An exposure method for controlling batch line width differences of flexible circuit boards

A technology of flexible circuit board and exposure method, which is applied in the field of circuit boards, can solve the problems of narrowing line spacing and large line width, and achieve the effects of shortening the manufacturing cycle, reducing production costs, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0027] Firstly, the nouns in the present invention will be explained.

[0028] The products mentioned in this article refer to flexible circuit boards.

[0029] Photoresist—a photosensitive solder resist that reacts with light to produce a substance soluble in a specific chemical solution Coating—a method of attaching photoresist to a product through a device

[0030] Exposure - photosensitive treatment of the photoresist coated on the product to change the properties of the photoresist at the desired position

[0031] Development - removal of photoresists whose properties have changed after exposure

[0032] Line Width - the width of the wire

[0033] Line spacing - the distance between two adjacent conductors

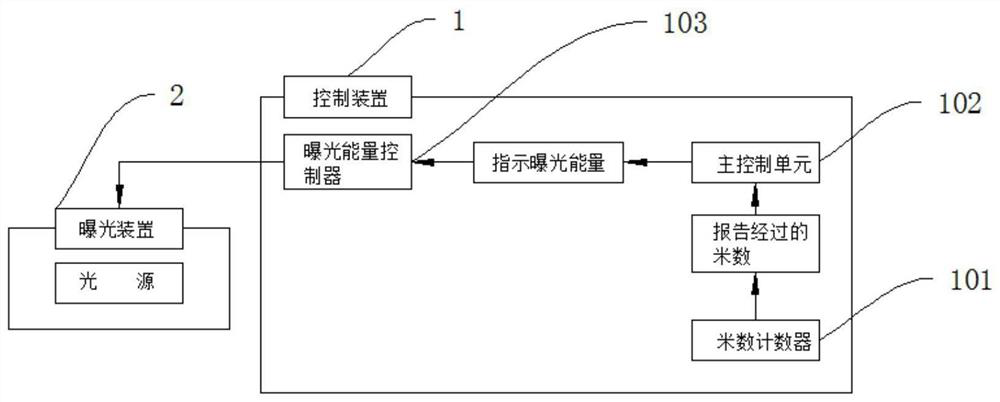

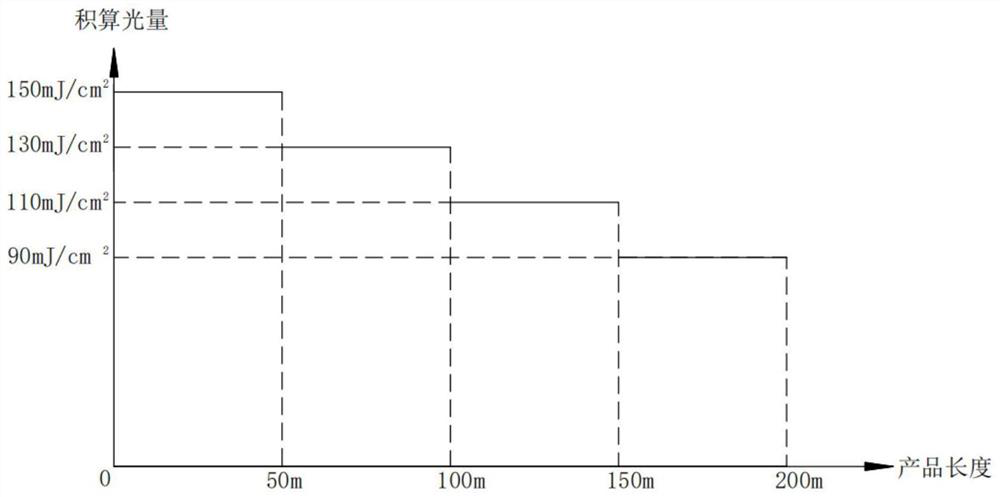

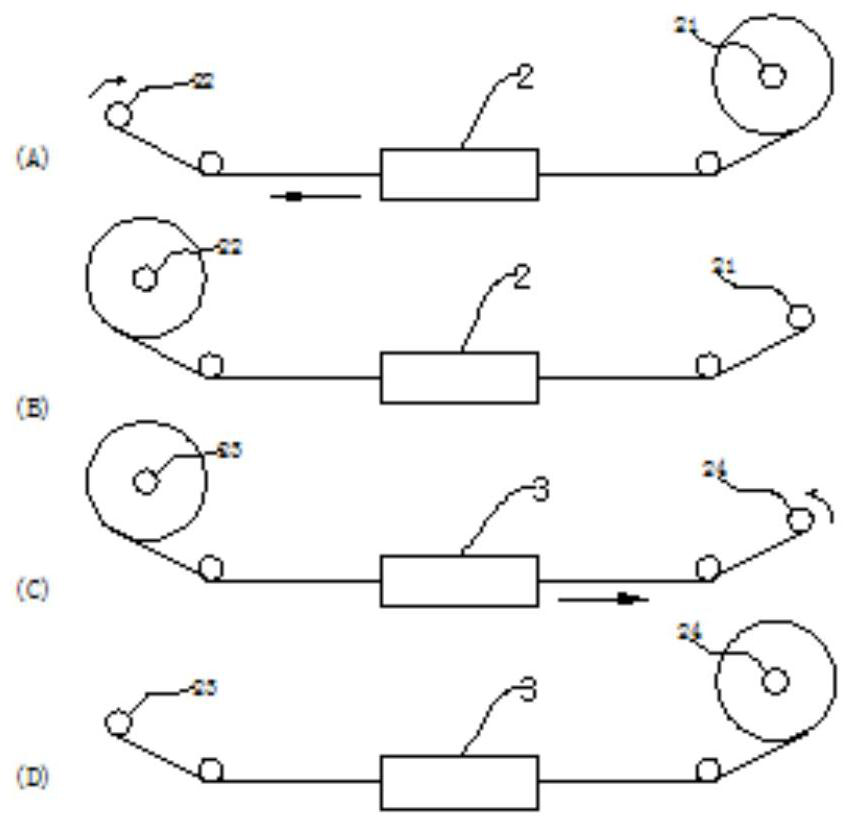

[0034] Such as figure 1 As shown, an exposure method for controlling the difference in line width of flexible circuit board ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com