Epoxy structural adhesive with high elongation at break and preparation method thereof

A technology of epoxy structural adhesive and adhesive, applied in the direction of epoxy resin adhesive, adhesive, adhesive additive, etc., can solve the problems of reduced bonding strength of materials, shortened service life, difficult process control, etc., to achieve good shearing , cost reduction, good transparency and anti-aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

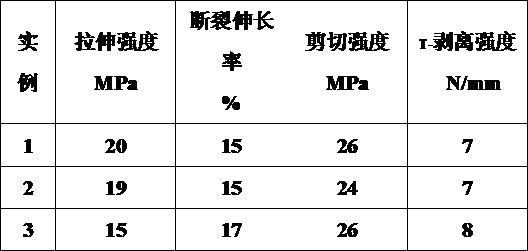

Examples

specific Embodiment 1

[0022] (1) Place 20% by weight epoxy resin E51 and 35% nano-core-shell modified resin in an oven at 50-80°C for 20-40 minutes and stir twice to make the materials evenly mixed.

[0023] (2) Add 15% didecyl phthalate, 5% dioctyl phthalate, 2% fumed white carbon black, and 16% heavy calcium carbonate to the above mixed material. , 3% dicyandiamide curing agent, 2% zinc oxide, 2% pigment, initially mixed.

[0024] (3) Mix 3-4 times on the three-roll mill to make the materials fully mixed evenly. During this period, control the temperature of the three-roll mill rolls below 40°C, and visually observe that the materials are uniform and free of particles, and the materials are discharged.

[0025] (4) Place the above-mentioned mixed materials in a vacuum degassing machine at a speed of 2000-3000r / min for 180-300 seconds, and discharge the material to obtain the adhesive.

[0026] Prepare samples according to customer test standards, and test after baking at 170°C for 20 minutes.

specific Embodiment 2

[0028] (1) Place 20% epoxy resin E51, 5% epoxy resin E44, 20% nano core-shell modified resin, and 10% liquid nitrile rubber in an oven at 50-80°C for heating 20-40 minutes, use a spatula to stir every ten minutes to make the ingredients evenly mixed.

[0029] (2) Add 11% didecyl phthalate, 4% dioctyl phthalate, 2% fumed white carbon black, and 26% heavy calcium carbonate to the above mixed material. , 4% silica powder, 3% dicyandiamide curing agent, 3% zinc oxide, 2% pigment, initially mixed.

[0030] (3) Mix 3-4 times on the three-roll mill to make the materials fully mixed evenly. During this period, control the temperature of the three-roll mill rolls below 40°C, and visually observe that the materials are uniform and free of particles, and the materials are discharged.

[0031] (4) Place the above-mentioned mixed materials in a vacuum degassing machine at a speed of 2000-3000r / min for 180-300 seconds, and discharge the material to obtain the adhesive.

[0032] Prepare sa...

specific Embodiment 3

[0034] (1) Put 22% epoxy resin E51 and 20% nano-core-shell modified resin by weight in an oven at 50-80°C for 20-40 minutes and stir with a spatula every ten minutes. Mix the ingredients well.

[0035] (2) Add 12% didecyl phthalate, 5% dioctyl phthalate, 3% polybutadiene, and 3% fumed silica to the above mixed material. , 18% of heavy calcium carbonate, 10% of polyvinyl chloride paste resin, 1.5% of dicyandiamide curing agent, 0.5% of acid anhydride curing agent, 3% of zinc oxide, 2% of pigment, preliminary mixing.

[0036] (3) Mix 3-4 times on the three-roll mill to make the materials fully mixed evenly. During this period, control the temperature of the three-roll mill rolls below 40°C, and visually observe that the materials are uniform and free of particles, and the materials are discharged.

[0037] (4) Place the above-mentioned mixed materials in a vacuum degassing machine at a speed of 2000-3000r / min for 180-300 seconds, and discharge the material to obtain the adhesiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com