Special-shaped lens full-automatic shearing machine

A shearing machine, fully automatic technology, applied in the field of lenses, can solve the problems of single storage structure, complex structure, low transmission efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

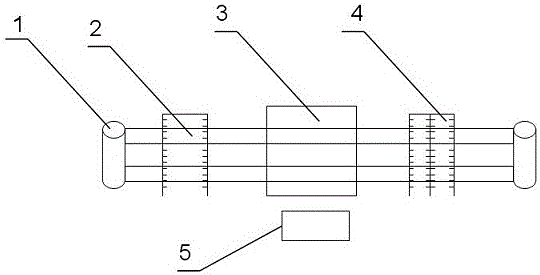

[0034] This embodiment provides a full-automatic shearing machine for special-shaped lenses, see figure 1 , figure 1 It is a schematic diagram of the structure of the special-shaped lens automatic shearing machine of the present invention. The special-shaped lens automatic shearing machine includes: special-shaped lens transmission mechanism 1, special-shaped lens feeding mechanism 2, special-shaped lens cutting mechanism 3, special-shaped lens unloading mechanism 4 and Waste collection mechanism 5.

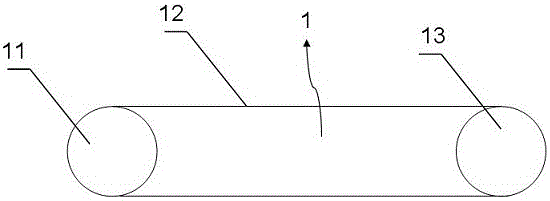

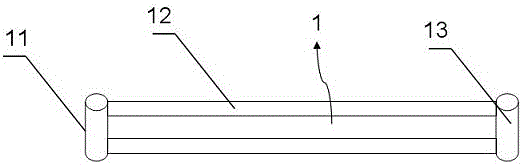

[0035] see Figure 2-Figure 3 , figure 2 It is a schematic diagram of the front view of the transmission mechanism of the special-shaped lens automatic shearing machine of the present invention, image 3 It is a top view schematic diagram of the transmission mechanism of the special-shaped lens automatic shearing machine of the present invention. The special-shaped lens transmission mechanism includes an active transmission wheel 13, a passive transmission wheel 11 and two co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com