Corrugated board recycling device for packaging box

A corrugated board and recycling device technology, applied in the field of packaging corrugated board, can solve the problem of high recycling cost, and achieve the effects of promoting the formation of pulp, saving costs and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

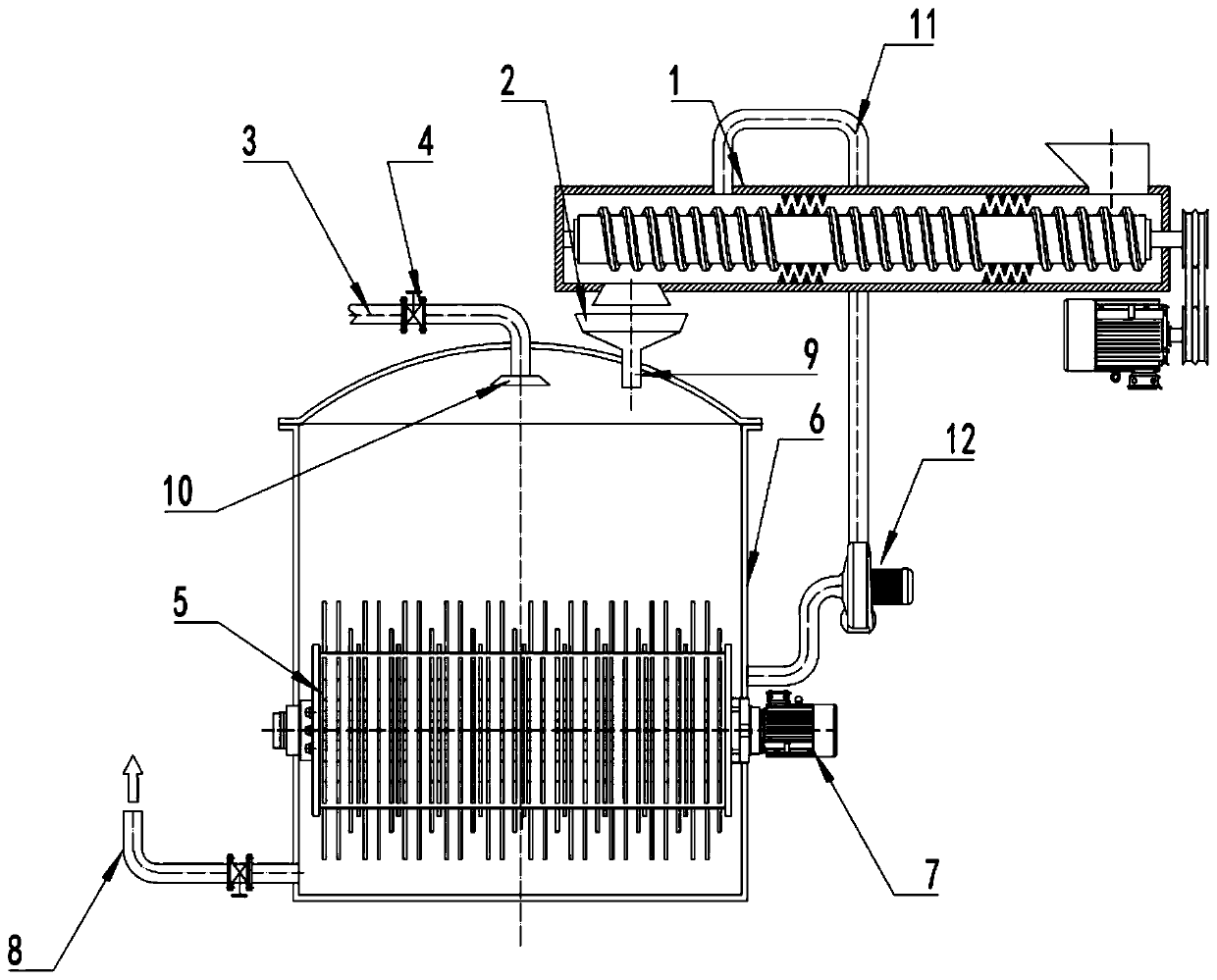

[0021] see Figure 1~2 , in an embodiment of the present invention, a corrugated cardboard recovery device for packaging boxes, including a primary crushing mechanism 1, a water inlet pipe 3, a beating mechanism 5, a beating tank 6, a drive motor 7 and a pulping pipe 8, the beating tank 6 The top is provided with a receiving hopper 2 corresponding to the primary crushing mechanism 1, and the bottom of the receiving hopper 2 is connected with a discharge pipe 9 leading to the beating tank 6, and the corrugated cardboard crushed by the primary crushing mechanism 1 can be input into the beating tank 6, the top and the bottom of the beating tank 6 are respectively connected with the water inlet pipe 3 and the outlet pipe 8, and the valve 4 is installed on the water inlet pipe 3 and the outlet pipe 8, and the beating mechanism 5 is installed in the beating tank 6, and the beating mechanism 5 Driven by drive motor 7 to rotate.

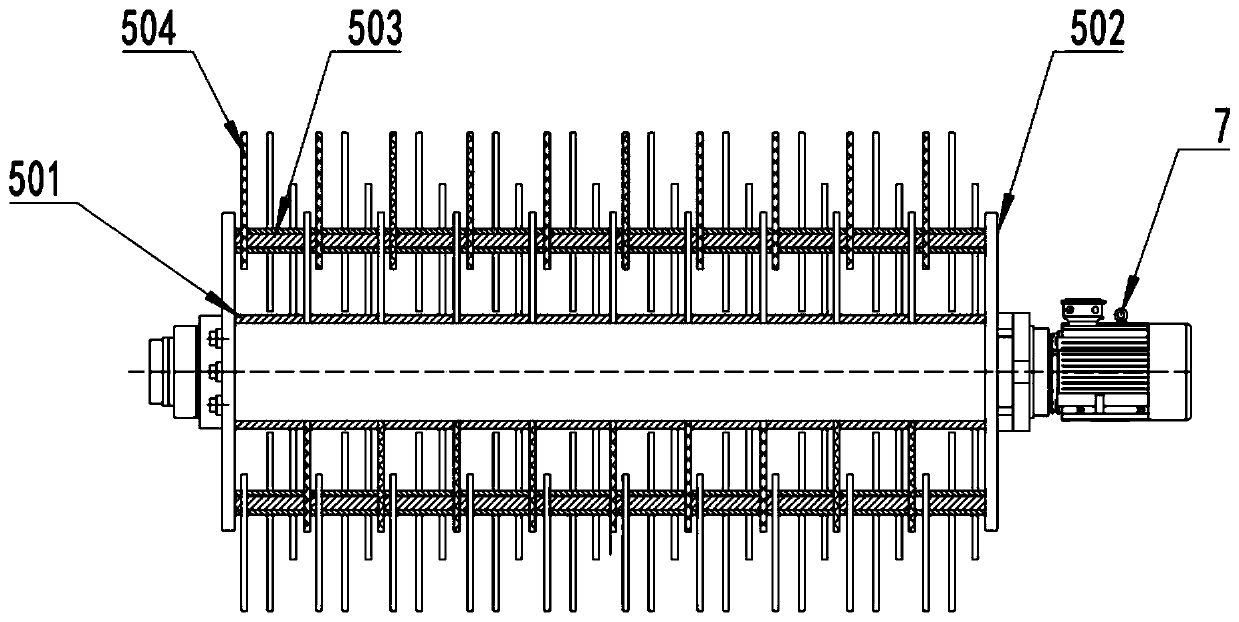

[0022] Specifically, the beating mechanism 5 includes...

Embodiment 2

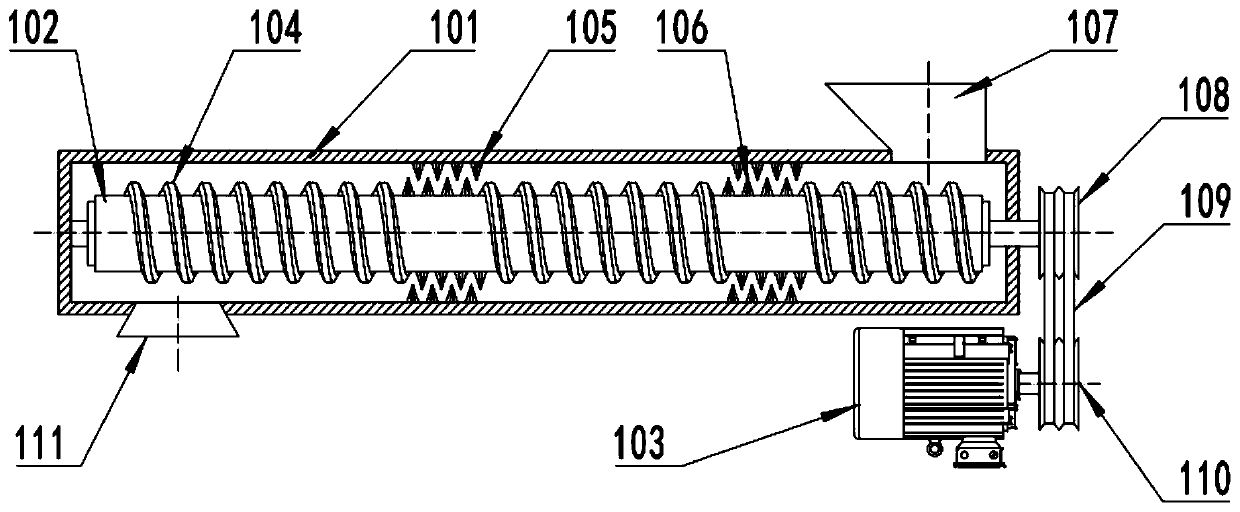

[0026] see Figure 1~3 , in an embodiment of the present invention, a corrugated cardboard recovery device for packaging boxes, the primary crushing mechanism 1 includes a crushing cylinder 101, a rotating shaft 102, a screw blade 104 and a crushing motor 103, and the rotating shaft 102 is installed in the crushing cylinder 101, Several sections of helical blades 104 are fixed on the outside of the rotating shaft 102, and the helical blades 104 can cut corrugated cardboard when rotating. Between adjacent sections of the helical blades 104, crushing teeth I105 and crushing teeth II106 are arranged, wherein the crushing teeth I105 and the crushing teeth II106 is respectively fixed on the crushing cylinder 101 and the rotating shaft 102, the positions of the crushing teeth I105 and the crushing teeth II106 are arranged alternately, and the rotating shaft 102 is driven to rotate by the crushing motor 103 through a transmission mechanism.

[0027] In actual application, the corruga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com