Production method for three-dimensional reinforced warp knitted spaced fabric

A technology of warp knitting spacer fabric, production method, applied in the direction of warp knitting, knitting, textile and paper making, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

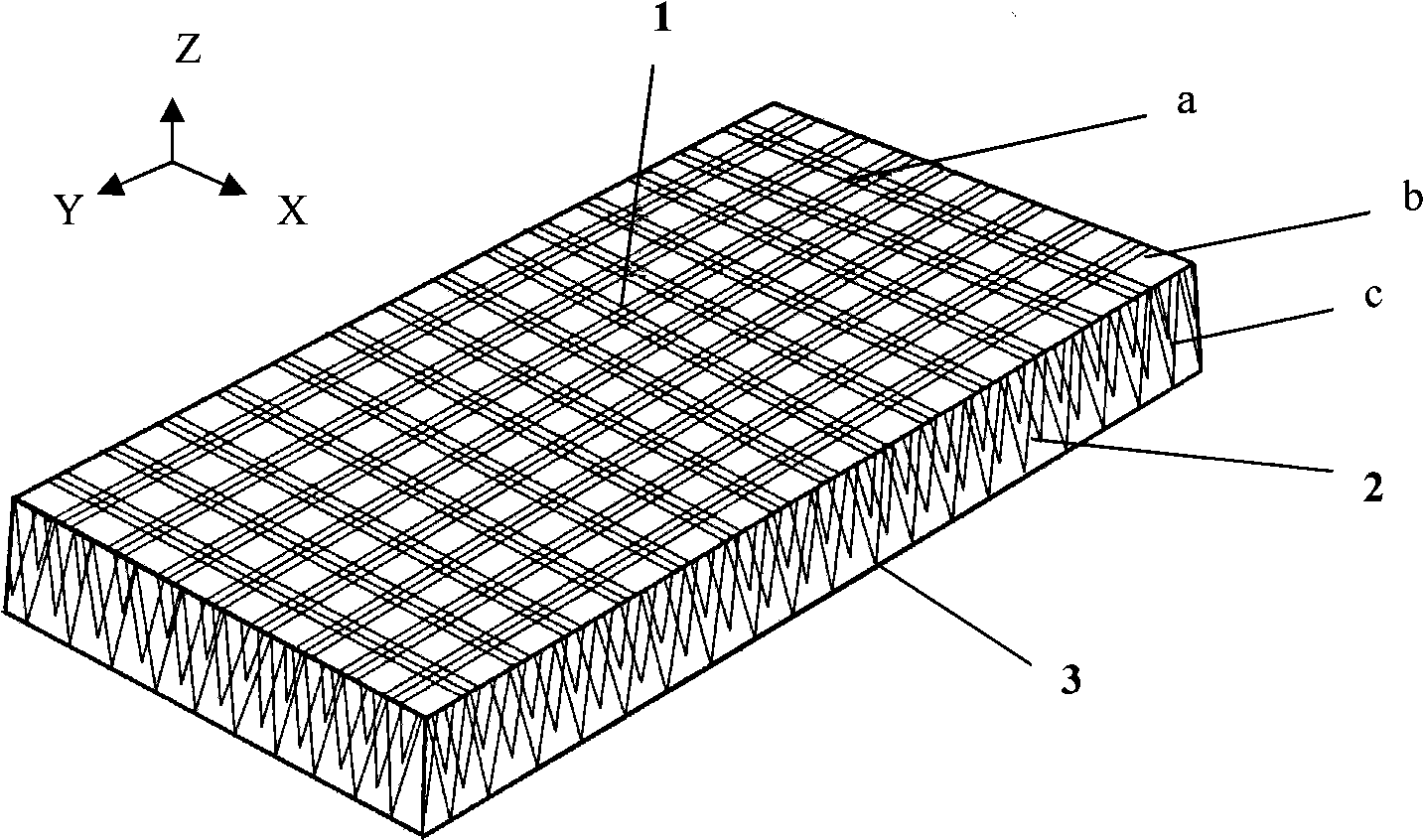

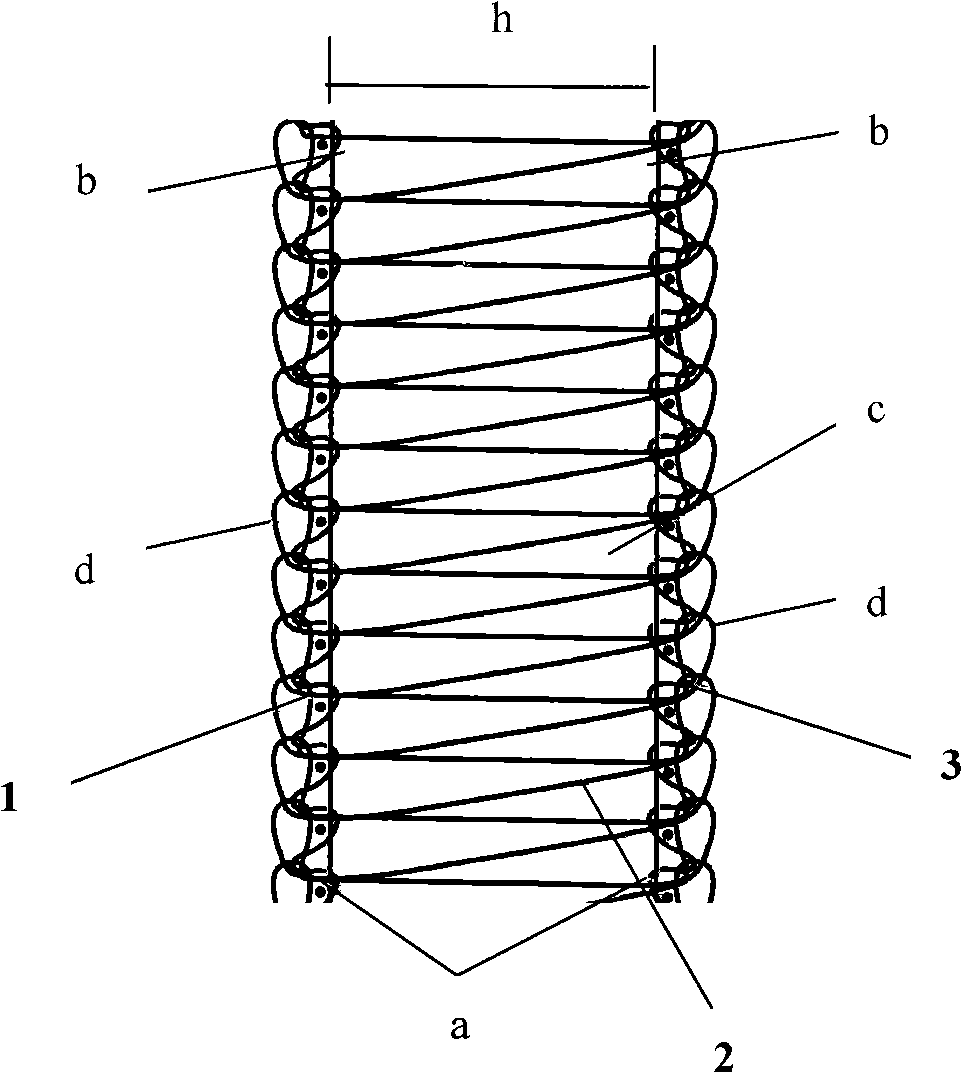

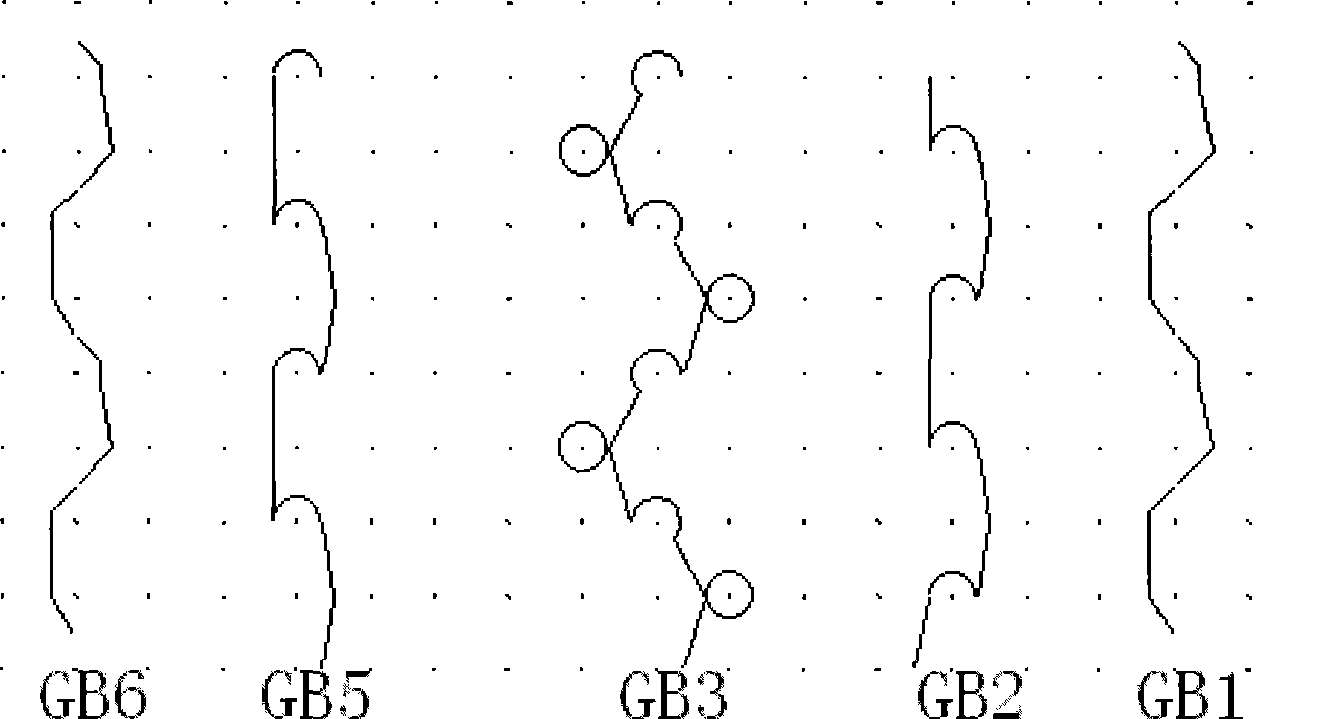

[0015] To refit the E12 or E16 six-comb double-needle bed Raschel warp knitting machine, install a single-head weft insertion device in front of the two needle beds. figure 1 , 2 The weft-inserted yarn a of the two surface layers of the machine is respectively fed to the clip chains of the two weft-inserted devices by two creels placed at the front and back of the machine, and is fixed, and then the thread end is cut, and then the thread end is fed from a special yarn guide needle Pull out, respectively from the front of the needle of each needle bed to the back of the needle, the change of the weft insertion yarn arrangement in the fabric can be realized by controlling the weft insertion device to feed or not feed the yarn; the interlining warp yarn b is controlled by the guide comb GB1 and GB6 is brought in, and the warp beam or creel is used to supply the yarn, and the interlining is carried out through the lapping structure as shown in Figure 4. Because the yarn is thick a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com