Aerated brick cutting device

A cutting device and aerated brick technology, applied in the field of aerated brick processing, can solve the problems of cutting deviation, aerated brick offset, and great effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following is further described in detail through specific implementation methods:

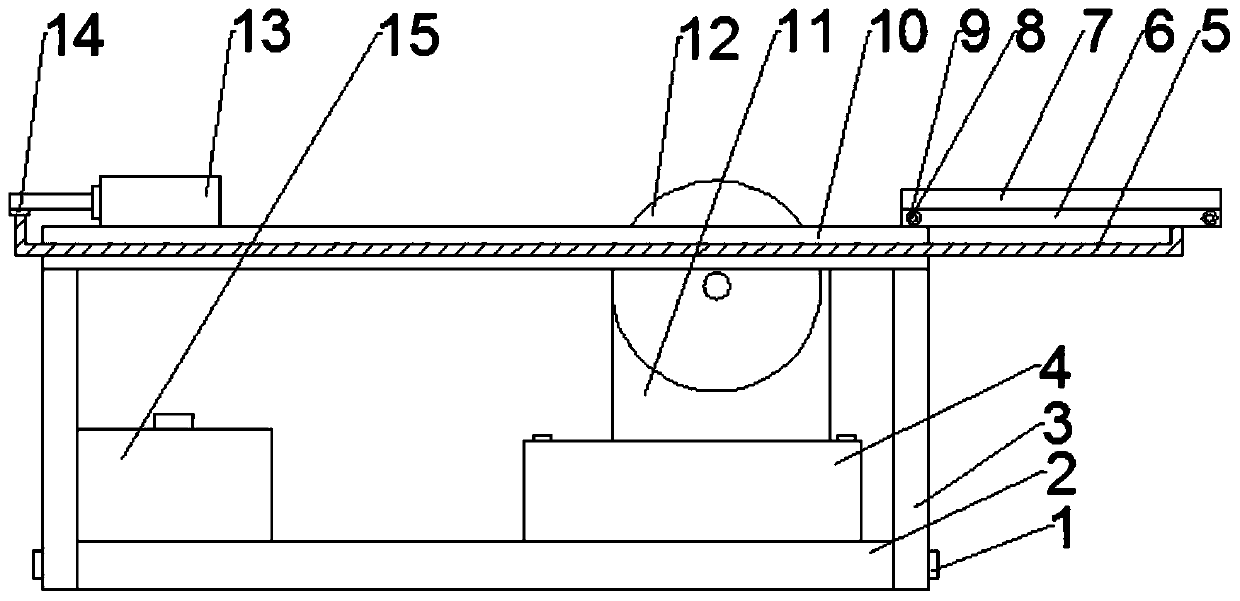

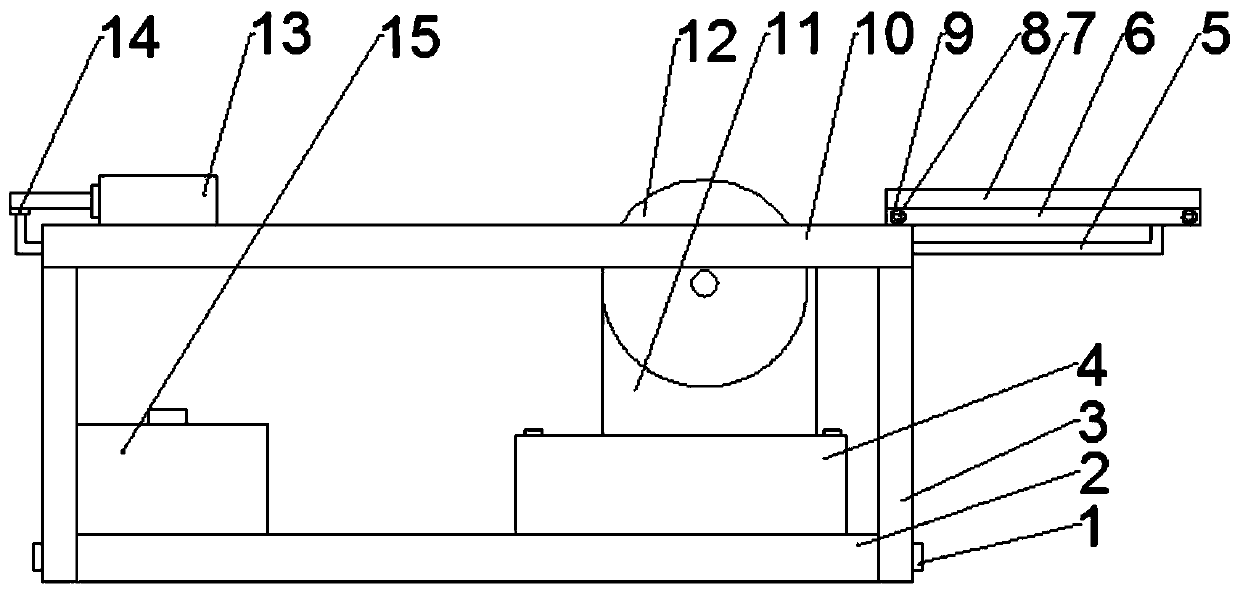

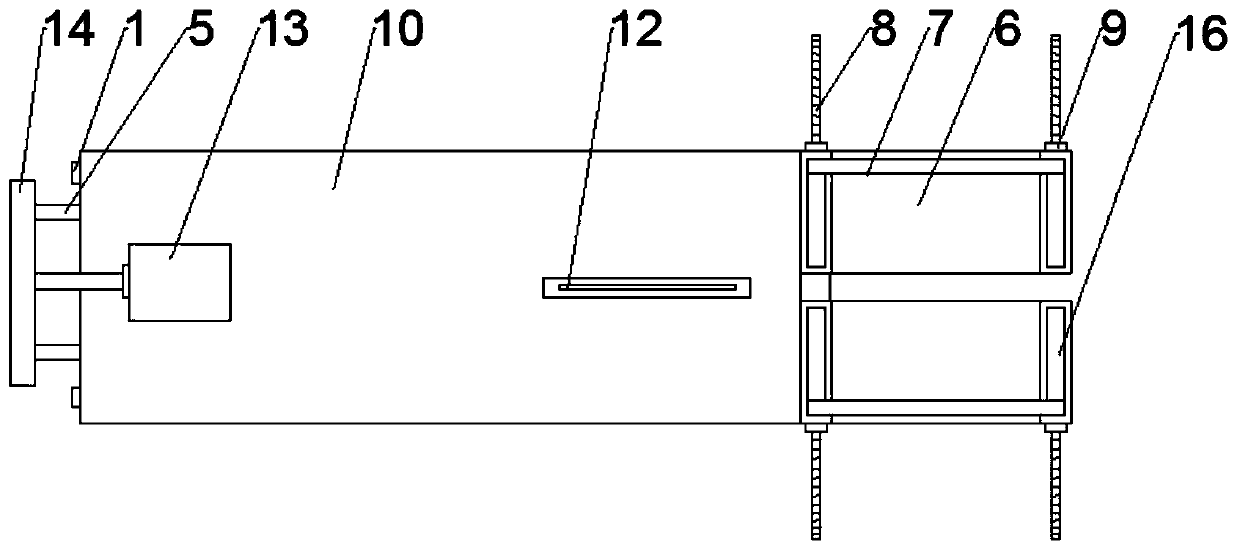

[0016] The reference signs in the drawings of the description include: screw 1, base 2, bracket 3, cushion seat 4, sliding rod 5, conveying table 6, baffle plate 7, push rod 8, lock nut 9, cutting table 10, motor 11 , cutting knife 12, cylinder 13, connecting plate 14, reinforcing seat 15, limit groove 16.

[0017] The embodiment is basically as attached figure 1 Shown: an aerated brick cutting device, including a base 2, a pedestal 4 is connected to the base 2 through a screw 1, a motor 11 is fixedly connected to the pedestal 4, a bracket 3 is threaded on the base 2 through a screw 1, and the bracket The top of 3 is welded with cutting table 10, and cutting table 10 is provided with such as figure 2 As shown in the groove, the output shaft of the motor 11 is fixedly connected with a circular cutting knife 12, the cutting knife 12 runs through the groove and cooperates with the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com