Rotary cutting edge mounting structure for crusher and crusher using such mounting structure

An installation structure and crusher technology, which is applied in the field of rotating blade installation structure and crusher, can solve problems such as cracks or gaps at the front end of the superhard knife tip 8, and achieve the effect of reducing material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

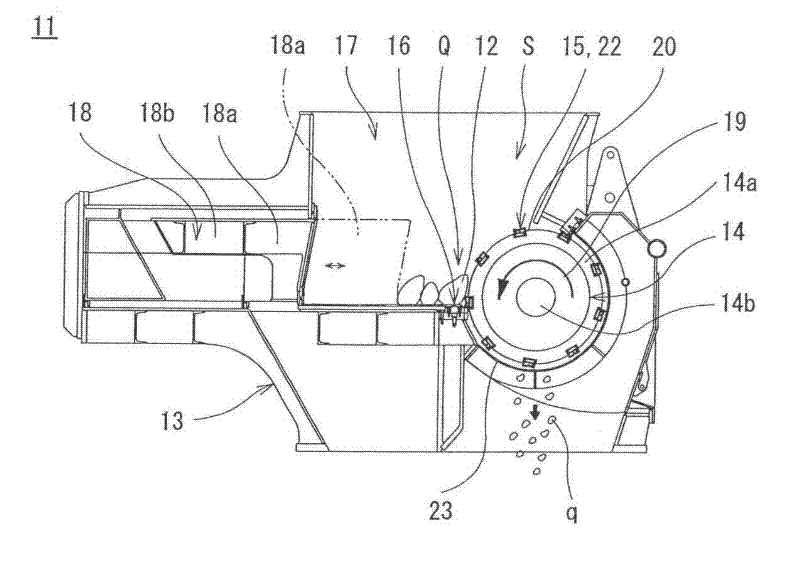

[0107] Refer to the following figure 1 Embodiment 1 of the rotary blade installation structure of the crusher of this invention and the crusher using this structure is demonstrated to FIG. 4. The shredder 11 is, for example, a single-shaft shredder, and is a device capable of shredding objects 12 to be shredded, such as waste wood, waste plastic, and used paper, into predetermined sizes. Furthermore, the purpose of crushing the object 12 to be crushed by the crusher 11 is to recycle the object to be crushed 12 such as waste as boiler fuel or agricultural materials.

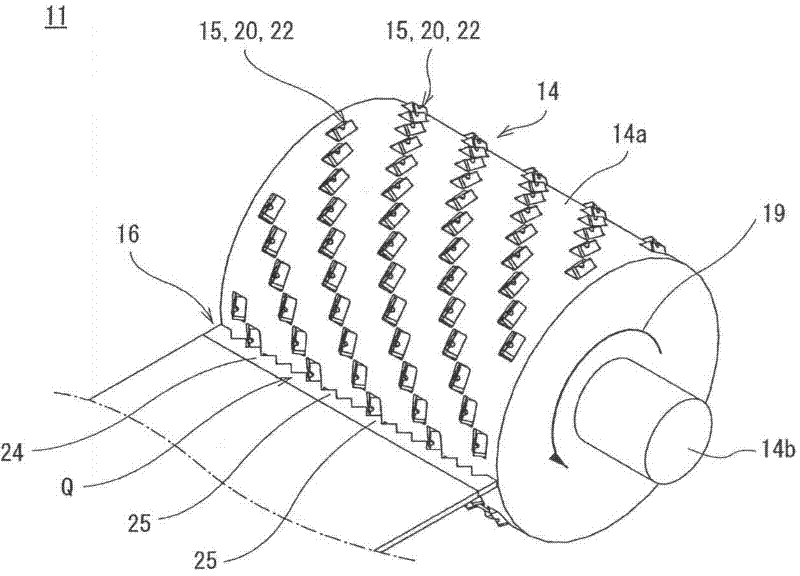

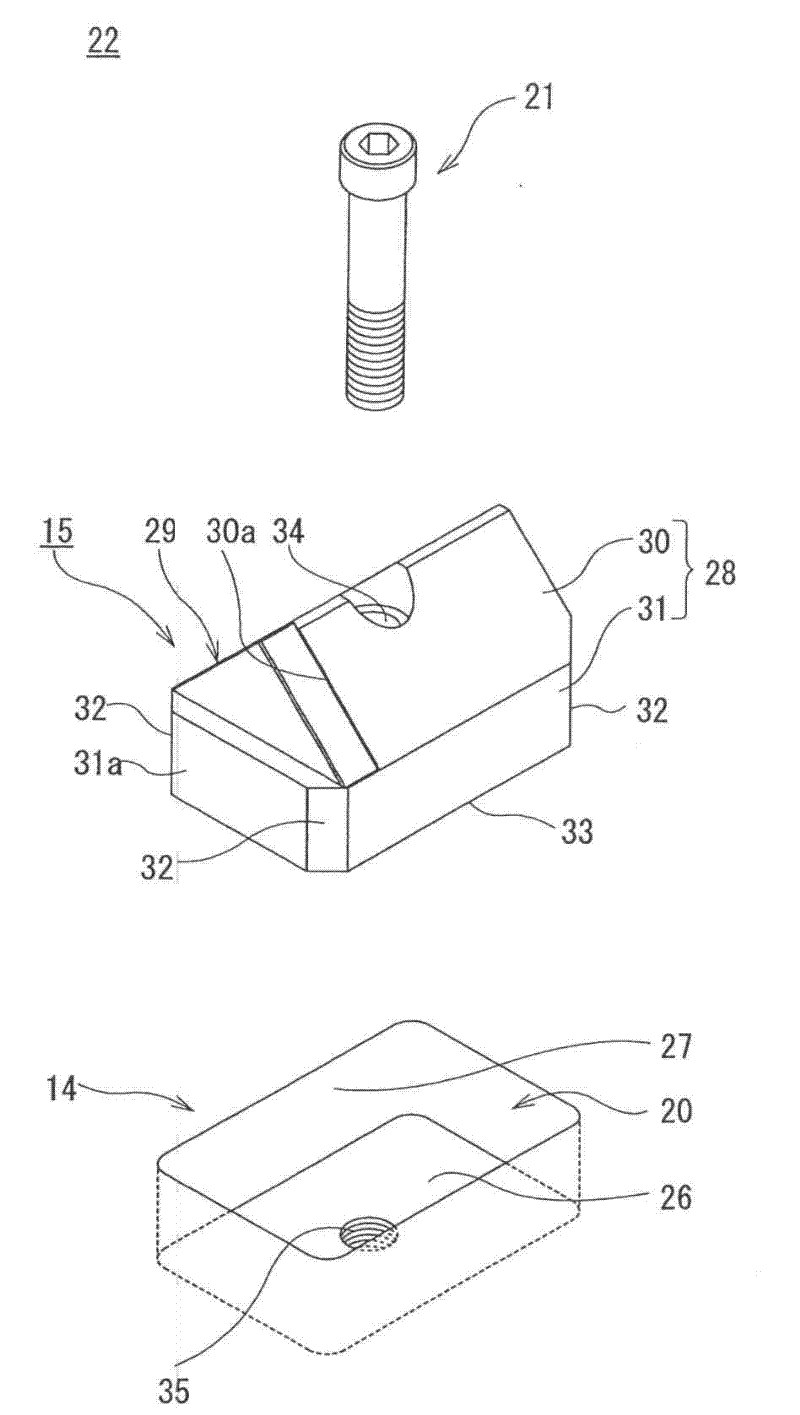

[0108] Crusher 11 AS figure 1 As shown, it includes a housing 13, a rotor 14 arranged inside the housing 13, a plurality of rotating blades 15 mounted on the surface of the rotor 14, a fixed blade 16 disposed on the housing 13 and arranged along the surface of the rotor 14, The hopper 17 installed on the upper part of the housing 13 and the push rod 18 installed on the side of the housing 13 .

[0109] The ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com