Self-adhesion waterproof rolls used for road bridge and preparation method thereof

A self-adhesive waterproof membrane, road and bridge technology, applied in the direction of roads, bridges, roads, etc., can solve the problems of potential safety hazards, unsatisfactory low temperature resistance of membranes, and low bonding strength, etc., to achieve high bonding strength , high construction efficiency and simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A preparation method for self-adhesive waterproof roll material for road and bridge, comprising the steps of:

[0028] ① Weigh 40-60 parts of No. 90 asphalt and 10-20 parts of softened oil according to the parts by mass, mix, stir, and heat up to 185-195°C;

[0029] ② Add 3~10 parts of styrene-butadiene-styrene block copolymer, 2~5 parts of styrene-butadiene rubber, 3~8 parts of recycled polypropylene, 0.5~3 parts of high-temperature modifier, and keep the temperature at 190~ 200°C, high-speed stirring and shearing for 2 hours;

[0030] ③After the pellets are completely melted, heat up to 200~210℃, add rubber powder for 5~15°C, stir and shear at high speed for 2h;

[0031] ④Add 25~40 parts of filler, keep the temperature at (170+10)℃, stir and shear at high speed for 1 hour, the mixture is ground and sheared by a colloid mill, and circulated 2~3 times to obtain a polymer modified asphalt mixture;

[0032] ⑤After checking that all indicators meet the requirements, open...

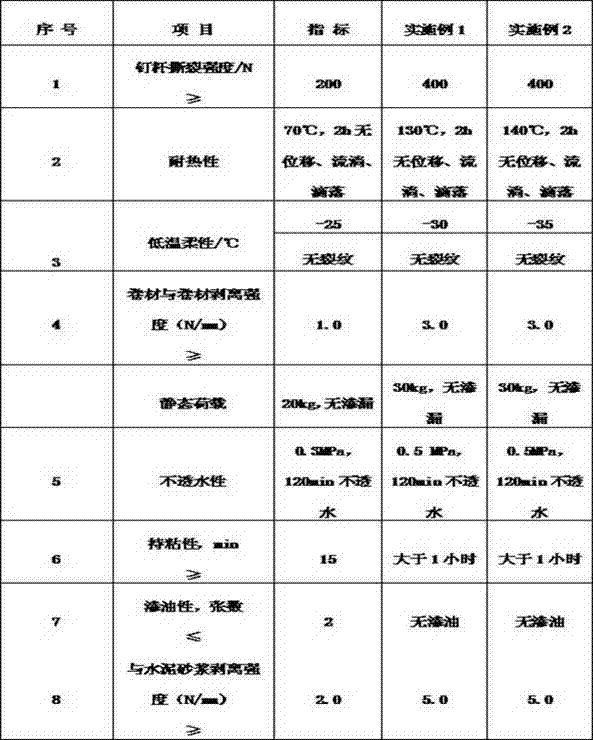

Embodiment 1

[0034] The mass parts of each component of self-adhesive waterproof coiled material for road and bridge of the present invention are as follows:

[0035] 50 parts of No. 90 asphalt, 14 parts of softening oil, 5 parts of styrene-butadiene-styrene block copolymer, 4 parts of styrene-butadiene rubber, 4 parts of recycled polypropylene, 1 part of high-temperature modifier, 7 parts of rubber powder And 32 parts of filler.

[0036] In this example, No. 90 bitumen is No. 90 bitumen from Qinhuangdao PetroChina Fuel Asphalt Co., Ltd., the softening oil is aromatic oil from Shandong Jiangshan Polymer Material Co., Ltd., and the styrene-butadiene-styrene block copolymer is from Sinopec For 1401, the styrene-butadiene rubber is P-styrene-butadiene rubber from Shandong Gaoshi Technology Industry and Trade Co., Ltd., the recycled polypropylene is green recycled polypropylene from Hongxing Plastic Factory in Qingyun County, Shandong Province, and the high-temperature modifier is Lotader resi...

Embodiment 2

[0045] The mass parts of each component of self-adhesive waterproof coiled material for road and bridge of the present invention are as follows:

[0046] 42 parts of No. 90 asphalt, 19 parts of softening oil, 8 parts of styrene-butadiene-styrene block copolymer, 2 parts of styrene-butadiene rubber, 5 parts of recycled polypropylene, 1.5 parts of high-temperature modifier, and 8.5 parts of rubber powder And 27 parts of stuffing.

[0047] In this example, the No. 90 bitumen is No. 90 bitumen of Qinhuangdao PetroChina Fuel Asphalt Co., Ltd., the softening oil is the reduced second-line oil of Qinhuangdao PetroChina Fuel Asphalt Co., Ltd., and the styrene-butadiene-styrene block copolymer is The 1401 of Yueyang Petrochemical, the styrene-butadiene rubber is the P-styrene-butadiene rubber (powder styrene-butadiene rubber) of Shandong Gaoshi Technology Industry and Trade, the recycled polypropylene is the green recycled polypropylene of Hongxing Plastic Factory in Qingyun County, Sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com