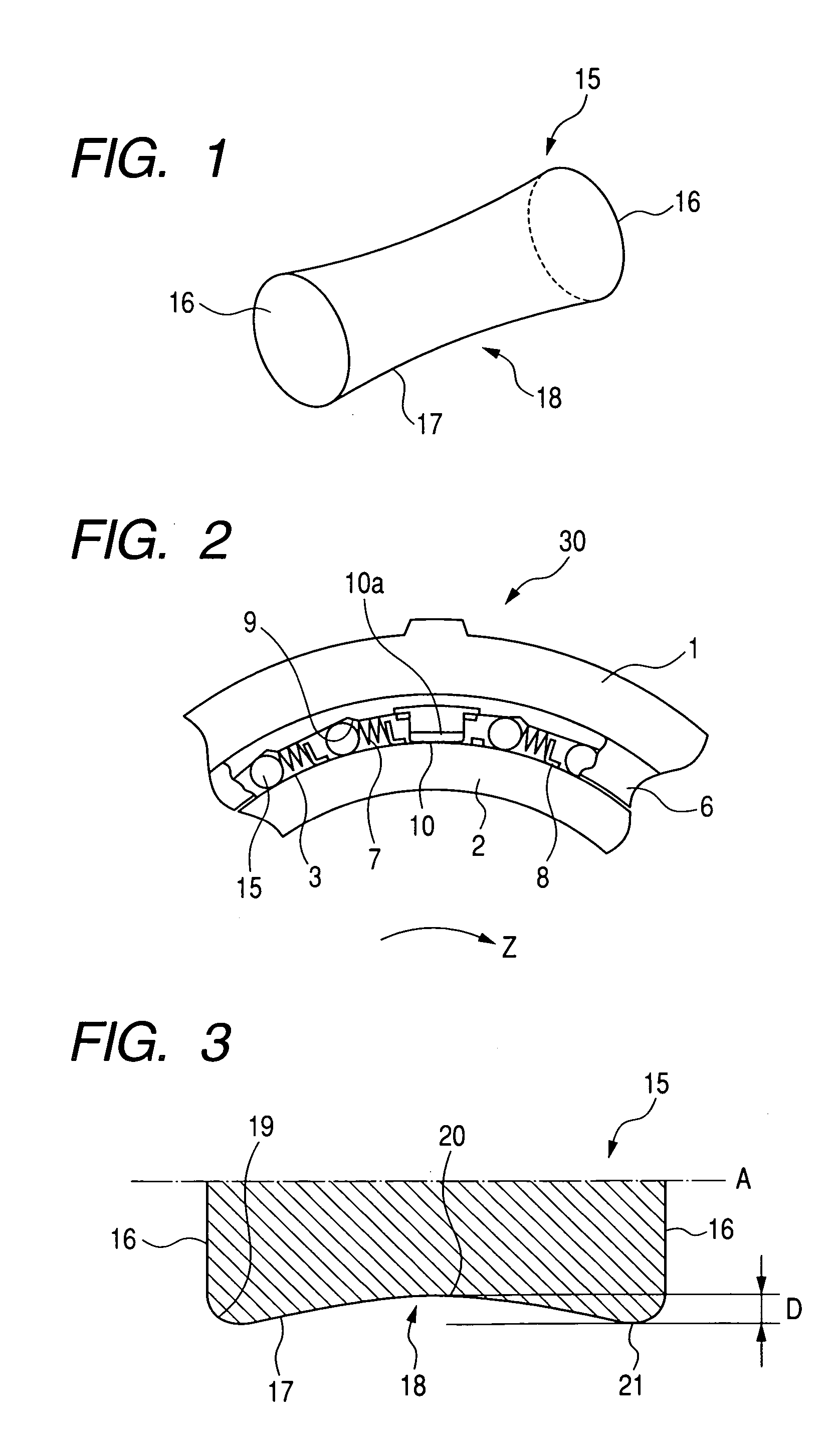

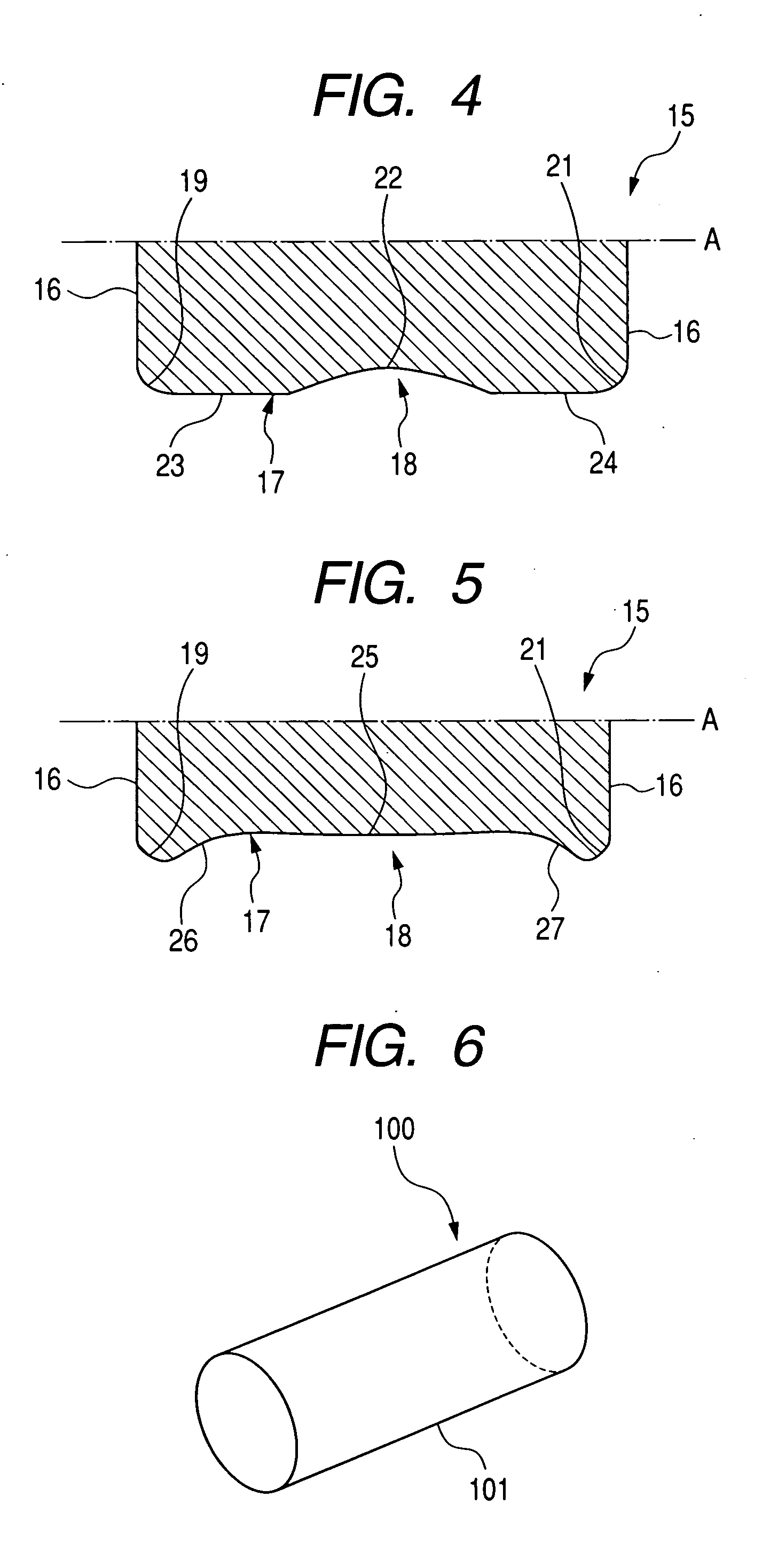

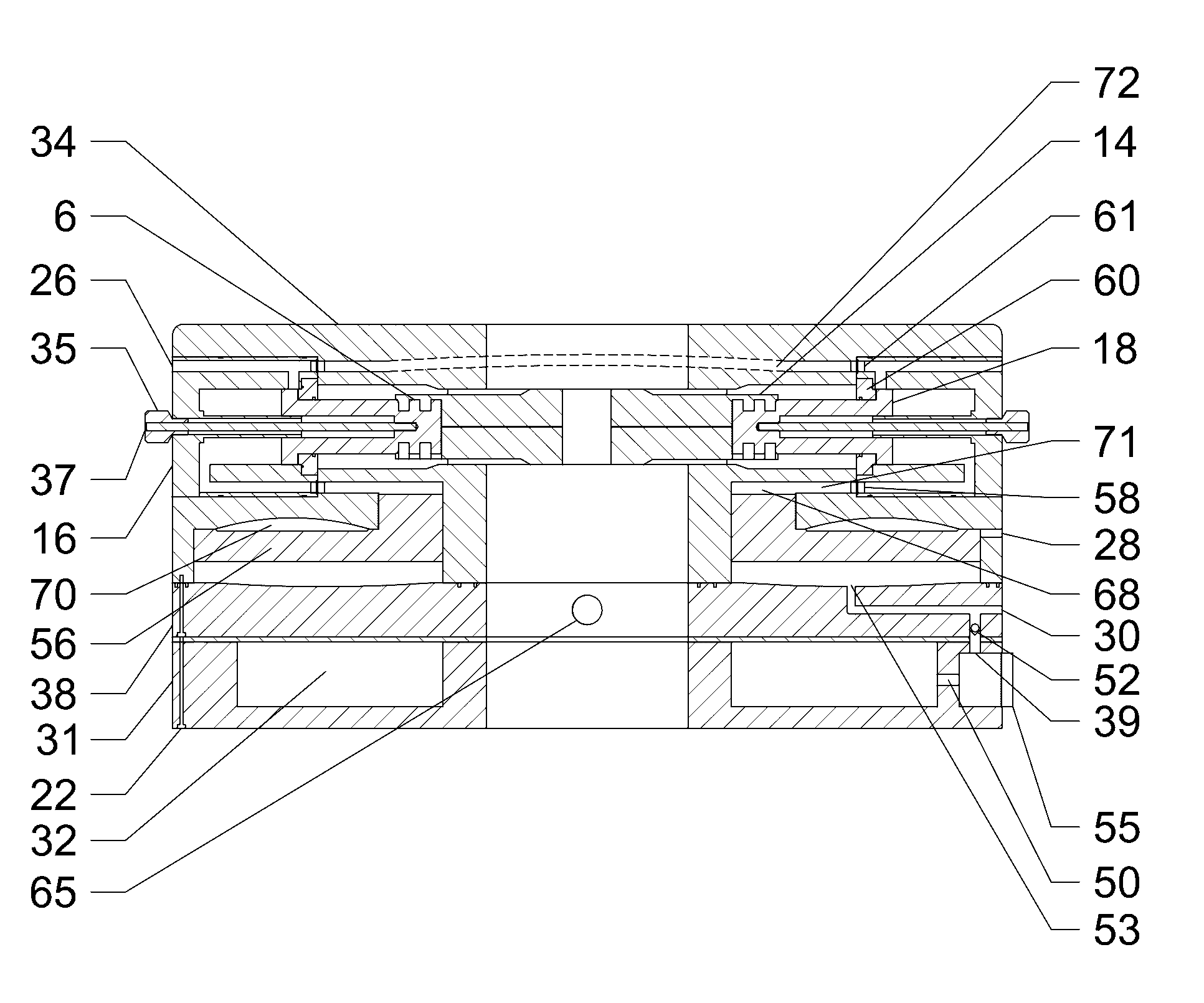

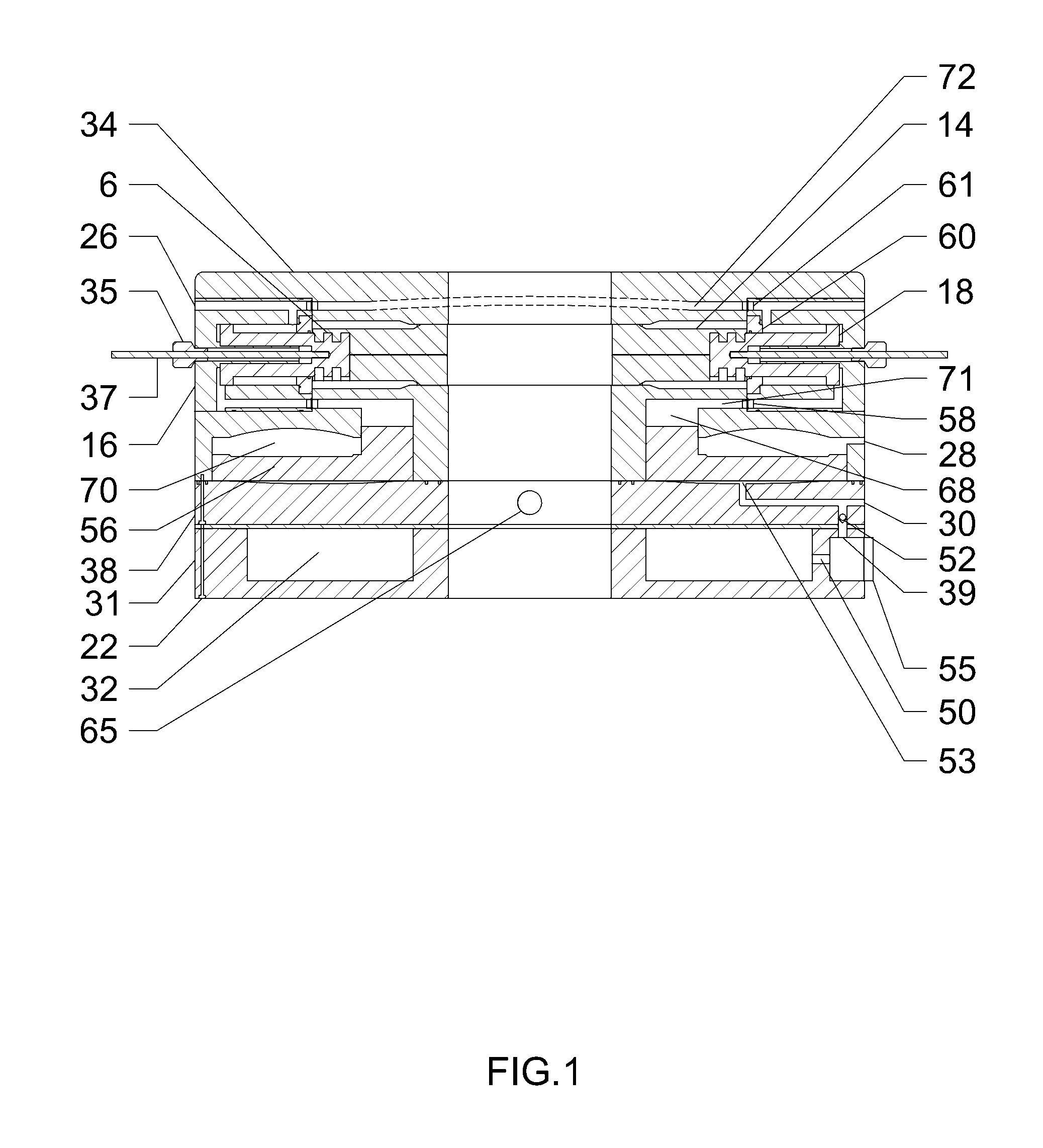

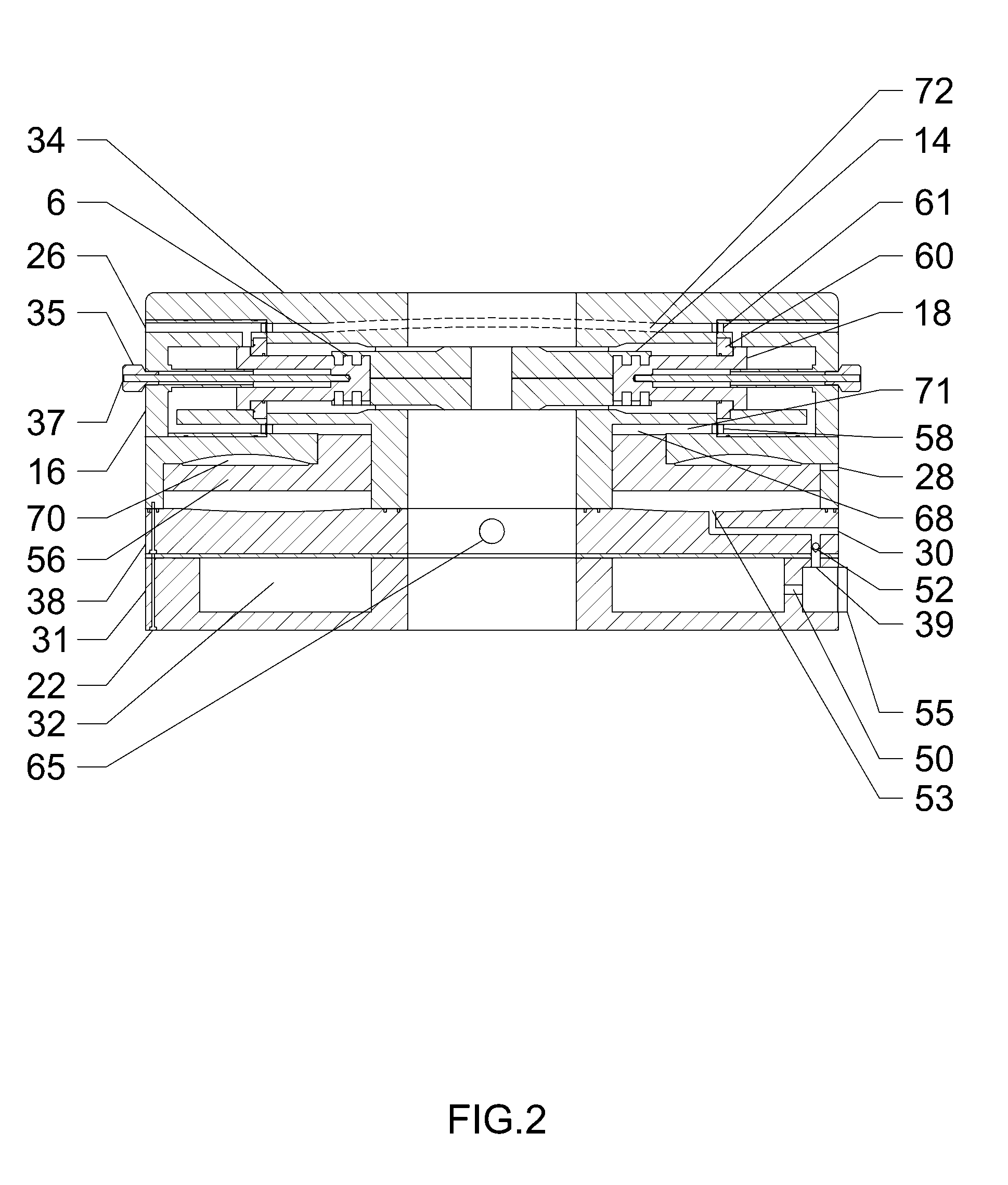

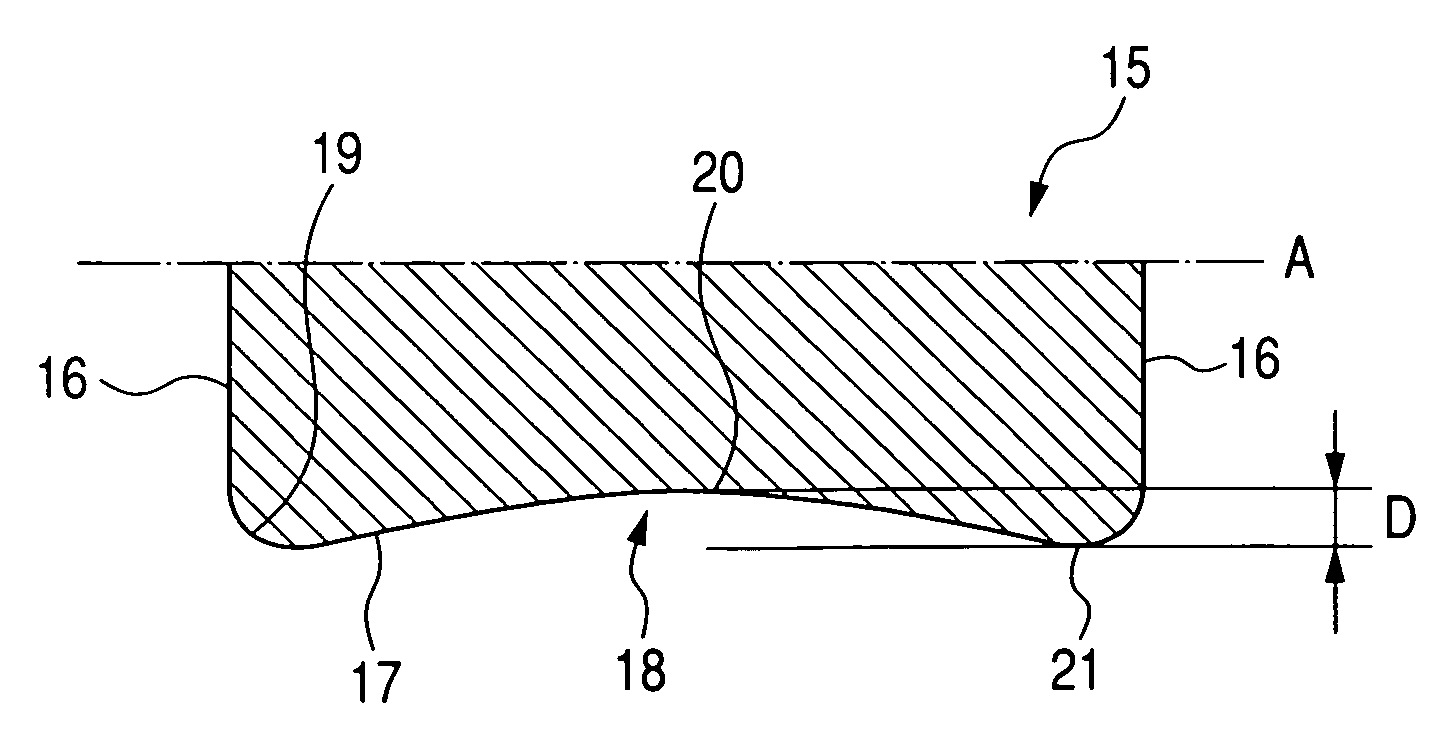

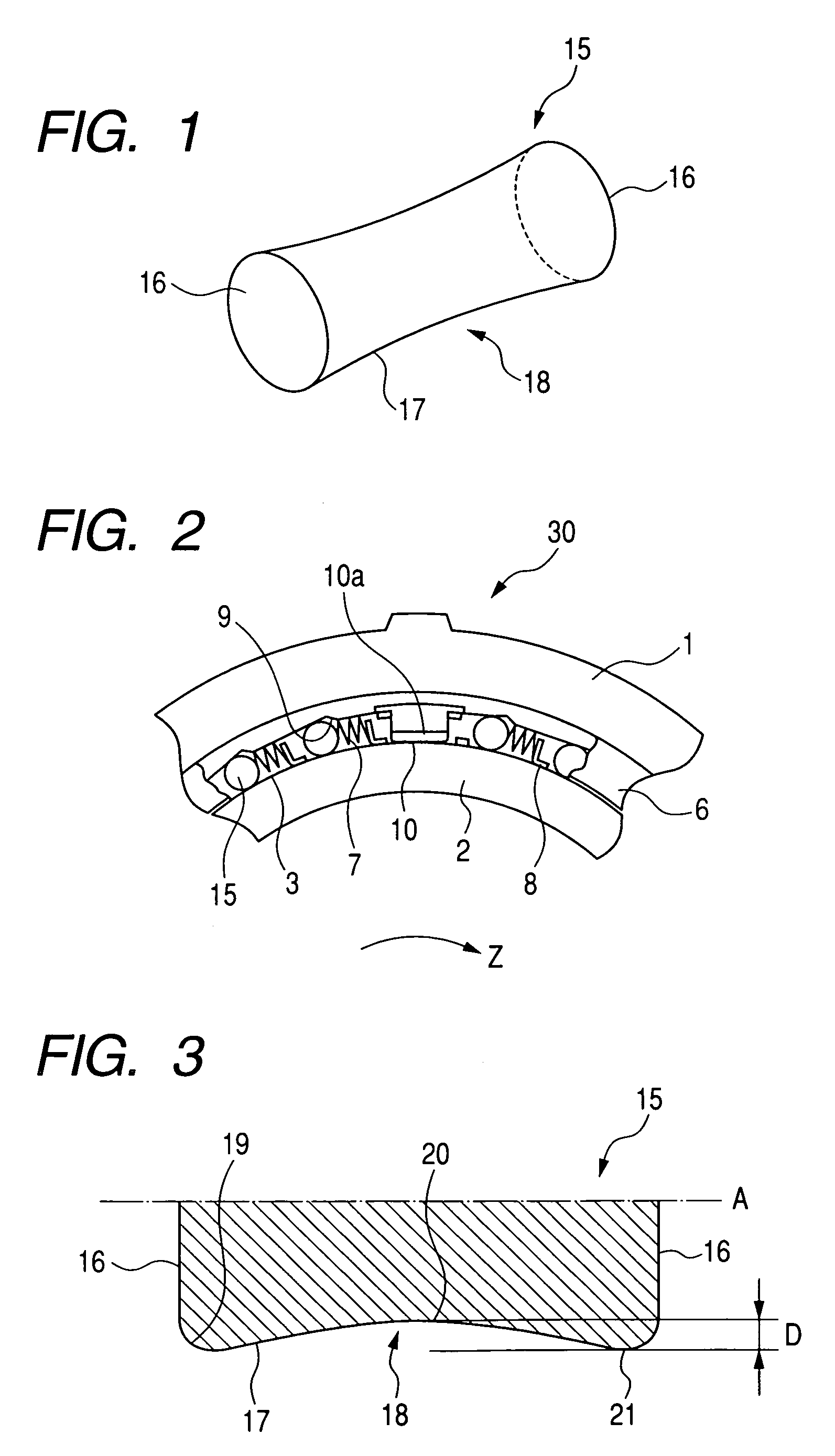

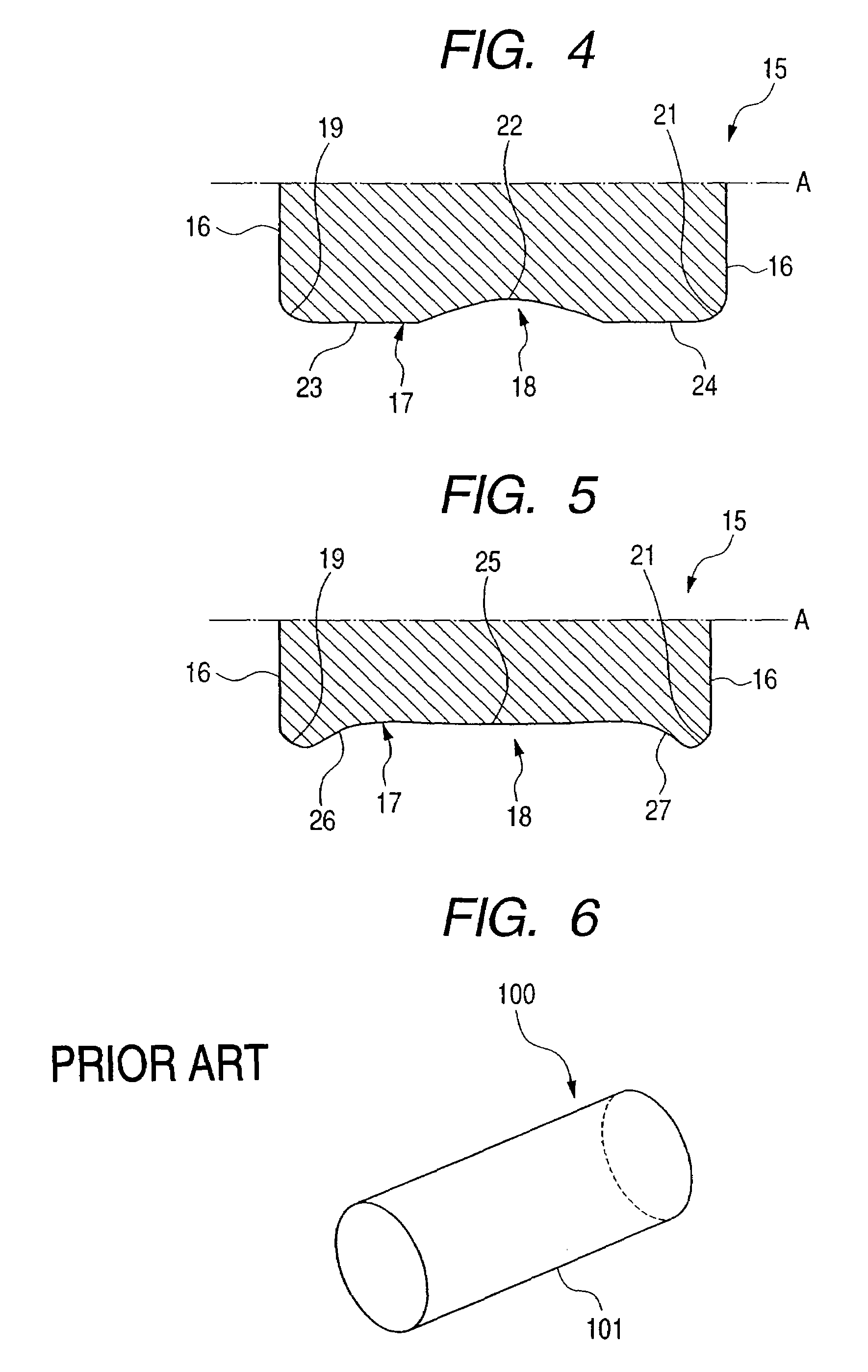

Roller type one-way clutch and roller for the roller type one-way clutch

ActiveUS20050284720A1FunctionalIncreased durabilityFriction clutchesAutomatic clutchesEngineeringCam

A roller type one-way clutch comprising an outer ring and an inner ring radially spaced apart from each other and disposed concentrically with each other for rotation relative to each other, the outer ring having an axially extending annular inner peripheral cam surface, the inner ring being disposed in the outer ring and having an annular outer peripheral raceway surface, and a plurality of rollers disposed between the outer ring and the inner ring for transmitting torque between the outer peripheral raceway surface and the inner peripheral cam surface is characterized in that the rolling surface of each of the rollers has a recess depressed toward the axis thereof over the entire circumference thereof. Also, a roller type one-way clutch comprising an outer ring and an inner ring radially spaced apart from each other and disposed concentrically with each other for rotation relative to each other, the outer ring having an axially extending annular inner peripheral raceway surface, the inner ring being disposed in the outer ring and having an annular outer peripheral cam surface, and a plurality of rollers disposed between the outer ring and inner ring for transmitting torque between the inner peripheral raceway surface and the outer peripheral cam surface is characterized in that the rolling surface of each of the rollers has a recess depressed toward the axis thereof over the entire circumference thereof.

Owner:NSK WARNER

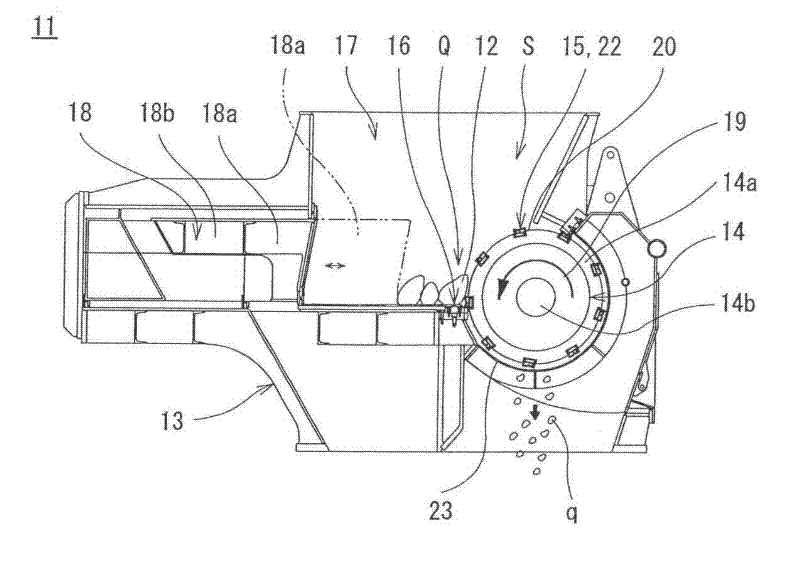

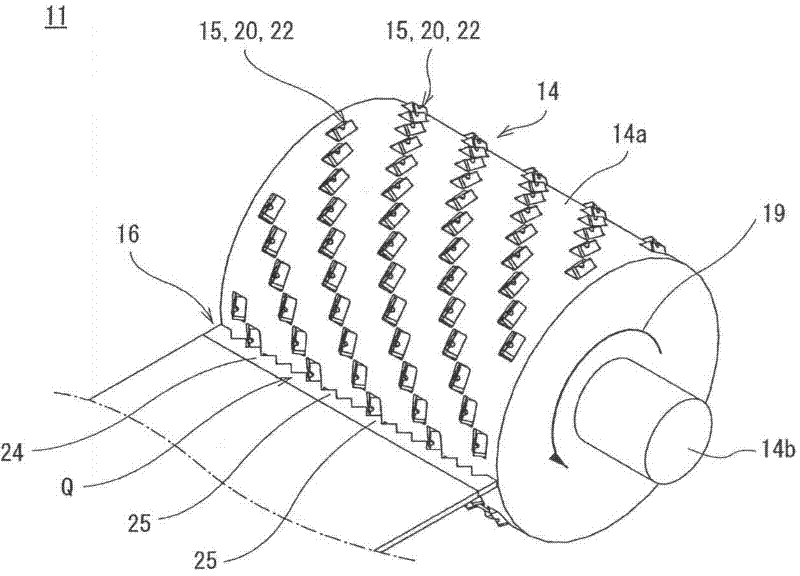

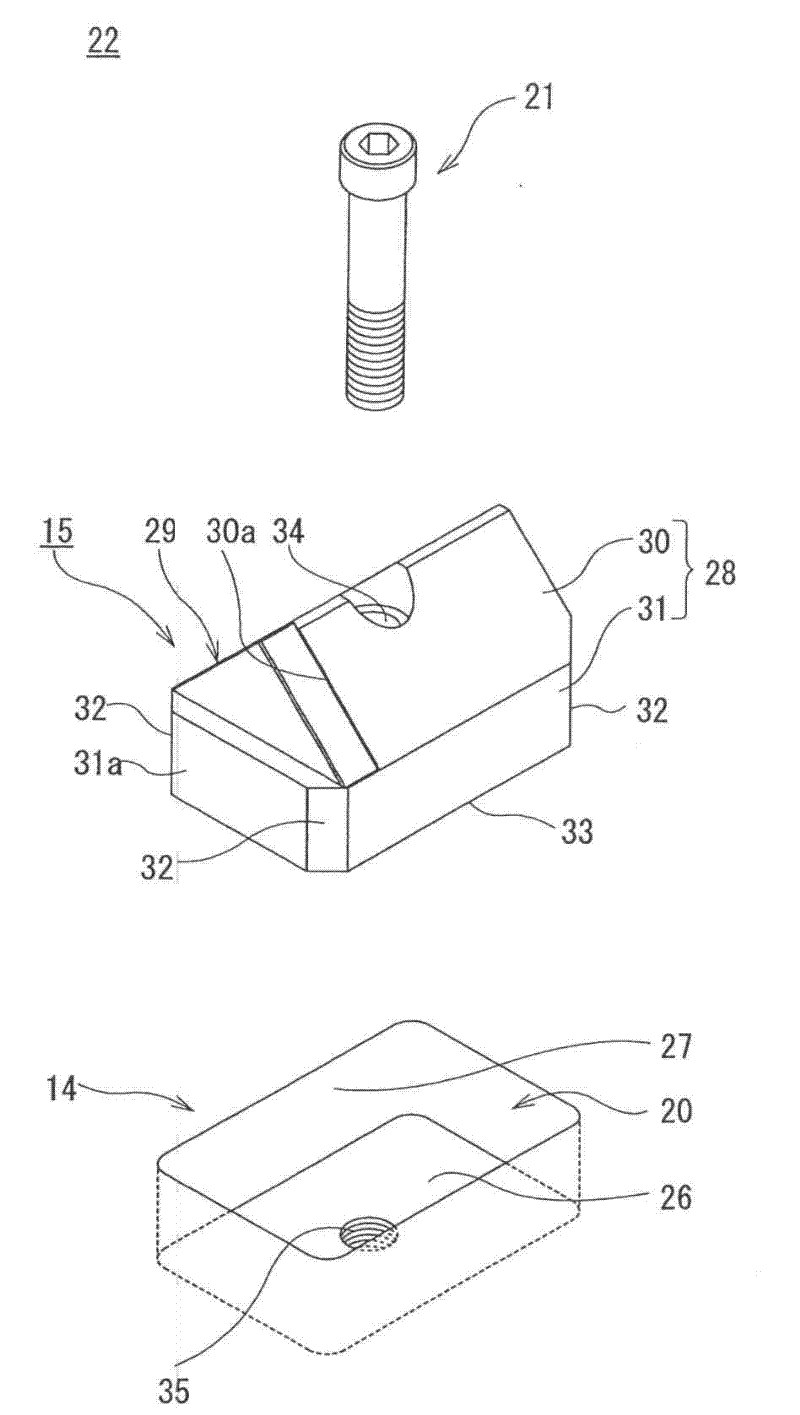

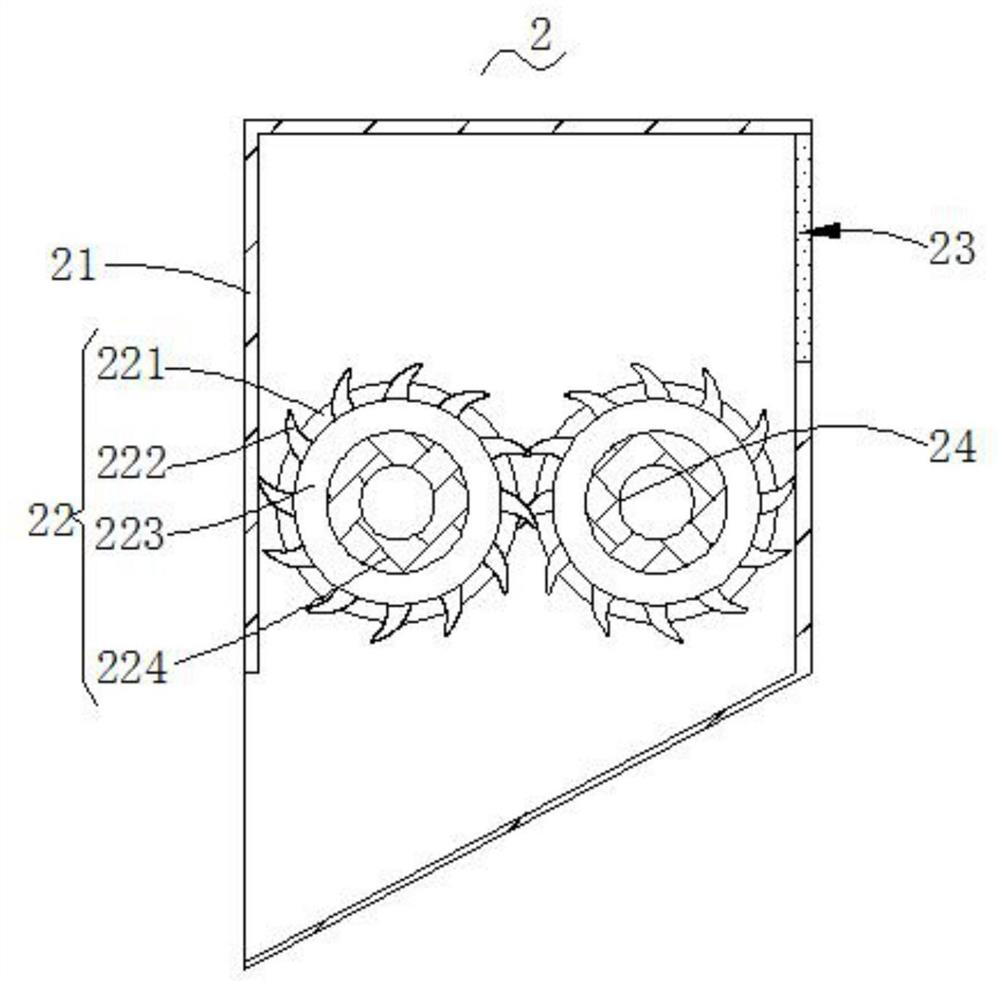

Rotary cutting edge mounting structure for crusher and crusher using such mounting structure

The invention provides a rotary cutting edge mounting structure for crusher and a crusher using such mounting structure, wherein the cutting edge portion is produced with a small size to improve the utilization ratio of resources, reduce the material cost of the cutting edge portion and allow the rotary cutting edge to be mounted on a rotor detachably conveniently. The crusher comprises a rotary rotor, a plurality of rotary cutting edges mounted on the surface of the rotor, and fixed cutting edges arranged on a housing to shear and crusher the crushed material between the rotary cutting edges, wherein the rotary cutting edge mounting structure for crusher comprises a plurality of mounting grooves processed on the surface of the rotor and provided with an even surface on bottoms thereof, wherein the rotary cutting edges are mounted on the inner side of the mounting grooves; the bottom surfaces of the rotary cutting edges are formed as even surfaces, and the rotary cutting edges are provided with a cutting edge portion for shearing and crushing the material to be crushed; the cutting edge portions are substantially triangle-shaped on front side faces formed as front sides thereof relative to the rotating direction of the rotary cutting edges.

Owner:KINKI KK

Forming method for large aluminum alloy die-casting fitting

The invention discloses a forming method for a large aluminum alloy die-casting fitting. First, an upper die forming region is machined on an upper die, and a low die forming region is machined on a lower die; an auxiliary cavity is machined in the position, corresponding to the lower exposed face of the die-casting fitting, of the parting face of the lower die, and an auxiliary ejector rod is arranged in the auxiliary cavity; when the upper die and the lower die are closed, the upper die forming region and the lower die forming region jointly construct a cavity of a die-casting die, a die-casting fitting is formed inside the cavity, and an auxiliary forming portion connected with the edge of the die-casting fitting is formed inside the auxiliary cavity; then, an ejector rod arranged on the lower die and the auxiliary ejector rod push the die-casting fitting and the auxiliary forming portion to move together, so that the die-casting fitting is separated from a cavity core; the die-casting fitting with the auxiliary forming portion is taken down, and the complete die-casting fitting can be obtained after the auxiliary forming portion is removed through a cutting device. The unbalanced stress when the product is ejected out can be effectively improved, in this way, deformation generated when the product is ejected out is avoided, and the forming quality of the large die-casting fitting is easily improved.

Owner:宁波环亚机械制造有限公司

Intensifier ram blowout preventer

InactiveUS9551200B2Reduce mass and footprintReducing mass and footprintFluid-pressure convertersSealing/packingPistonSupercharger

An apparatus for containing pressure associated with a well includes a ram fluid chamber, a ram piston, and an intensifier piston within a housing. The ram piston has ends associated with a ram and with the ram fluid chamber. The intensifier piston has ends associated with the ram fluid chamber and a fluid source. The end of the intensifier piston associated with the fluid source has a larger surface area than the end associated with the ram fluid chamber. Fluid from the fluid source applies a first pressure to the second end of the intensifier piston to move the intensifier piston. Movement of the intensifier piston applies a second pressure greater than the first pressure to fluid in the ram fluid chamber to move the ram piston and associated ram toward a closed position.

Owner:BOP TECH

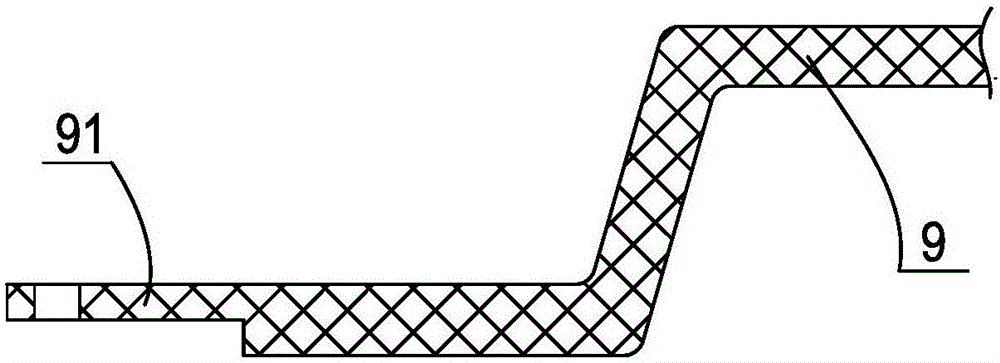

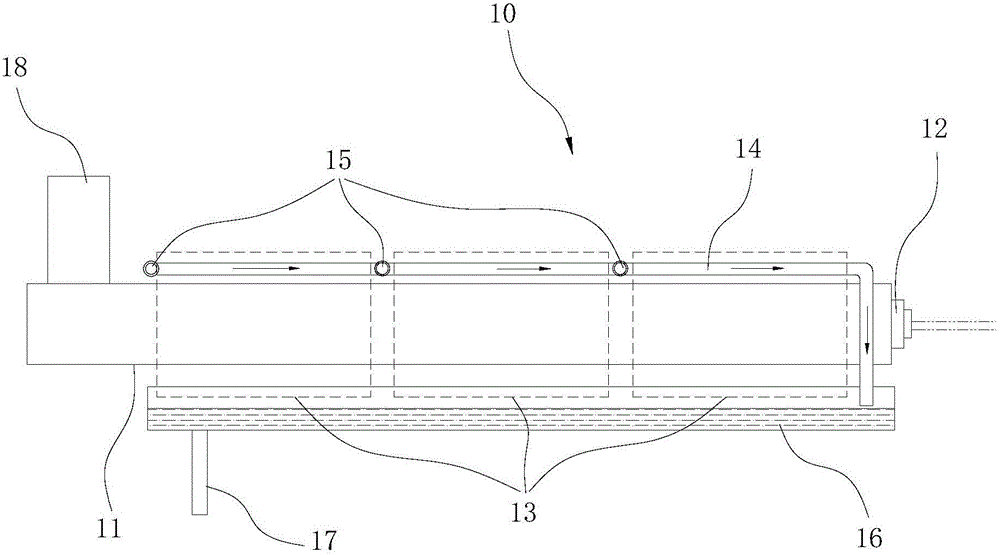

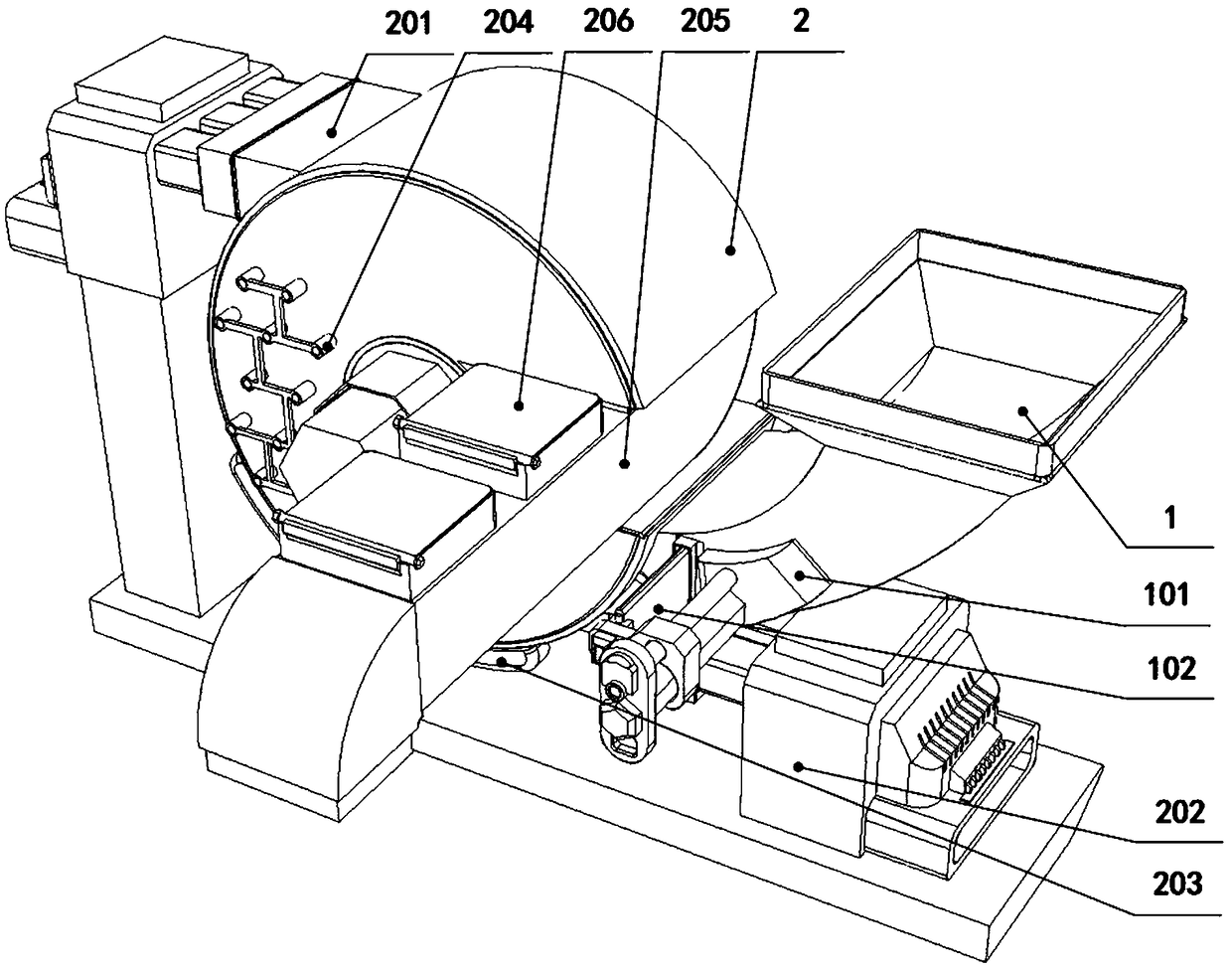

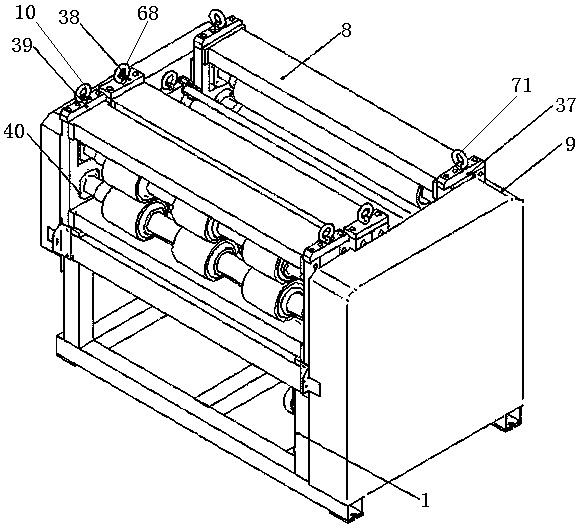

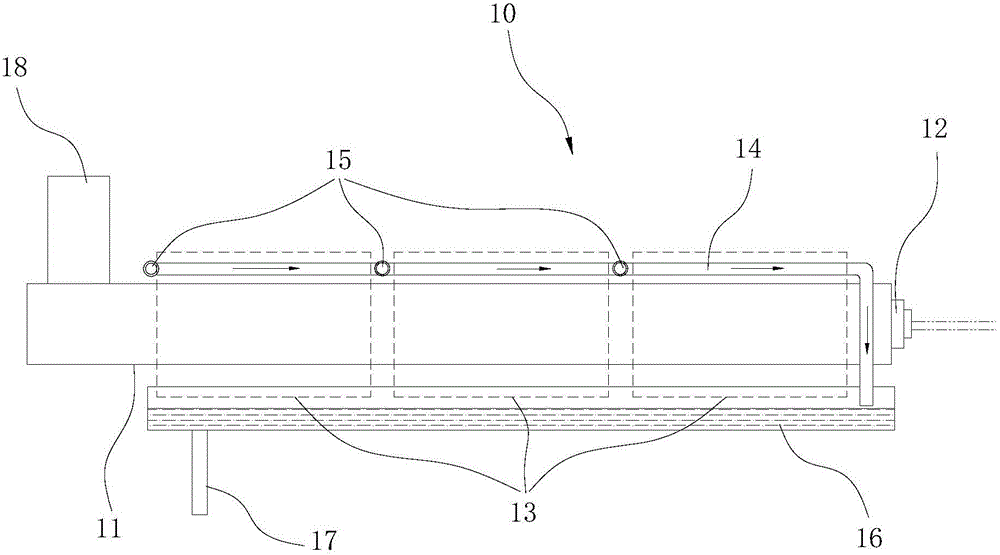

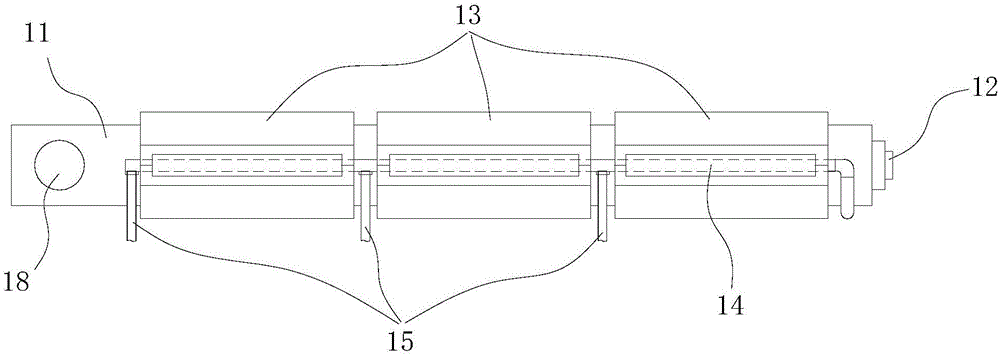

Cooling, conveying and cutting device for eraser strip

ActiveCN106079367ARapid cooling and solidificationEfficient shearingMetal working apparatusEngineeringMechanical engineering

The invention belongs to the field of eraser production and processing and particularly relates to a cooling, conveying and cutting device for an eraser strip. The cooling, conveying and cutting device comprises a cooling water tank and a cutting device body, wherein the cooling water tank is arranged along an extrusion opening of an extruder in an extension mode and filled with cooling water; the eraser strip extruded by the extruder enters the cooling water tank, so that cooling and hardening of the eraser strip are accelerated; after being cooled in the cooling water tank, the eraser strip enters the cutting device body; the cutting device body comprises a fodder chopper and an intermittent feeding mechanism; the fodder chopper moves back and forth in the vertical direction and is matched with a workbench to do a shearing action for cutting the eraser strip; and the intermittent feeding mechanism can convey the eraser strip to the position below the fodder chopper in an intermittent mode, specifically, when the fodder chopper is lifted, the eraser strip is fed forwards, and when the fodder chopper falls, the eraser strip is stopped being fed. According to the cooling, conveying and cutting device for the eraser strip, the extruded eraser strip can be rapidly cooled and cured through the cooling water tank, and deformation is prevented; and the eraser strip can be efficiently sheared through the cutting device body, so that breaking or stacking of the eraser strip is prevented.

Owner:宿州市超晟文具有限公司

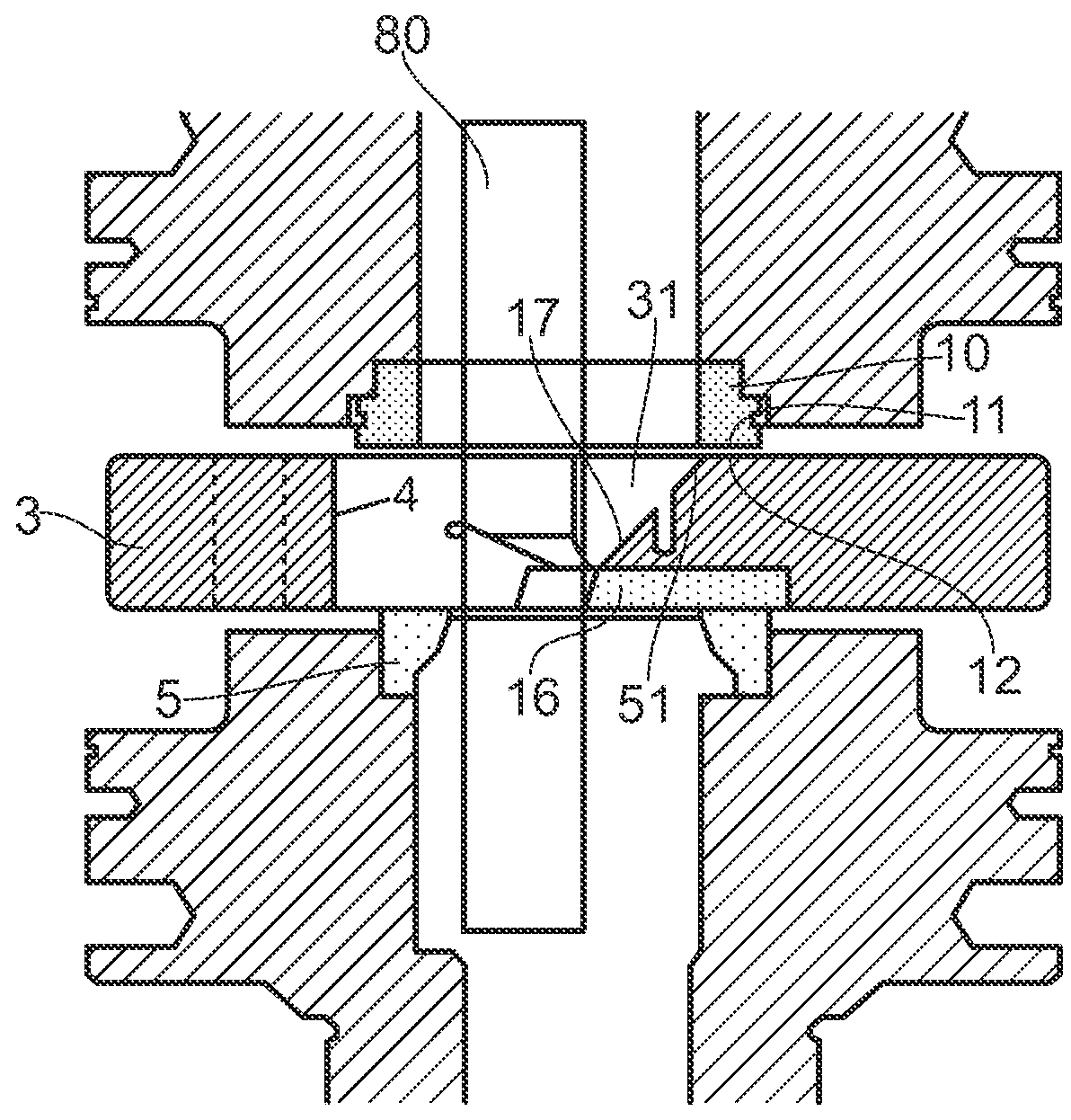

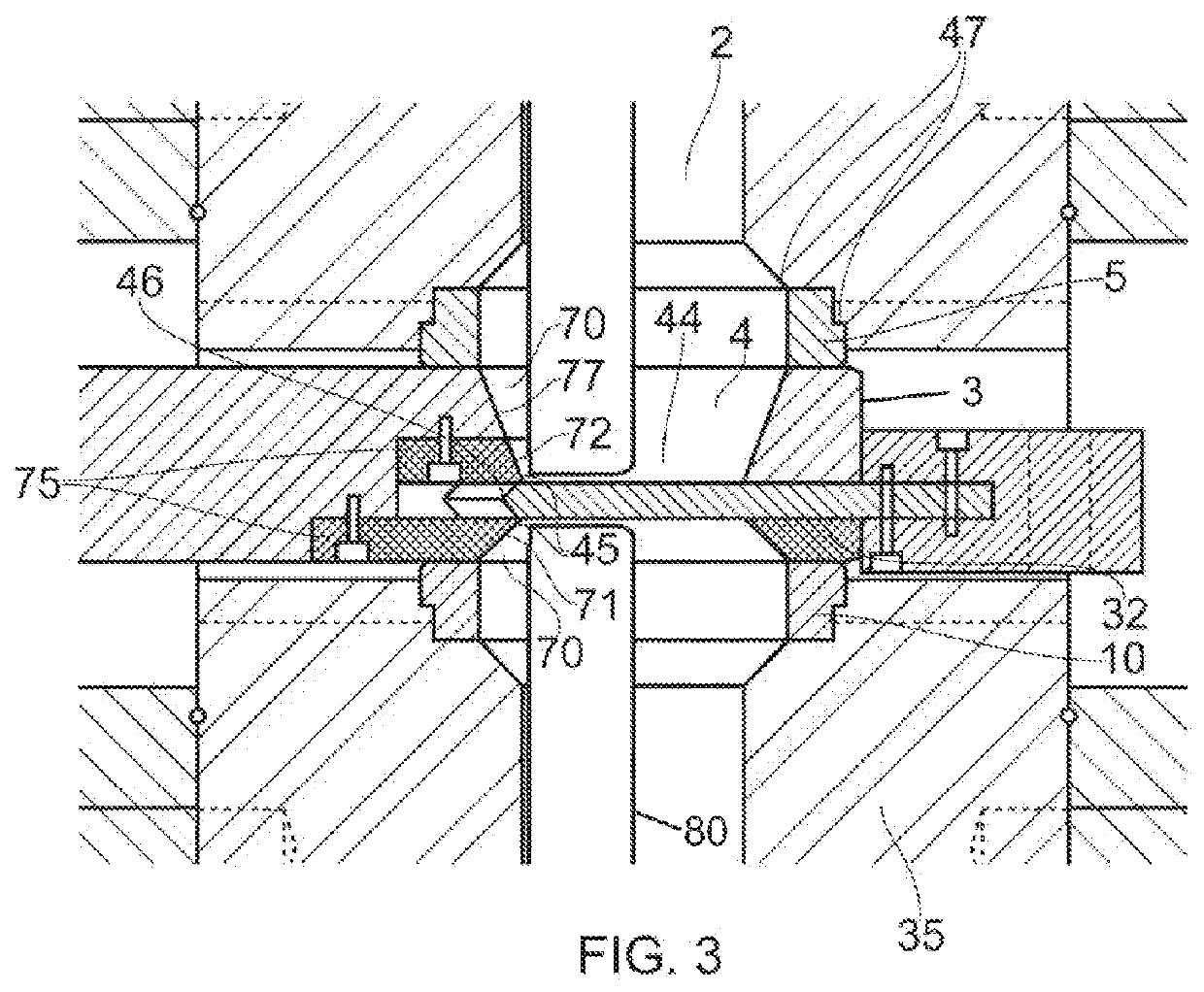

Gate valve assembly comprising a support member

InactiveUS20160032676A1Reliable working principleSimple operationFluid removalWell/borehole valve arrangementsGate valve

A gate valve assembly having a through bore adapted for fluid communication with a well bore and prepared for receiving an elongated member. The gate valve assembly comprises a gate element which is movably arranged in a gate valve housing, wherein the gate element has a gate bore arranged for receiving the elongated member, wherein a cutting tool is arranged in the gate bore first and second seats, wherein at least one of the first or second seat is arranged to provide sealing contact with a sealing surface of the gate element. A support member arranged with an opening encompassing the through bore and an expanded opening portion which is open to the through bore in the axial direction of the through bore, wherein a reduced section of the support member defines the expanded opening portion, and the opening has a decreasing radius along the reduced section in the axial direction of the support member toward a contact surface area arranged at an end portion of the support member adjacent the cutting tool, wherein the radius of the opening corresponds essentially to the radius of the through bore. The contact surface area is prepared for engagement with the elongated member and provides a counter acting area interacting with the cutting tool when shearing the elongated member. The invention also includes a method.

Owner:FMC TECH INC

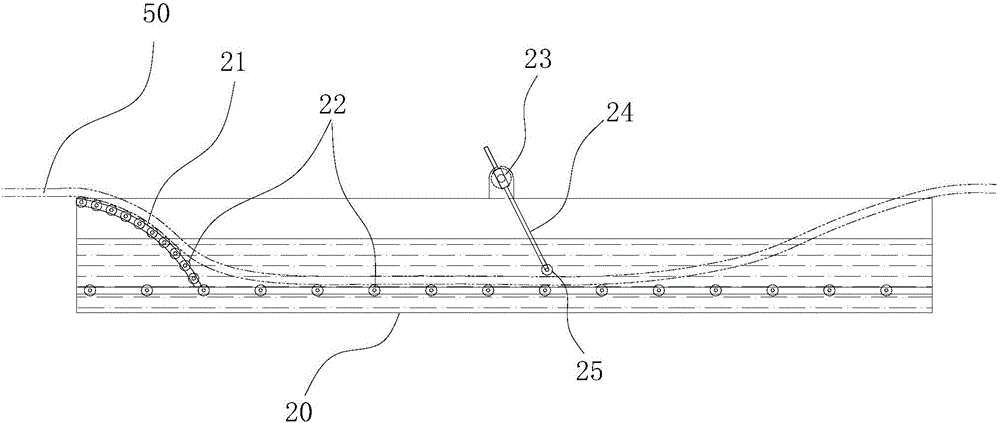

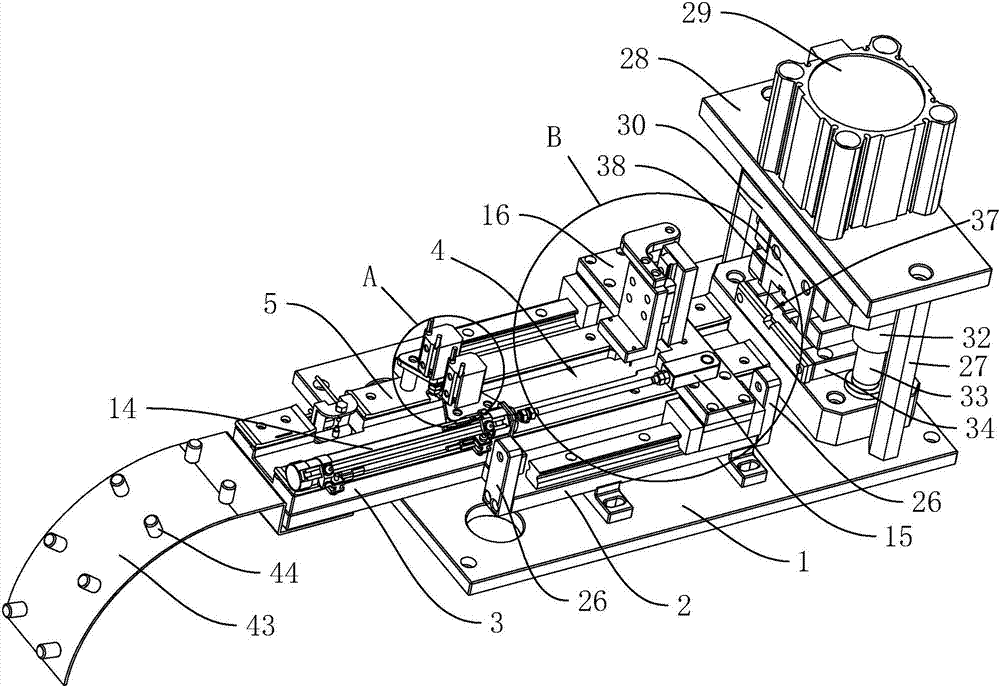

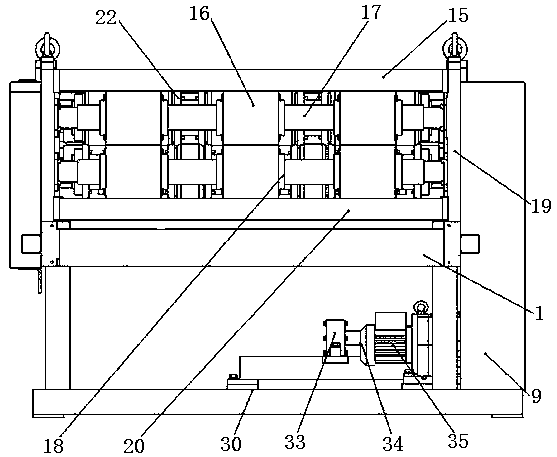

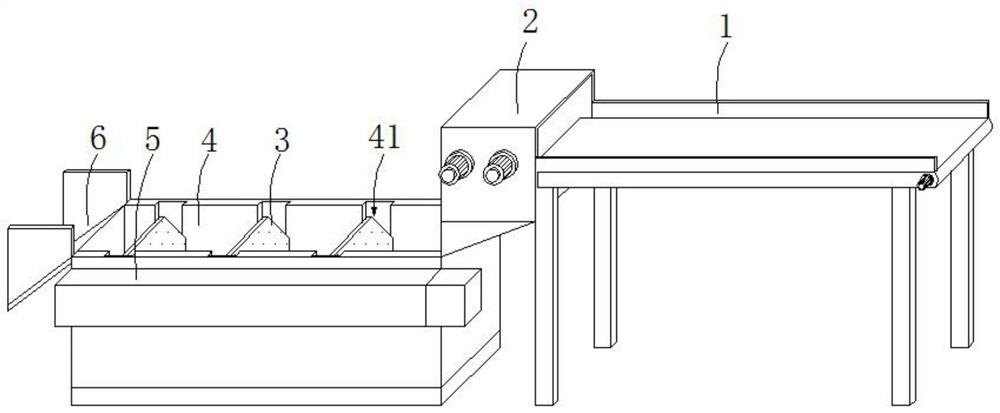

Automatic feeding and cut-off machine for material belts

ActiveCN107571298APrevent movementLess prone to errorsMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic feeding and cut-off machine for material belts. The problems of low shearing efficiency and large shearing error of an existing material belt during shearing are solved. According to the technical scheme, the automatic feeding and cut-off machine for the material belts comprises a baseplate, and the upper surface of the baseplate is fixedly provided with a fixed plate; the upper surface of the fixed plate is fixedly provided with guide plates, and the middle positions of the upper surfaces of the guide plates are provided with stepped grooves arranged in the length direction of the guide plates; the guide plates on both sides of the stepped grooves are also fixedly provided with batten plates of which both ends are upturned, and a pressing device and afeeding device are arranged above the batten plates in sequence; and the baseplate is also fixedly provided with a shearing device used for shearing the material belts following the feeding device. The automatic feeding and cut-off machine disclosed by the invention is rational in structure, and the material belts are prevented from shifting through the pressing device; the accurate feeding of thematerial belts is ensured through the feeding device, and then the material belts are sheared accurately through the shearing device, so that the shearing efficiency of the material belts is high, and the shearing error of the material belts is small.

Owner:平湖市宇达精密机械有限公司

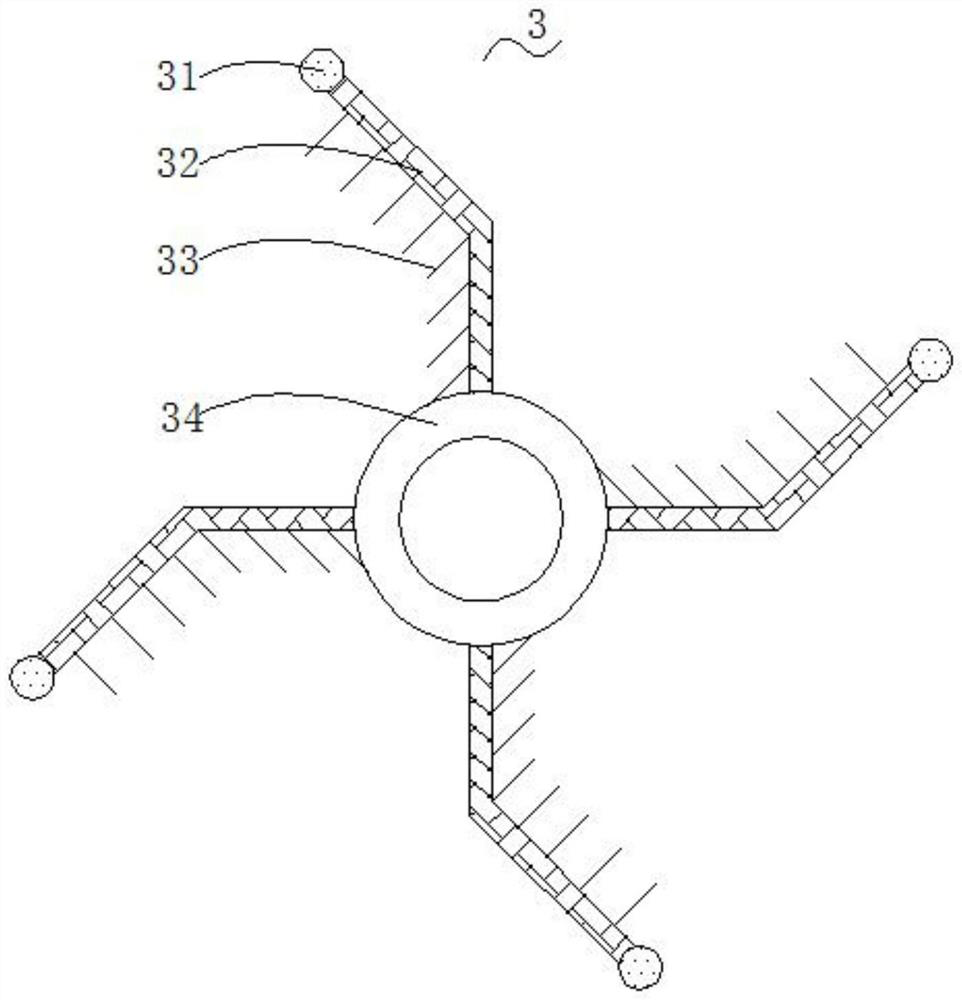

Jujube deep processing device

PendingCN109380681AWork without interruptionGuaranteed service lifeFruits/vegetable preservation by heatingFood dryingCooking & bakingMachine selection

The invention belongs to the technical field of agricultural equipment, in particular to a jujube deep processing device. The jujube deep processing device comprises a screening system, a chipping removing system, a graded slicing system, a scalding system, a cooling system and a baking system. The jujube raw material can be screened with high efficiency in a compound machine selection mode of airseparation and circulation filtration, and most impurities can be stripped out by screening and separation on the basis of difference in weight and size, work of subsequent equipment is prevented from being affected, and the service life of the equipment is ensured. With the compound chipping removal process of adhesion adsorption and electrostatic adsorption, fine impurities carried in the jujube raw material and on the surface of the jujubes can be removed completely, and the jujubes are continuously rolled in the chipping removal process, so that chipping removal is free of dead angle. Bythe process design of cleaning a chipping removing part in real time, the service life of the chipping removing system can be long enough, the shutdown maintenance frequency can be reduced, and the production cost can be saved.

Owner:SHANDONG AGRI & ENG UNIV

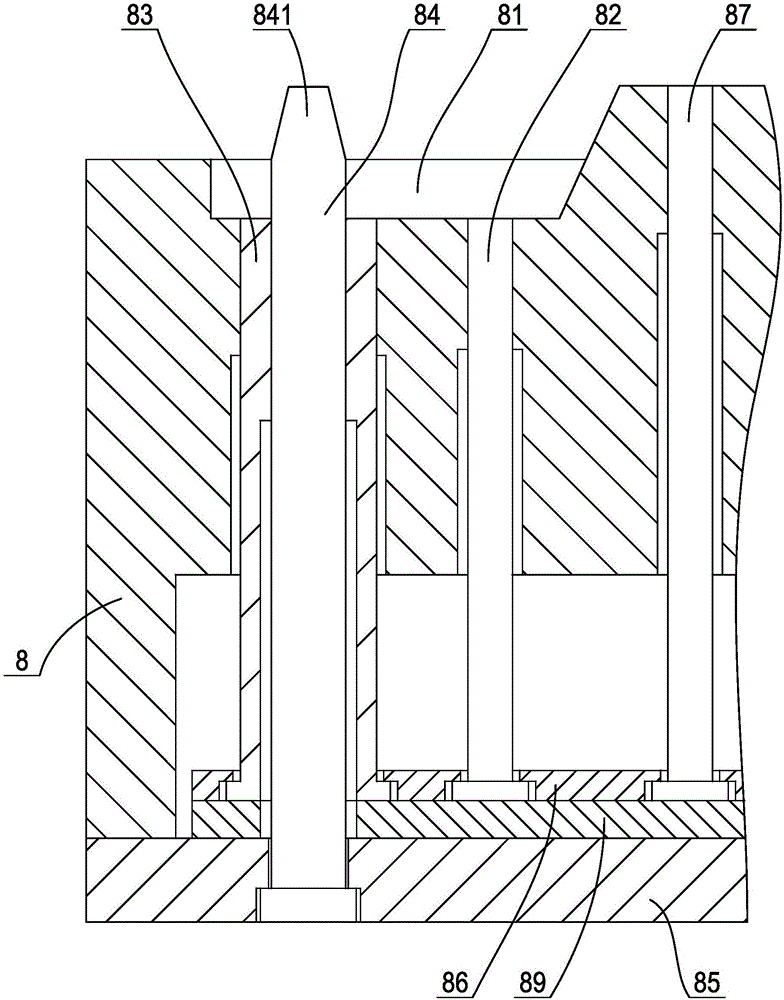

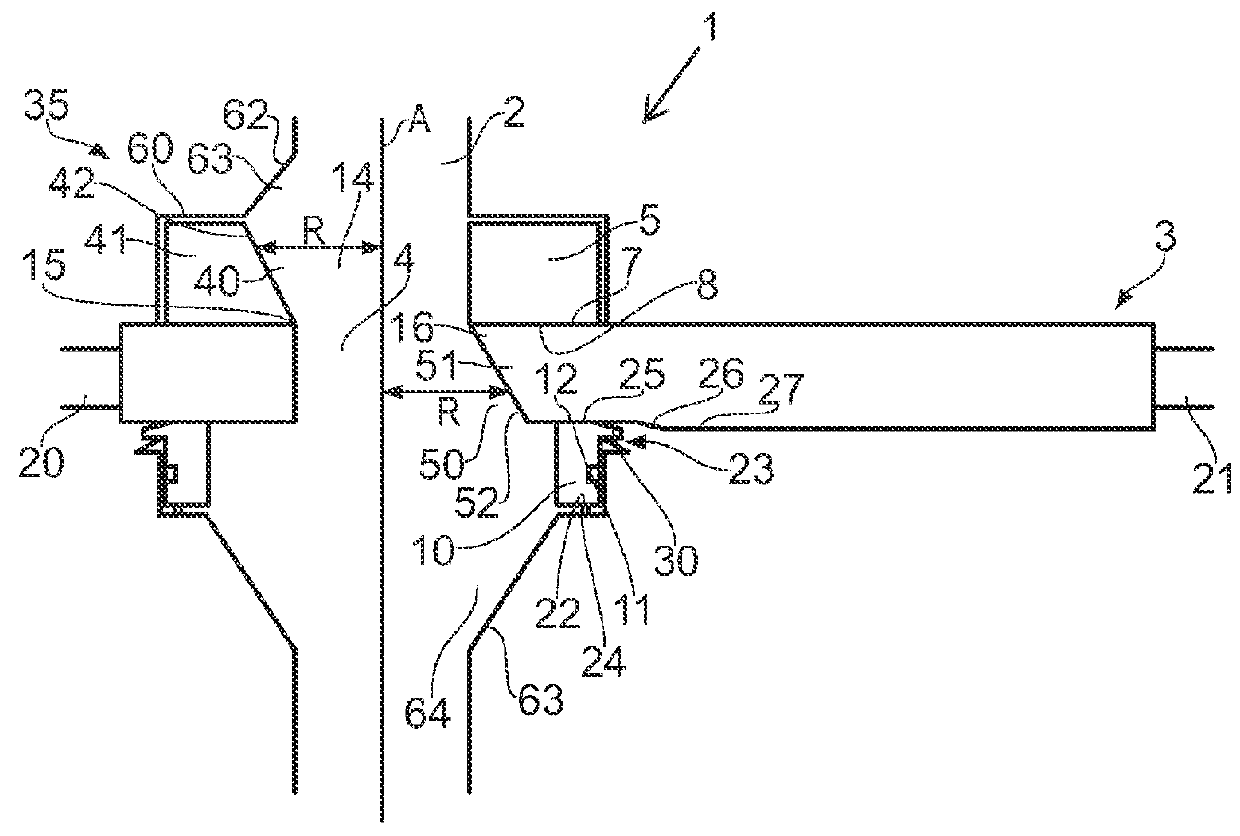

Device for blanking blanks of circular saw

InactiveCN101637830AEfficient shearingWon't changeShearing machinesShearing machine accessoriesAcute angleLow transmission

The invention provides a device for blanking blanks of a circular saw. The device comprises a rack, wherein, a rotary working table is arranged on the rack; a vertical regulating device and a horizontal regulating device are arranged on the rotary working table; a rotation driving device is mounted at the other end of the rack; the rotation driving device is connected with an upper shearing wheelof an upper tool apron via an upper transmission connecting rod; a lifting device is arranged at the upper part of the upper tool apron and connected with the upper tool apron; the rotation driving device is connected with a lower shearing wheel of a lower tool apron via a lower transmission connecting rod; the lower tool apron is fixedly connected with the rack; the upper shearing wheel is matched with the lower shearing wheel; and an acute angle is formed by projecting the axes of the upper shearing wheel and the lower shearing wheel onto a vertical plane. By dispensing with the procedures of annealing and roughing after blanking, the device provided by the invention can simplify the procedures for processing circular saw blades, improve the efficiency and save raw materials; and the processed blanks of the circular saw has the advantages of neat and smooth edges and high quality.

Owner:YICHANG DISEN MACHINERY

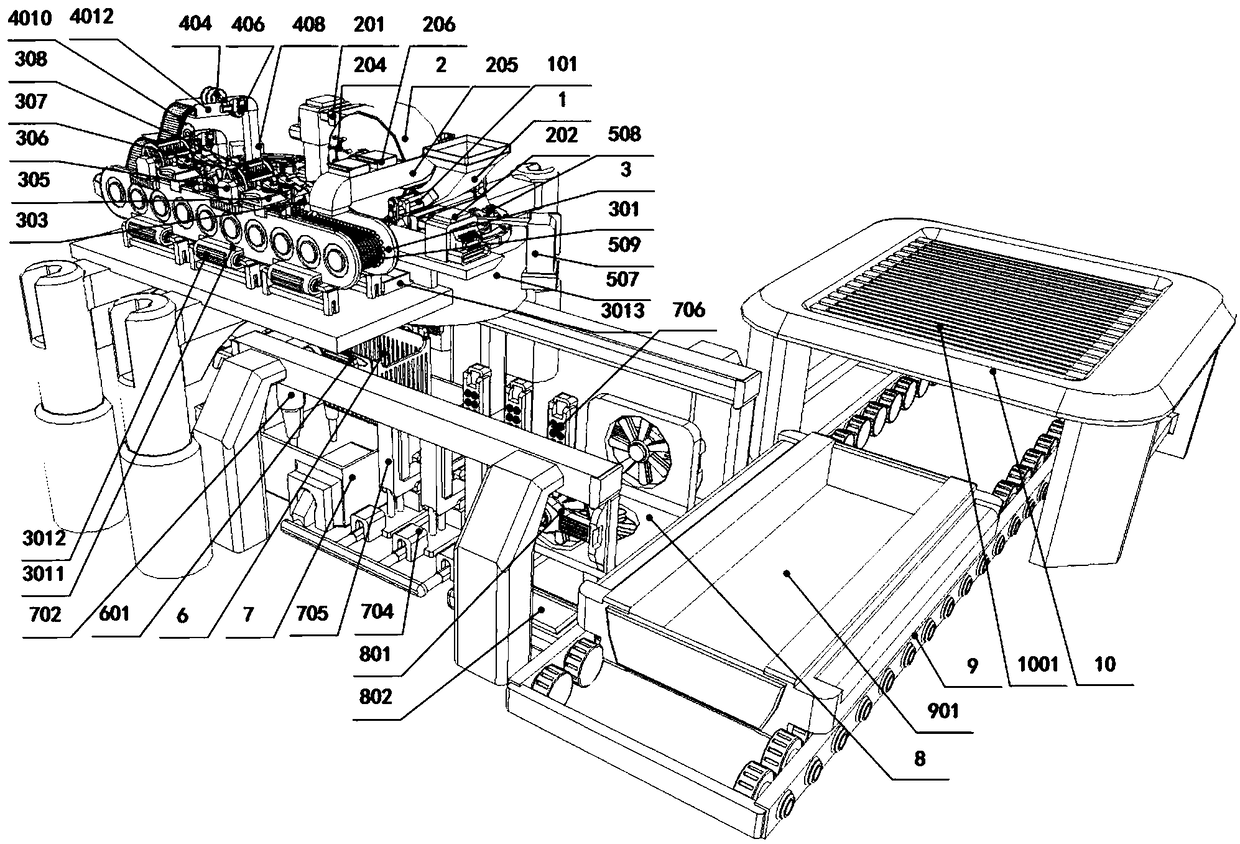

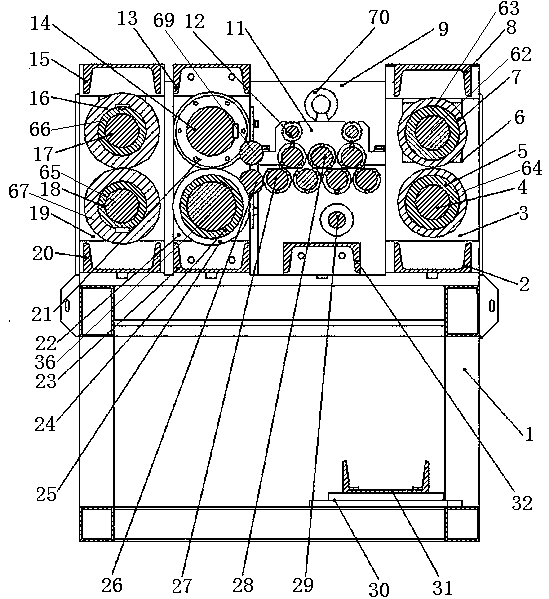

Copper lifting lug shearing and flattening device

PendingCN107791030AEfficient shearingShear leveling and high efficiencyShearing machinesOther manufacturing equipments/toolsModularityTransmission system

The invention discloses a copper lifting lug shearing and flattening device. The device mainly comprises a feeding module, a rolling and shearing strip module, a copper lifting lug straightening module, a flattening module and a transmission system. Power is transmitted to the feeding module, the rolling and shearing strip module, the copper lifting lug straightening module and the flattening module through the transmission system. A copper starting sheet can be effectively shorn into copper lifting lugs of certain specifications and sizes, and shaping of the copper lifting lugs is achieved; and the problems that at present, a tool rest is fractured, a blade is broken, and edges of copper lifting lugs deform and curl after shearing is completed are effectively solved. According to the copper lifting lug shearing and flattening device, modularized design is adopted; the copper lifting lug shearing and flattening device is compact in structure and high in reliability and modularization degree, feeding, shearing, straightening and flattening are integrated, and the copper lifting lugs can be shorn, straightened and flattened efficiently; production efficiency and production quality oflug pieces are greatly improved; all the modules are easy to demount, maintain and upgrade; and operating cost and time are saved for an enterprise.

Owner:JINCHUAN GROUP LIMITED

Roller type one-way clutch and roller for the roller type one-way clutch

A roller type one-way clutch includes an outer ring and an inner ring disposed concentrically with each other for rotation relative to each other, the outer ring having an axially extending annular inner peripheral cam surface, the inner ring being disposed in the outer ring and having an annular outer peripheral raceway surface, and a plurality of rollers disposed between the outer ring and the inner ring for transmitting torque between the outer peripheral raceway surface and the inner peripheral cam surface. The rolling surface of each of the rollers has a recess depressed toward the axis thereof over the entire circumference thereof. In an alternative arrangement, an axially extending annular inner peripheral raceway surface is provided on the outer ring and an annular outer peripheral cam surface is provided on the inner ring.

Owner:NSK WARNER

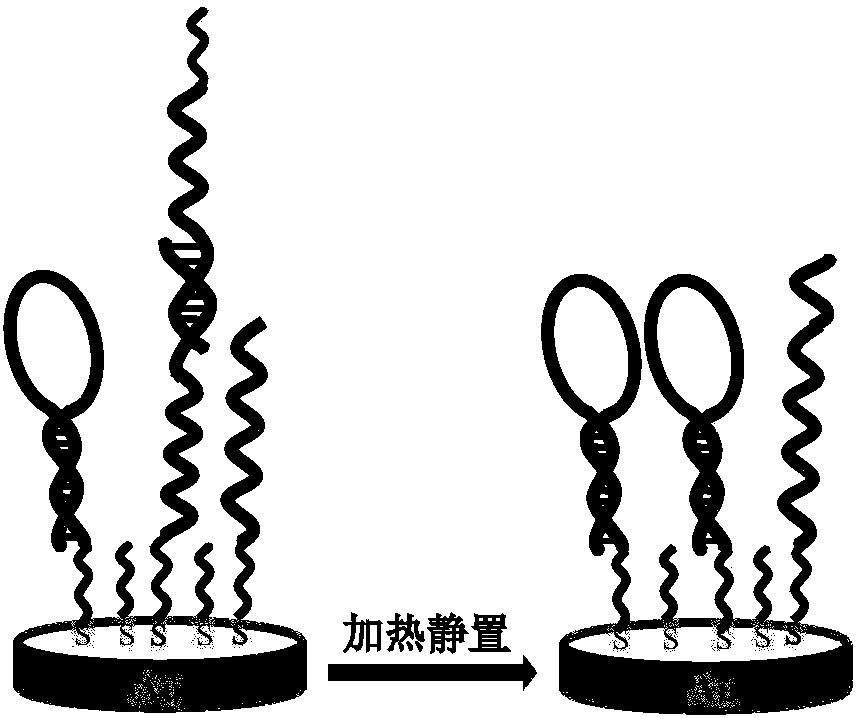

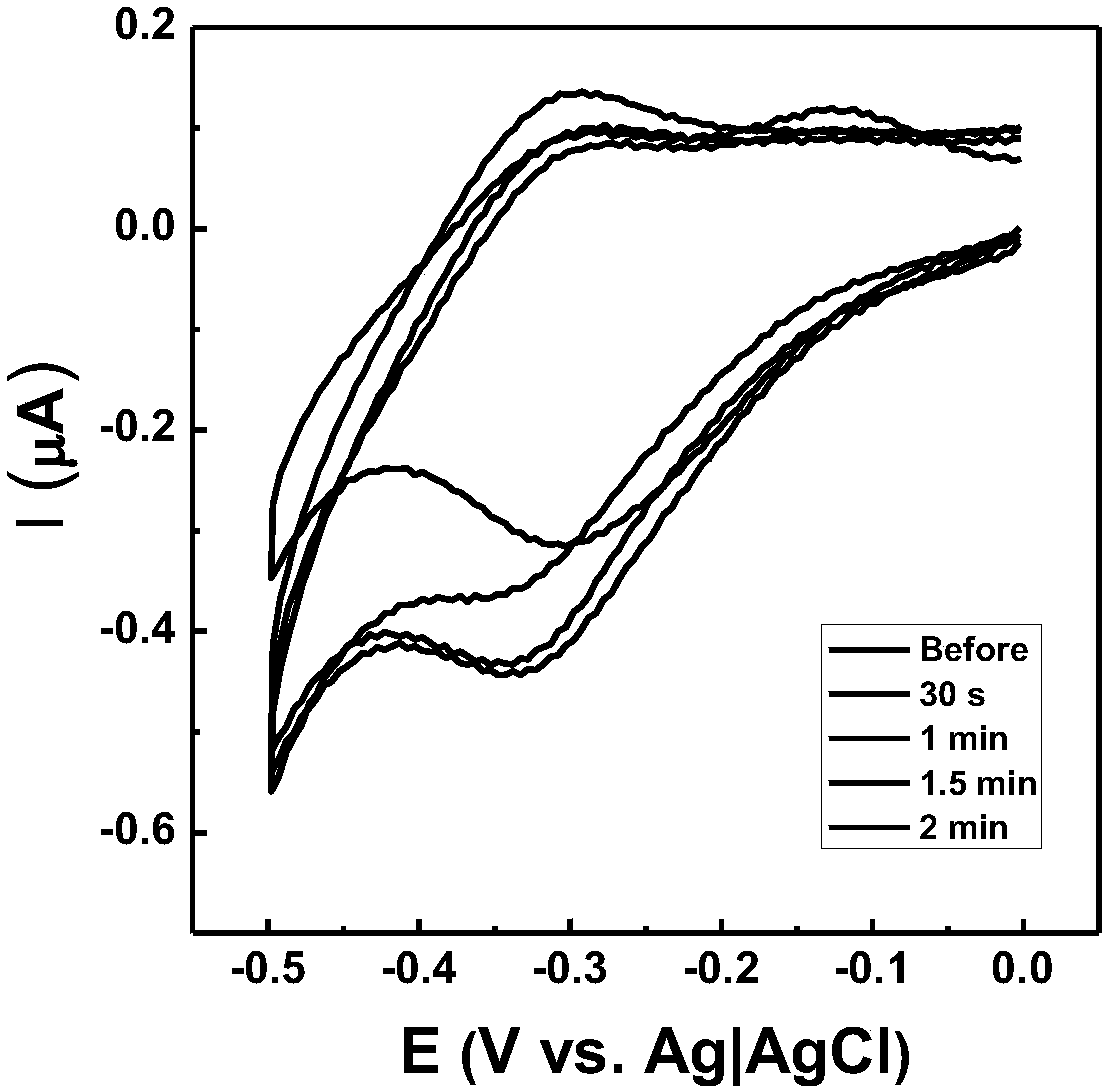

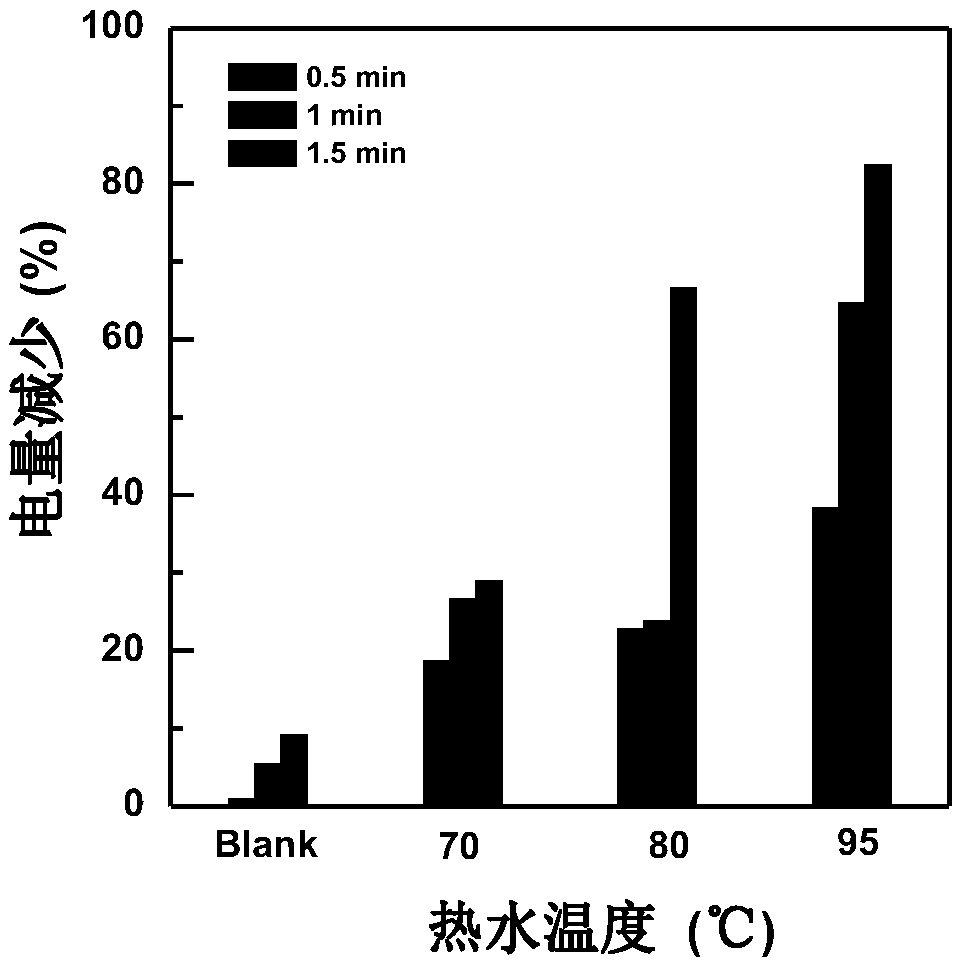

Method for quantitative evaluating HP DNA hairpin configuration on substrate surface based on enzymic hydrolysis ability and background signal eliminating method based on enzymic hydrolysis ability

InactiveCN108195919AEfficient removalWon't hurtMaterial electrochemical variablesElectricityElectrochemistry

The invention relates to the technical field of DNA self-assembled membranes, particularly to a method for quantitative evaluating the HP DNA hairpin configuration on a substrate surface based on enzymic hydrolysis ability and a background signal eliminating method based on enzymic hydrolysis ability. The specific steps comprise: removing dimers through high temperature denaturation; immersing a substrate in an exonuclease I buffer solution having an enzyme amount of 100-300 U, and carrying out hydrolysis; and determining the proportion of the HP DNA hairpin configuration on the surface of anelectrode by using an electricity integration technology. According to the present invention, exonuclease has difference between in hydrolysis of ssDNA and in hydrolysis of HP DNA hairpin configuration, and the electrochemical method is combined to quantitatively evaluate the proportion of the HP DNA hairpin configuration on the surface of the substrate; and with the exonuclease I, the backgroundsignal caused by non-hairpin configuration can be effectively eliminated so as to substantially improve the detection sensitivity of the Hairpin DNA-based biosensor.

Owner:BEIJING NORMAL UNIVERSITY

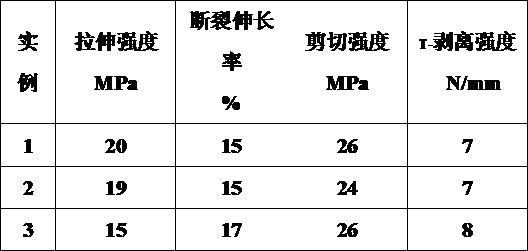

Epoxy structural adhesive with high elongation at break and preparation method thereof

InactiveCN111635724ASimple preparation processEasy to operateNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePlasticizer

The invention discloses an epoxy structural adhesive with high elongation at break and a preparation method thereof. The epoxy structural adhesive is composed of the following raw materials in percentage by weight: 20-30% of epoxy resin, 10-20% of a plasticizer, 20-35% of a flexibilizer, 15-25% of filler, 2-5% of a curing agent and 1-5% of an accelerant. The epoxy structural adhesive with high elongation at break is obtained by mixing the materials according to a certain ratio, rolling by a three-roller open mill at normal temperature, and defoaming by a vacuum defoamer. The elongation at break of the cured epoxy structural adhesive reaches 10% or above, the tensile strength can reach 15 MPa, and the cured epoxy structural adhesive has high elongation at break and tensile strength while meeting the requirements for conventional shearing and peeling strength. The bonding requirements of high-deformation and high-strength parts of airplanes, automobiles, mechanical structural parts and the like can be met.

Owner:三友(天津)高分子技术有限公司

A filling material and preparation method for controlling karst ground subsidence

The invention discloses a filling material for treating karst ground collapse and a preparation method of the filling material. The filling material mainly comprises an organic excitation cementing material and a structural foam material, wherein the organic excitation cementing material consists of an inorganic mixed material, polystyrene and phthalic anhydride according to a weight ratio of 1:(1.5-3.5):(2.8-4.9), and the inorganic mixed material consists of zeolite, gypsum and sodium sulfate according to a weight ratio of 1:1:1; the structural foam material consists of urea formaldehyde and polyurethane according to a weight ratio of 1:(2.3-3.5); and the weight ratio of the organic excitation cementing material to the structural foam material is 1:(2.5-3.8). The filling material disclosed by the invention is simple in composition, is environmental friendly and pollution-free, and has good mechanical performance, water permeability and cementing strength.

Owner:桂林矿产地质研究院工程有限公司

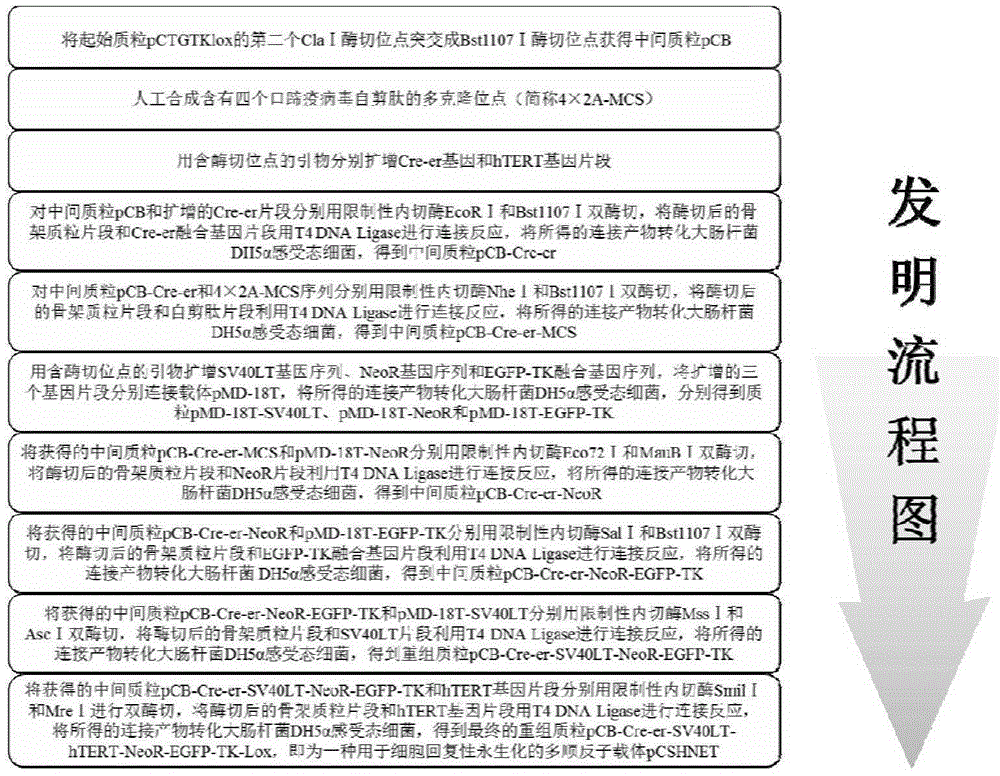

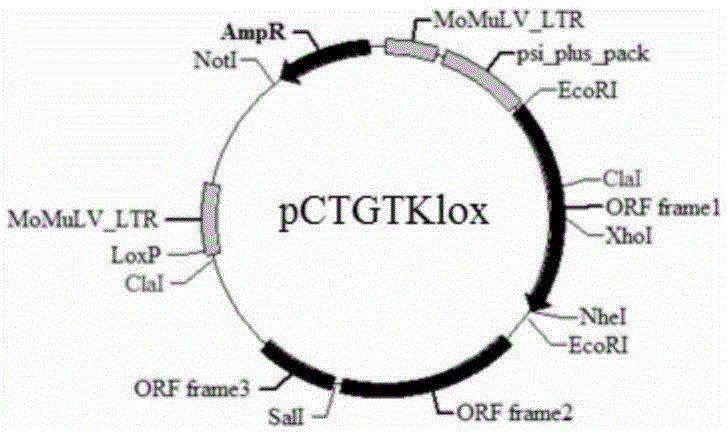

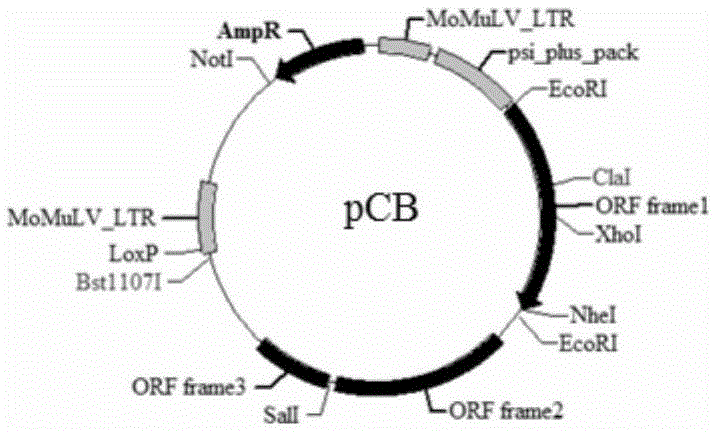

Multicistron vector achieving reversible immortalization of cells and construction method thereof

InactiveCN105400819AOvercome securitySolve the problem of in vitro proliferation and passageNucleic acid vectorFermentationEstrogen receptorViral vector

The invention relates to a multicistron plasmid type reverse transcription virus vector and a construction method thereof, and belongs to the field of gene engineering. The multicistron plasmid type reverse transcription virus vector is obtained through a gene recombination method, and the method comprises the steps that a recombinase gene, a simian virus large T antigen gene, a human telomerase gene which are fused with an estrogen receptor and five cistrons of a strengthened green fluorescent protein gene fused with thymidine kinase are inserted into the reverse transcription virus vector, and the a recombinant plasmid is obtained. Compared with the prior art, by means of an immortalized cell line established through the plasmid type reverse transcription virus vector, non-transformed normal cells can be obtained after tamoxifen drug treatment, and meanwhile by means of a thymidine kinase suicide gene mechanism, non-returned cells can be made to suicide after ganciclovir drug treatment; therefore, complete non-transformed normal cells are obtained. The multicistron plasmid type reverse transcription virus vector and the construction method thereof have the advantages that the biological safety of the recombinant reverse transcription virus vector is guaranteed, high expression of multicistron selectivity is promoted, and follow-up screening of a positive cell group and detection of multicistron expression are facilitated.

Owner:HUAZHONG AGRI UNIV

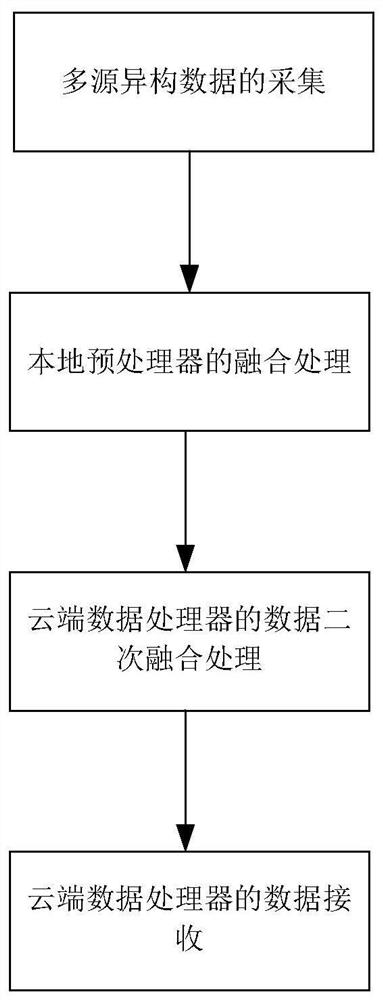

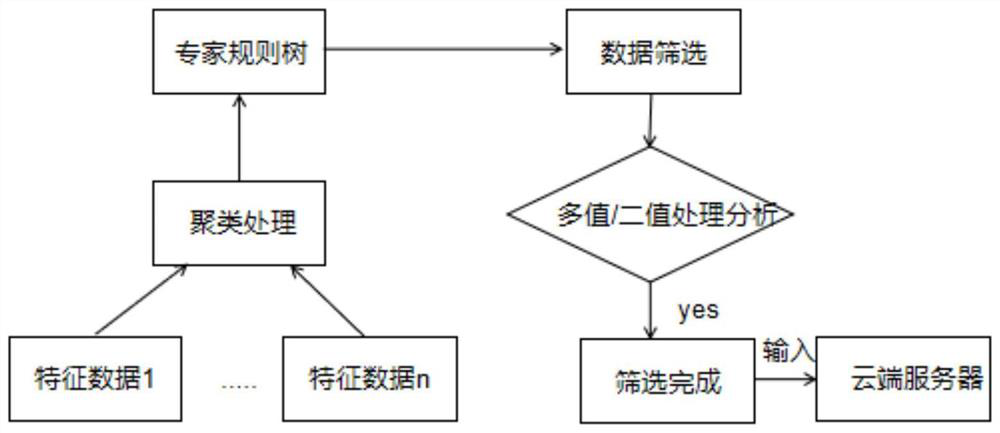

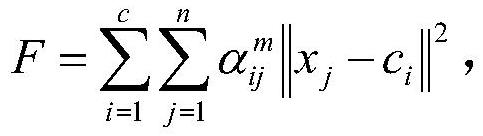

Industrial data cloud service platform data transmission method for new energy automobile driving motor assembly production line

ActiveCN111885146AAvoid lostFast transfer processingCharacter and pattern recognitionManufacturing dynamo-electric machinesNew energyDrive motor

The invention relates to an industrial data cloud service platform data transmission method for a new energy automobile driving motor assembly production line, and solves the problems that when an advanced machine learning algorithm is utilized to transmit and analyze industrial big data, in order to reduce the data scale and improve the analysis efficiency, simple processing is performed on a data transmission method, large analysis deviation is caused, and enterprise technology adjustment and operation and maintenance decisions are influenced. The method comprises the following steps: acquiring multi-source heterogeneous data; performing fusion processing of a local preprocessor; performing secondary fusion processing on the data of the cloud data processor; and receiving data of the cloud data processor. An OI network regularization method is used for optimization, the relevance of continuous channels is considered to the maximum extent, trimmed channels are applied to verificationset data to verify the accuracy of an inference effect, meanwhile, redundant channel compression is completed, and rapid transmission processing of cloud industrial big data is achieved.

Owner:HEFEI UNIV

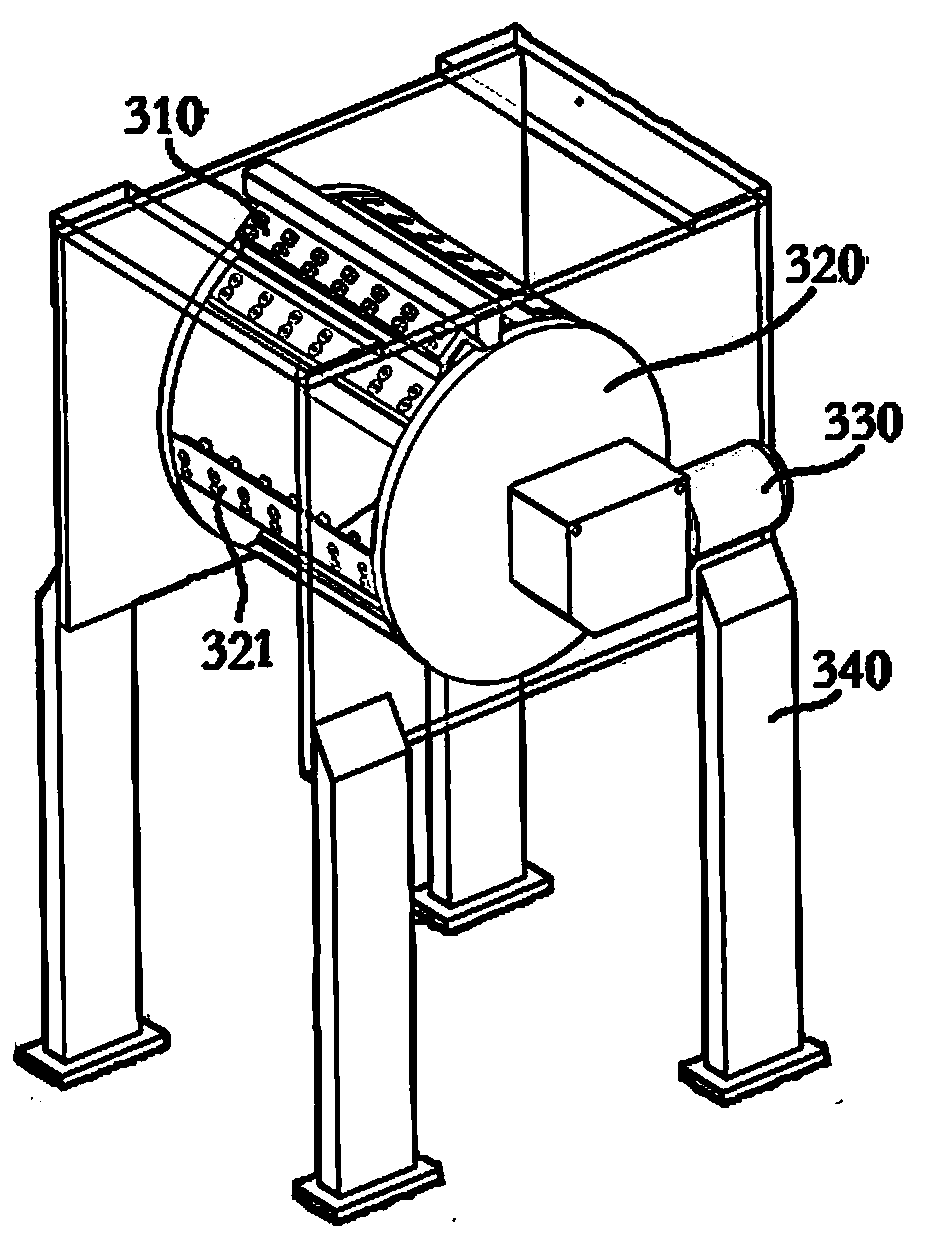

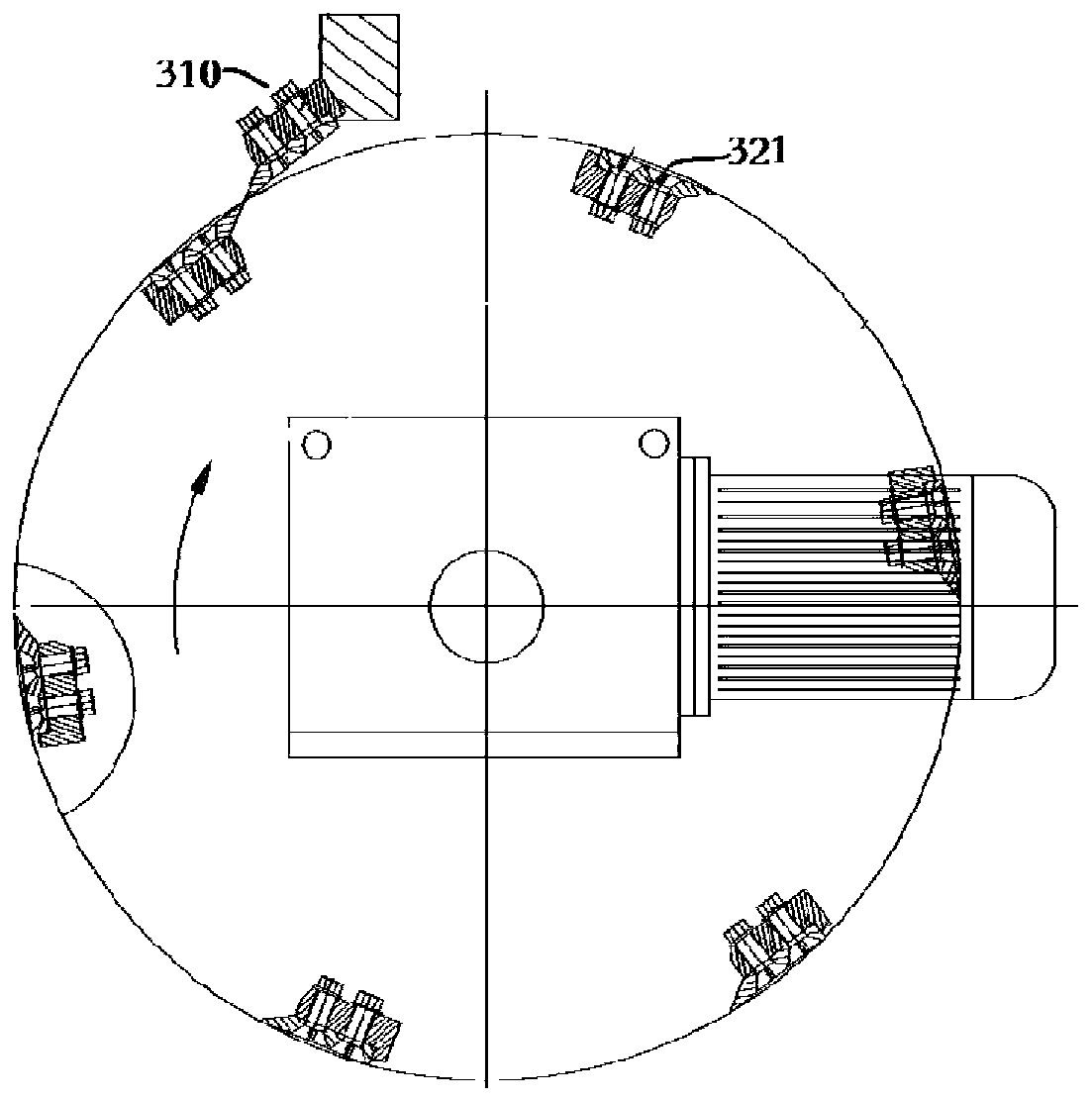

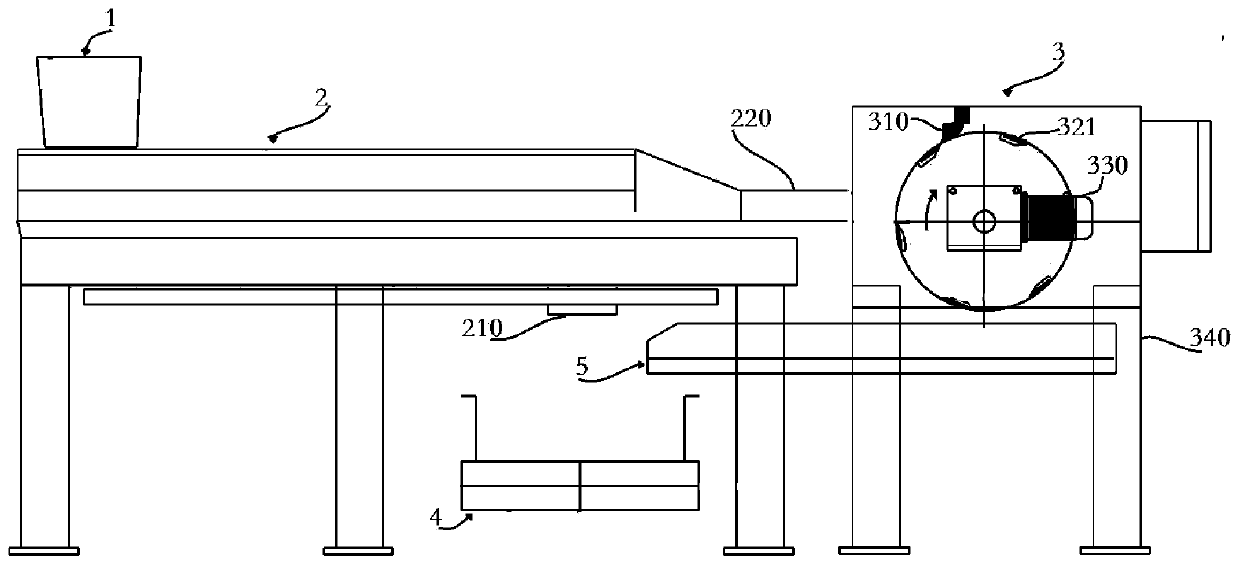

Ultra-long tobacco shred rotary shearing machine, and shearing equipment and shearing method

The invention provides an ultra-long tobacco shred rotary shearing machine, and shearing equipment and shearing method. The rotary shearing machine comprises a plurality of rotary parting tools and fixed parting tools, the rotary parting tools are used for hanging ultra-long tobacco shreds, the rotary parting tools are matched with the fixed parting tools, cutting motion can be formed, and the ultra-long tobacco shreds carried by the rotary parting tools are cut off instantaneously; the ultra-long tobacco shred shearing equipment comprises a vibrating sieving machine used for tobacco shred sieving, and the rotary shearing machine, tobacco shred shearing is conducted by utilizing the ultra-long tobacco shred shearing equipment, the tobacco shreds can pass through the sieving, and after carding, the ultra-long tobacco shreds are cut off in the direction of tobacco shred extension. According to the shearing equipment, the shearing effect of the tobacco shreds is good, the degree of automation is high, the structure of the tobacco shred shearing equipment is reasonable, and occupation of area is few.

Owner:ZHISI HLDG GRP

Special-shaped lens full-automatic shearing machine

The invention provides a special-shaped lens full-automatic shearing machine. The machine comprises a special-shaped lens conveying mechanism, a special-shaped lens loading mechanism, a special-shaped lens shearing mechanism, a special-shaped lens unloading mechanism and a waste collecting mechanism. The special-shaped lens conveying mechanism includes a driving conveying wheel, a driven conveying wheel and two conveying belts; and the two conveying belts penetrate through the special-shaped lens loading mechanism, the special-shaped lens shearing mechanism and the special-shaped lens unloading mechanism in sequence. The special-shaped lens loading mechanism includes a loading frame, and a loading frame driving mechanism for driving the loading frame to move up and down. The special-shaped lens unloading mechanism includes an unloading frame, and an unloading frame driving mechanism for driving the unloading frame to move up and down. The special-shaped lens full-automatic shearing machine solves the technical problems of complex structure, low conveying efficiency and limited storage space caused by single storage structure in special-shaped lens full-automatic shearing machine equipment in the prior art, and realizes quick conveying, efficient shearing and large-batch storage.

Owner:福建省永春冠怡花卉苗木专业合作社

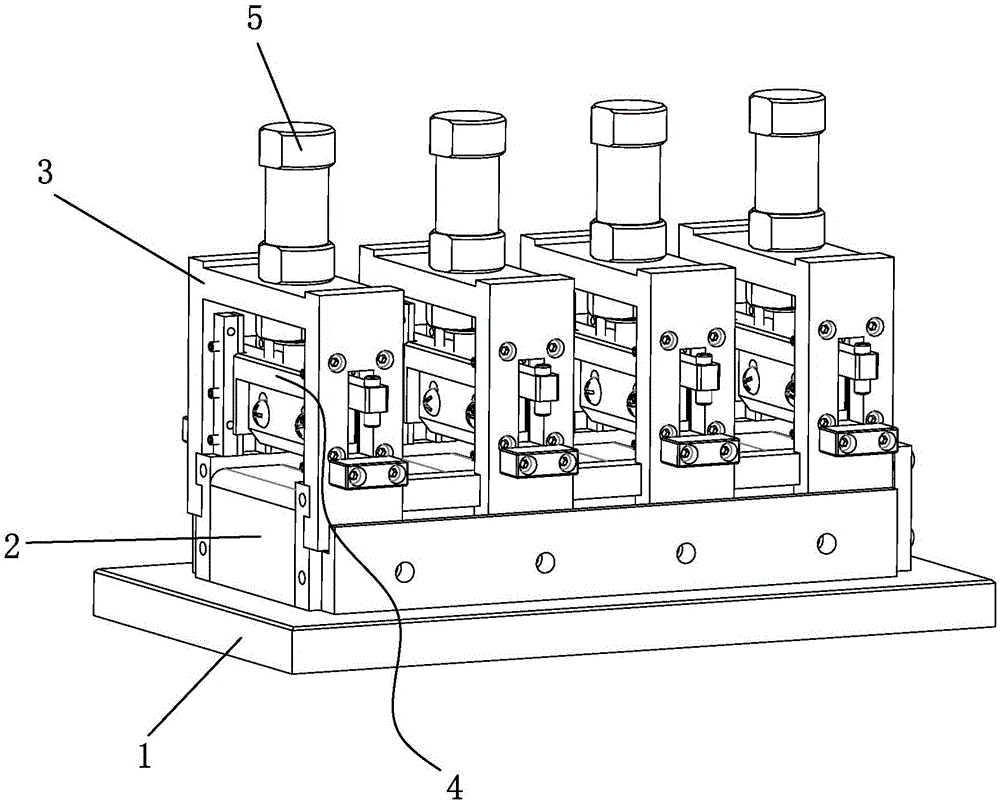

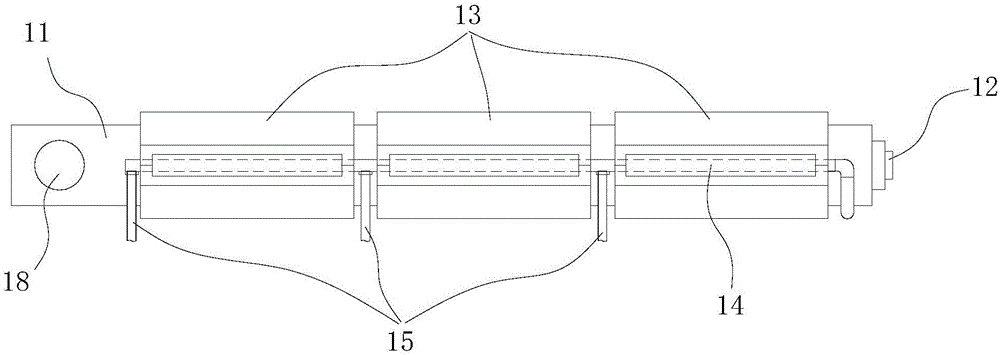

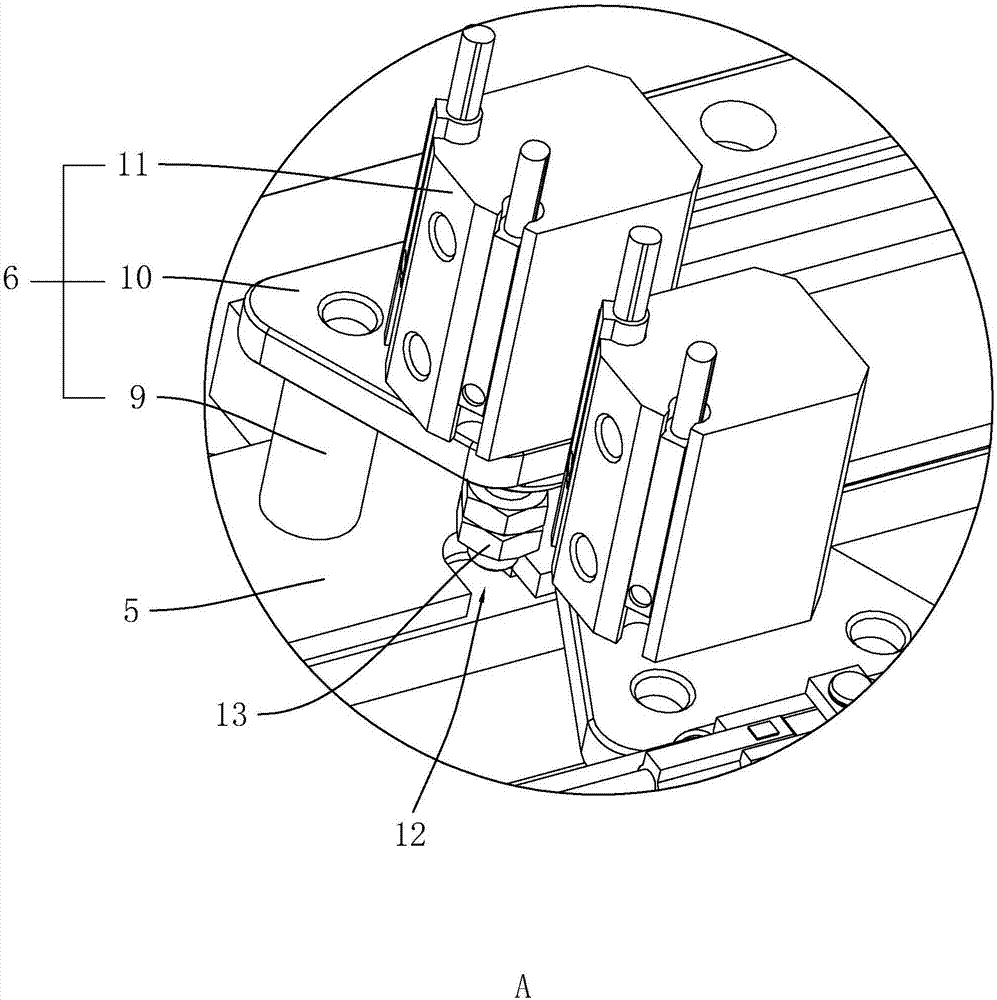

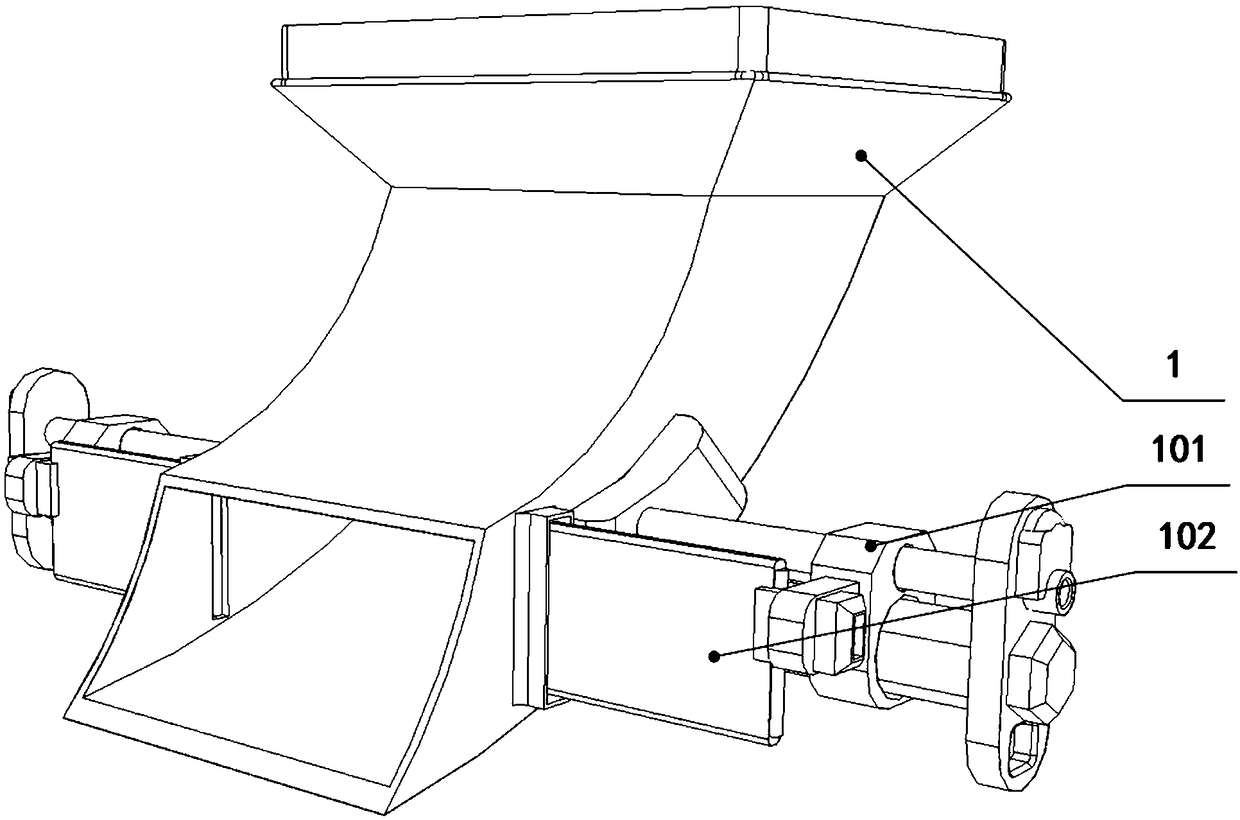

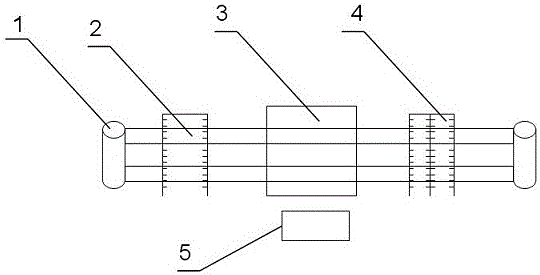

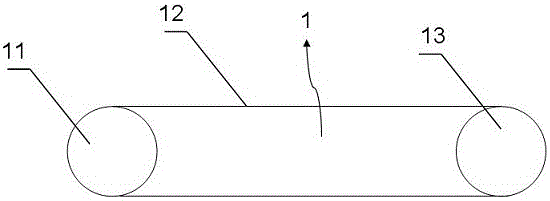

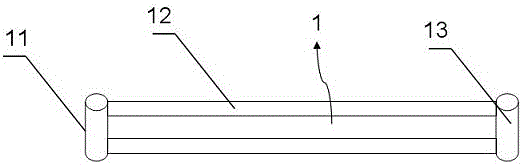

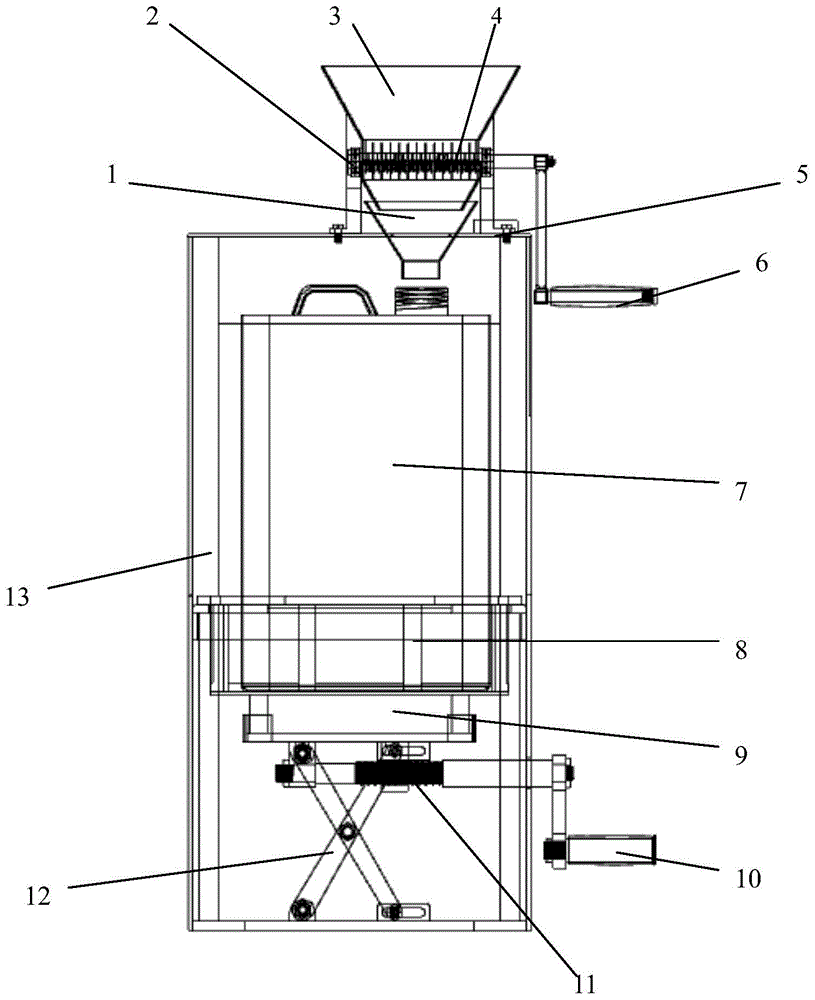

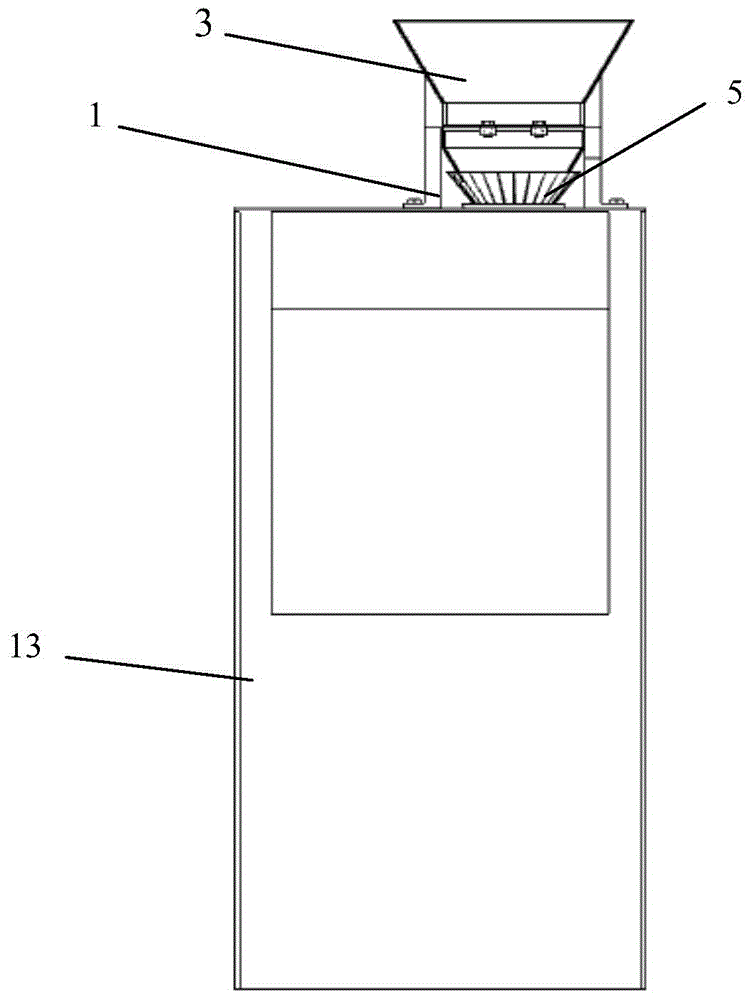

Cutting device for eraser strip

InactiveCN106078834AEfficient shearingAvoid breakingMetal working apparatusEngineeringMechanical engineering

The invention belongs to the field of eraser production and processing and particularly relates to a cutting device for an eraser strip. The cutting device comprises a fodder chopper and an intermittent feeding mechanism. The fodder chopper moves back and forth in the vertical direction and is matched with a workbench to do a shearing action for cutting the eraser strip. The intermittent feeding mechanism can convey the eraser strip to the position below the fodder chopper in an intermittent mode, specifically, when the fodder chopper is lifted, the eraser strip is fed forwards, and when the fodder chopper falls, the eraser strip is stopped being fed. According to the cutting device for the eraser strip, the eraser strip can be efficiently sheared, so that breaking or stacking of the eraser strip is prevented.

Owner:宿州市超晟文具有限公司

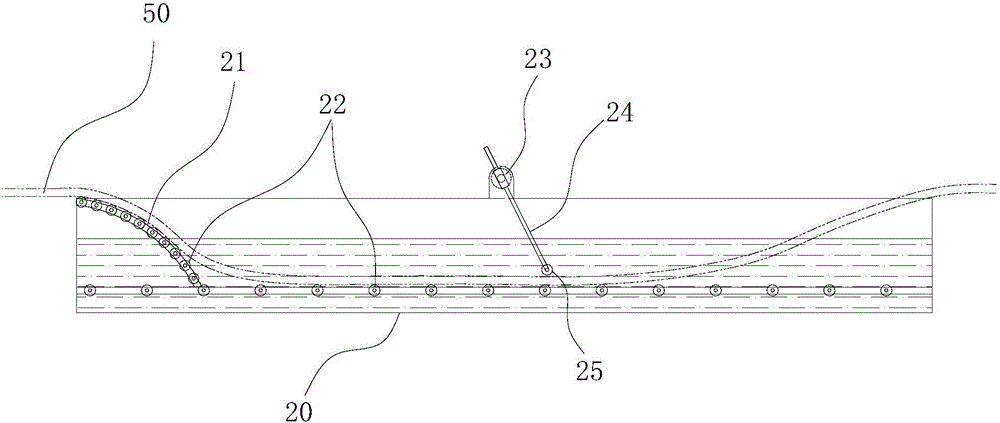

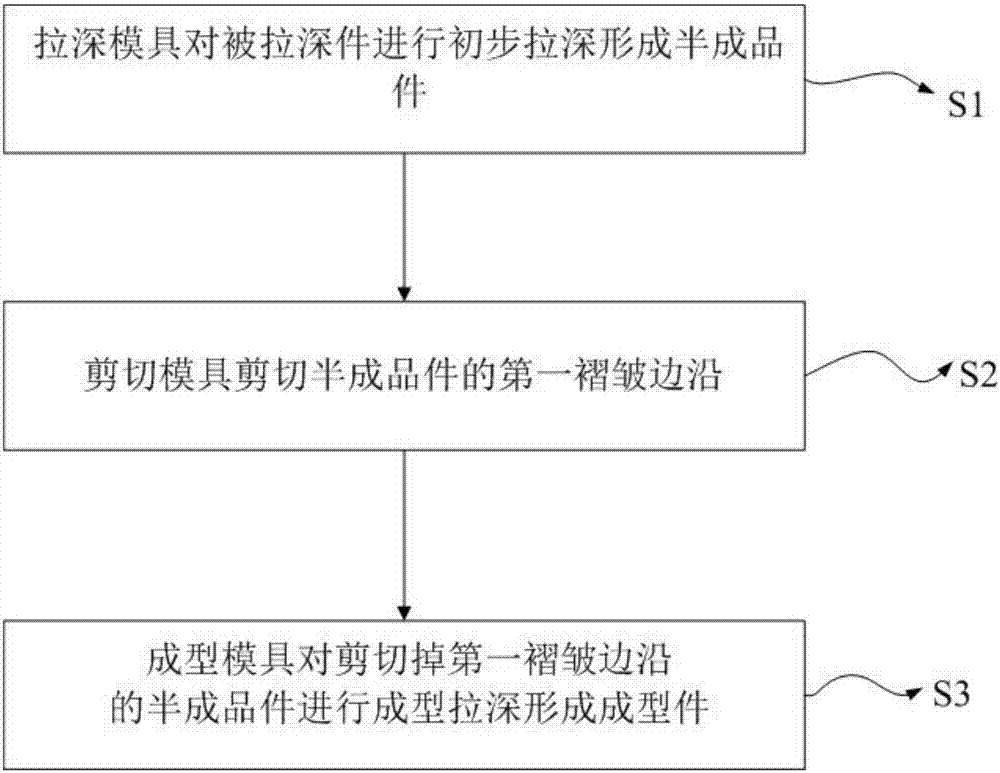

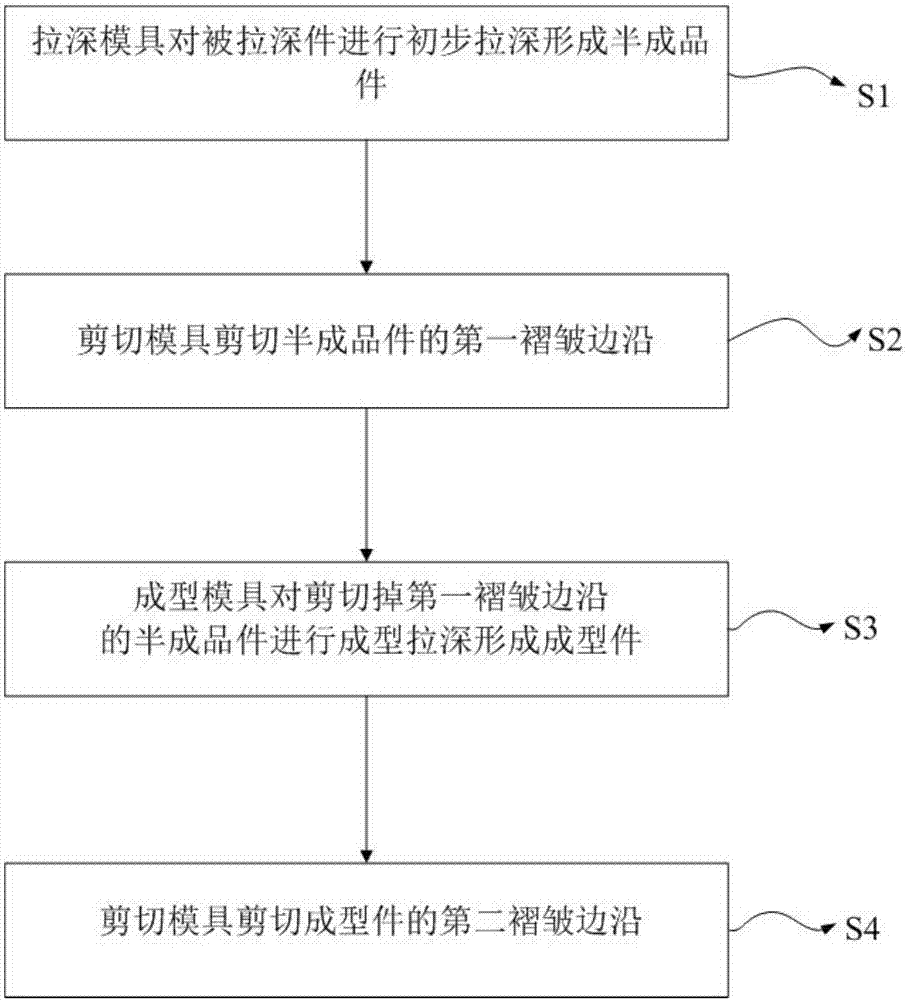

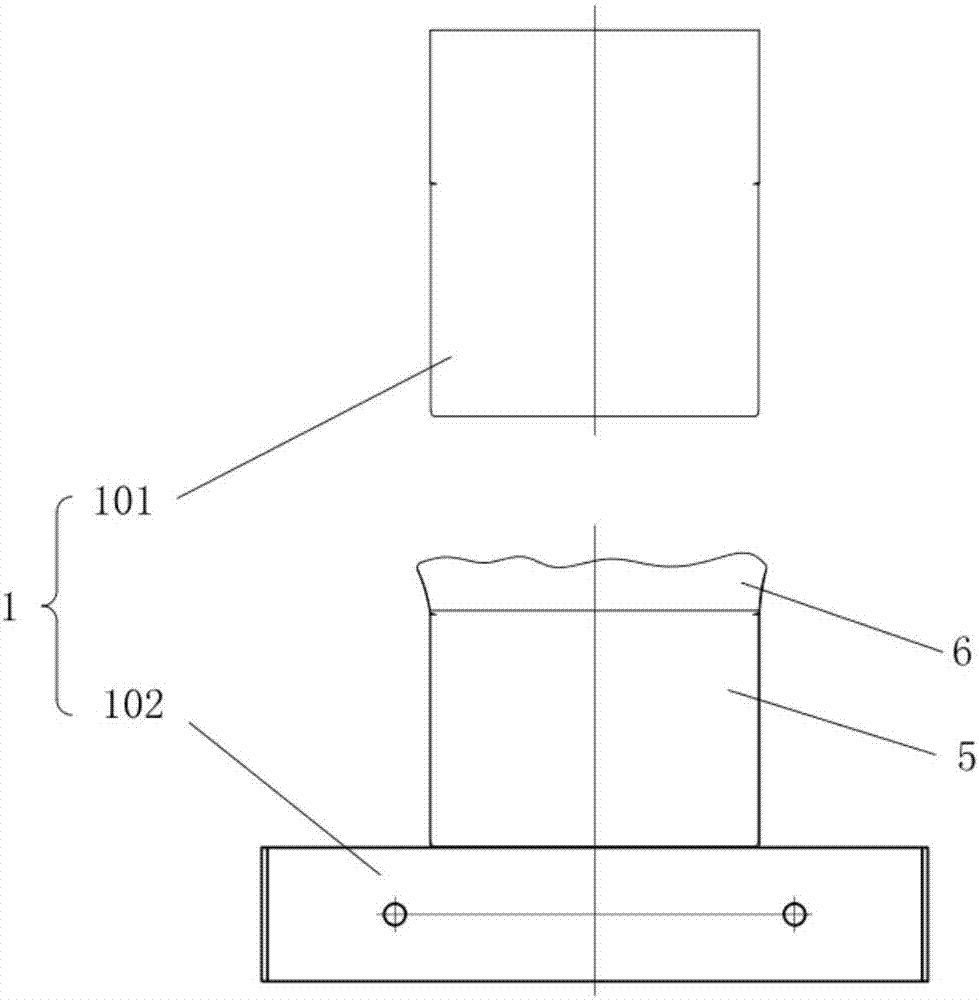

Drawing method and device

The invention discloses a drawing method and a drawing device and belongs to the technical field of machining. The drawing method comprises the steps of primary drawing, shearing of the edge of a first wrinkle, and forming drawing. The step of shearing the edge of the first wrinkle of a semi-finished product through a shearing die is added between the primary drawing step and the forming drawing step, so that the stress of the edge of the semi-finished product can be released before the forming drawing step, and the situation that the stress concentrated at the edge of the semi-finished product affects the quality in the next procedure, and finally the quality of a formed part is decreased is avoided. The drawing device provided by the invention comprises a drawing die, the shearing die and a forming die. By arranging the shearing die, the edge of the first wrinkle of the semi-finished product can be sheared off accurately and efficiently, thus, the edge stress of the semi-finished product is released effectively, and the quality of the final formed part is improved.

Owner:SHENZHEN KEDALI IND CO LTD

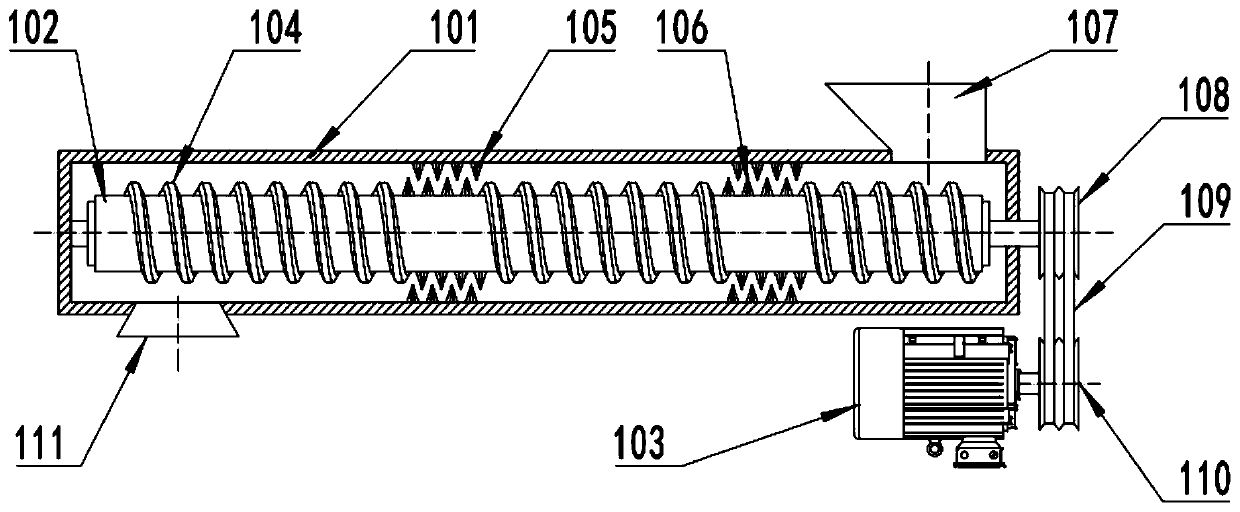

Corrugated board recycling device for packaging box

InactiveCN110004755AEfficient shearingPromote formationPulp beating methodsRaw material divisionSpiral bladeElectric machinery

The invention discloses a corrugated board recycling device for a packaging box, and relates to the technical field of corrugated paper for packaging. The device comprises a primary crushing mechanism, a water inlet pipe, a pulping mechanism, a pulping tank, a driving motor and a pulp outlet pipe; the top of the pulping tank is provided with a material receiving hopper corresponding to the primarycrushing mechanism; the bottom of the material receiving hopper is connected with a material dropping pipe leading to the pulping tank; the top and the bottom of the pulping tank are respectively connected with the water inlet pipe and the pulp outlet pipe; the water inlet pipe and the pulp outlet pipe each are provided with a valve; the pulping tank is internally provided with the pulping mechanism; and the pulping mechanism is driven by the driving motor to rotate. The device has the following beneficial effects: corrugated boards can be subjected to rotary cutting by spiral blades, and crushing teeth I and crushing teeth II can be used for tearing the corrugated boards; the corrugated boards subjected to preliminary crushing can enter the pulping tank, and the corrugated boards in water can be effectively sheared; and then small corrugated paper boards are broken, so that crushing and pulping are effectively combined into a whole, and the cost can be better saved.

Owner:温州天炽包装有限公司

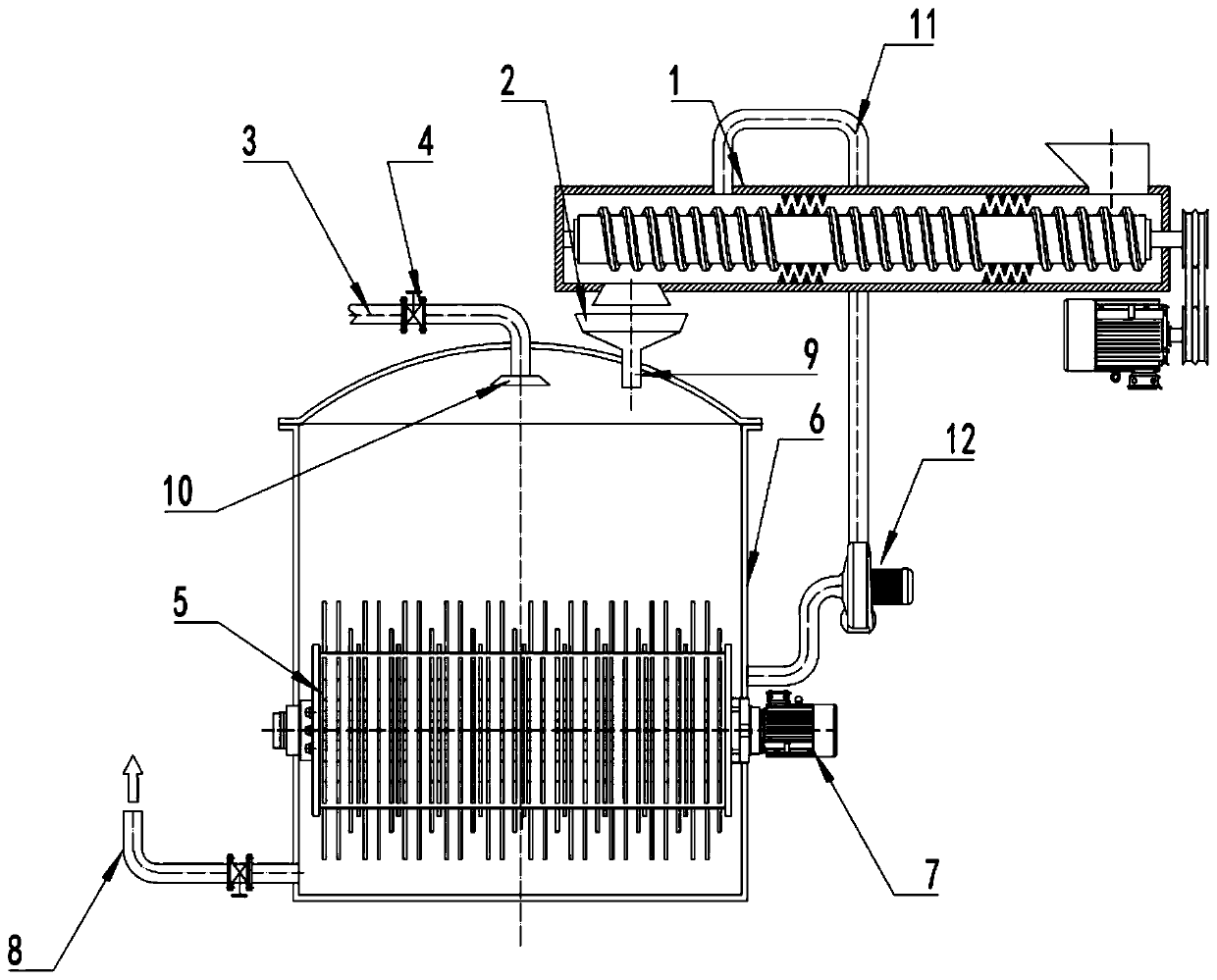

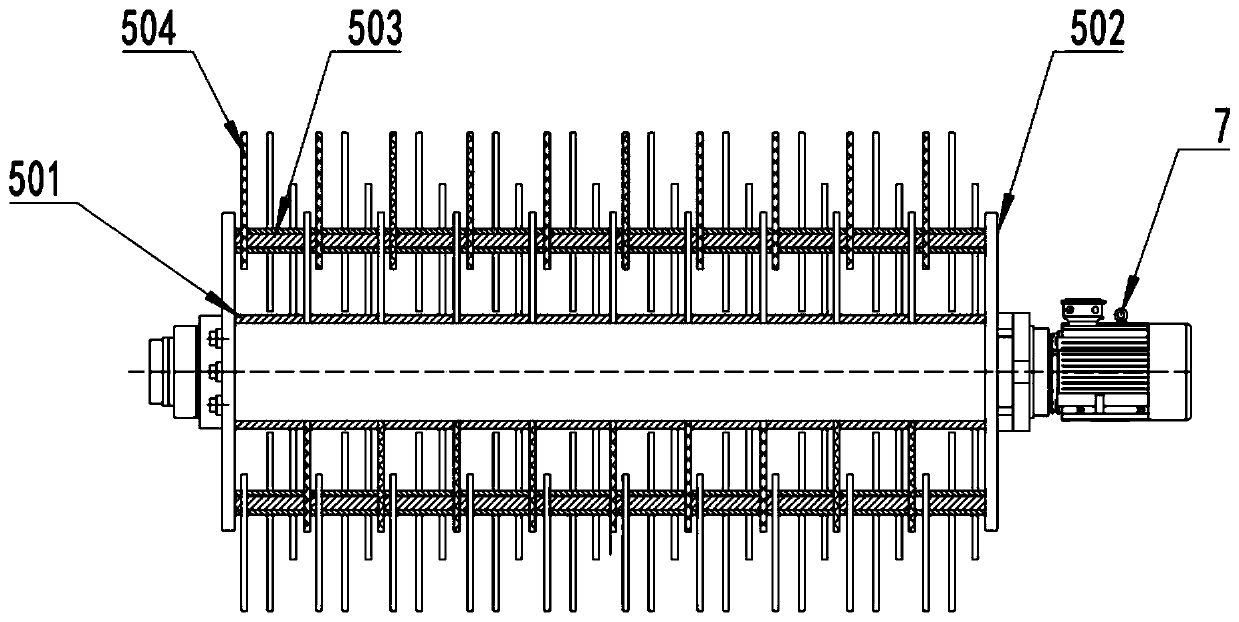

Processing mechanism for recycling kitchen waste

ActiveCN105060945ARealize recyclingSimple structureClimate change adaptationOrganic fertilisersBall bearingEngineering

The invention relates to a processing mechanism for recycling kitchen waste. The processing mechanism comprises a rack, a shearing mechanism, a compost container, a weighing support mechanism and a lifting mechanism, wherein the weighing support mechanism comprises a support platform, a weighing body and a support control display, and a convex edge capable of being clamped on the rack is arranged on the edge of the support platform; the weighing body is mounted below the support mechanism and is connected with the lifting mechanism, and the weighing body is connected with the support control display through a weighing controller and a CPU operation control unit; the compost container is placed on the support platform; a feeder house of the shearing mechanism is taken as a feeder hose for the waste, a shearing knife tackle is mounted at the lower part of the feeder house through a deep groove ball bearing, a discharge hole of the feeder house is connected with a funnel, and the tail end of the funnel corresponds to an opening of the compost container; and the shearing rotation of the shearing knife tackle is controlled by a shearing rotation handle. The processing mechanism has the advantages of simple structure and simple and convenient operation, the shearing efficiency can be well improved, repeated utilization of the waste is realized, and finally the reduction and recycling of the waste are realized.

Owner:GUANGXI UNIV

A waste plastic recycling device

ActiveCN108544688BImprove cleaning efficiencyIncrease the mixing areaPlastic recyclingMechanical material recoveryEnvironmental engineeringMechanical engineering

The invention relates to the field of plastic treatment, in particular to a waste plastic recovery device. The waste plastic recovery device comprises a feeding conveying belt, a crushing mechanism, stirring mechanisms, a cleaning box, a lifting mechanism, a discharging hopper, a transmission mechanism, a material collection mechanism and supporting rods. The feeding conveying belt is used for conveying plastic, meanwhile, the plastic is crushed by the crushing mechanism, the stirring mechanisms can stir and clean the plastic in the cleaning box, the material collection mechanism can be liftedup by the lifting mechanism, the plastic with cleaning completed can be pushed out conveniently, and the stirring mechanisms can be driven by the transmission mechanism to rotate. According to the waste plastic recovery device, through the multiple stirring mechanisms arranged in the cleaning box, the stirring area is large, and the stirring amplitude is high; meanwhile, steel wire balls and brushes are utilized for brushing, and no dead corner exists during plastic cleaning; and after cleaning is completed, the plastic with cleaning completed is lifted through an ascending material collection box, the plastic with cleaning completed is drained off, meanwhile, the drained-off plastic is pushed out through a push plate, and discharging of the plastic with cleaning completed is achieved.

Owner:安徽凯峰智能装备有限责任公司

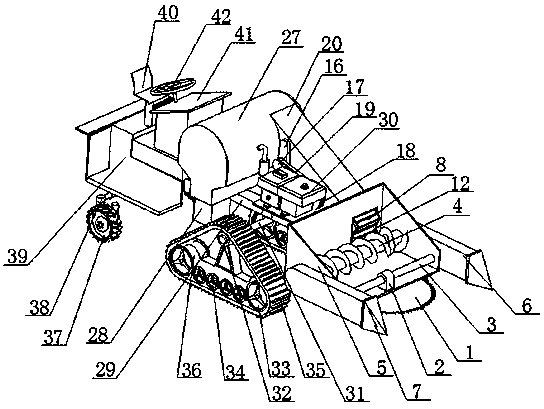

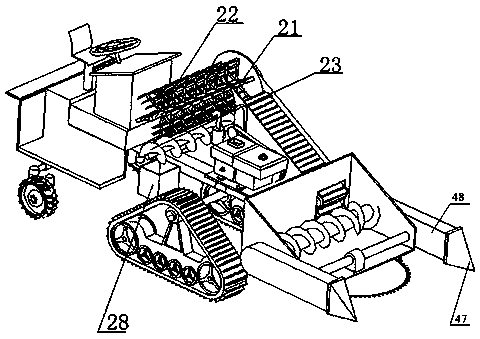

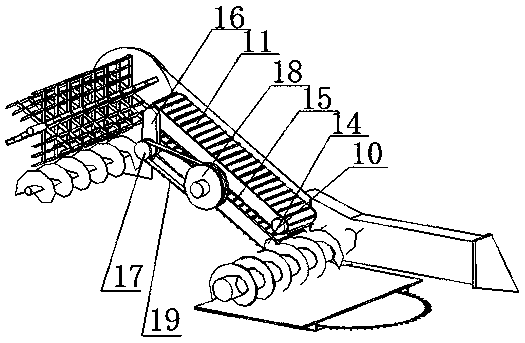

Rose branch trimmer combining wheels with caterpillar band

The invention relates to a rose branch trimmer combining wheels with a caterpillar band and belongs to the technical field of agricultural machinery. The rose branch trimmer includes a rack, a cuttingmechanism, a conveying mechanism, a smashing mechanism, a walking mechanism and a driving mechanism. The rose branch trimmer is mainly applied to a process of cutting, smashing and mulching of rose branches, a driver drives the rose branch trimmer to move forwards, rose stalks are cut off by a disk saw in front of the rose branch trimmer, and the rose branches are conveyed into the conveying mechanism through a spiral feeding roller; rose branches are drawn into the conveying mechanism by two belt-type conveyors on the upper and lower portions of the interior of the conveying mechanism and then conveyed into the smashing mechanism; a smashing cutter in the smashing mechanism smashes the rose branches through high-speed rotation, and finally the smashed branches are scattered from a mulching hopper into a field through a spiral discharging roller. The rose branch trimmer not only improves the efficiency of trimming the rose branches but also avoids the problem that workers are scratched by the rose branches. The rose branch trimmer is reasonable in structural design, high in work quality and work efficiency and capable of reducing the labor intensity and the production cost at thesame time.

Owner:KUNMING UNIV OF SCI & TECH

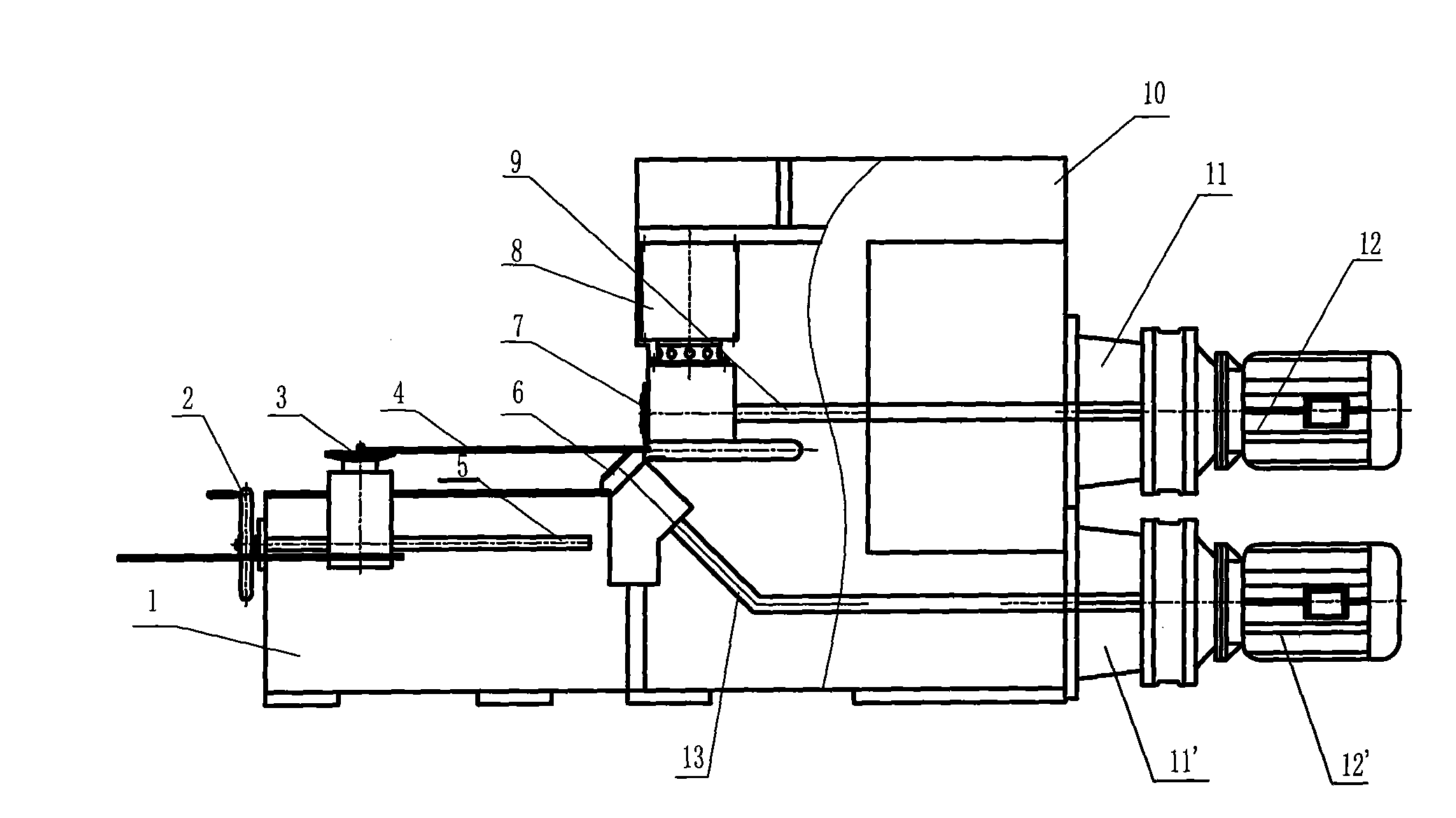

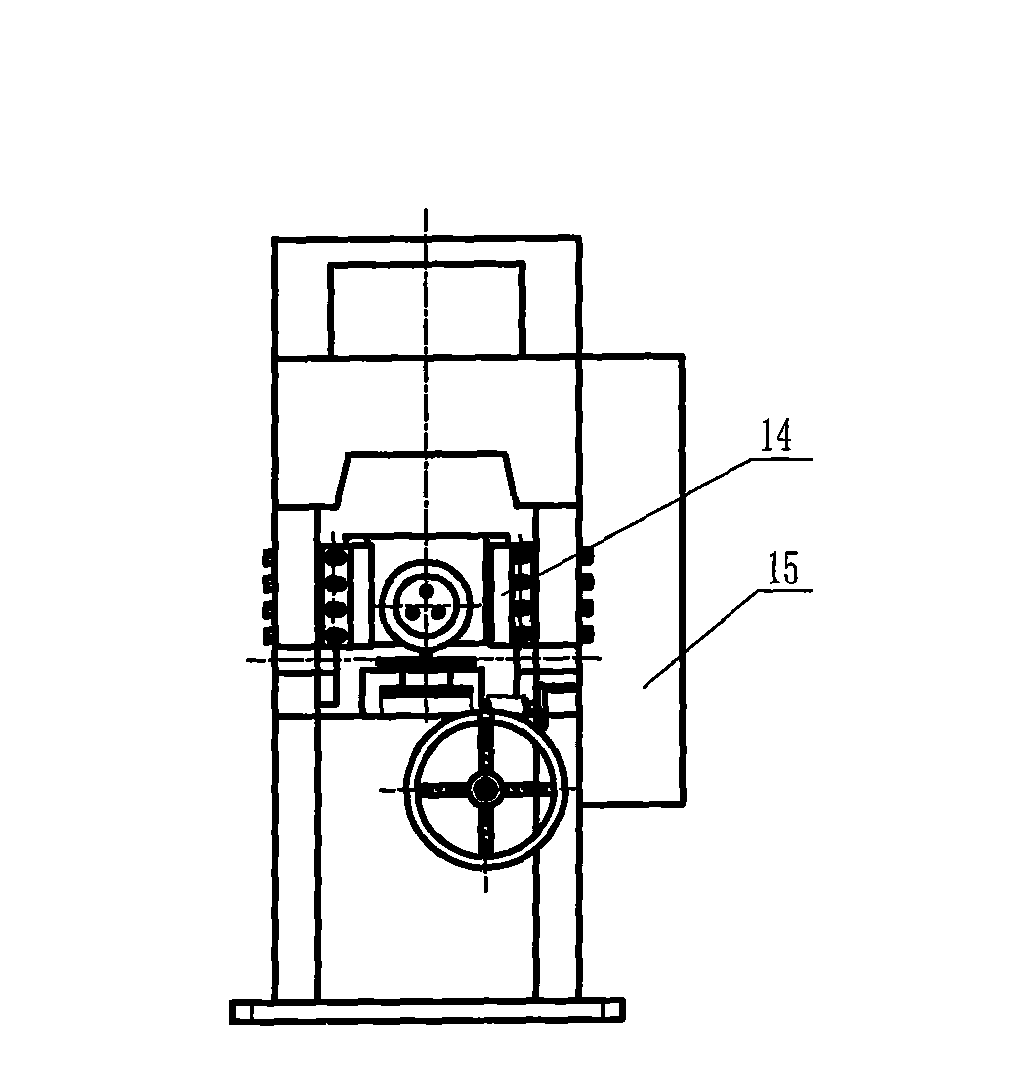

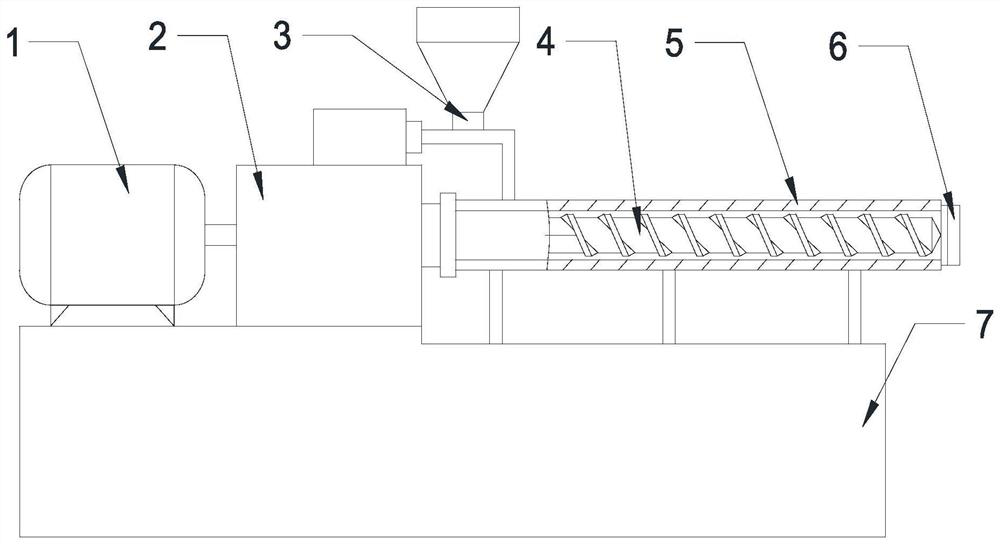

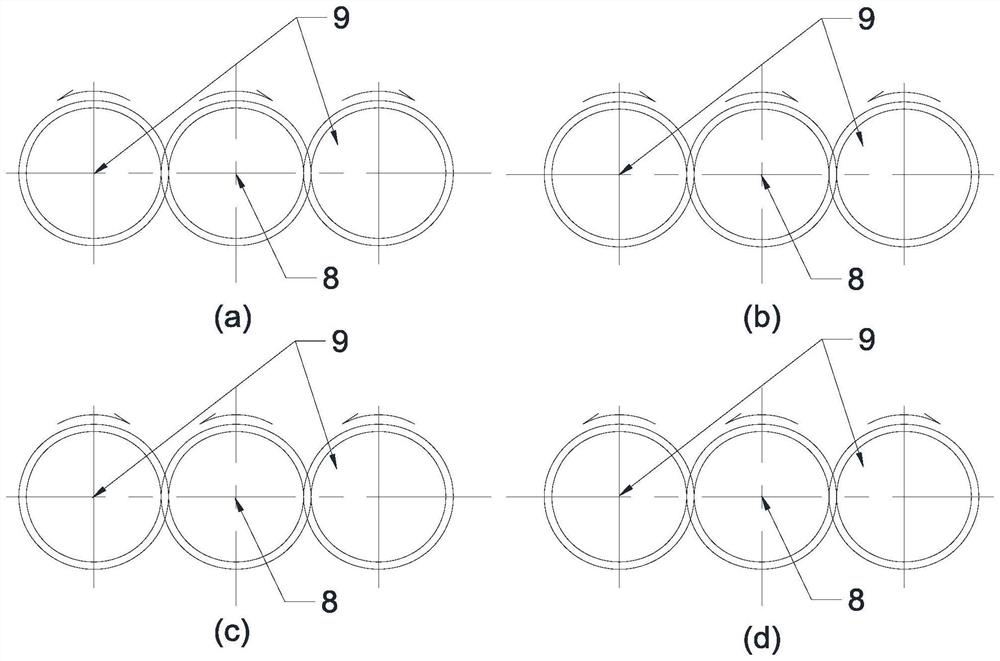

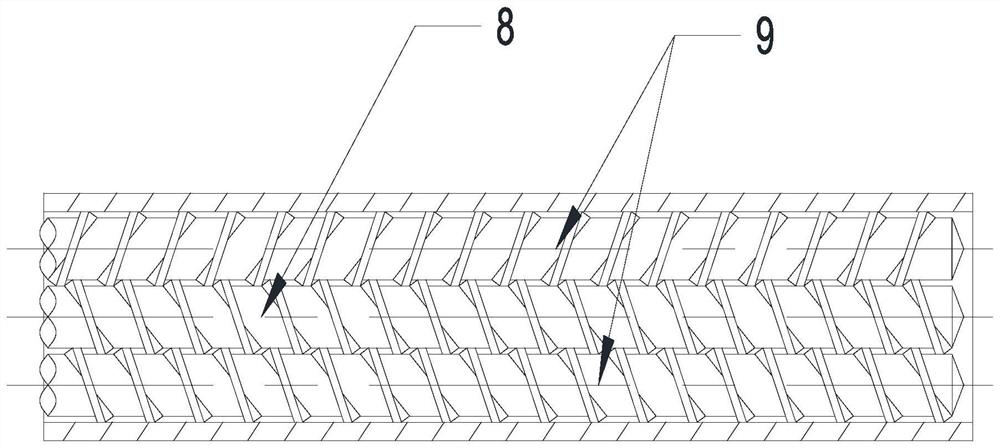

Bidirectional synergistic three-screw reinforced plasticizing mixing extrusion method and equipment

PendingCN114474670AQuality improvementGood plasticizing and mixing effectPlasticultureElectric machine

The invention discloses a bidirectional synergistic three-screw reinforced plasticizing mixing extrusion method and equipment, and the method is characterized in that homodromous rotation and incongruous rotation exist in a three-screw system at the same time so as to form a homodromous meshing area and an incongruous meshing area for cooperative work, and materials alternately and repeatedly pass through the homodromous meshing area and the incongruous meshing area in the material conveying process, so that the materials are uniformly mixed and extruded; therefore, the plasticizing and mixing effect of the material is enhanced. The device comprises a driving motor, a speed reduction distribution transmission case and a three-screw system, the driving motor is connected with the speed reduction distribution transmission case through a coupler, three output shafts in the speed reduction distribution transmission case are connected with the three-screw system through spline housings, the three-screw system comprises a main screw and two auxiliary screws, and the main screw and the two auxiliary screws are connected through a coupler. The main screw is meshed with one of the auxiliary screws in a rotating mode in the same direction, and the main screw is meshed with the other auxiliary screw in a rotating mode in the opposite direction. According to the invention, co-rotating and counter-rotating work is cooperated, so that the plasticizing and mixing effect is improved.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com