Drawing method and device

A deep-drawing die and multiple deep-drawing technology, applied in the field of mechanical processing, can solve problems that affect the quality of deep-drawing, easy to appear wrinkles, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

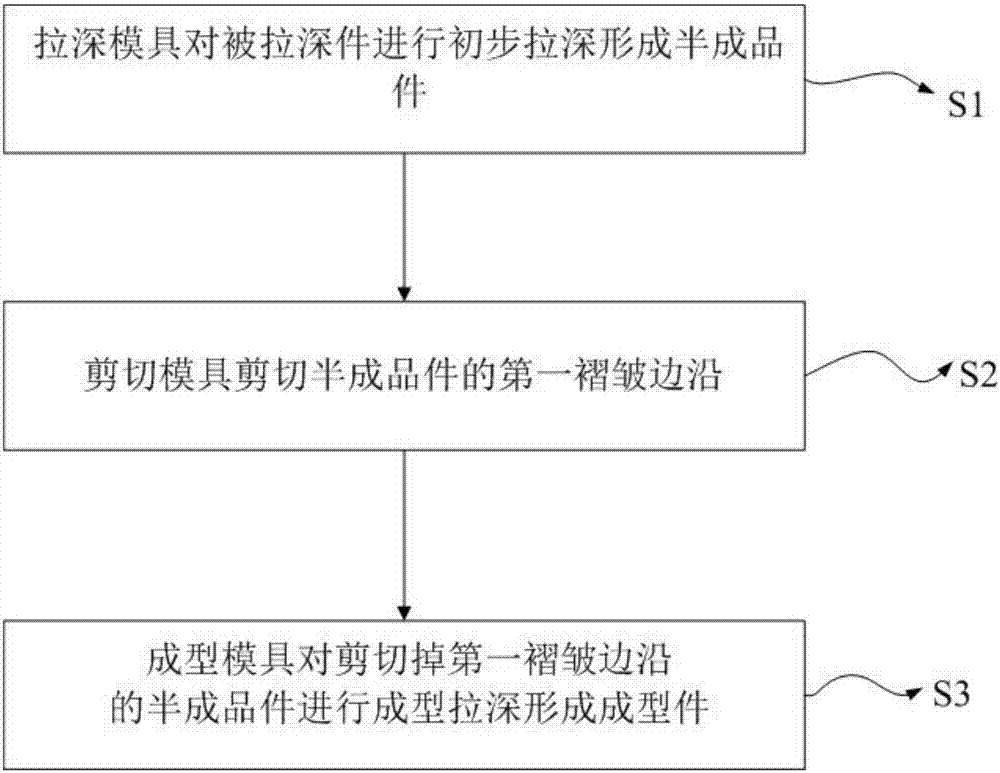

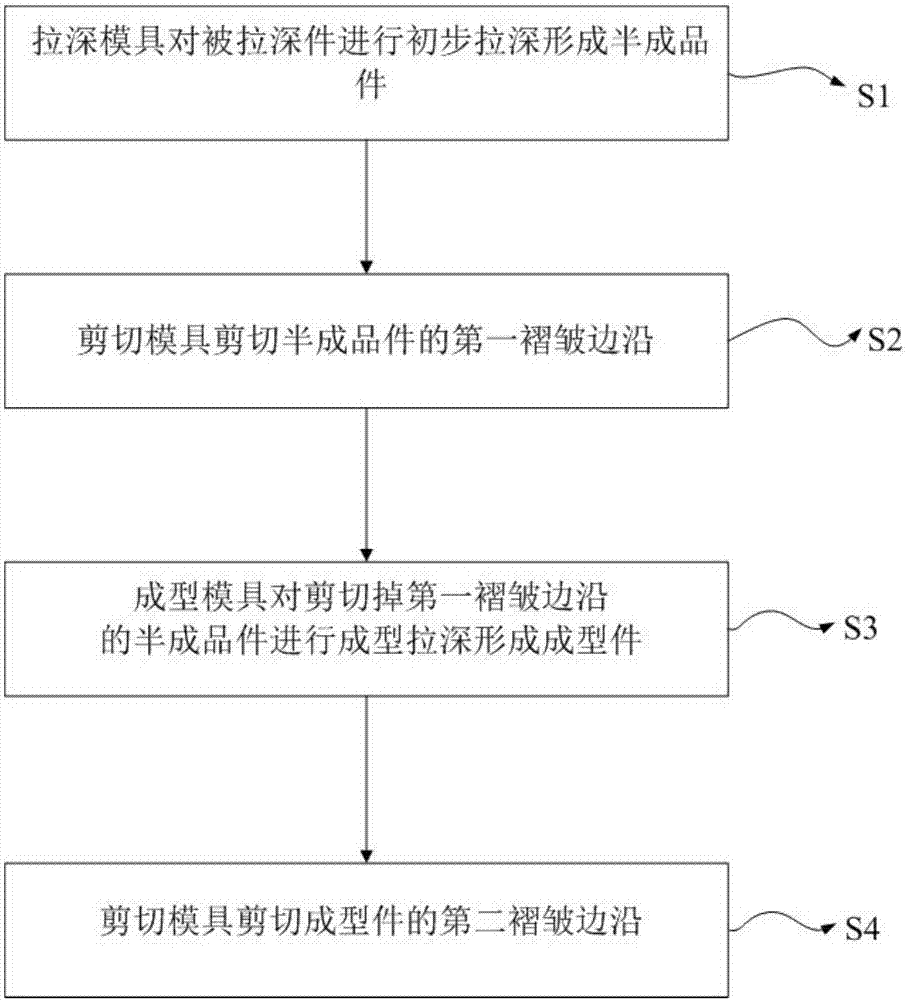

[0035] Such as figure 1 As shown, the drawing method includes the following steps:

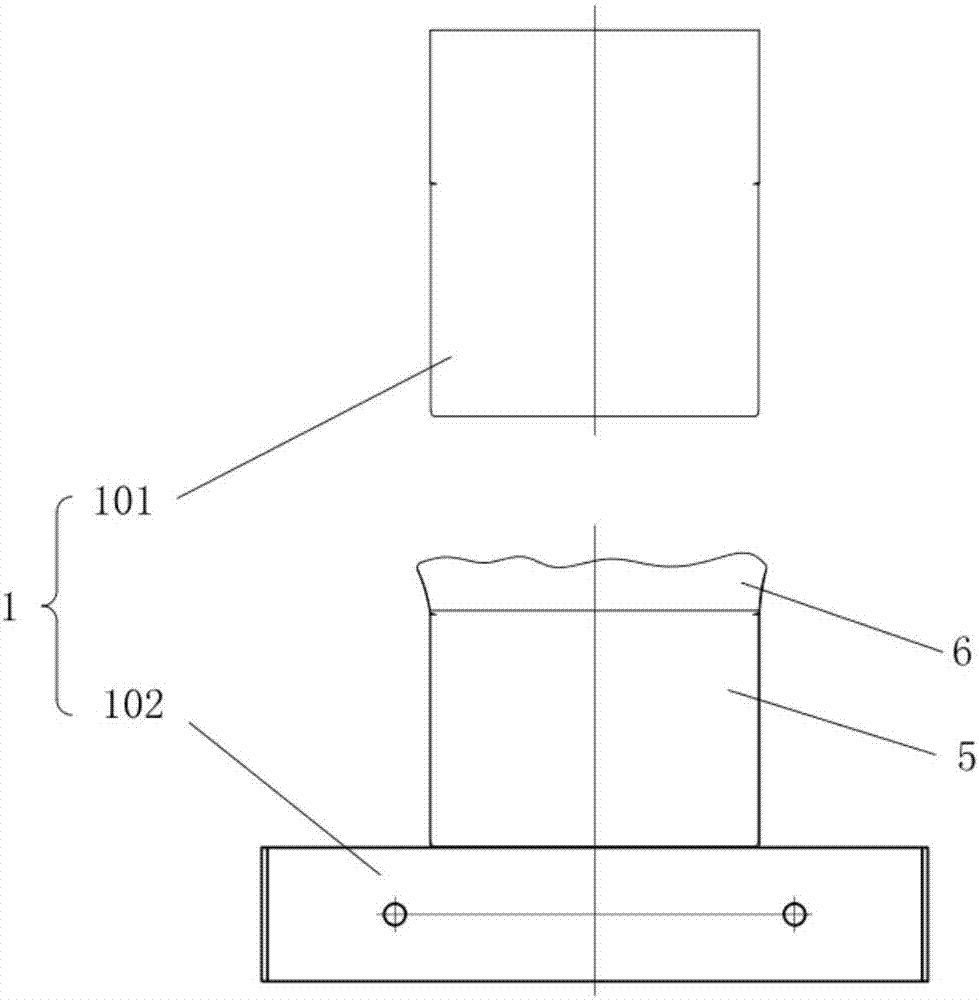

[0036] S1: The drawing die performs preliminary drawing on the drawn part to form a semi-finished part 7;

[0037] S2: the cutting die 3 cuts the first fold edge 6 of the semi-finished product 7;

[0038] S3: The forming die 4 performs forming and deep drawing on the semi-finished product 7 with the edge 6 of the first fold cut off to form a formed product 8 .

[0039] By setting a shearing process between the preliminary drawing and forming drawing process, the first wrinkle edge 6 of the semi-finished product 7 is cut by using the shearing die 3, so that the stress at the edge of the semi-finished product 7 can be released before the forming drawing , to prevent the stress concentrated at the edge of the semi-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com