Ultra-long tobacco shred rotary shearing machine, and shearing equipment and shearing method

A technology of rotary shearing and shearing equipment, applied in the direction of tobacco, tobacco processing, application, etc., can solve the problems of uneven distribution of tobacco length, reduce filament rate, etc., and achieve more uniform discharge, less broken, and easy to manufacture. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific embodiments.

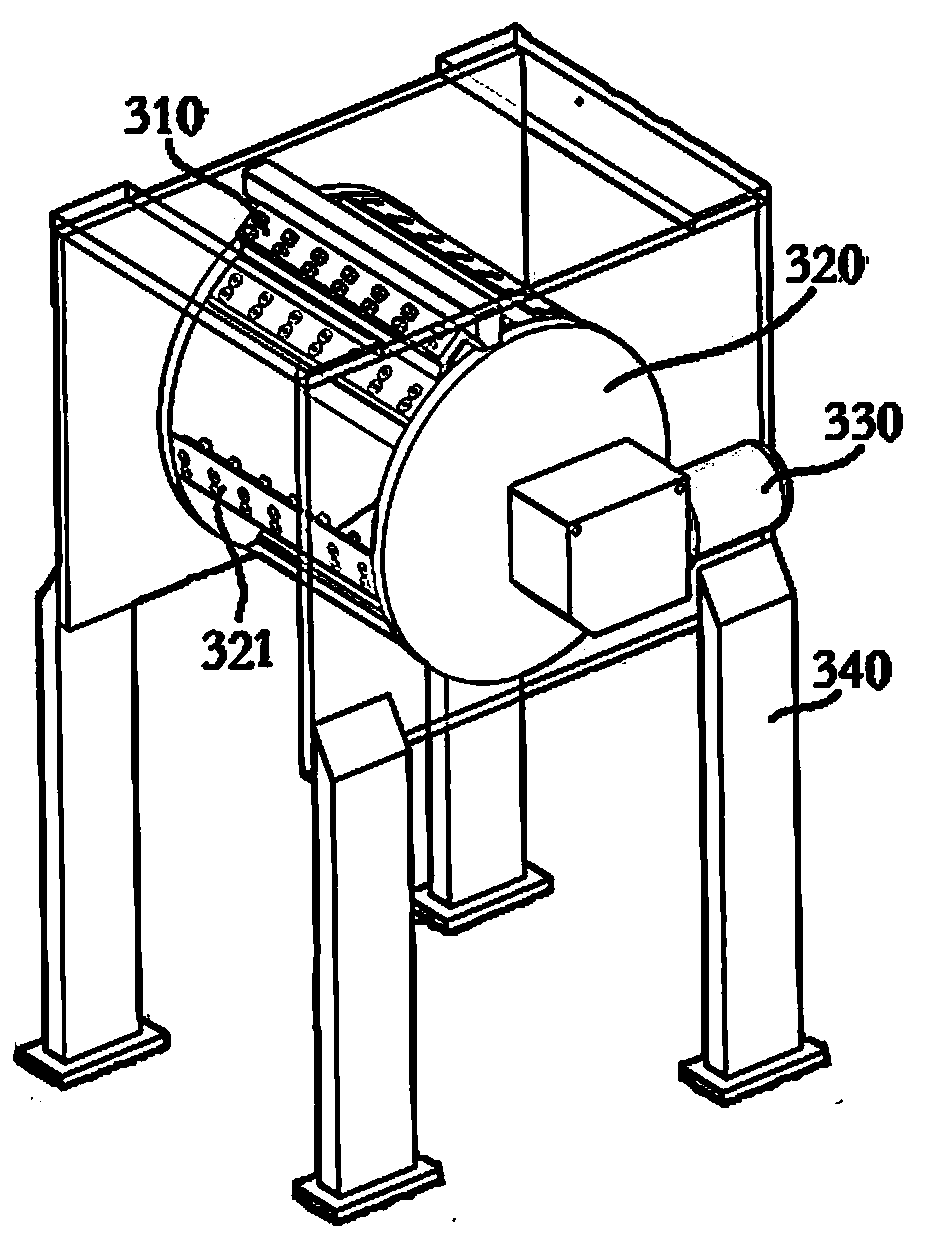

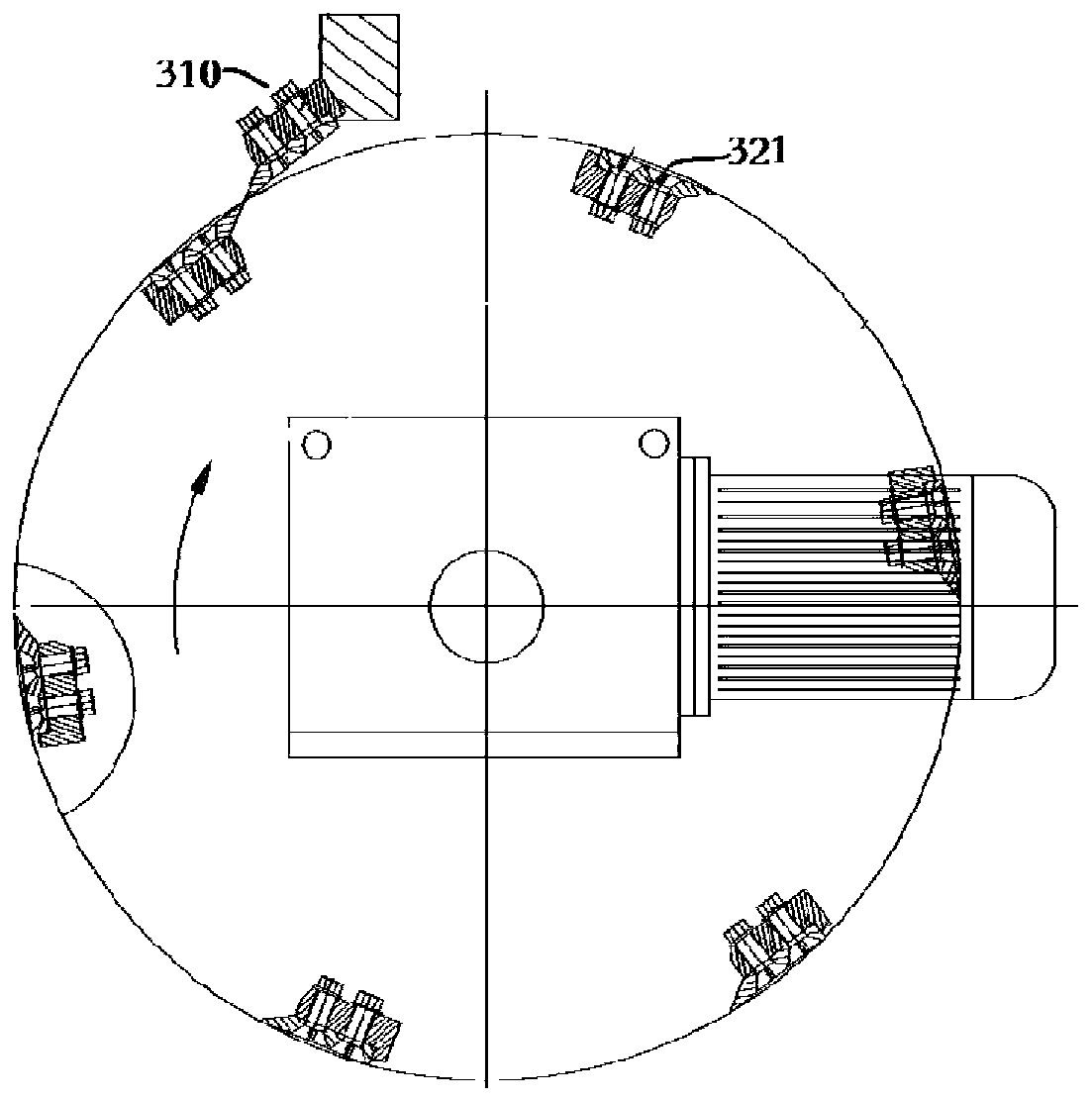

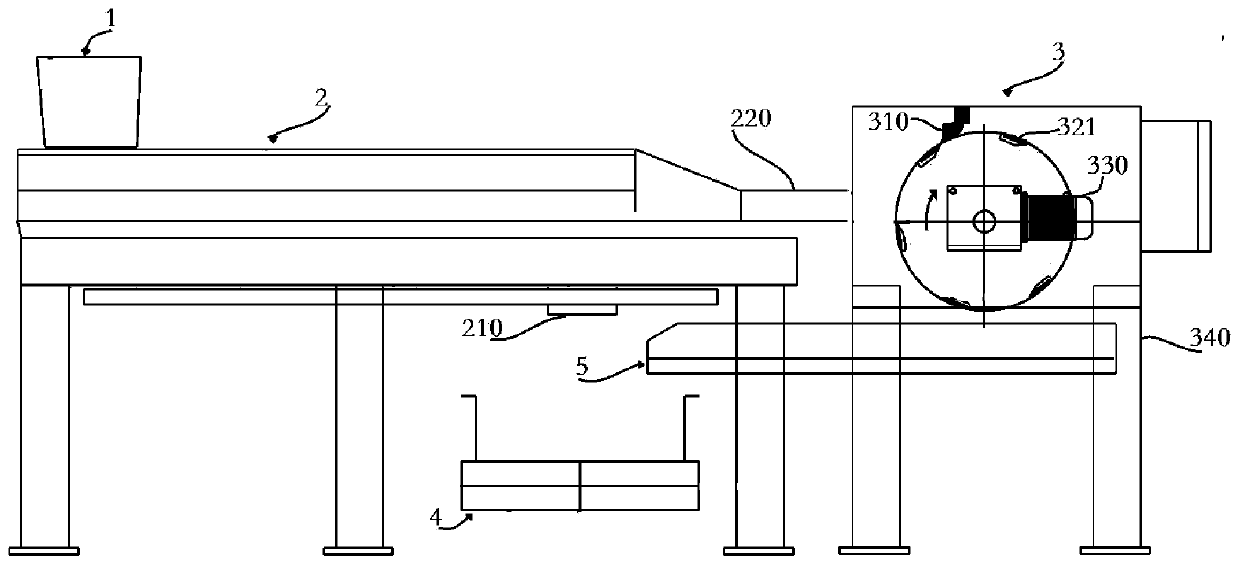

[0040] Such as figure 1 As shown, the ultra-long shredded tobacco rotary shearer 3 provided by the present invention includes a frame 340 on which a rotating frame and a motor reducer 330 for driving the rotating frame to rotate are installed. A rotary cutter 321 for wrapping extra-long shredded tobacco is installed on the peripheral surface, and the blade orientation of the rotary cutter 321 is consistent with the rotation direction of the rotary frame. A fixed cutter 310 is also installed on the frame 340 . Such as figure 2 As shown, the blade orientation of the fixed cutter 310 is set corresponding to the blade orientation of the rotary cutter 321; when the rotating frame rotates, it will drive the rotary cutter 321 on its outer peripheral surface to rotate, and the fixed cutter 310 and the passing rotary cutter 321 can form a cutting motion, and the super long shred...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal length | aaaaa | aaaaa |

| Vertical depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com