Rose branch trimmer combining wheels with caterpillar band

A combined, pruning machine technology, applied in the field of agricultural machinery, can solve the problems of reducing pressure and small size, and achieve the effects of reducing labor intensity, small size and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

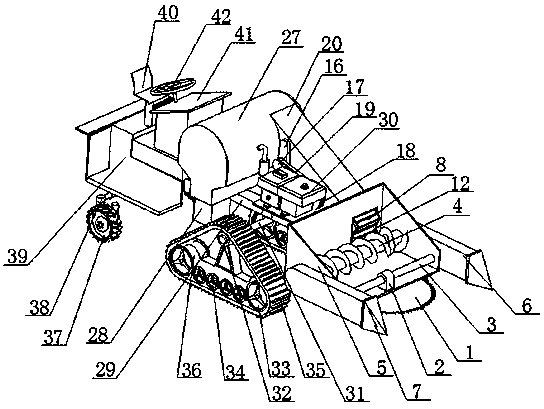

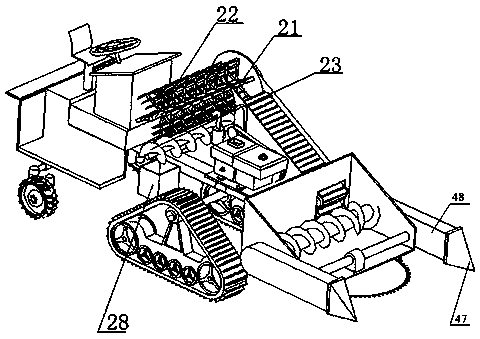

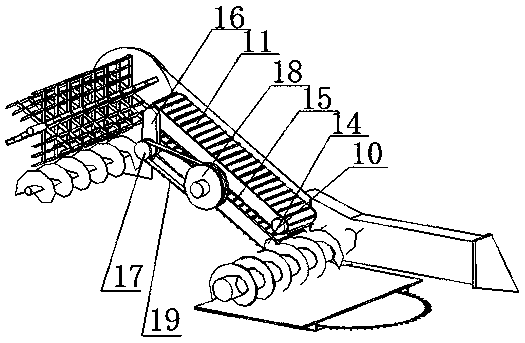

[0032] Embodiment 1: as Figure 1~8 As shown, this wheel-track combined rose pruning machine includes a frame 29, a shearing mechanism, a conveying mechanism, a crushing mechanism, a walking mechanism, and a driving mechanism;

[0033] The shearing mechanism includes a circular saw 1, a gearbox 2, a transmission shaft I3, a screw feed roller 4, a header 5, a left brancher 6, and a right brancher 7; the header 5 is fixed on the frame 29 front end, the left branching device 6 and the right branching device 7 are respectively arranged on both sides of the header 5, the spiral feeding roller 4 is located in the header 5, and the two ends of the main shaft of the screw feeding roller 4 pass through The header 5 is respectively connected with the left splitter 6 and the right splitter 7. The gearbox 2 is fixed on the header 5 and is located in front of the screw feed roller 4. The transmission shaft I3 passes through the gearbox 2 and drives Both ends of the shaft I3 pass through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com