Female massager intermediate layer flexible rubber filling forming process and assembly method

A molding process and massager technology, applied in the direction of vibration massage, genital massage, massage auxiliary products, etc., can solve the problems of inconvenient filling of silica gel, poor filling, and inconvenient assembly, so as to avoid loose fit and reduce assembly Process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

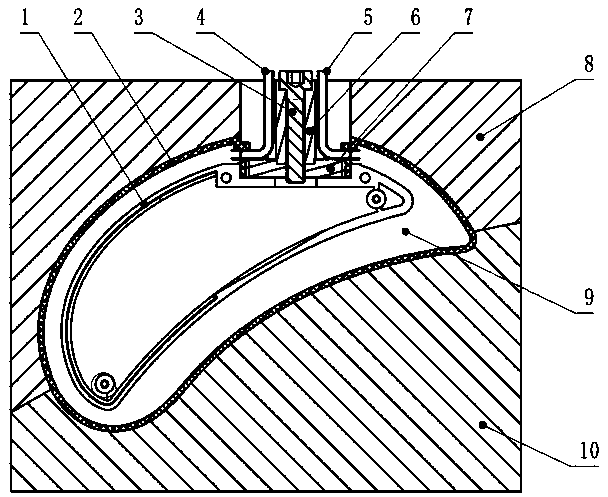

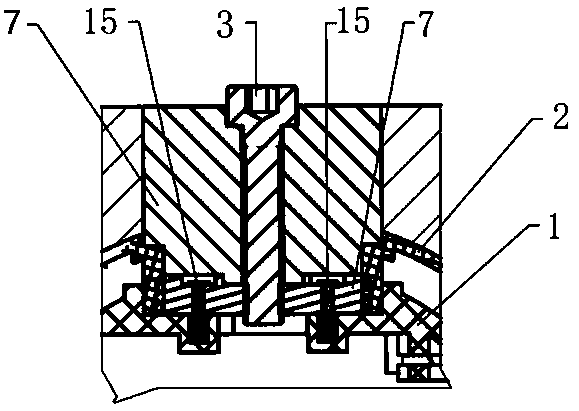

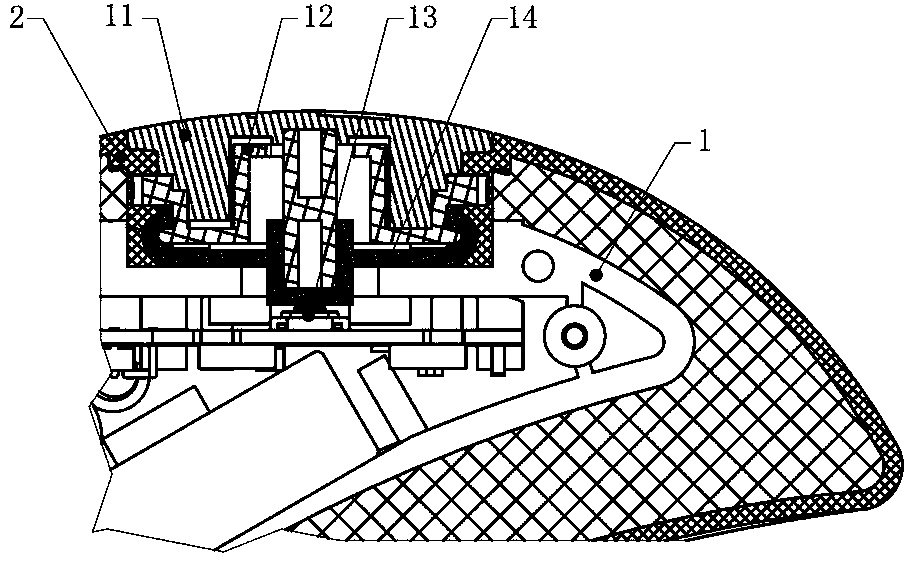

[0023] Embodiment one: see image 3

[0024] The upper part of the core shell 1 is provided with a groove, and a silicone interlayer 14 is placed in the groove. The middle part of the silica gel interlayer 14 is a cylindrical cavity for setting the button assembly. The circumference of the cylindrical cavity extends outwards, and the edge is On the cylindrical side, the silicone interlayer 14 is close to the inner shell 1 and the silicone skin 2 . Put the pressure plate 12 above the silicone interlayer 14, and the middle part of the pressure plate 12 is provided with a guide column integrally formed with the pressure plate 12, which is used to press the switch 13. The switch 13 is placed at the bottom of the center of the silica gel interlayer 14, and the pressure plate 12 is fixed by threaded connection. On the core shell 1 , make the silicone skin 2 and the silicone spacer 14 form an interference fit. A silica gel cover 11 is installed on the top to form a closed whole. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com