Device for blanking blanks of circular saw

A blank material and circular saw technology, applied in the field of metal cutting devices, can solve the problems of irregular edges of circular plates, low utilization rate of raw materials, complex processing technology, etc., and achieve the effect of saving raw materials, simple structure, and simplified processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

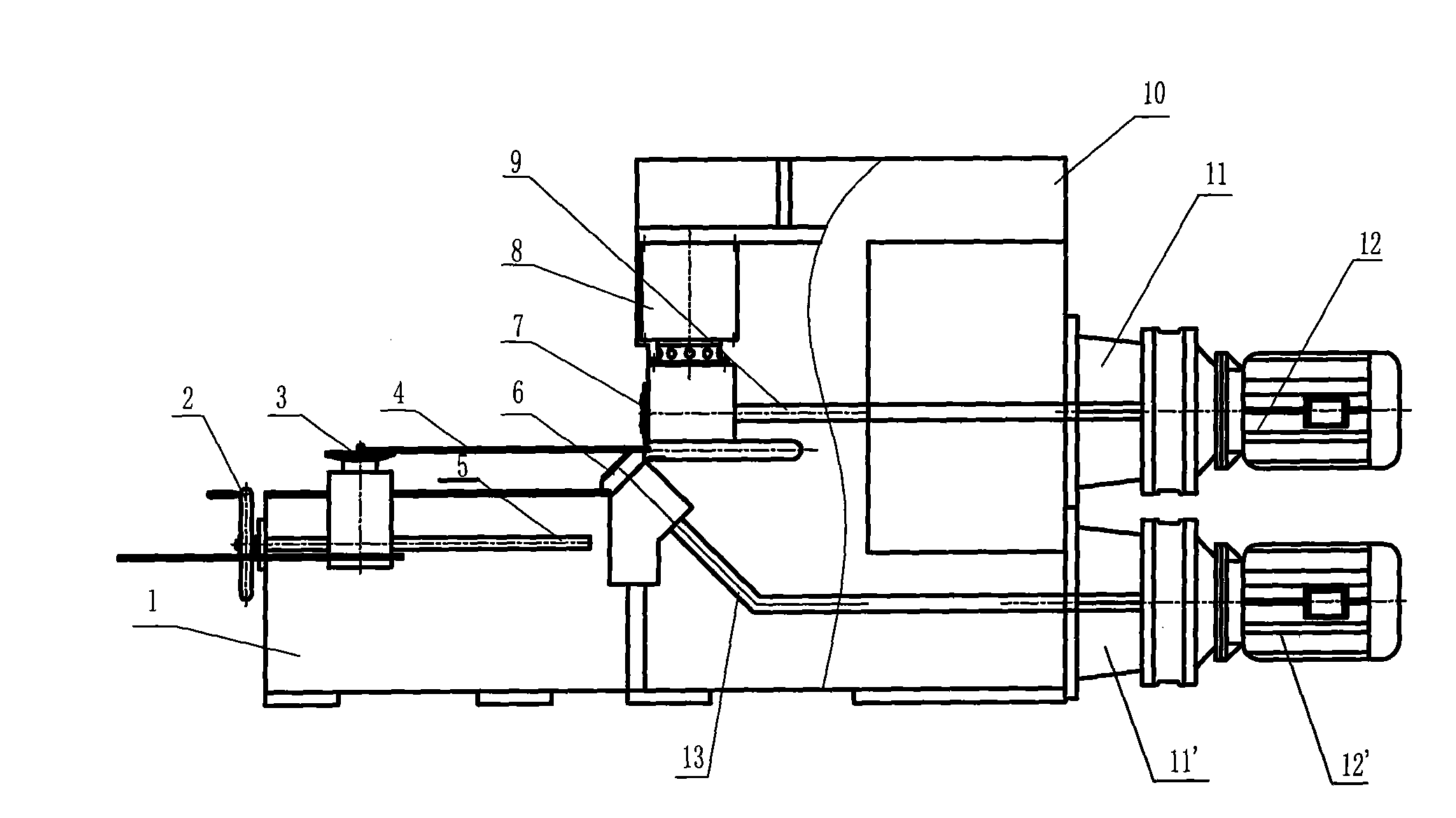

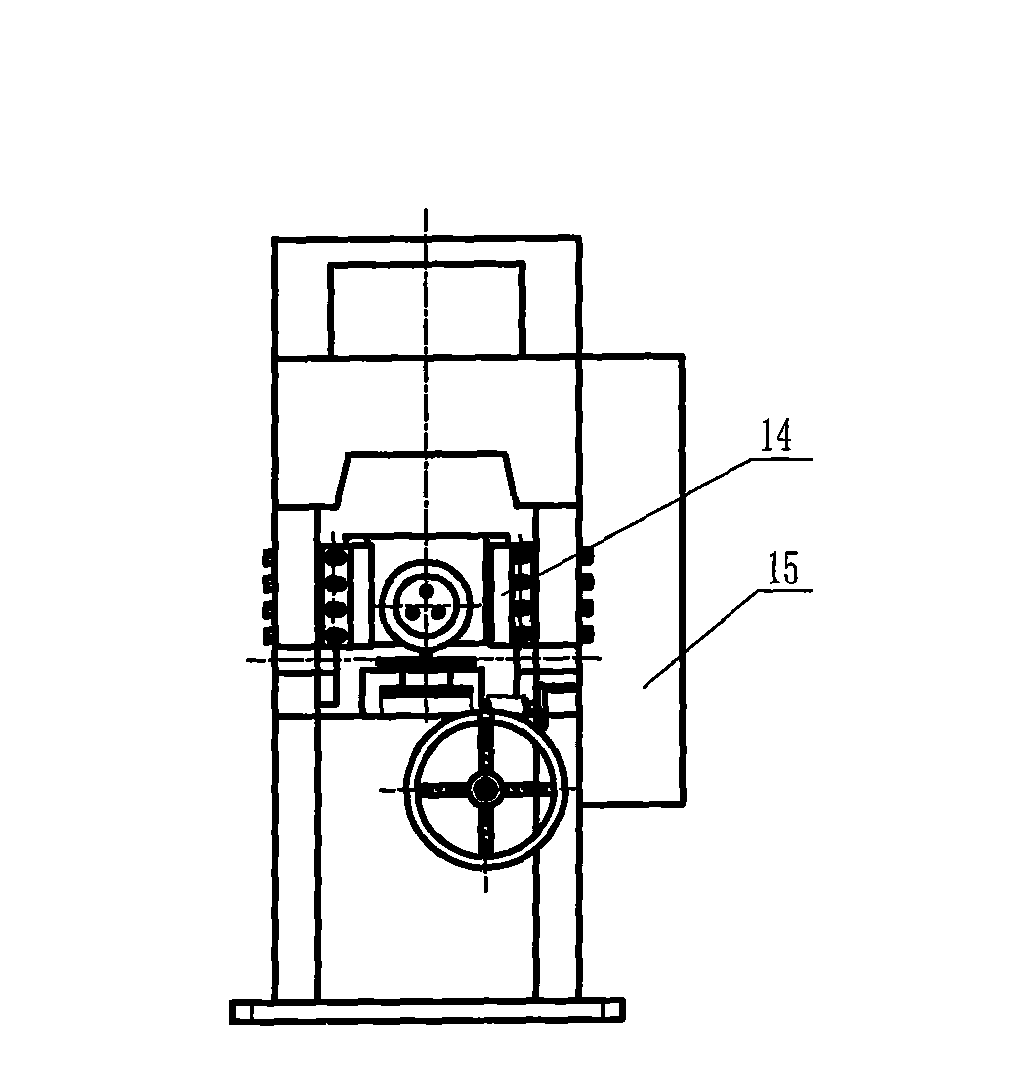

[0020] Such as figure 1 with figure 2 As shown, the present invention comprises frame 1, and frame 1 is provided with rotary table 3, and rotary table 3 is provided with longitudinal adjustment device and lateral adjustment device, and the other end of frame 1 is equipped with rotary drive device, and rotary drive device The upper transmission link 9 is connected with the upper shearing wheel 7 of the upper knife seat, the lifting device is set on the upper part of the upper knife seat and connected with the upper knife seat, and the rotary drive device is connected with the lower shearing wheel 7 of the lower knife seat through the lower transmission link 13. The wheel 6 is connected, the lower tool holder is fixedly connected with the frame 1, the upper shear wheel 7 is matched with the lower shear wheel 6, and the wheel axis of the upper shear wheel 7 and the wheel axis of the lower shear wheel 6 are on the vertical plane The projection of is at an acute angle.

[0021] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com