Gate valve assembly comprising a support member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

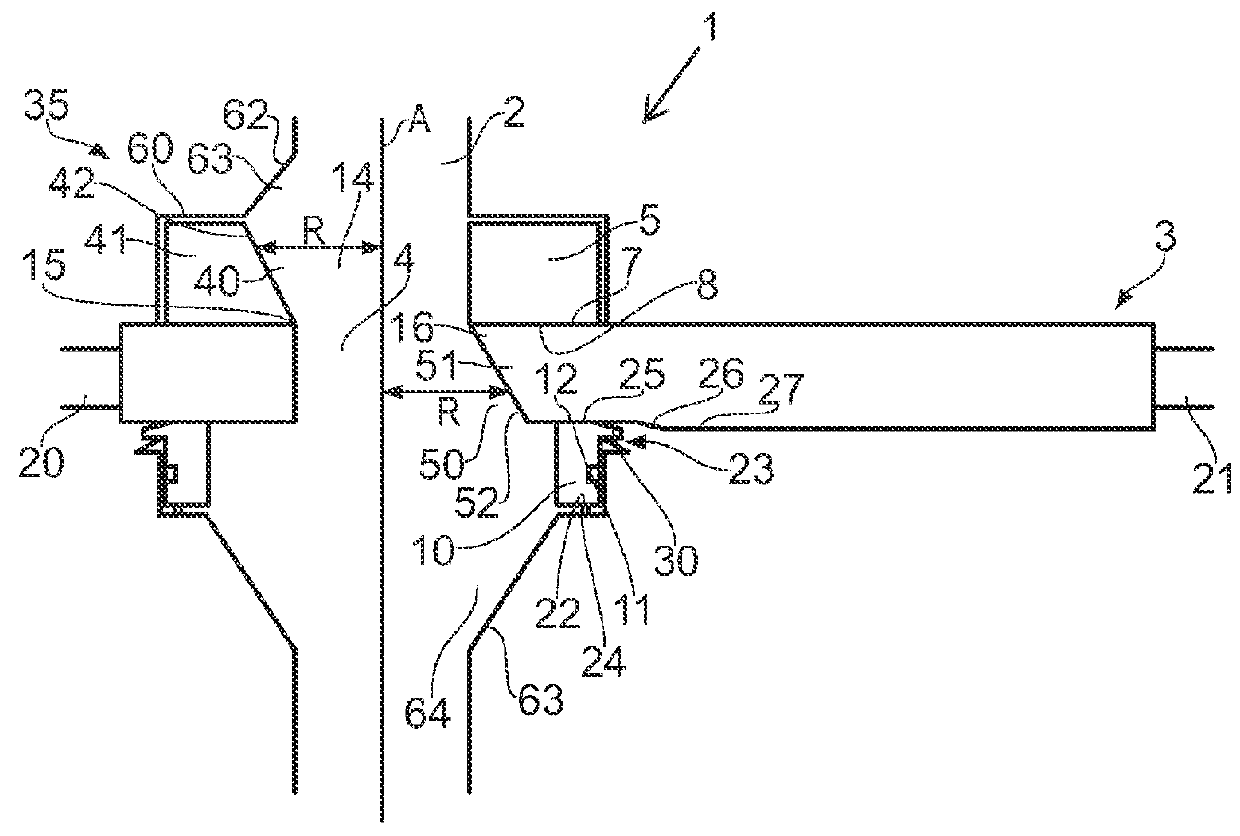

[0052]FIG. 1 shows a gate valve assembly 1 arranged with a through bore 2 for receiving an elongated member (not shown). A movable gate element 3 has a gate bore 4 for receiving the elongated member and arranged with a cutting tool 16. The minimum opening of the gate bore 4 is essentially equal to the through bore 2. A first seat 5 may be provided as a cutting seat and has an engagement surface 7 arranged in sliding contact with a first surface 8 of one side the gate element 3. A second seat 10 has a seal surface 11 arranged in sealing contact with a sealing surface 12 at the other side of the gate element 3. It is possible to provide the first seat 5 so that the engagement surface 7 provides a seal surface in sealing contact with the first surface of the gate element, in which event the first surface will then act as a sealing surface.

[0053]The first seat 5 is arranged as a support member with an opening 14 encompassing the through bore 2 and an expanded opening portion 40 which is...

second embodiment

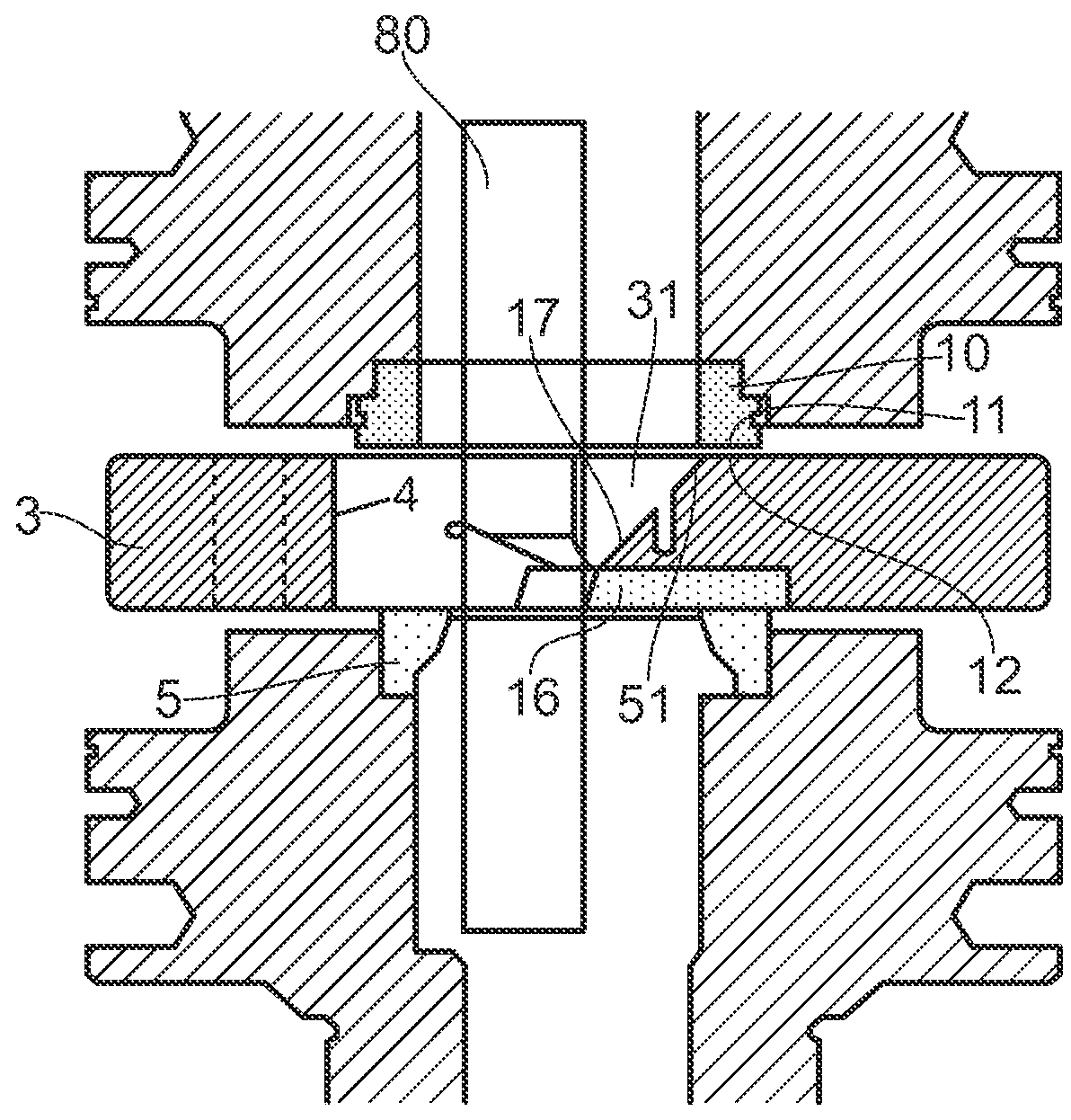

[0064]FIG. 2 shows the gate valve assembly 1. In this embodiment the first seat 5 and the second seat 10 have some configurations which may differ from the configurations shown in FIG. 1, but the overall components and the working principles for shearing the elongated member described in connection with FIG. 1 are the same. The gate element 3 is in FIG. 2 shown partly moved from its open position to a closed position. The elongated member 80 to be cut is indicated in the drawing in abutment between the first seat 5 and the gate element 3. A temporary seal surface protection element 31 is arranged for protection of the seal surface 11 of the second seat 10 before the shearing of the elongated element is to take place. The temporary seal surface protection element 31 is arranged to be removed from the gate valve or possibly destroyed prior to the shearing of the elongated member. The protection element 31 may be provided as a brittle material which is easy to destroy. Another possibil...

third embodiment

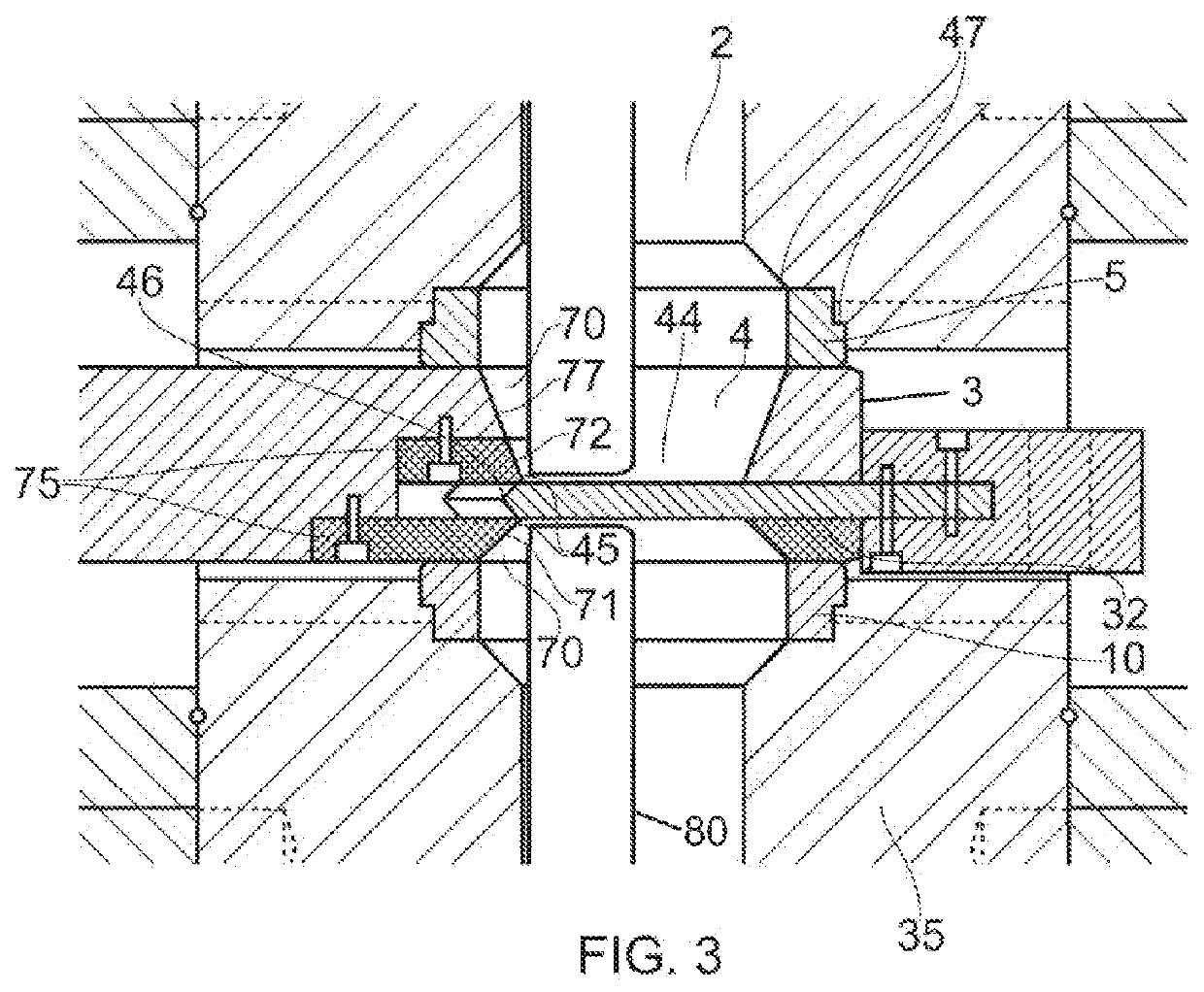

[0066]FIG. 3 shows the invention, in which the cutting tool 46 is movably arranged in a transverse recess 32 in the gate element 3 opening into the gate bore 4. The cutting tool 46 is arranged to be separately moveable relative to the gate element 3. The gate bore 4 has an inclined surface 77 providing the gate bore 4 with a varying radius in the axial direction of the gate bore.

[0067]The support member is arranged in the gate element 3 with the opening 44 encompassing the through bore 2 for receiving the elongated member and an expanded opening portion 70 which is open to the through bore 2 in the axial direction of the through bore. A reduced section 75 of the support member has an inclined surface 71, 72 which defines the expanded opening portion 70. The opening 44 has a decreasing radius along the reduced section in the axial direction of the support member toward a contact surface area 45 arranged at an end portion of the support member adjacent the cutting tool 46 at both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com