Patents

Literature

31results about How to "No scrapping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alcohol-group coating for V-method casting and preparation method thereof

The invention discloses an alcohol-group coating for V-method casting, wherein the coating is powdery or granulous and is formed by blending 100 parts of fire-resistant powder and 10-14 parts of composite sizing agent by weight. Meanwhile, the invention further discloses a method for preparing the alcohol-group coating for V-method casting. Compared with the prior art, the costing disclosed by the invention is powdery or granulous, so that the advantages of convenience and safety in transportation are achieved; the packaging cost is low because barrels are not required for package; the transportation cost is low because the phenomenon of sediment hardening does not occur during the transportation so as not to result in material scrap; meanwhile, the coating further has the advantages that the adhesion and bond strength of a coating layer is high, the capability of resisting metal fluid machinery and thermal shock is strong, the drying time is short, the production efficiency is high, and the sand cohesiveness resistance is excellent.

Owner:NINGBO CANGHAI NEW MATERIALS DEV

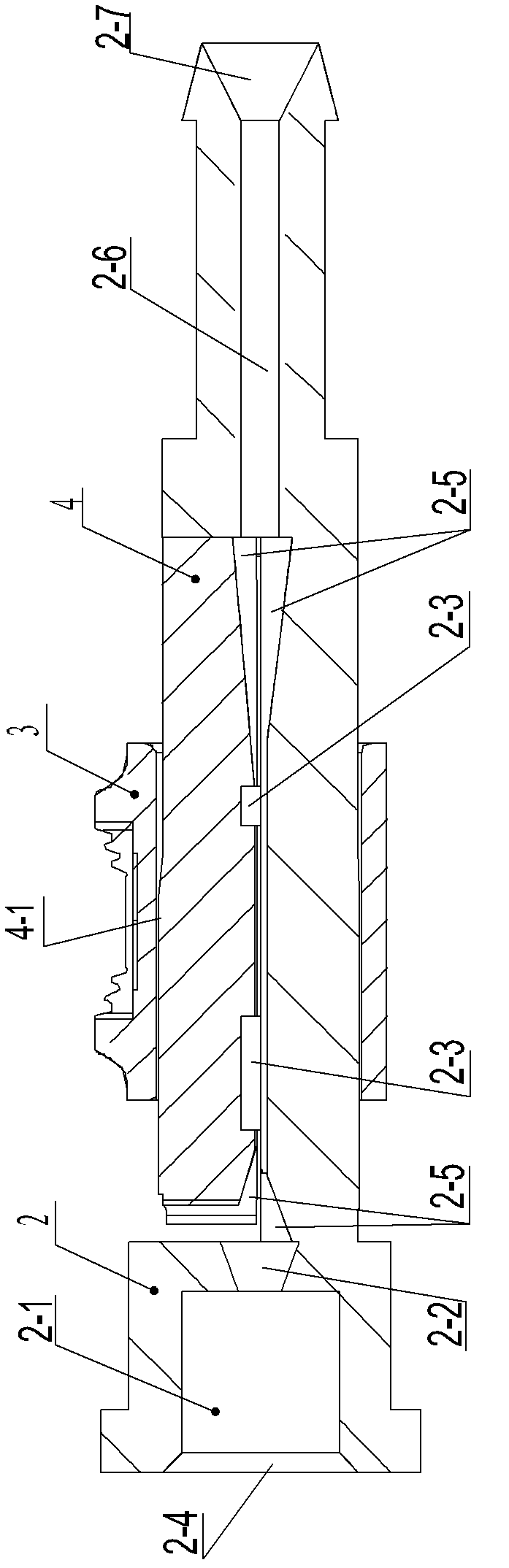

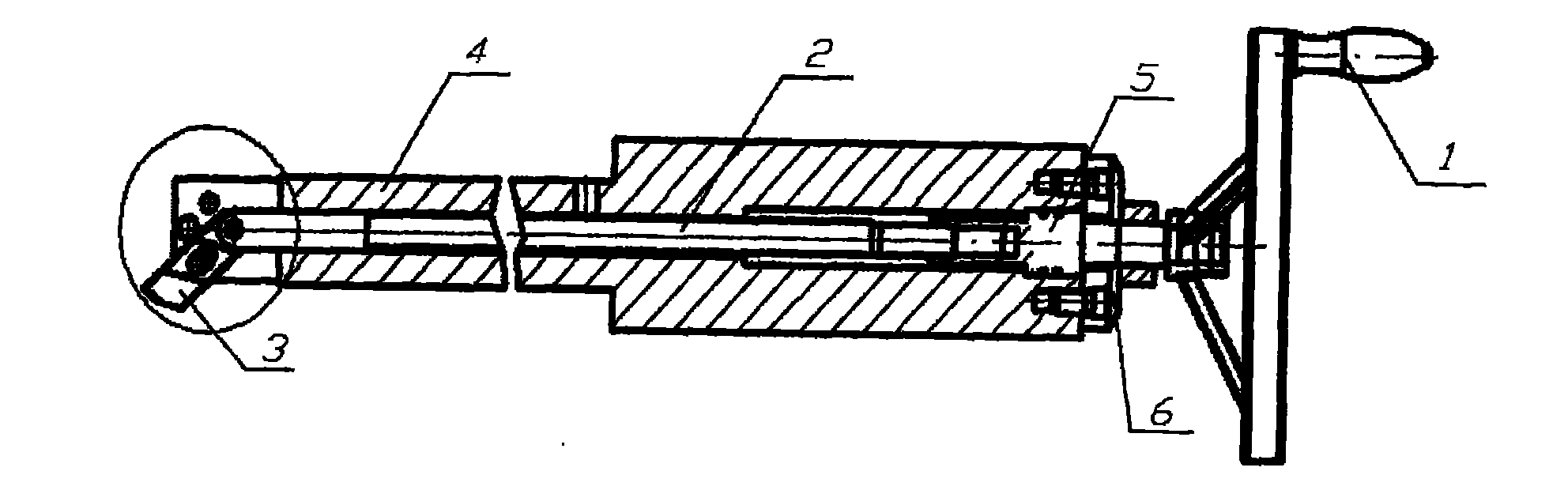

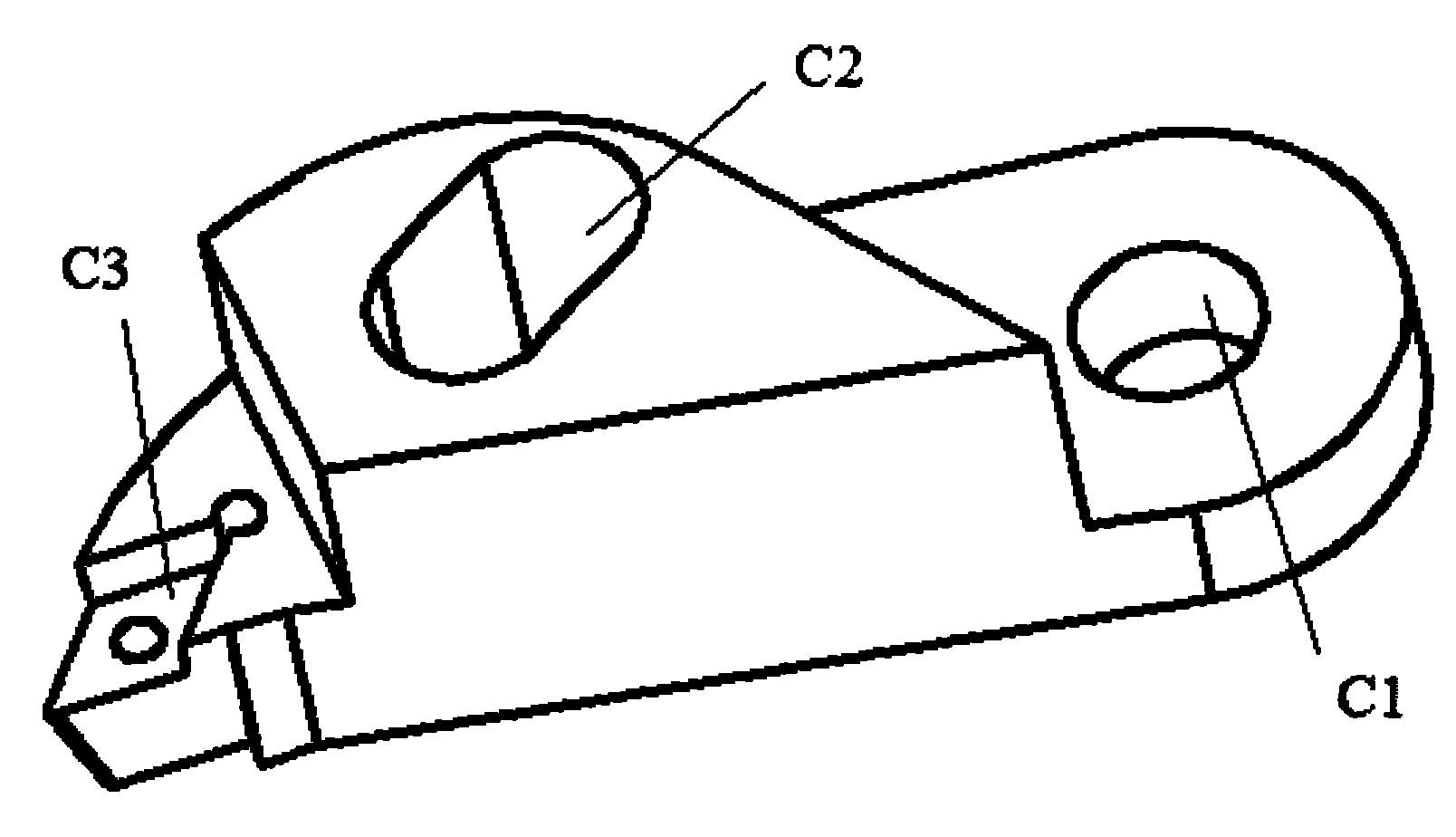

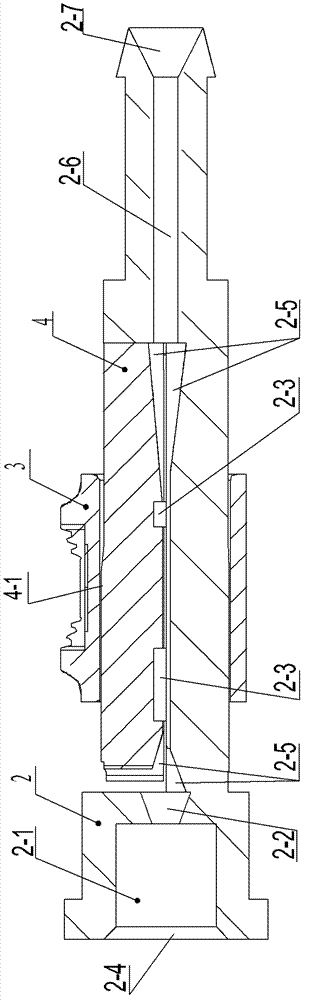

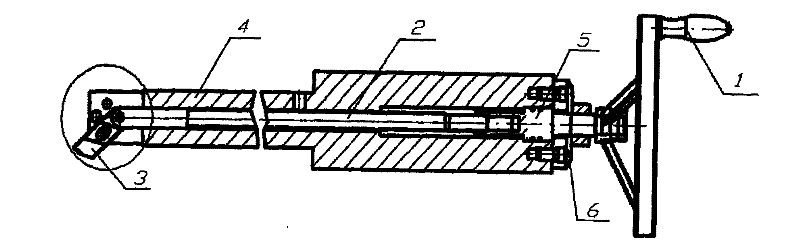

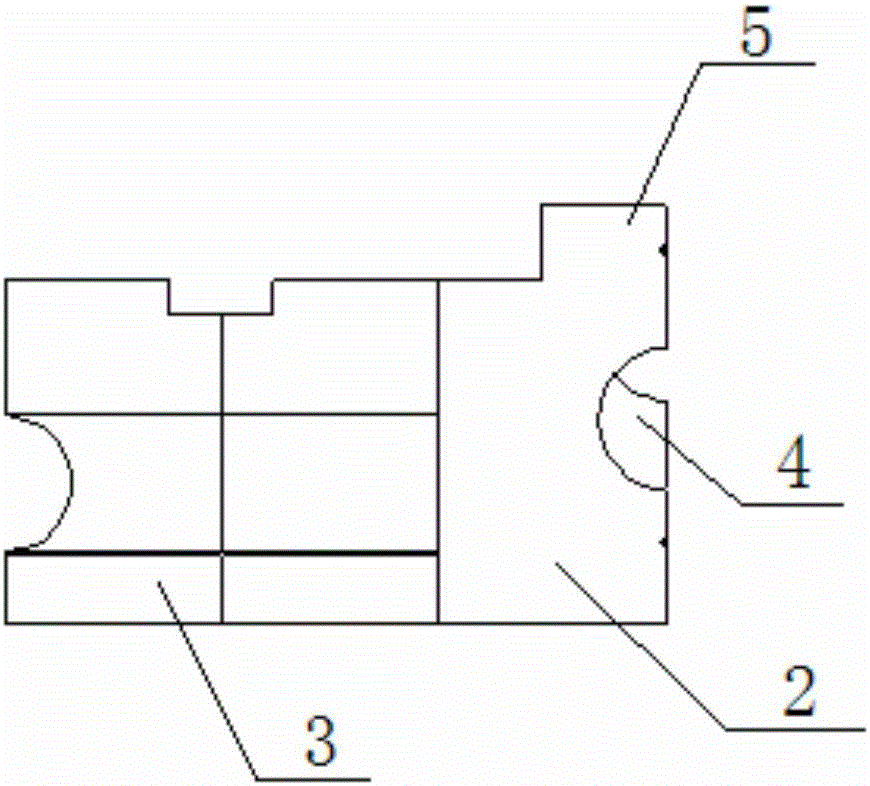

Telescopic double-edged deep-hole boring cutter

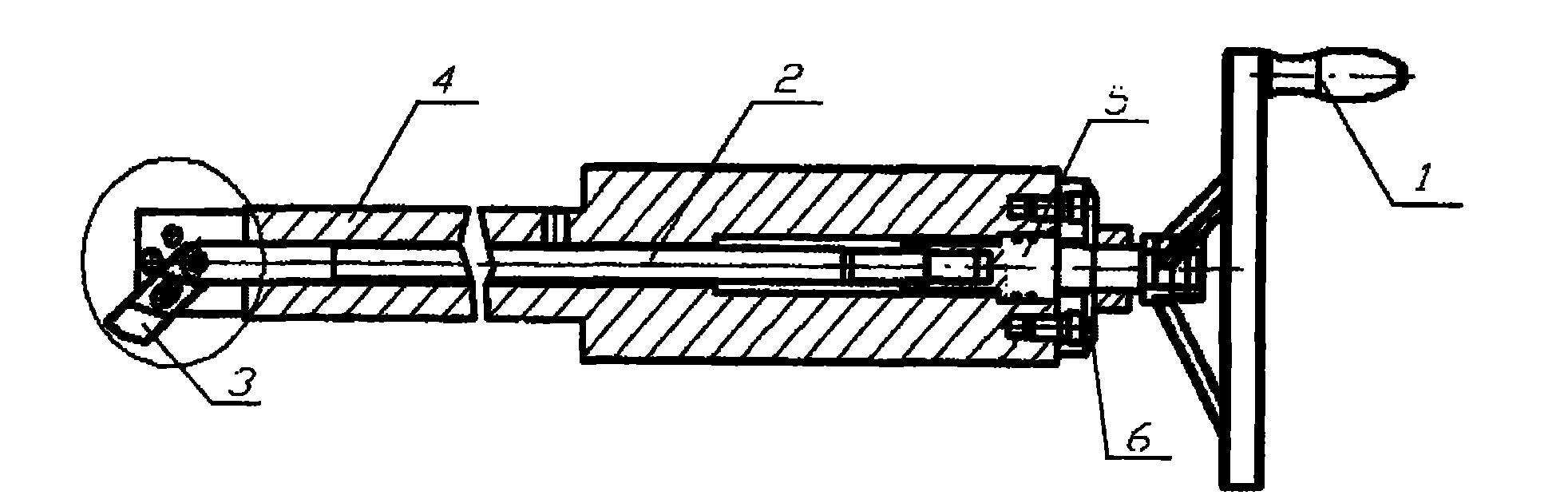

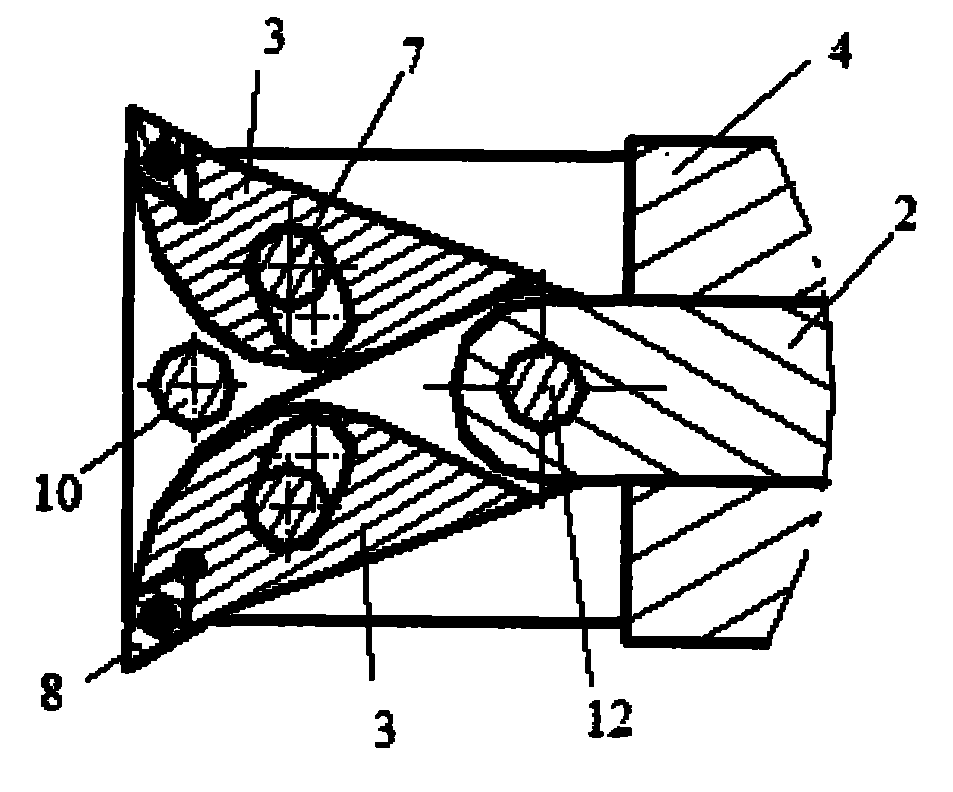

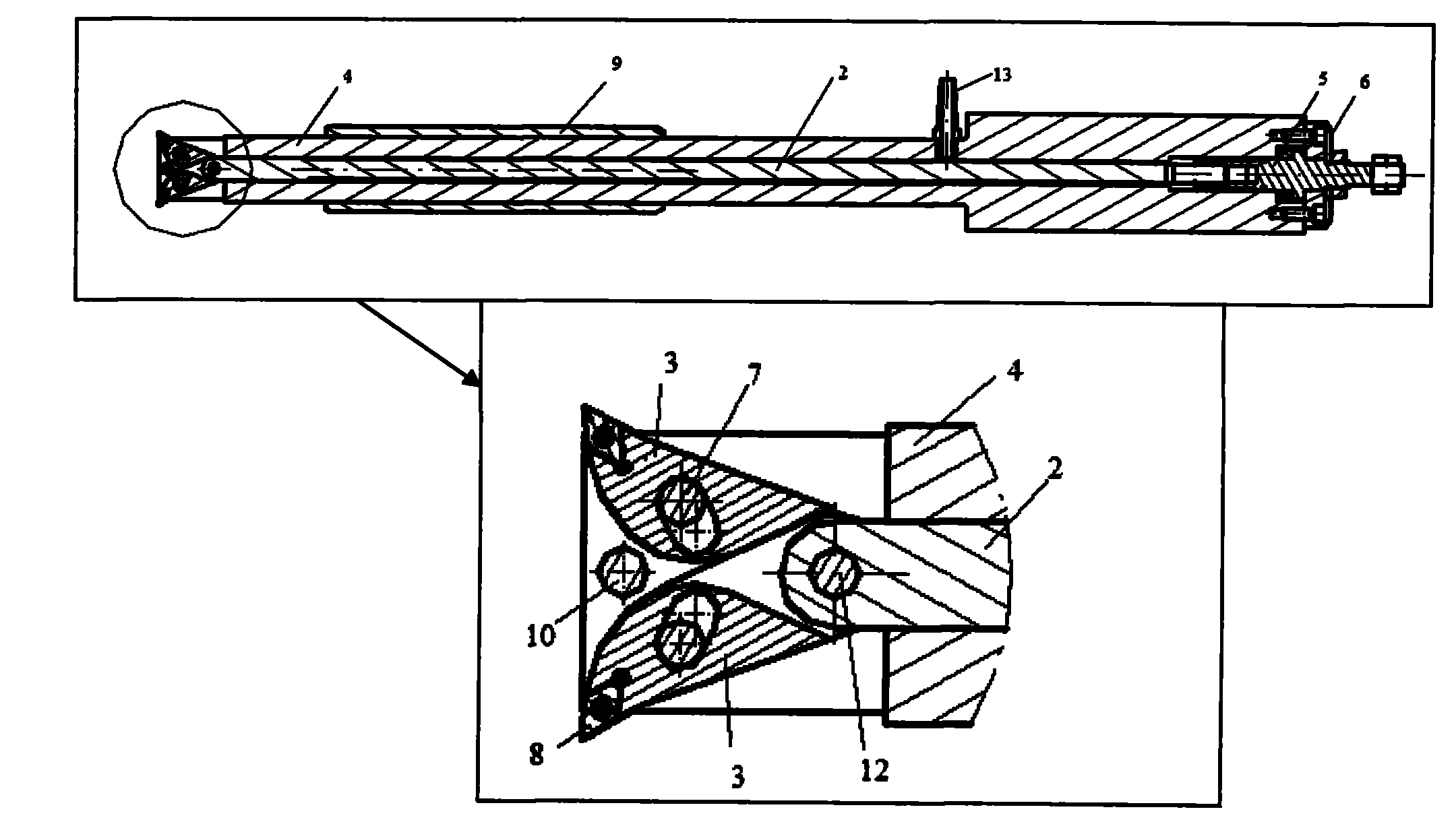

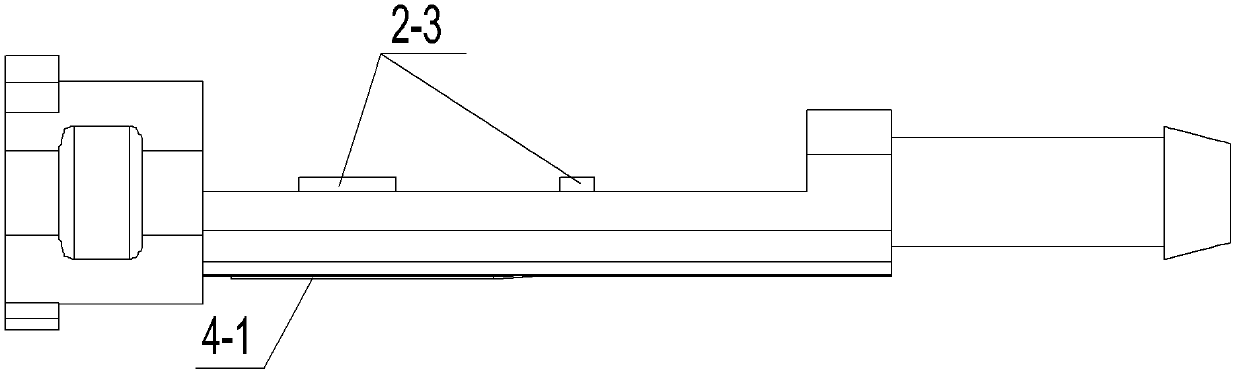

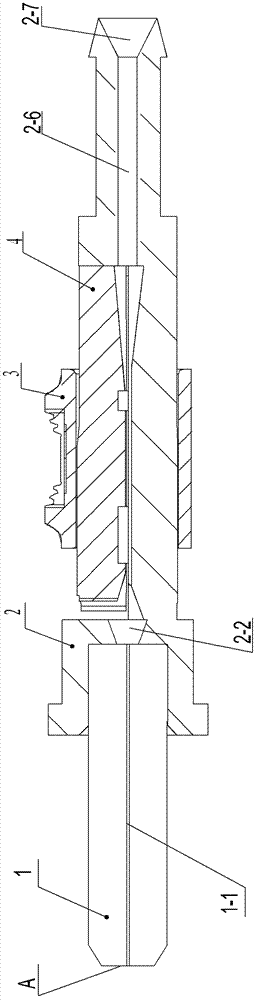

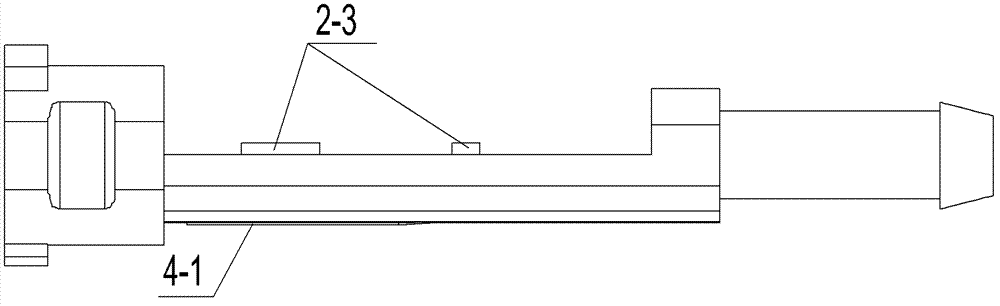

The invention provides a telescopic double-edged deep-hole boring cutter, aims to provide a deep-hole drilling boring cutter which has large length-diameter ratio, small self-excited vibration of a boring bar, reliable and stable feeding operation, no radial motion of a cutter arbor, and radial feeding of a cutting edge in a cutting process, and solves the problem that the deep-hole bottle cavity with large length-diameter ratio has large processing difficulty. The boring cutter comprises the boring bar which can extend to the deep-hole bottle cavity, wherein the central axis of the boring bar is provided with a through hole which runs through the central axis; a push rod (2) which is connected with a radial feeding device of the head of the boring bar is arranged in the through hole; the rear end of the push rod (2) is provided with a rotating handle; the rotating handle rotates a screw (5) and pushes the push rod (2) to do radial telescopic motion in the through hole of the boring bar; and the push rod (2) moves by way of pushing or pulling to drive the radial feeding device connected with the push rod and adjust the cutting edge of the double-edged boring cutter on a cutter block (3) to radically feed in the deep-hole bottle cavity.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP +1

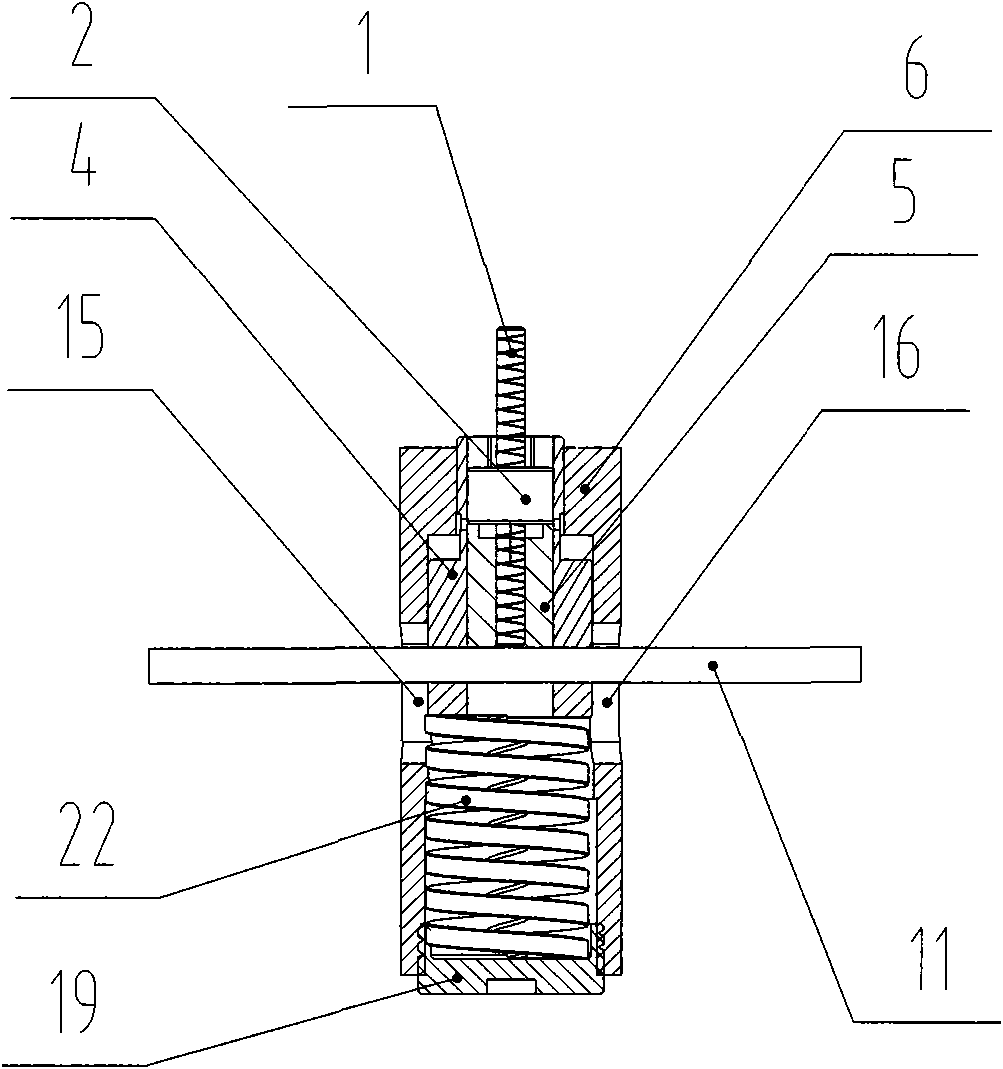

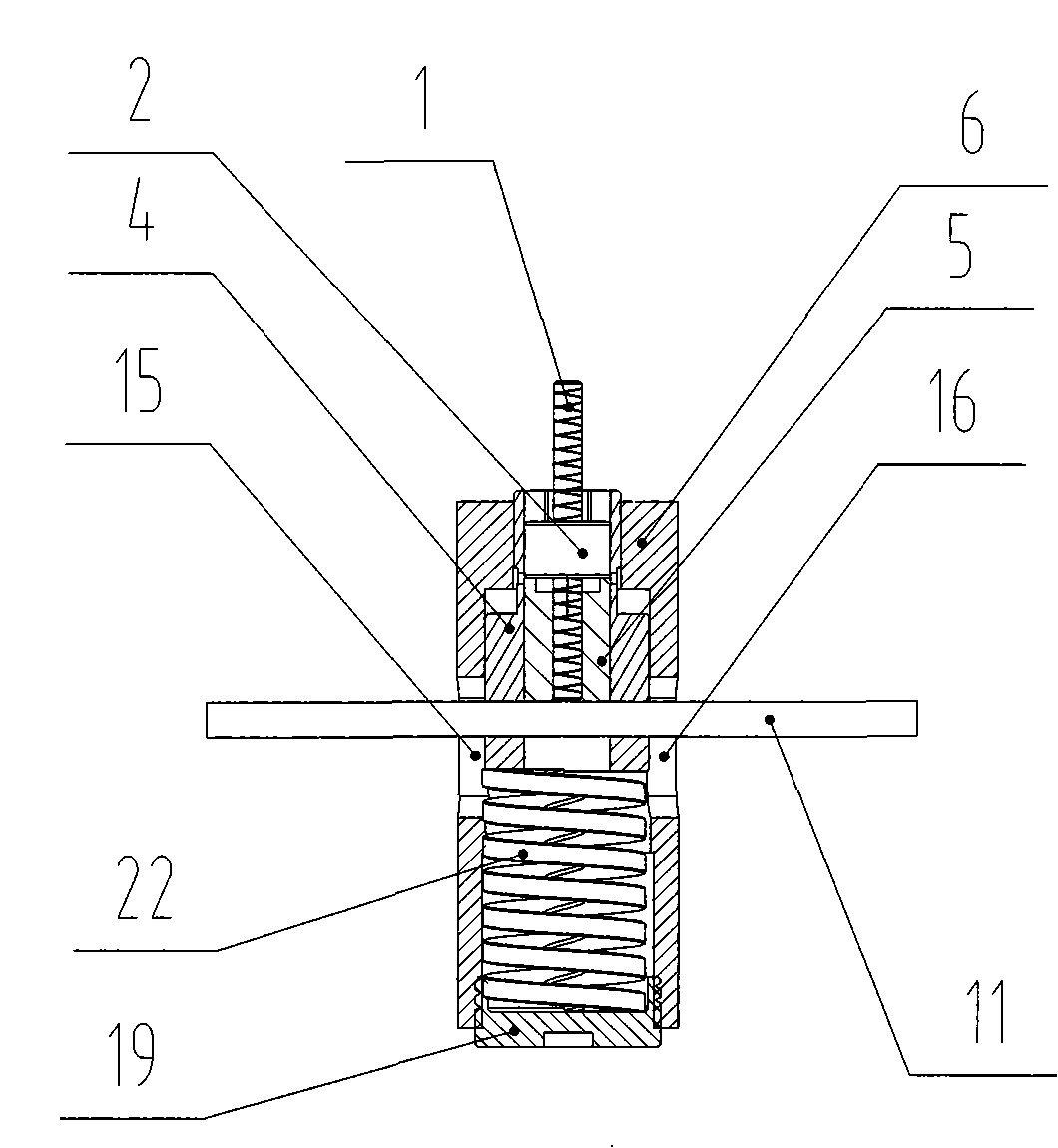

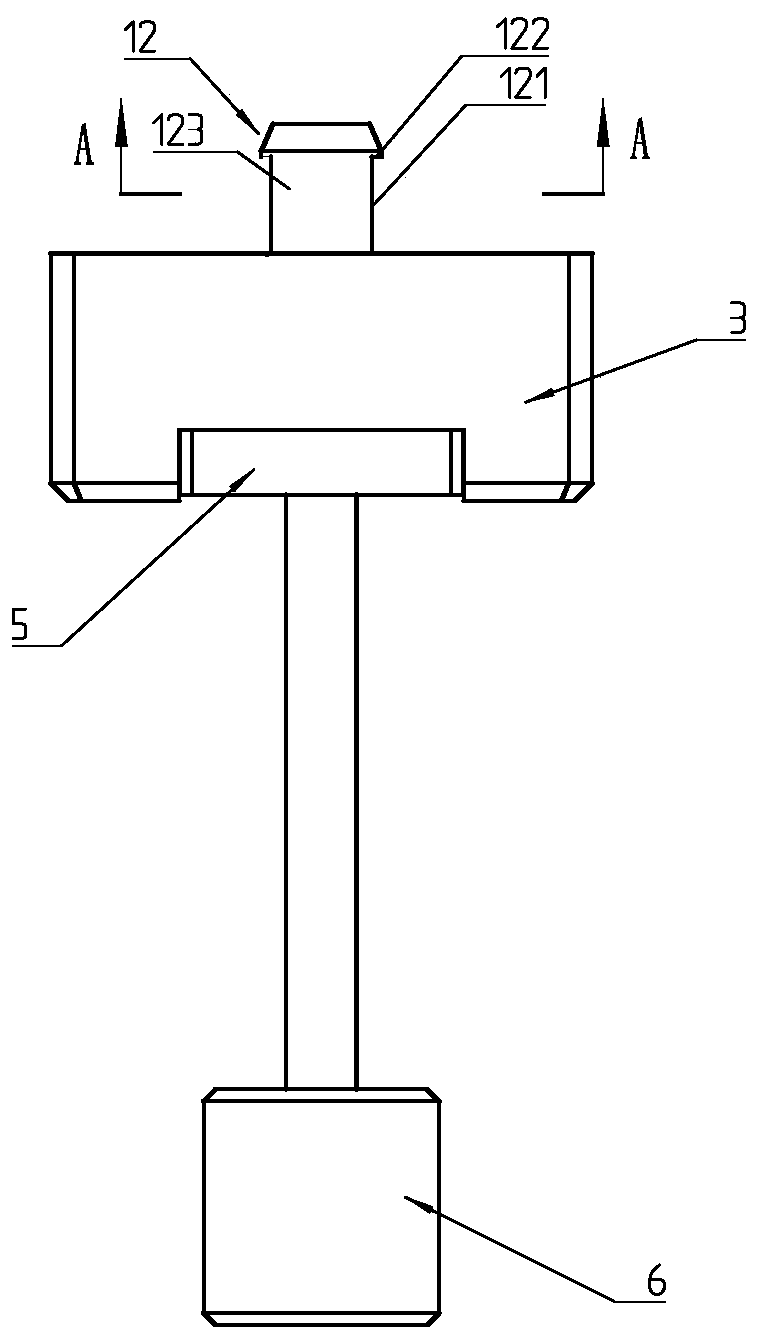

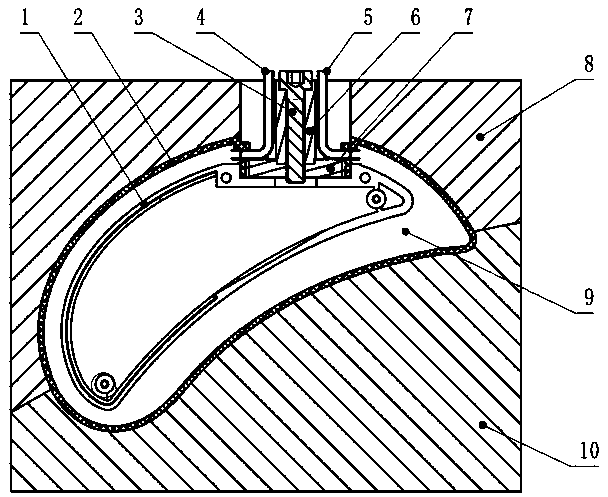

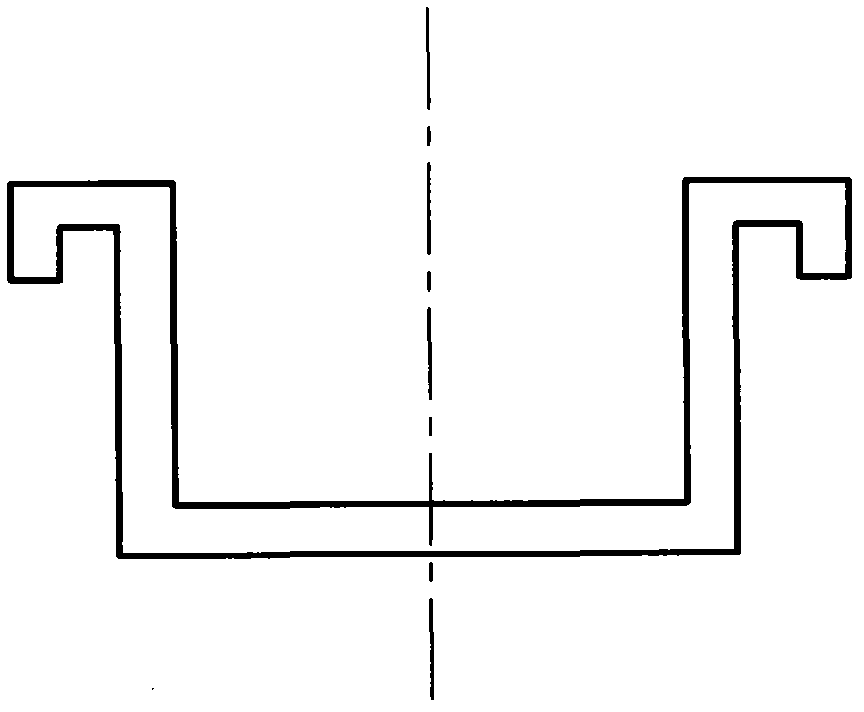

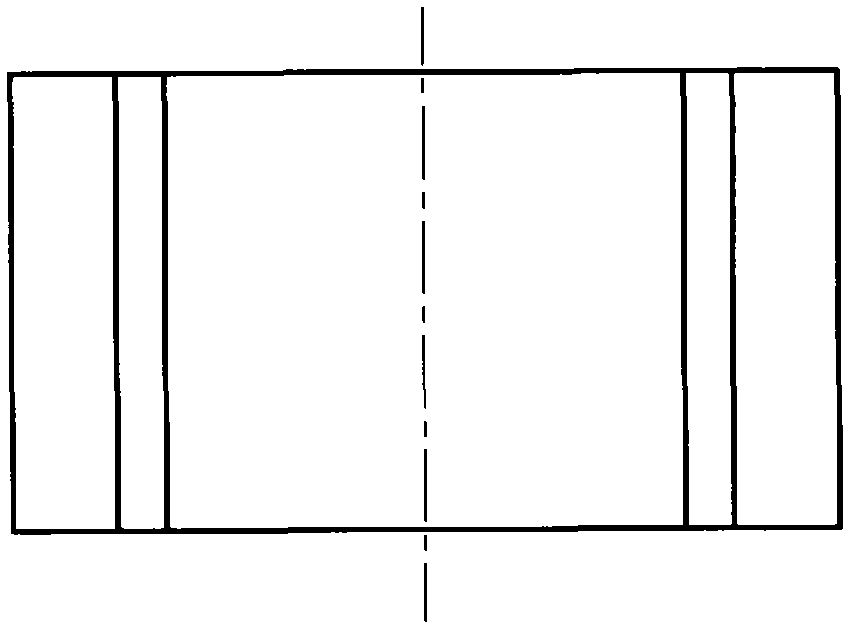

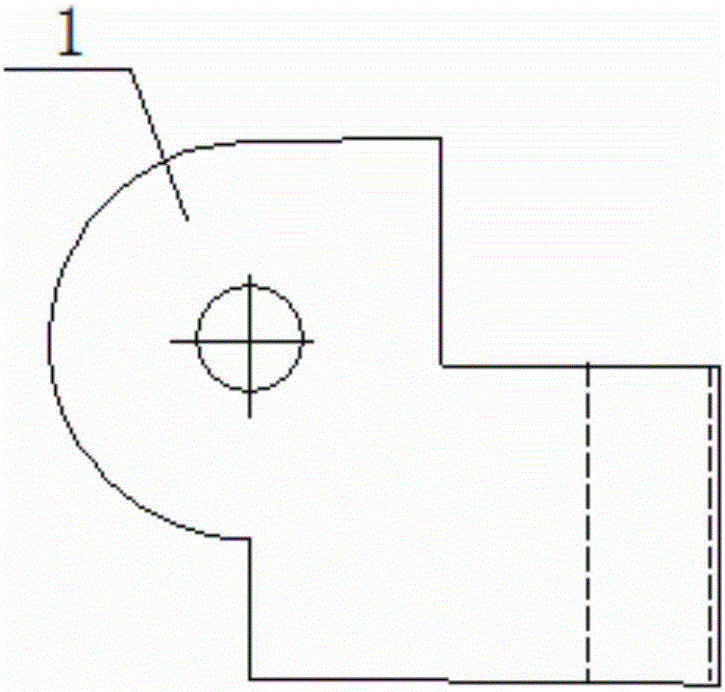

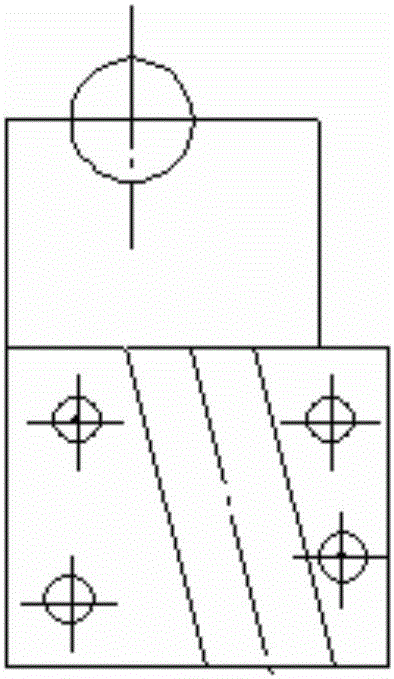

Simple U-shaped bending piece stamping mould

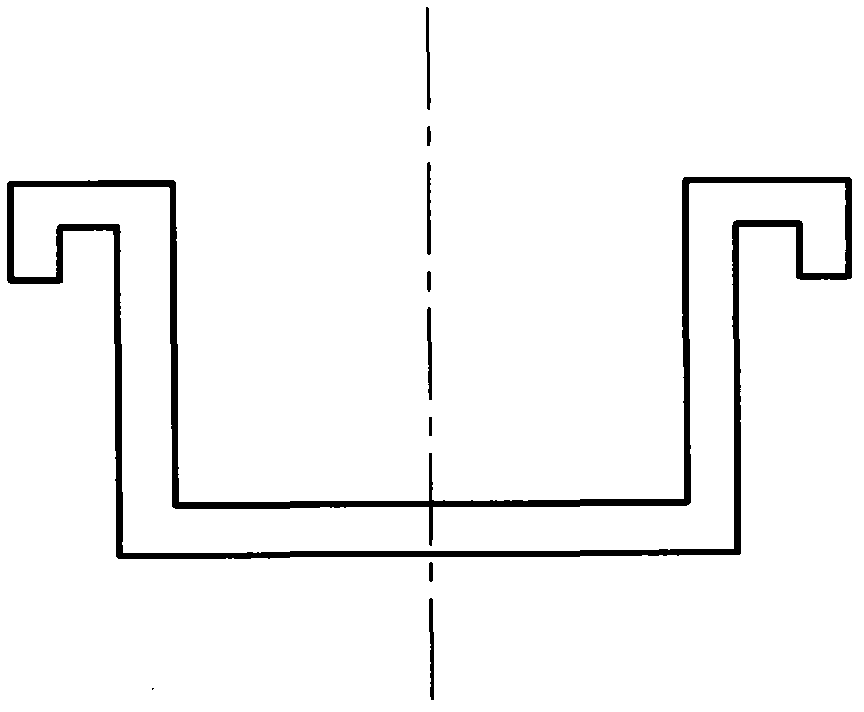

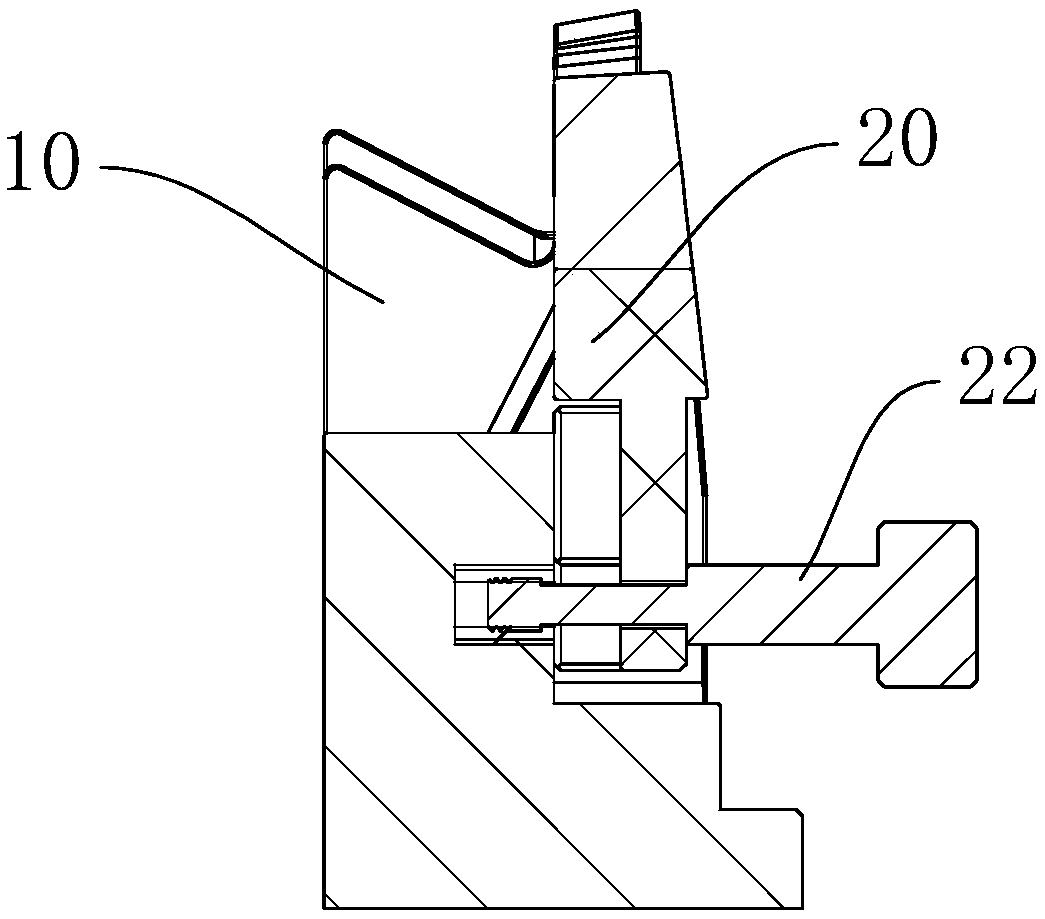

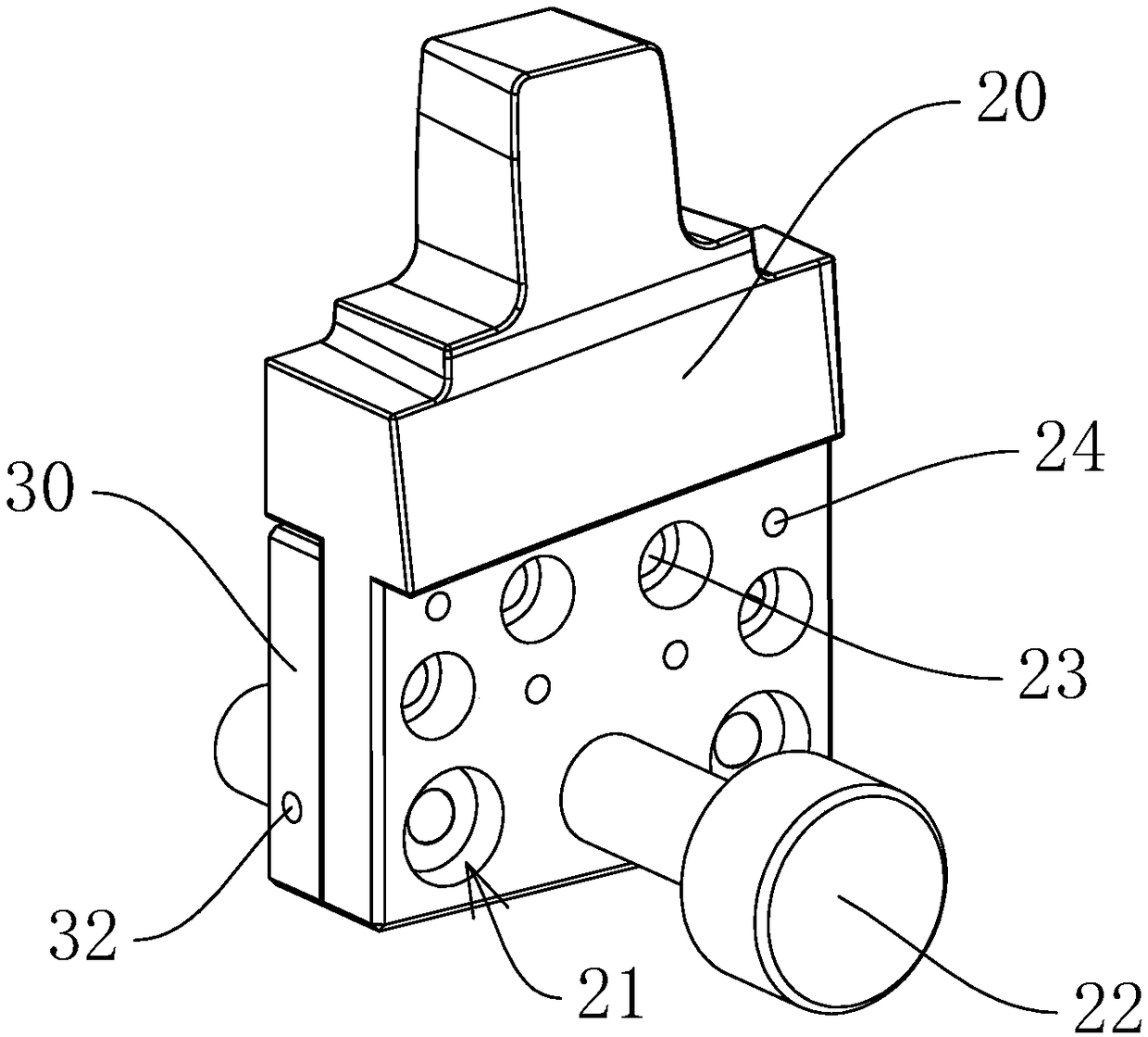

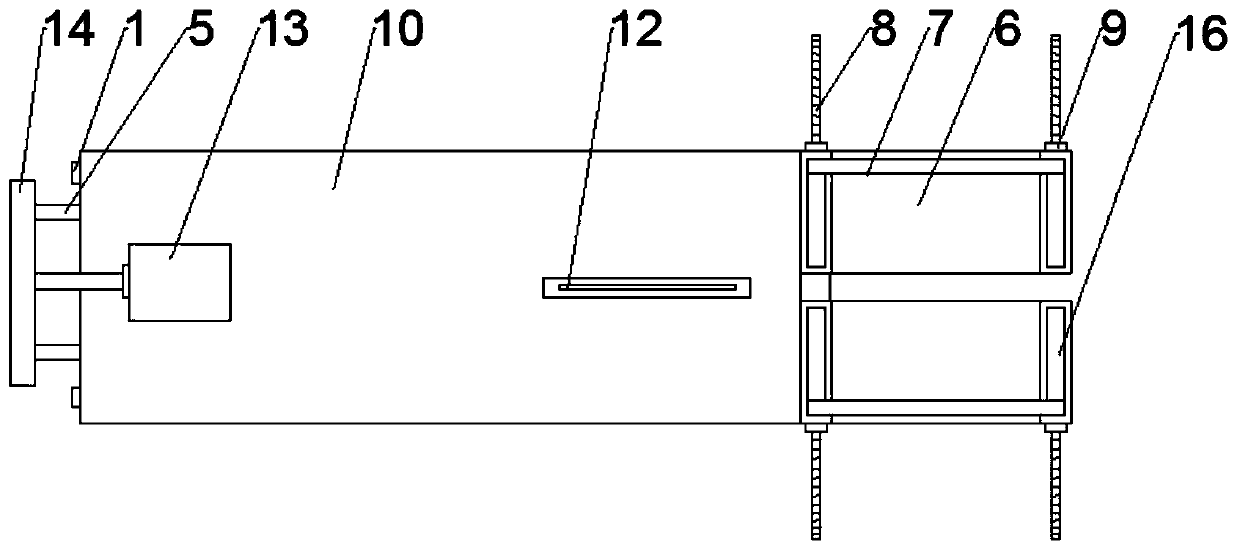

InactiveCN103357748AEnsure scrapNo scrappingShaping toolsEjection devicesPunch pressMaterials science

The invention aims to provide a simple U-shaped bending piece stamping mould and belongs to the technical field of stamping moulds. By means of arranging rubber below a lower mould base, the problem that parts cannot be demoulded smoothly in a bending process, an upper mould and a lower mould cannot be clamped, and the upper mould and the lower mould of the stamping mould cannot be displaced. The simple U-shaped bending piece stamping mould comprises an upper mould base (1), screws (2), a mould shank (3), a stop pin (4), a pin (5), a guide sleeve (6), a cushion plate (7), a guide column (8), a male mould fixing plate (9), a positioning plate (10), screws (11), a female mould (12), the lower mould base (13), a pin (14), a screw (15), an upper cushion plate (17), the rubber (17), screws (18), a lower cushion plate (19), an ejection rod (20), screws (21), a male mould (22) and an ejection plate (23). The simple U-shaped bending piece stamping mould is basically free from maintenance, simple to operate, practical and reliable, and acts with cooperation of a special punch press.

Owner:朱敏忠

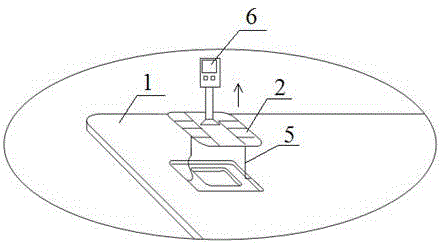

Production method of optical fiber preset core insert and positioning device

The invention relates to a production method of an optical fiber preset core insert, which has the characteristics that the insertion loss of the optical fiber core insert in the production process can be detected by an instrument. The technical scheme is as follows: the production method of the optical fiber preset core insert is characterized by comprising the following steps: (a) horizontally fixing a ceramic core insert on a workbench of a core insert grinder; (b) sheathing a protective sleeve on a bare optical fiber which is not cut; (c) inserting the bare optical fiber into an optical fiber hole from the tail part of the ceramic core insert; (d) starting the core insert grinder to grind the end surface of the head part of the ceramic core insert and the end surface of the bare optical fiber; (e) conducting return loss test on a light guiding surface; (f) if the test result is disqualified, repeating the steps (d-e) until the test is qualified; and (g) if the test result is qualified, stripping the protective sleeve of the bare optical fiber, and taking the core insert out of the core insert grinder, and preserving a tail fiber with a certain length, and cutting with a cutter.

Owner:WANMA TECH CO LTD

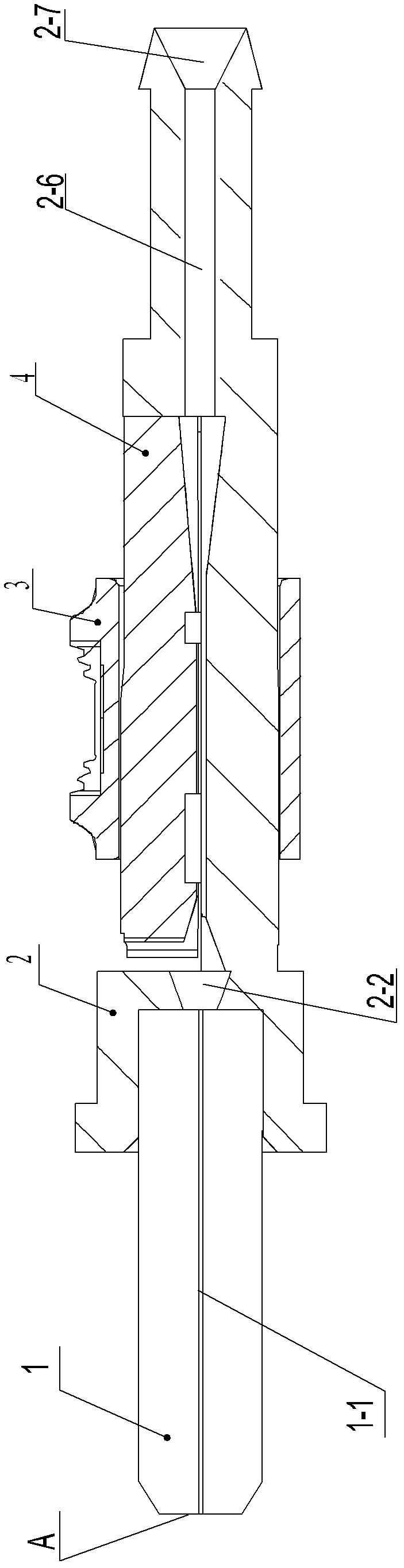

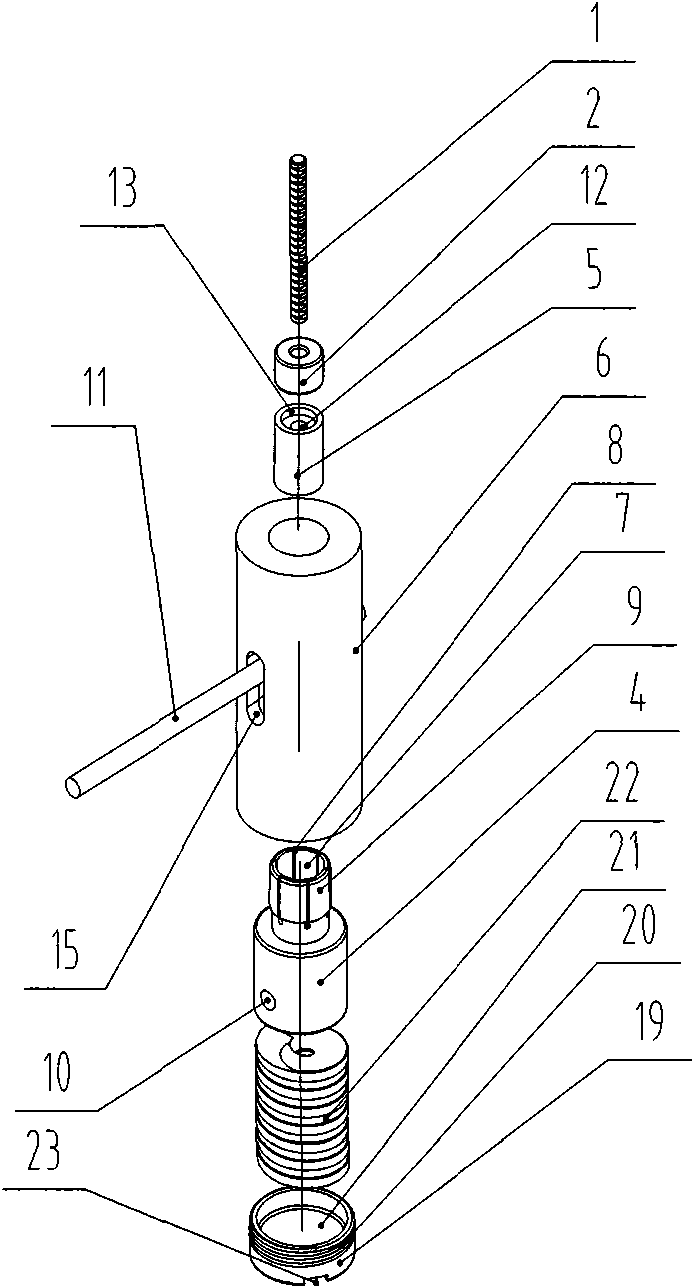

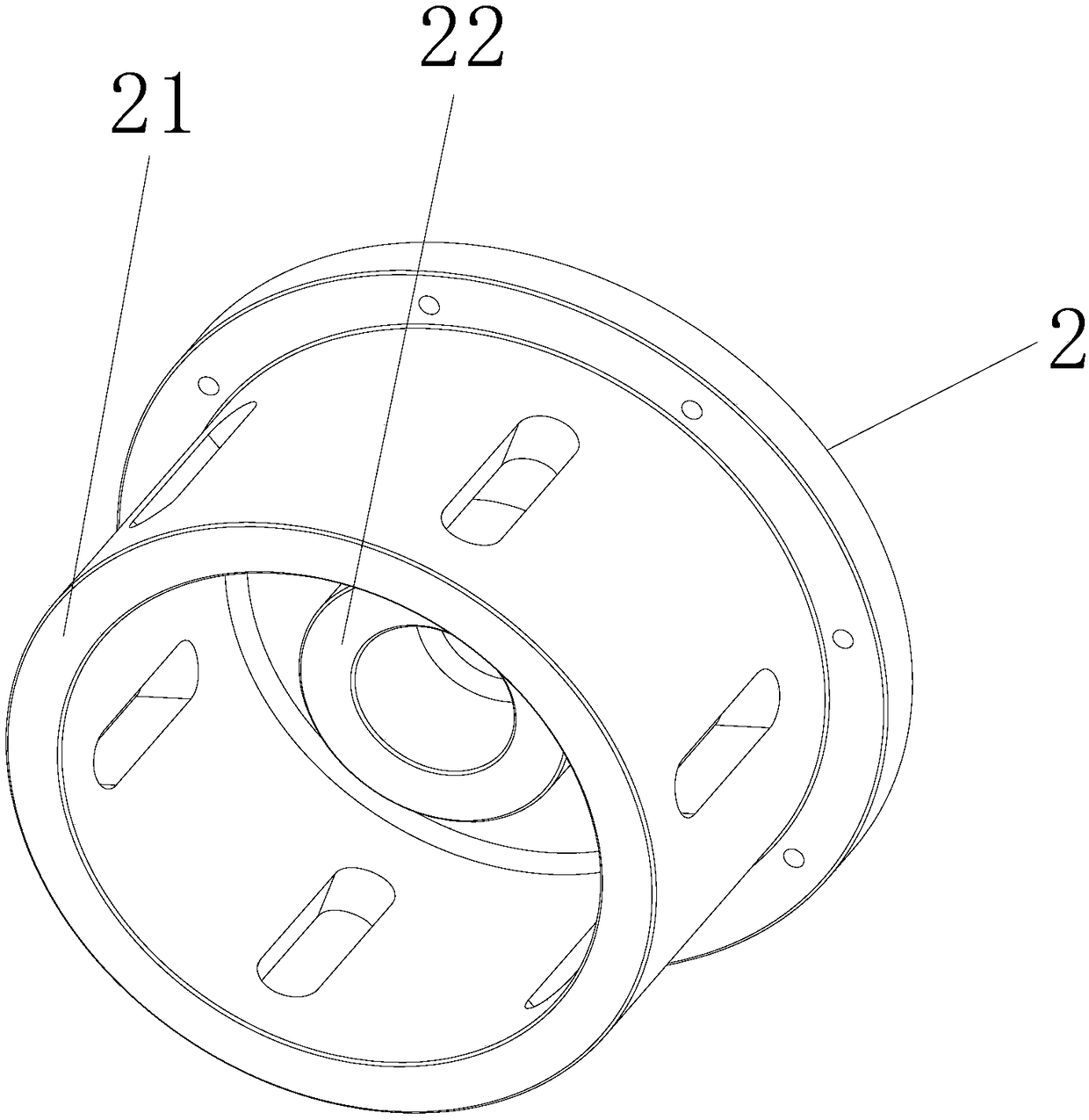

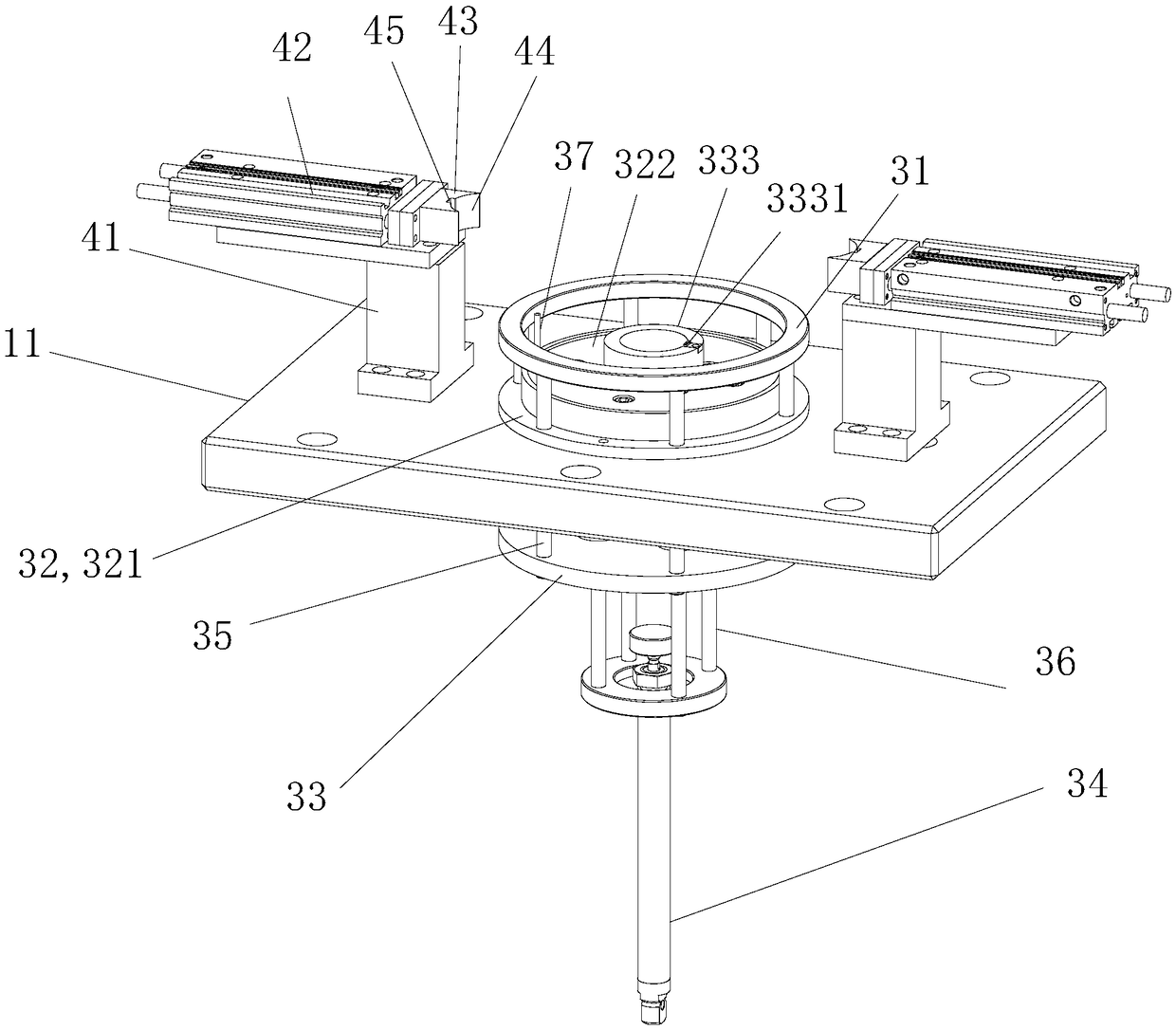

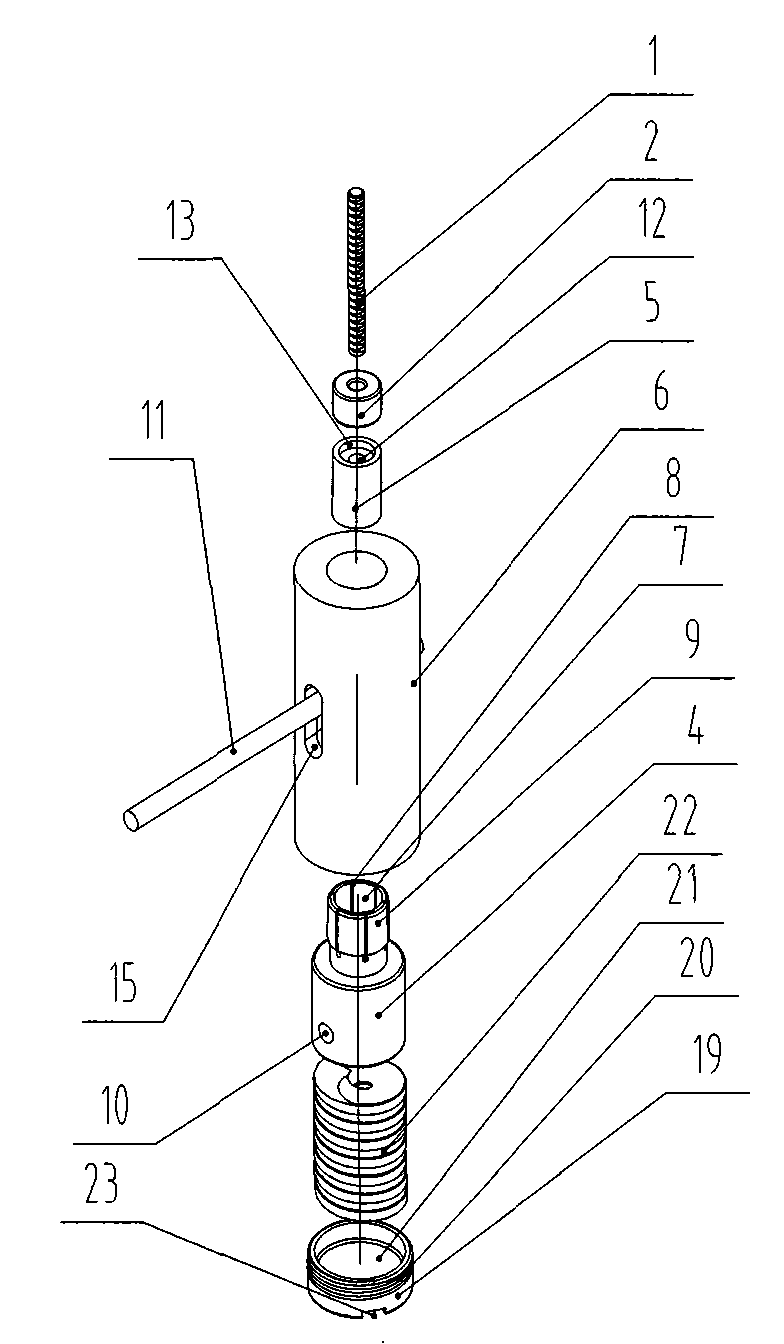

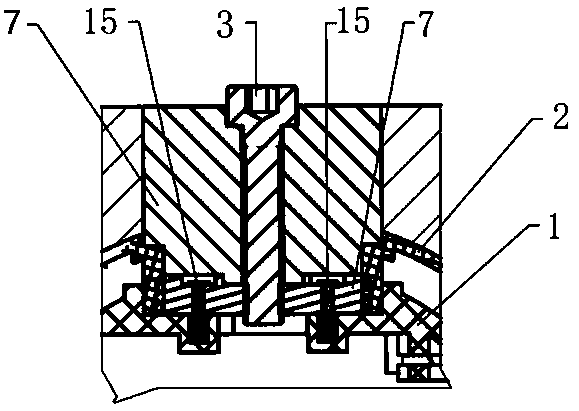

Method for manufacturing motor rotor and self-aligning positioning mechanism used thereby

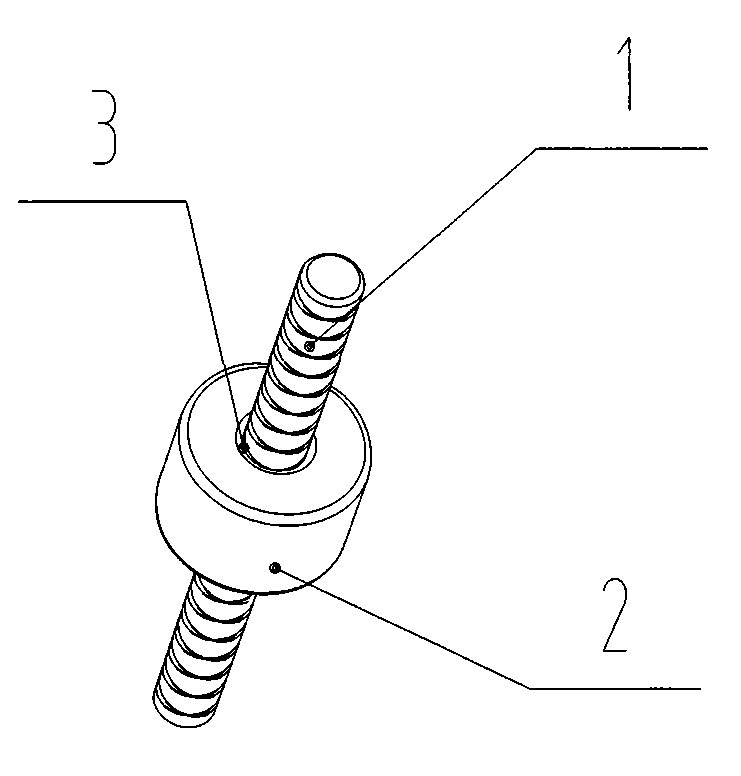

ActiveCN101599674AImprove manufacturing precisionSolve the technical problems of weak combination and easy falling offMagnetic circuit rotating partsManufacturing stator/rotor bodiesScrew threadConical surface

The invention provides a method for manufacturing a motor rotor and a self-aligning positioning mechanism used thereby. The method for manufacturing the motor rotor is characterized in that the motor rotor is formed by splicing a mandrel and magnetic steel by the self-aligning positioning mechanism through binding agent. The self-aligning positioning mechanism consists of a locating column, an aligning rod, an outer sleeve, a spring and a regulating rod, wherein the locating column contains a locating hole, communicating grooves are arranged around the upper part of the aligning rod, the side of the aligning rod at the communicating grooves is a reversed-V-shaped conical surface which is matched with a corresponding reversed-V-shaped conical surface at the upper part of an inner cavity of the outer sleeve, and the lower part of the aligning rod is provided with a transverse through hole that is in clearance fit with a pressure bar; the outer sleeve is provided with an inner hole which is in clearance fit with the aligning rod, the two sides of the outer sleeve are symmetrically provided with two long grooves, the pressure bar is inserted into the inner hole of the aligning rod and can move up and down inside the two long grooves, the lower part of the outer sleeve is matched with the regulating rod by screw thread, and the spring is arranged between the aligning rod and the regulating rod. The invention has the advantages of greatly improving the accuracy of product and manufacturing efficiency as well as reducing the manufacturing cost of the product.

Owner:NINGBO YUNSHENG +3

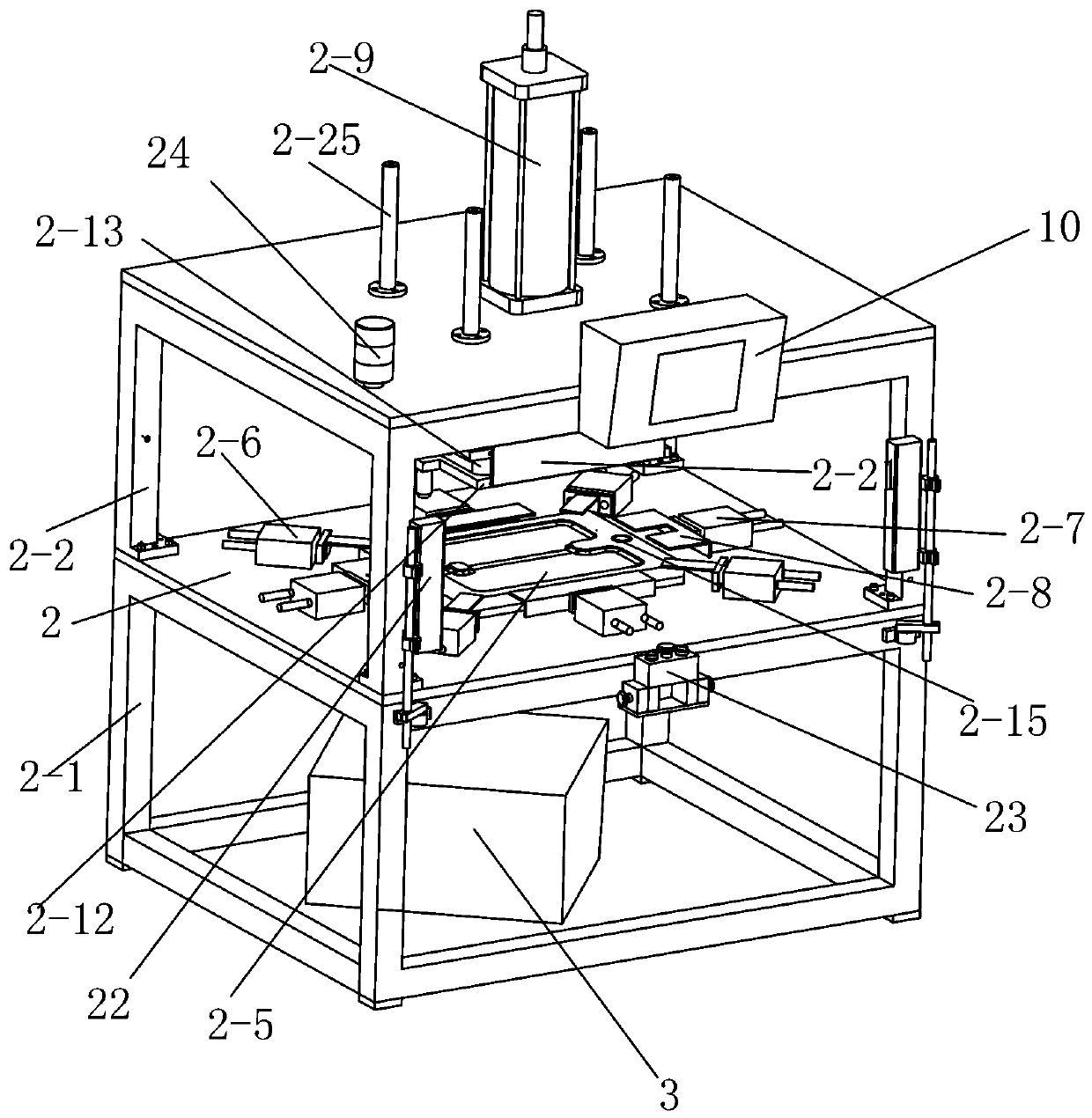

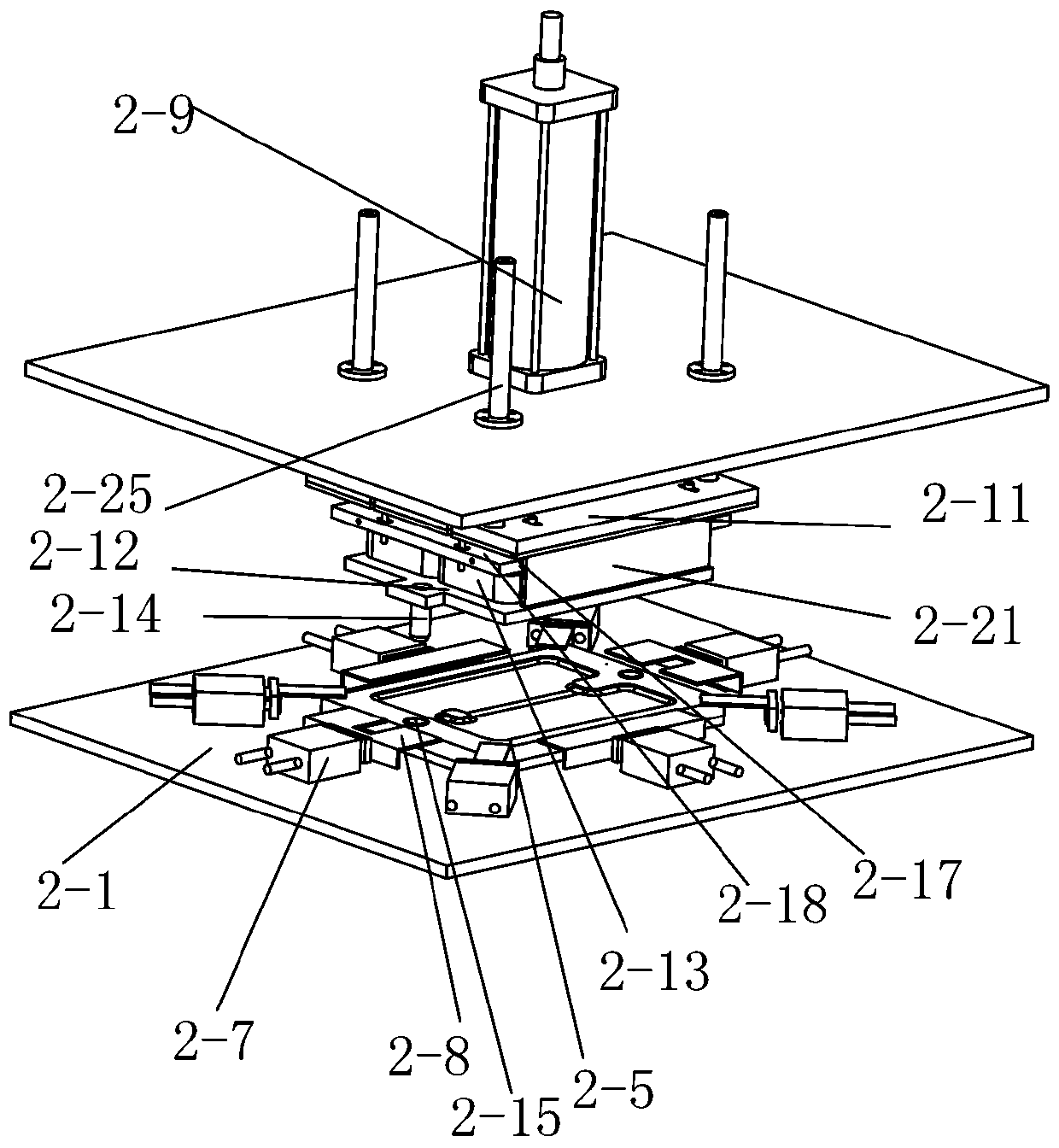

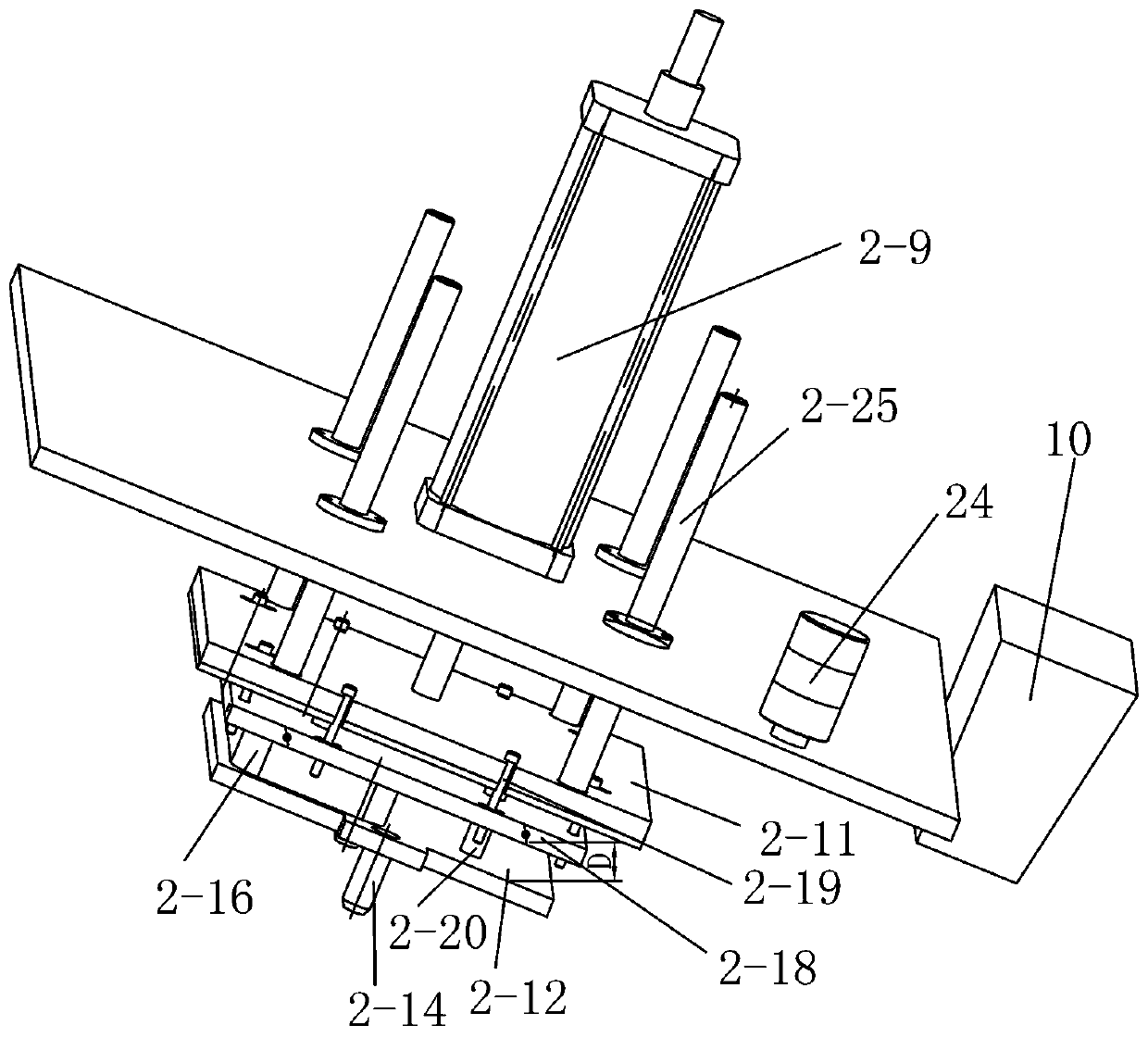

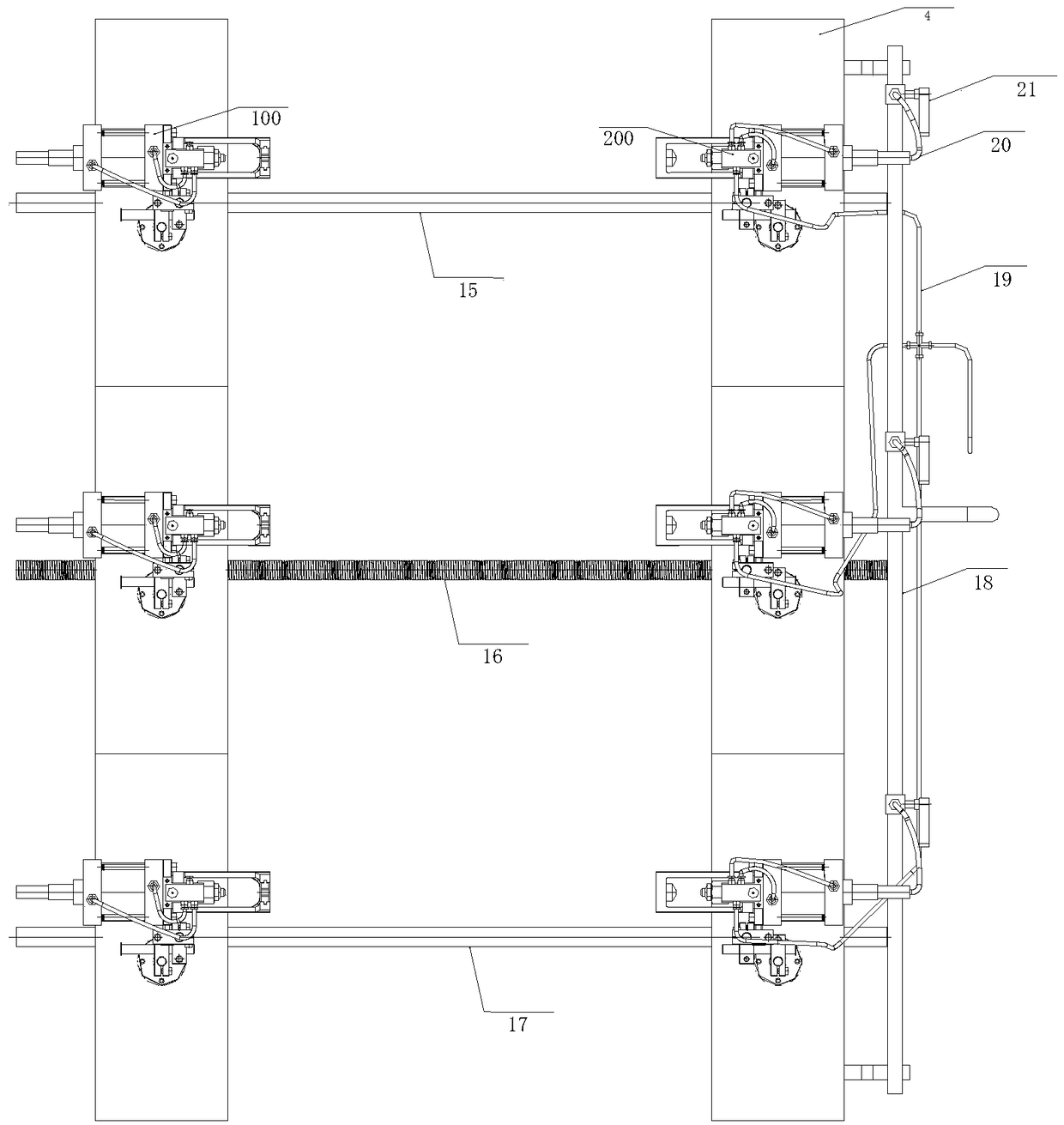

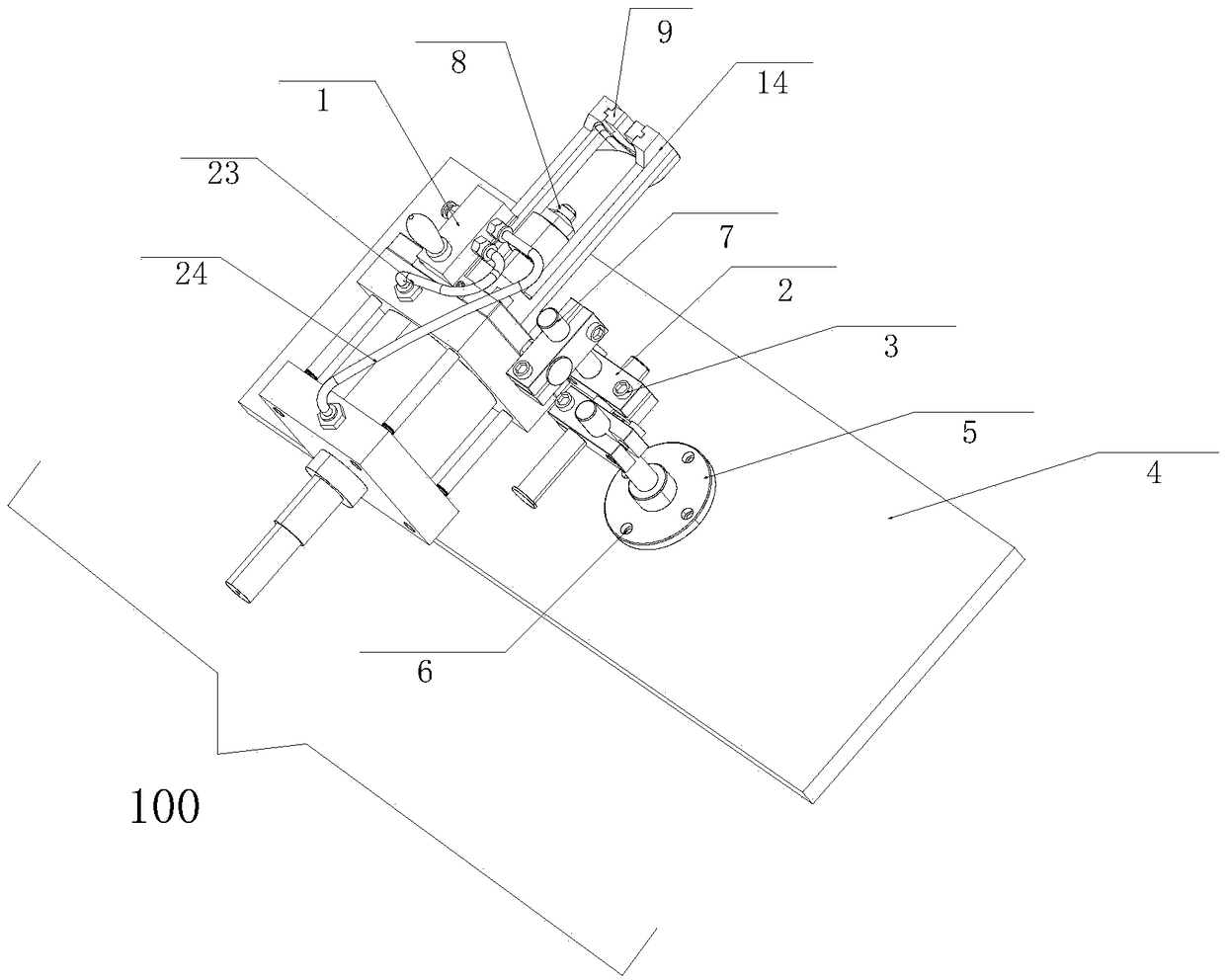

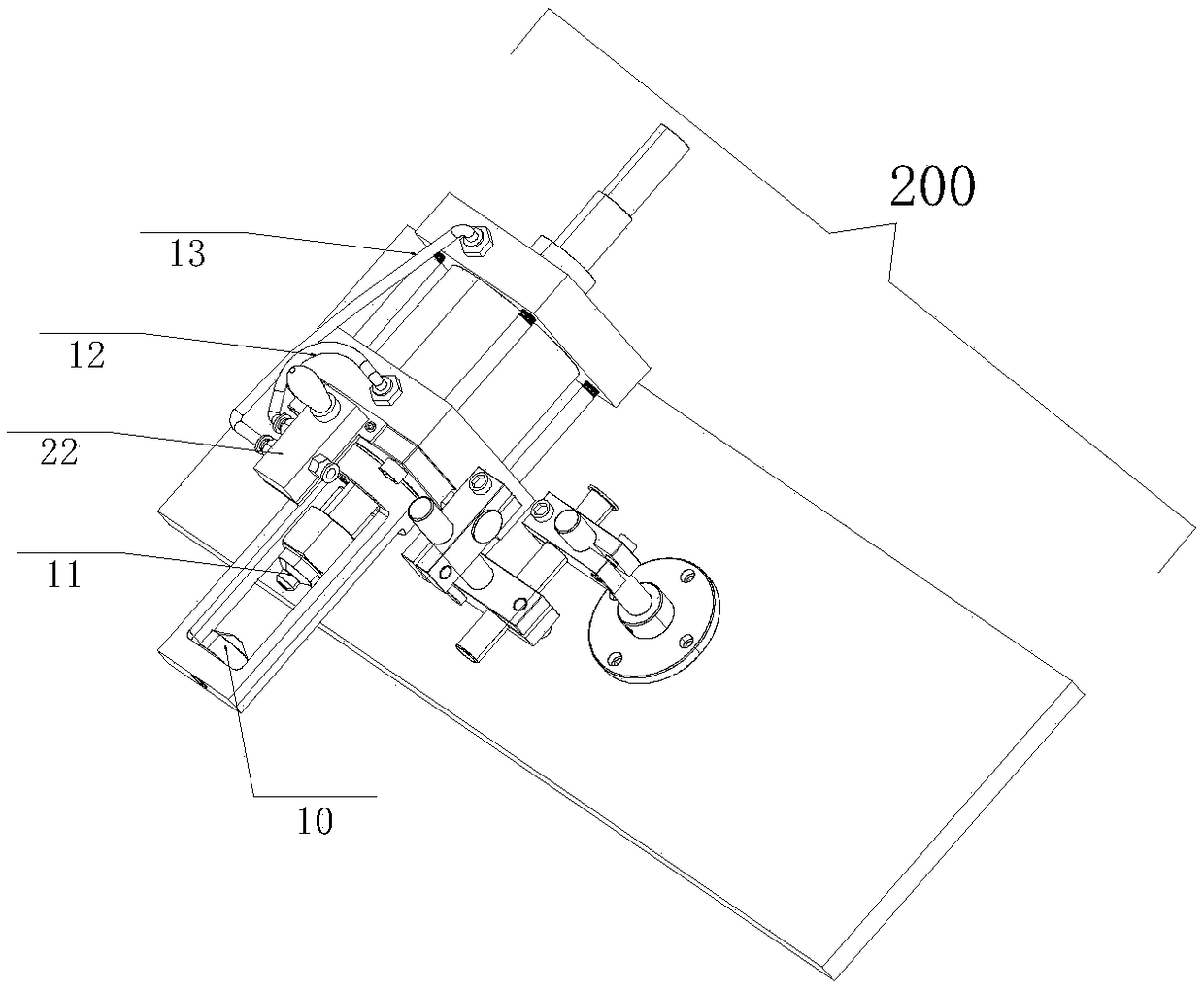

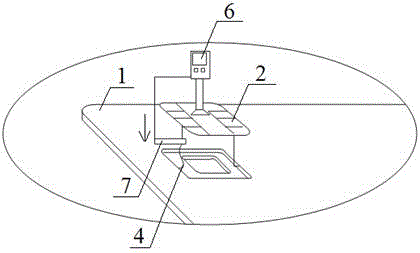

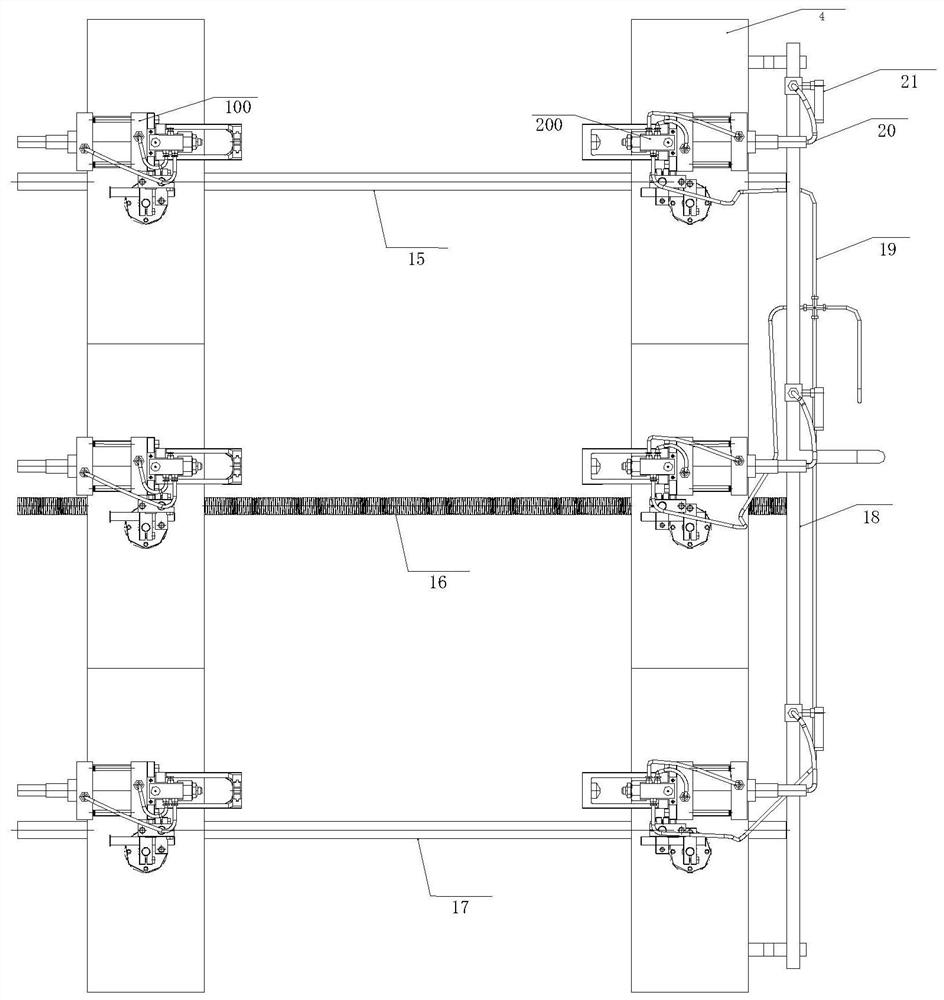

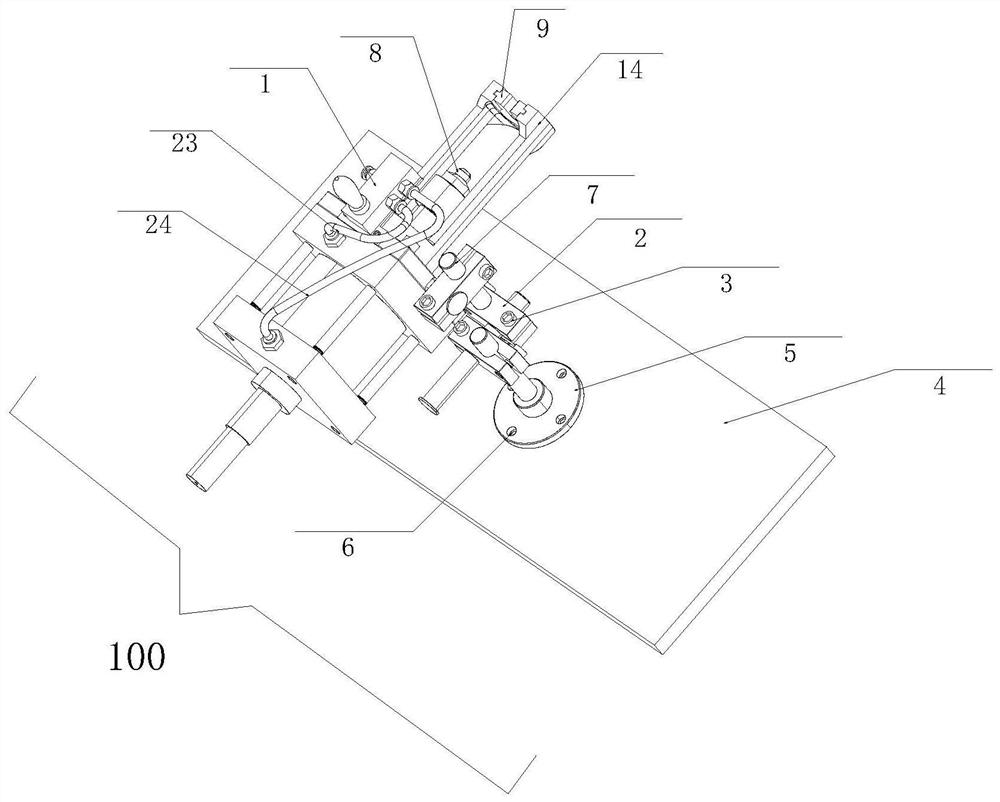

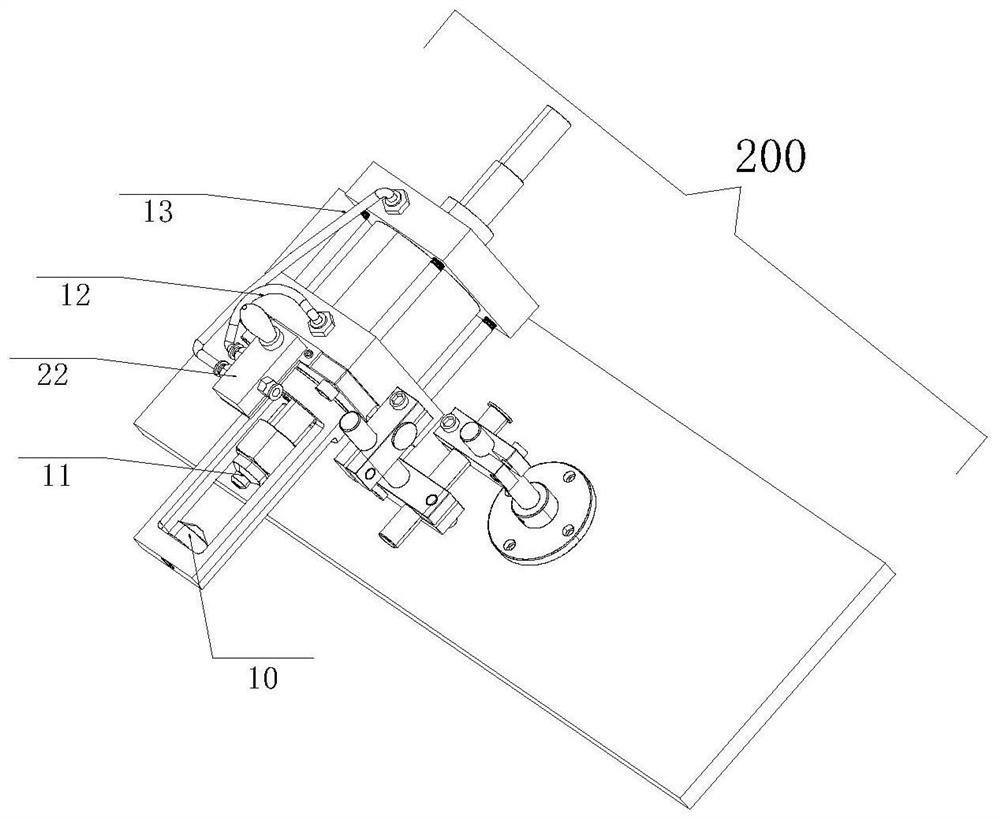

Automatic heat sealing and edge wrapping device for automobile sun visor and preparation method of sun visor

The invention discloses an automatic heat sealing and edge wrapping device for an automobile sun visor and a preparation method of the sun visor. The automatic heat sealing and edge wrapping device comprises a power supply box, an edge wrapping mechanism which is electrically connected with the power supply box, and a heat sealing mechanism for heat sealing an upper framework and a lower frameworkwhich are completed by the edge wrapping mechanism; the edge wrapping mechanism comprises a product lower die for placing a foamed polypropylene framework; air cylinder pushing and pressing mechanisms and up-and-down moving and heating parts are arranged around the product lower die and at the four diagonal corners of the product lower die; the air cylinder pushing and pressing mechanisms move towards the product lower die and push fabric to advance towards the periphery and the corners of the foamed polypropylene framework; the up-and-down moving and heating parts can move up and down and cooperate with the product lower die to realize heating and softening; the heat sealing mechanism comprises a first half lower die, a second half lower die, a die assembly mechanism and a heating pressing plate; the first half lower die and the second half lower die can be opened left and right and can be covered with each other after one of the first half lower die and the second half lower die isrotated; the die assembly mechanism drives the second half lower die to rotate and cover the first half lower die; and the heating pressing plate heats and melts the product in advance and can move upand down. The automatic heat sealing and edge wrapping device is simple in structure and the cost is lowered.

Owner:NINGBO SUNLIGHT MOTOR PARTS

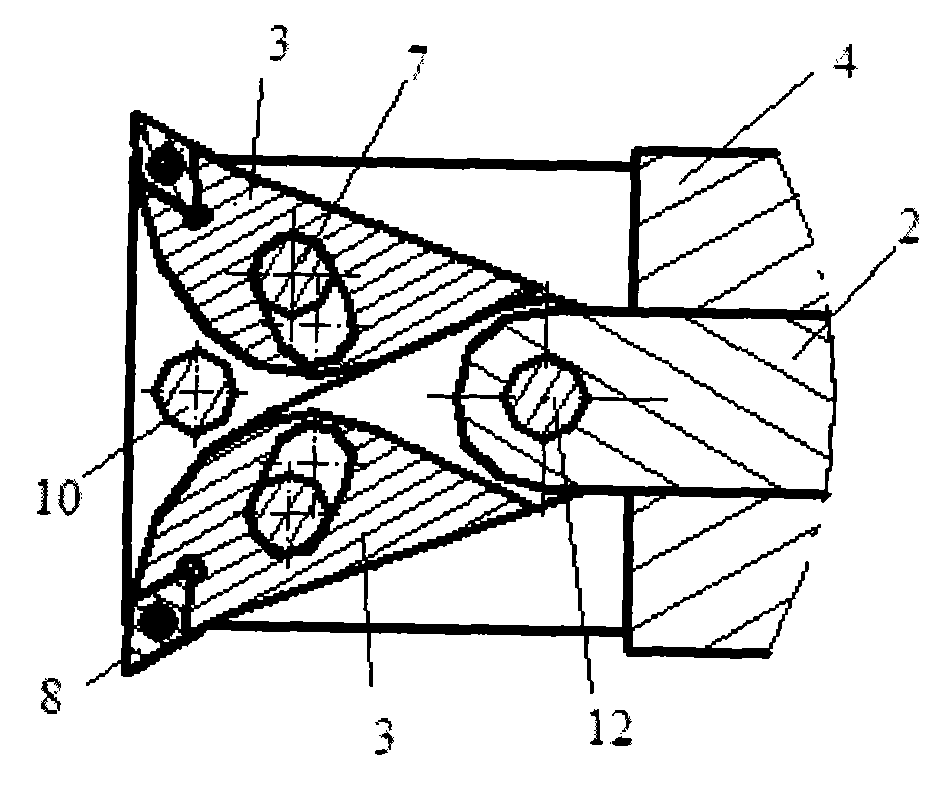

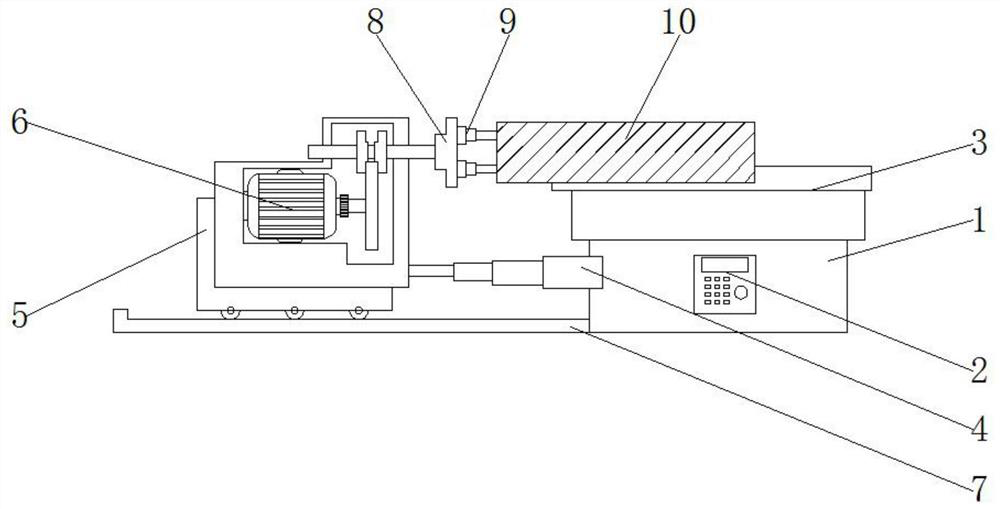

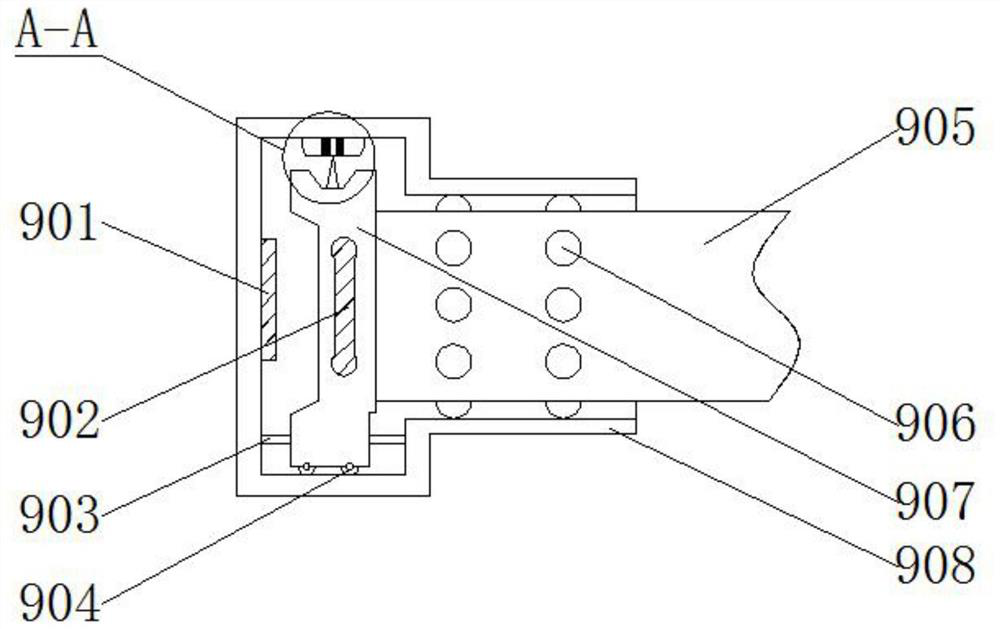

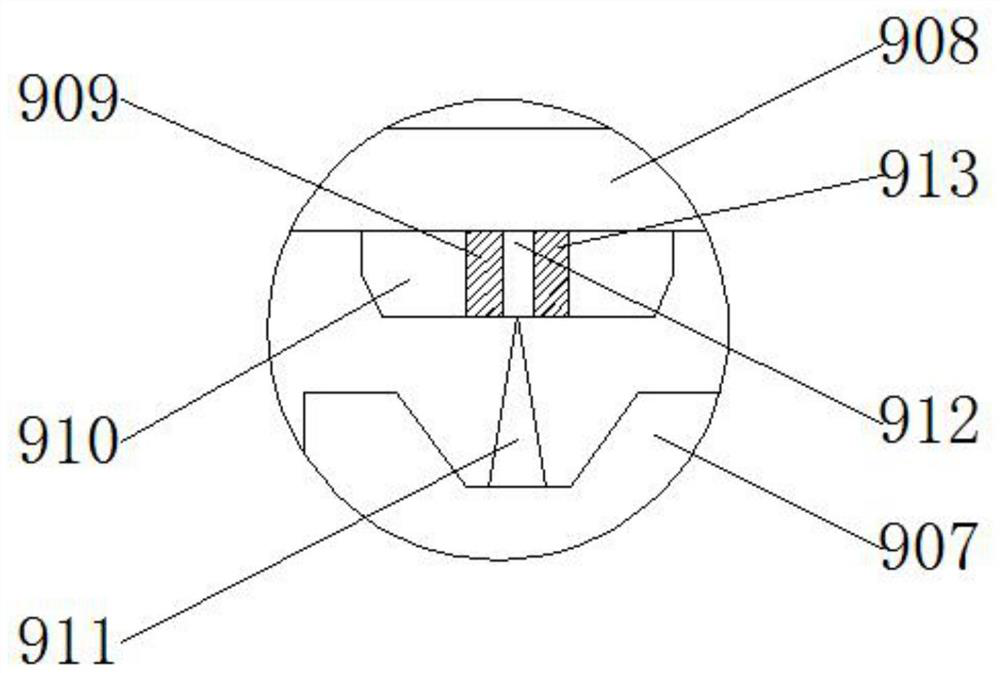

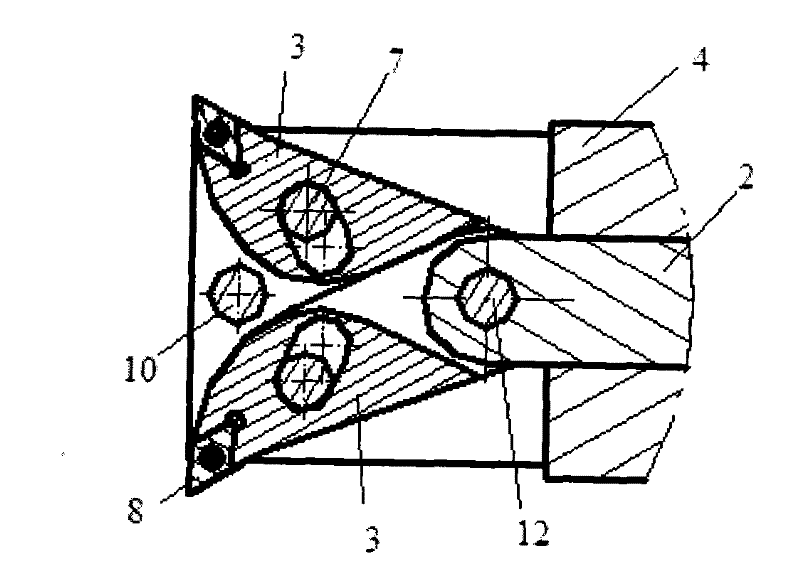

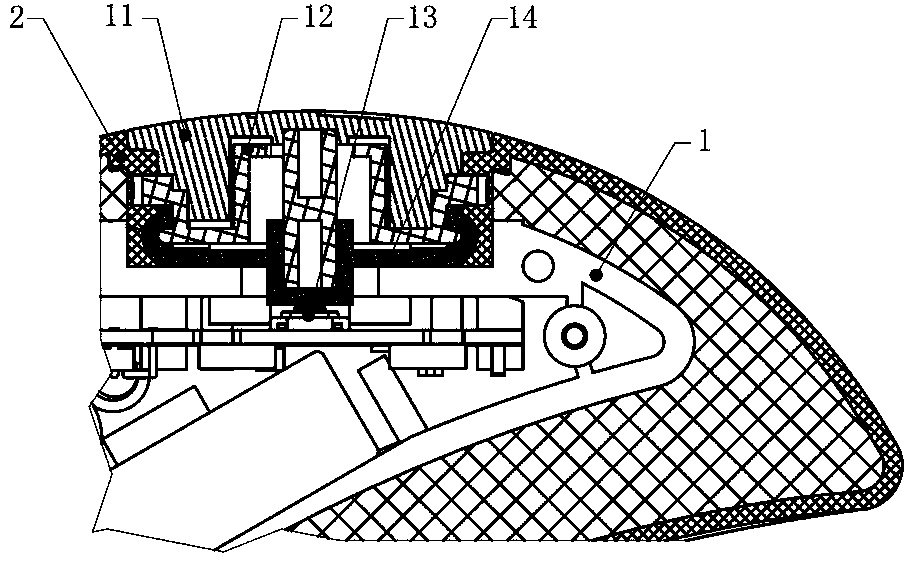

Double-blade boring cutter head without radial motion for cutter bar

ActiveCN101786175AReduce self-excited vibrationImprove stabilityTool holdersRadial motionSelf excited

The invention provides a double-blade boring cutter head without radial motion for a cutter bar, aiming to provide a stable and reliable boring cutter head capable of reducing the self-excited vibration of a boring bar. The double-blade boring cutter head comprises a cutter base which is fixedly connected to the end head of a boring bar (4) and can be used for replacing a blade; and the cutter base comprises two symmetrical crescent base bodies in a shear fork shape, wherein end part same-hole shafts of the two symmetrical crescent base bodies can be rotatably connected to a sunken platform of a push rod (2) and the boring bar (4). Since the two symmetrical crescent base bodies in a shear fork shape are used, the cutter bar does not do radial motion but can realize self-radial feeding in the boring and cutting process. By the invention, radial cutting forces of two blades on the boring cutter head can be mutually offset, so that asymmetrical unidirectional forced condition of the cutter bar can be changed; and the boring bar is not a cantilever beam single side of which is forced any longer and cannot generate the phenomena of deviation of blade center, cutter relieving or cutter scraping like a single-blade boring cutter.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP +1

Alcohol-group coating for V-method casting and preparation method thereof

ActiveCN102527928BImprove adhesion strengthHigh bonding strengthFoundry mouldsFoundry coresDrying timeBond strength

The invention discloses an alcohol-group coating for V-method casting, wherein the coating is powdery or granulous and is formed by blending 100 parts of fire-resistant powder and 10-14 parts of composite sizing agent by weight. Meanwhile, the invention further discloses a method for preparing the alcohol-group coating for V-method casting. Compared with the prior art, the costing disclosed by the invention is powdery or granulous, so that the advantages of convenience and safety in transportation are achieved; the packaging cost is low because barrels are not required for package; the transportation cost is low because the phenomenon of sediment hardening does not occur during the transportation so as not to result in material scrap; meanwhile, the coating further has the advantages that the adhesion and bond strength of a coating layer is high, the capability of resisting metal fluid machinery and thermal shock is strong, the drying time is short, the production efficiency is high, and the sand cohesiveness resistance is excellent.

Owner:NINGBO CANGHAI NEW MATERIALS DEV

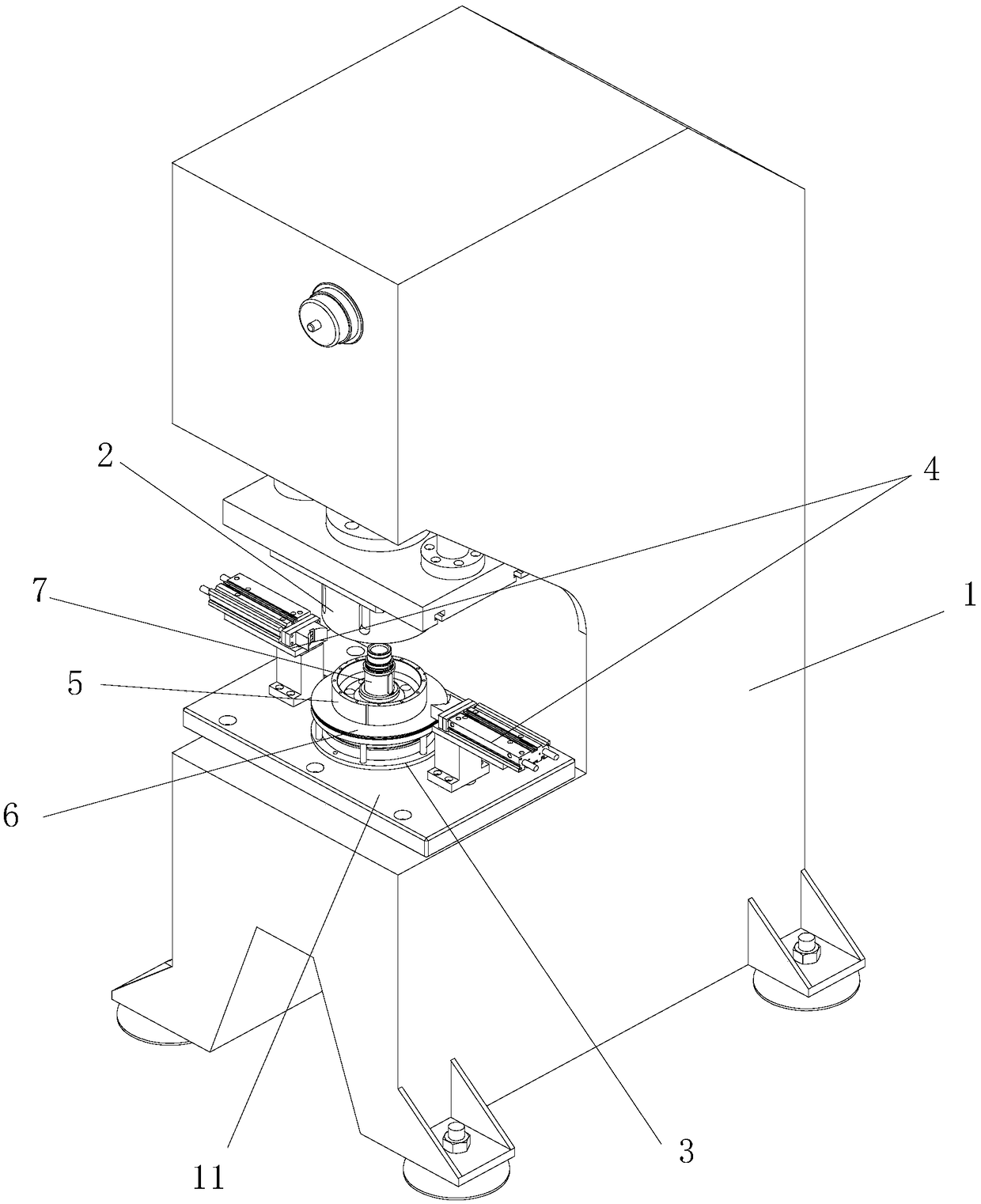

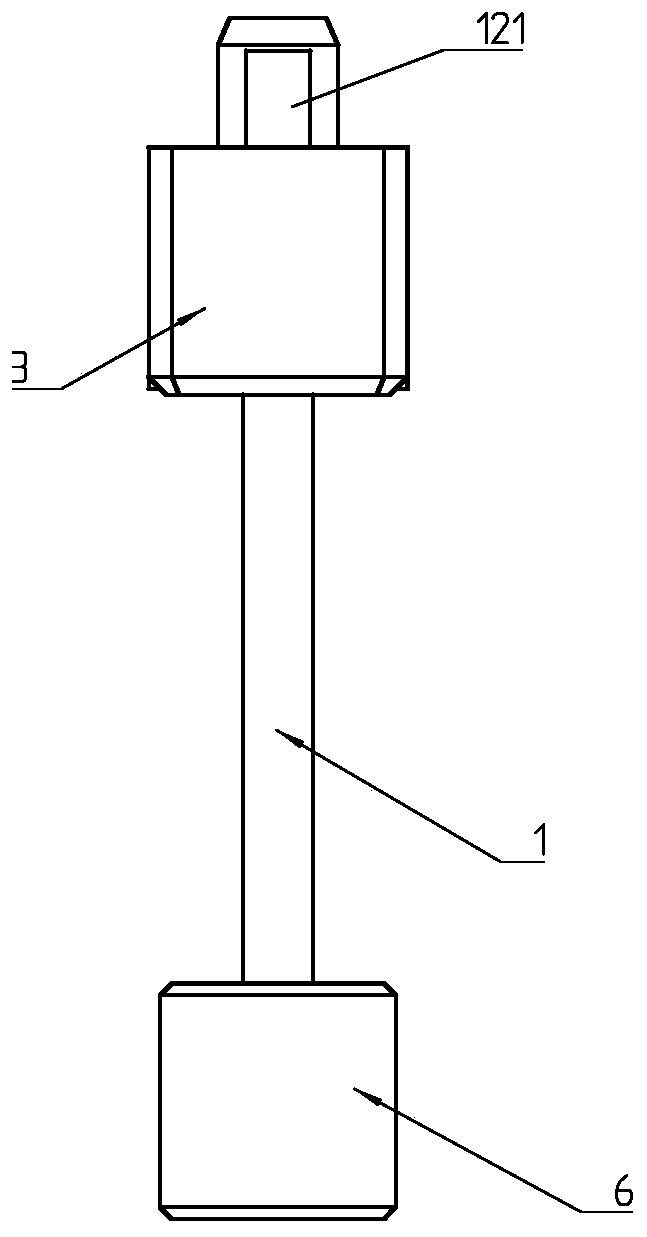

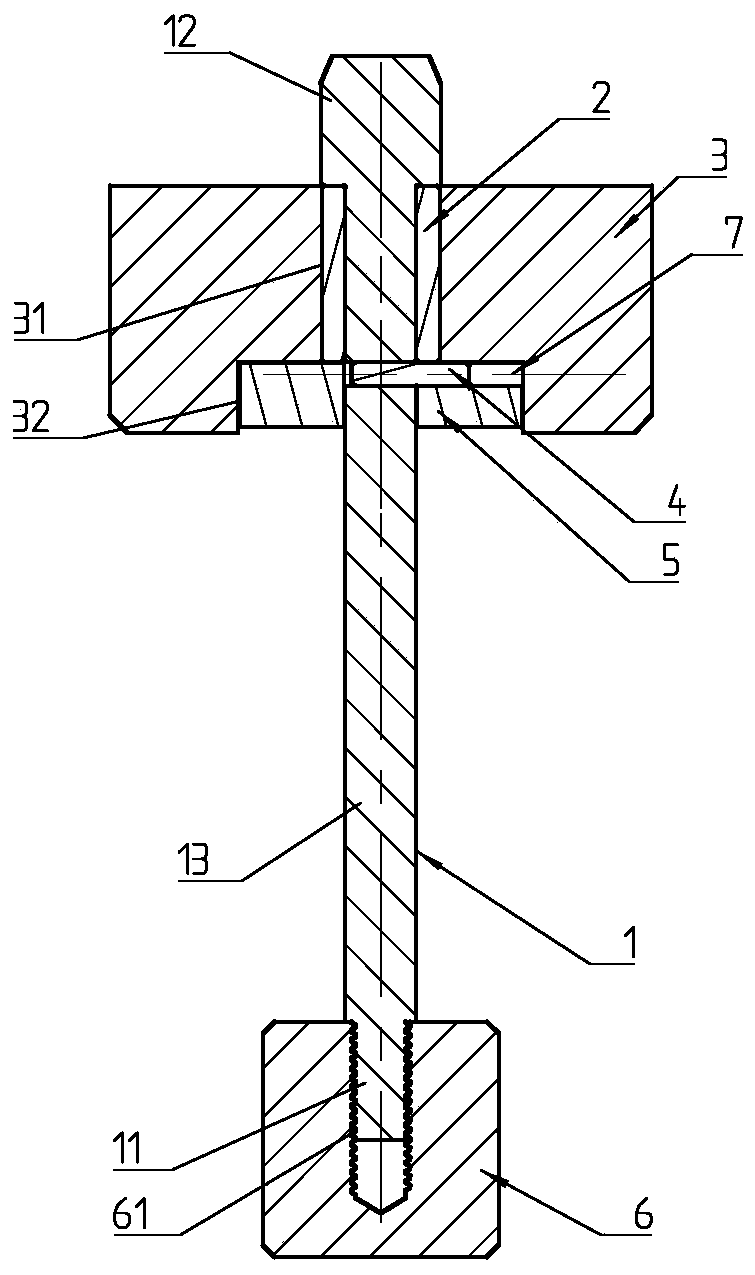

Rotor support shaft-pressing tool

PendingCN109396797AAvoid lossEasy to operateManufacturing dynamo-electric machinesVehicle componentsMechanical engineeringEnergy consumption

The invention discloses a rotor support shaft-pressing tool. The rotor support shaft-pressing tool comprises a press machine, a pressing head and a balance end plate positioning mechanism; the press machine is provided with a supporting platform, the balance end plate positioning mechanism is arranged on the supporting platform, the balance end plate positioning mechanism is used for bearing a rotor support and a balance end plate arranged on the rotor support in a sleeved mode, the pressing head is located right above the balance end plate positioning mechanism and is connected with the pressmachine, the bottom surface of the pressing head is provided with an outer extrusion surface used for extruding the balance end plate, the outer extrusion surface acts on the balance end plate, so that the balance end plate is fixedly connected with the rotor support. The tool has the characteristics of being low in energy consumption, safe to operate, clean in field environment, reliable in quality, high in production efficiency and the like.

Owner:迈思维动力技术(常州)有限公司

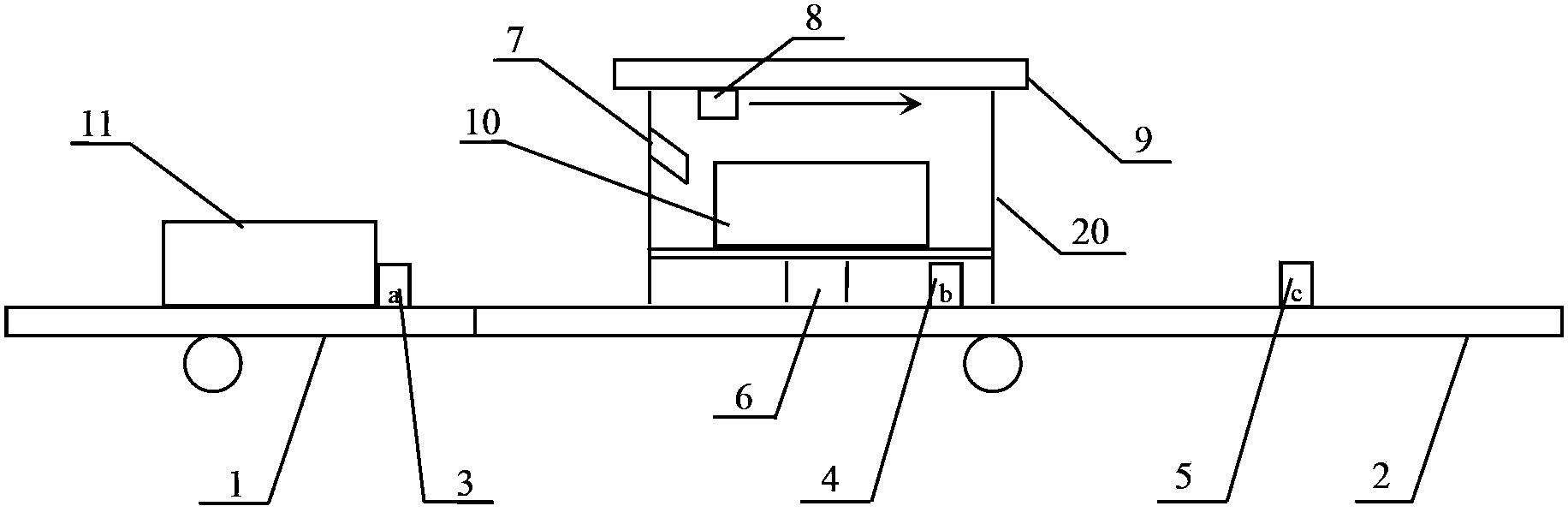

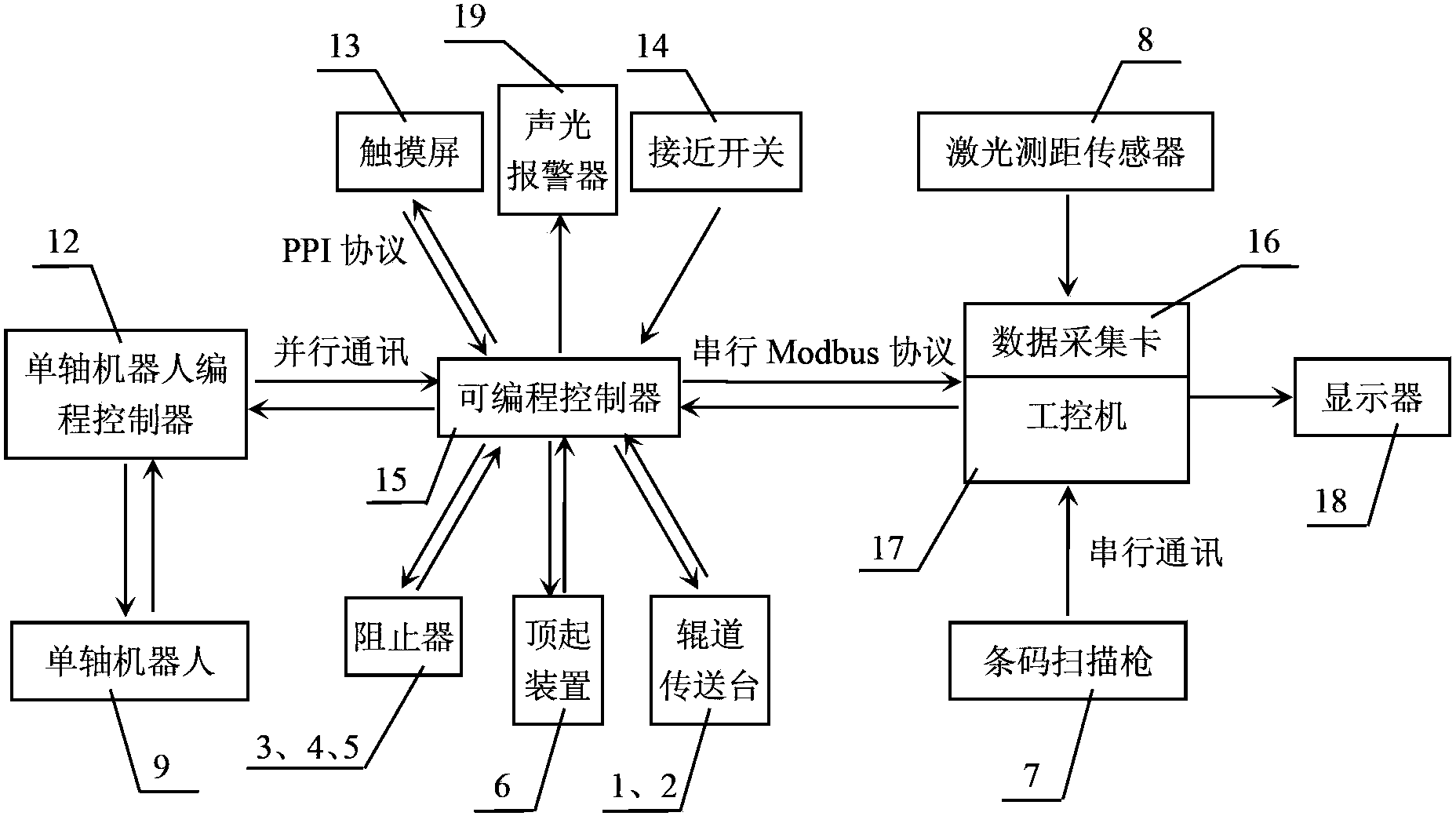

Error-proofing monitoring system and method for automobile engine valve assembling process

InactiveCN102749881BNo scrappingTo achieve the purpose of error preventionMetal working apparatusProgramme control in sequence/logic controllersData acquisitionDisplay device

The invention discloses an error-proofing monitoring system for an automobile engine valve assembling process. The error-proofing monitoring system comprises a detection platform, a control system and a man-machine information communication panel, wherein the detection platform comprises two roller way conveying tables, three stoppers, a jacking device, a barcode scanning gun, a laser ranging sensor and a single-shaft robot; the control system comprises a single-shaft robot programming controller, a programmable controller, a data acquisition card, an industrial personal computer and a proximity switch; and the man-machine information communication panel comprises a display, a touch screen and a combined aural and visual alarm. According to the error-proofing monitoring system disclosed by the invention, after the assembly of an air valve is finished, a correct-error result is immediately obtained according to an assembling situation, and an error assembling result is classified according to error types so as to provide a maintenance prompt for a maintainer. The error-proofing monitoring system disclosed by the invention is arranged at one section of an engine assembly line and only allows correctly assembled cylinders to pass the detection and enter a subsequent continuous engine assembling process in a working mode so as to reach an error-proofing purpose.

Owner:DALIAN JIAOTONG UNIVERSITY

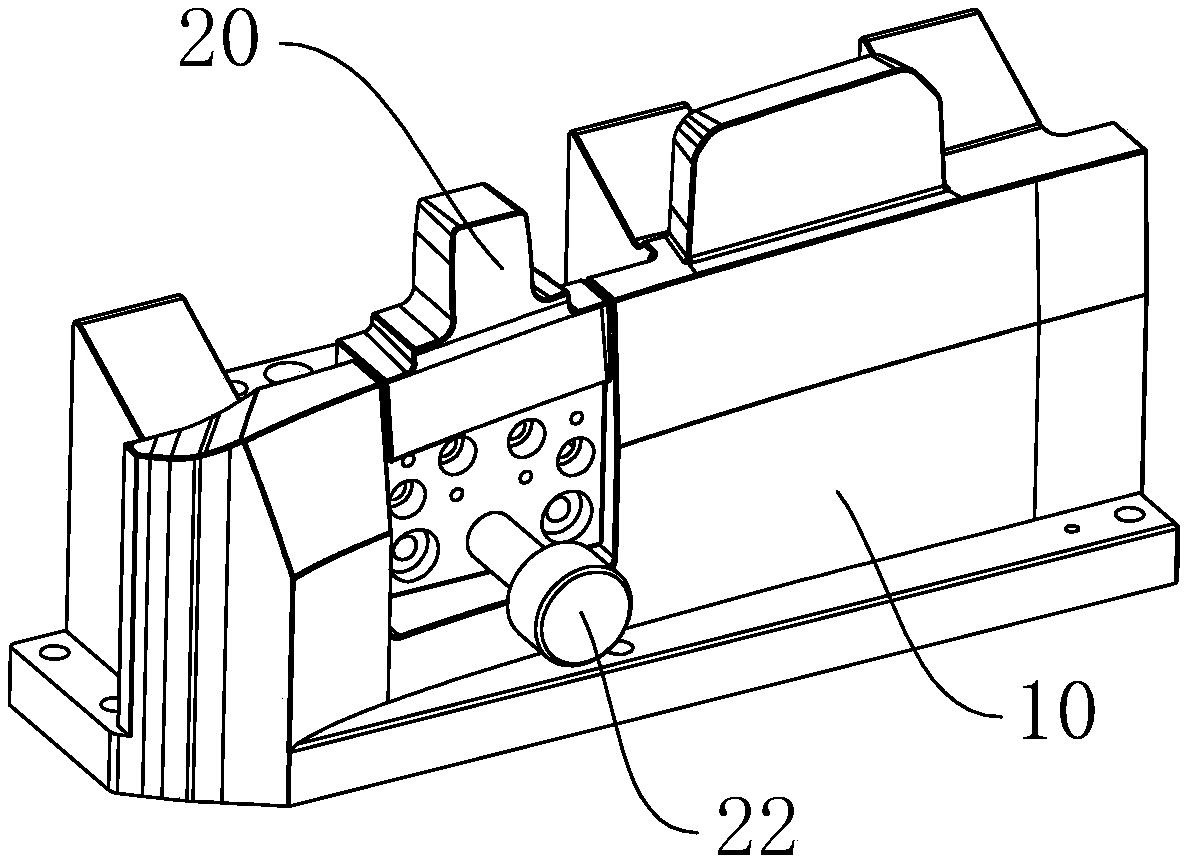

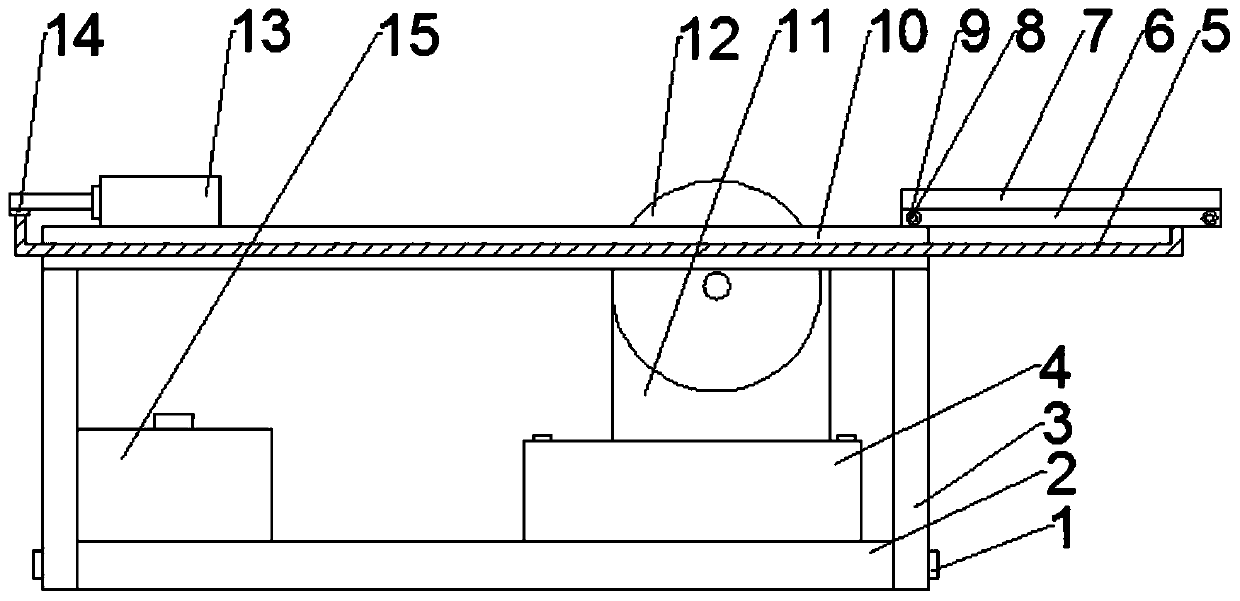

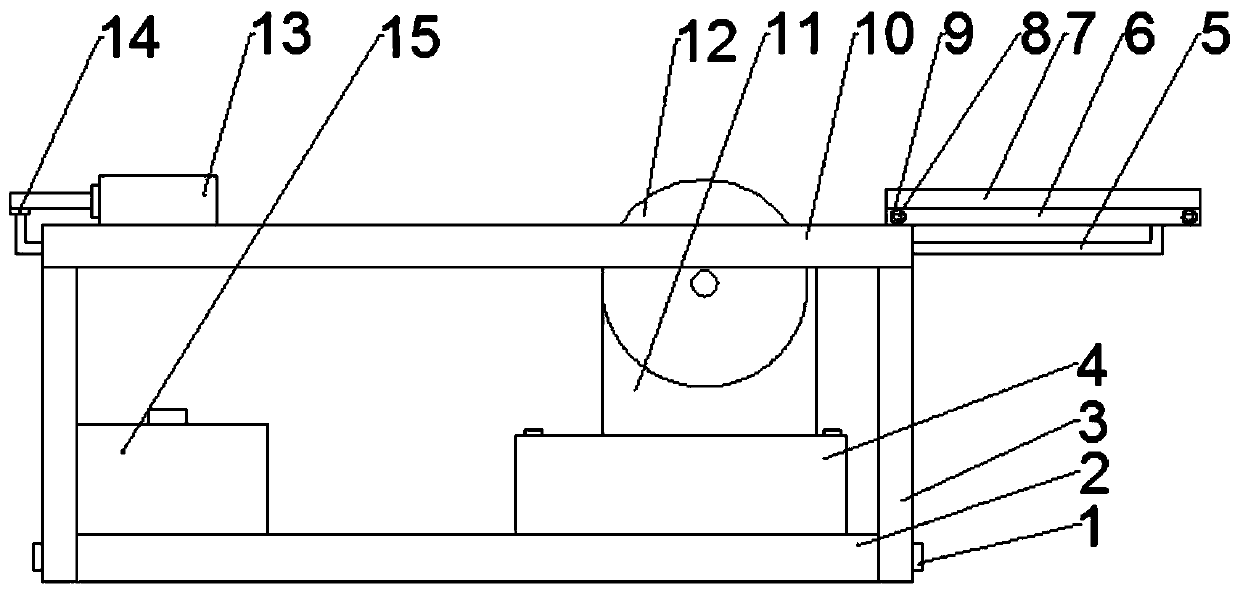

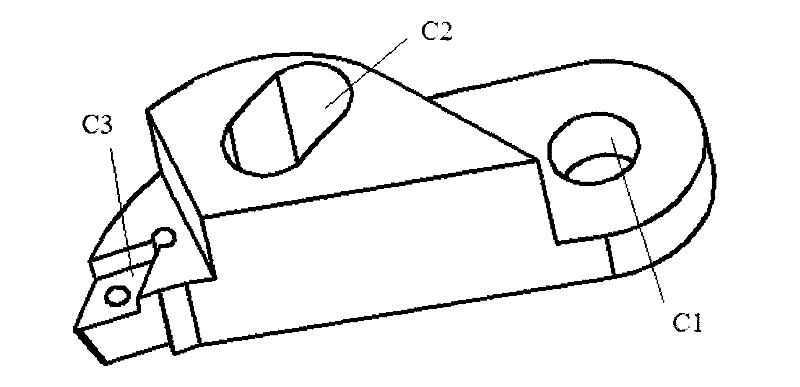

Quick interchanging mechanism for inspection device

PendingCN108240531AReasonable structureImprove guidance and positioning accuracyMeasurement devicesStands/trestlesMechanical engineering

The invention provides a quick interchanging mechanism for an inspection device and belongs to the technical field of machinery. The quick interchanging mechanism for the inspection device solves theproblem that an existing inspection device is inconvenient to operate. The quick interchanging mechanism for the inspection device comprises a base, an interchanging block, an adjusting block and a rotary handle; a lock hole is formed in the middle of the mechanism, and two positioning pins are symmetrically arranged in two sides of the lock hole; the interchanging block covers the base, and two through holes corresponding to the two positioning pins one by one are formed in the interchanging block; the adjusting block is located between the base and the interchanging block, two mounting holescorresponding to the two through holes one by one are formed in the adjusting block, linear bearings are embedded into the mounting holes, and each positioning pin penetrates the corresponding linearbearing; and the rotary handle successively penetrates through the interchanging block and the adjusting block from outside to inside and is partially screwed into the lock hole. When the rotary handle leaves the lock hole, the interchanging block and the adjusting block can be driven to leave the base together. The quick interchanging mechanism provided by the invention has the characteristic ofbeing convenient to operate.

Owner:浙江信正精密科技有限公司

Aerated brick cutting device

InactiveCN110815600ANo scrappingNo deviationWorking accessoriesStone-like material working toolsBrickElectric machinery

The invention discloses an aerated brick cutting device and belongs to the technical field of aerated brick processing. The aerated brick cutting device comprises a base. A motor and bracket are arranged on the base, the bracket is fixedly connected to the base, the top end of the bracket is fixedly connected to a cutting table, a groove is formed in the cutting table, an output shaft of the motoris fixedly connected to a round cutting knife, the cutting knife penetrates the groove and is in clearance fit to the groove, a conveying mechanism is arranged on the side, parallel to the axis of the cutting knife, of the cutting table, the conveying mechanism comprises two conveying tables arranged in a spaced manner, the lower surfaces of the two conveying tables are slidably connected to theupper surface of the cutting table, fixing assemblies for fixing aerated bricks are arranged on the two conveying tables, the lower surfaces of the two conveying tables are fixedly connected to slidebars, the slide bars penetrate the cutting table and are slidably connected to the cutting table, the other end of the cutting table is fixedly connected to an air cylinder, and a telescopic rod of the air cylinder is fixedly connected to the slide bar. Deviation of the aerated brick cut by the aerated brick cutting device according to the scheme can be avoided effectively, and meanwhile, the aerated brick cutting device cuts the aerated brick quite precisely.

Owner:贵州彬腾越新型建材有限公司

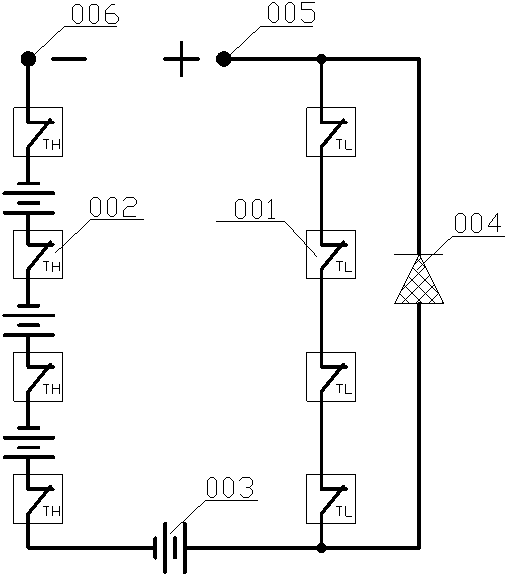

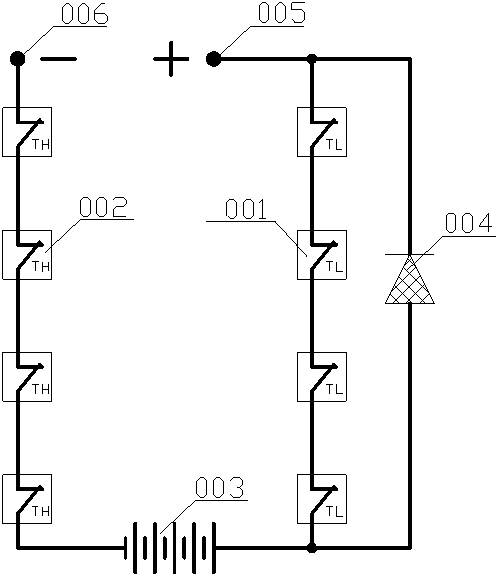

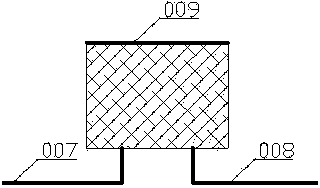

Overheat protection technology for storage battery case of electric vehicle

InactiveCN104051809AAvoid accidentsAvoid damageBatteries circuit arrangementsSecondary cells testingElectric vehicleEngineering

The invention discloses an overheat protection technology for a storage battery case of an electric vehicle. Low-temperature thermostat switches (001), high-temperature thermostat switches (002), a storage battery (003), a diode (004) and the like are involved, wherein the low-temperature thermostat switches (001) are connected in parallel with the diode (004) to form a low-temperature thermostat module which is connected in series with the high-temperature thermostat switches (002) and the storage battery (003); the low-temperature thermostat module is used for protecting the storage battery (003) from being damaged by overheat in a charging process; the high-temperature thermostat switches (002) are used for preventing an electric vehicle failure and even a fire accident caused by instantaneous overheat, due to line short-circuit, of a wire or the storage battery (003).

Owner:李文忠

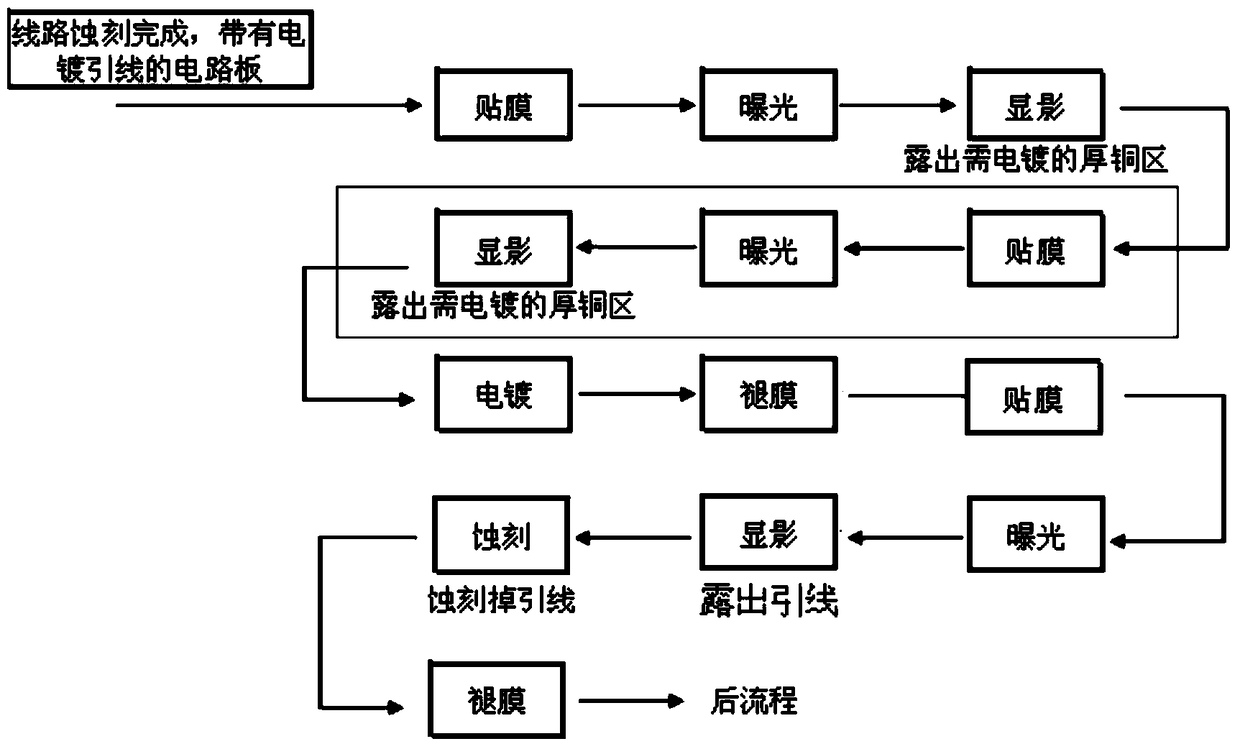

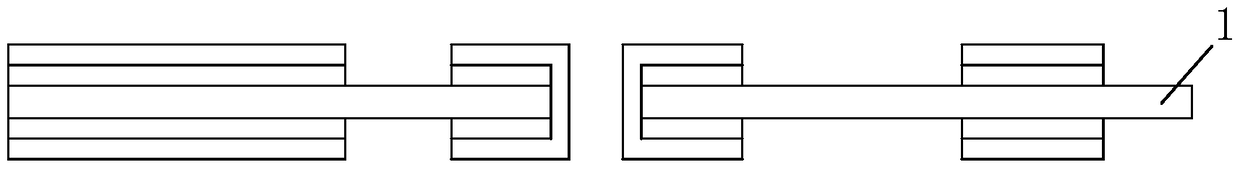

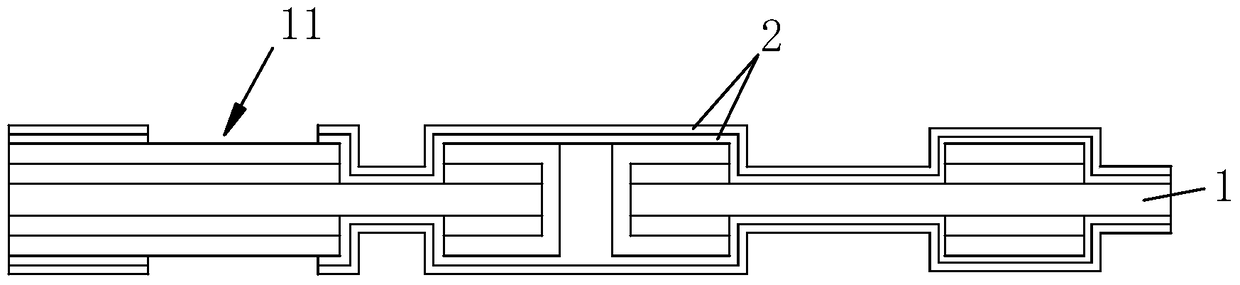

A kind of manufacturing method of partial thick copper pcb

ActiveCN105430929BImprove yieldAvoid pinchingPrinted circuit aspectsConductive pattern reinforcementCopper

The present invention relates to the technical field of a PCB, and particularly relates to a manufacturing method of a locally thick copper PCB. The manufacturing method comprises the following steps: A, a step of preparation; B, a step of pasting primary dry films: pasting at least two layers of primary dry films in areas on a circuit board, where thick copper does not need to be plated, and carrying out exposure and development to expose areas where the thick copper needs to be plated; C, a step of locally plating the thick copper; D, a step of taking off the primary dry films; E, a step of pasting secondary dry films; F, a step of carrying out lead etching; and G, a step of taking of the secondary dry films. According to the manufacturing method disclosed by the present invention, a phenomenon of film clipping can be effectively avoided, and a local copper thickness can be made to be 2-3 oz and even greater according to the number of film pasting times, so that the difficult problem that the local copper thickness is greatly different from other areas to result in difficult production can be effectively solved; and moreover, the method is simple in manufacturing process, can well achieve local planting of the thick copper without special control, can be used for manufacturing products in batches, and cannot generate rejections basically, thereby enabling product yield to be very high and improving product quality.

Owner:东莞森玛仕格里菲电路有限公司

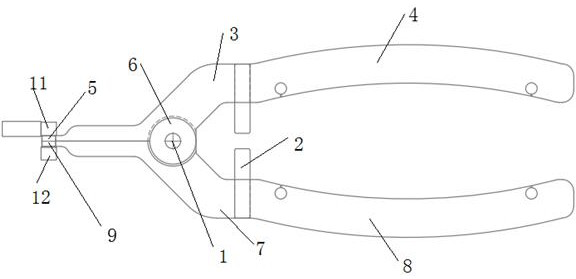

Disassembling clamp for MMCX connector

PendingCN113644523AEasy and smooth disassemblyReduce the difficulty of operationCoupling device engaging/disengagingStructural engineeringMechanical engineering

Owner:FLEXTRONICS ELECTRONICS TECH SUZHOU

Tool device convenient for testing pressure of high-pressure oil pipe

ActiveCN109443939AEasy to operateEasy to installMaterial strength using tensile/compressive forcesHigh pressurePiston rod

The invention discloses a tool device convenient for testing pressure of a high-pressure oil pipe. The tool device comprises a left-side oil pipe fixing component, a right-side oil pipe fixing component, a bottom plate, a water incoming pipe, an air incoming pipe and a connection water pipe, the left-side oil pipe fixing component comprises a first manual valve, a first end cap, a retaining plate,a rotating seat, a first air pipe and a second air pipe, and the right-side oil pipe fixing component comprises a second end cap, a third end cap, a third air pipe, a fourth air pipe and a second manual valve. The first end cap and the third end cap are pushed by a piston rod to tightly clamp joints at two ends of the high-pressure oil pipe by pulling the first manual valve and the second manualvalve, so that operation is simple and convenient; for the high-pressure oil pipe different in length, proper distance is reached by adjusting a screw for the convenience of mounting; angle of a grooving position on a retaining plate is adjusted by utilizing the rotating seat for the convenience of mounting the oil pipe; distance and angle are adjusted through sliding of a clamping plate on a connection rod to realize adjusting on direction of the left-side oil pipe fixing component and the right-side oil pipe fixing component.

Owner:南京海王汽车零部件有限公司

Highly-stable composite die base material

The invention relates to a highly-stable composite die base material. The material contains an additive and a carrier, and the formula of the material comprises 0.5-6 wt% of modified rubber particles,10-35 wt% of unsaturated polyester resin, 1-10 wt% of sands, 0-3 wt% of a processing aid, 0-2.5 wt% of a flame retardant, 5-20 wt% of a foaming agent, 10-20 wt% of a stabilizer and 30-60 wt% of lightburnt magnesium powder. The product prepared through the method has the advantages of excellent stability, avoiding of lateral displacement of a die in the heating and pressurizing process, low basehardness, avoiding of die scrap directly caused by misoperation of die loading and unloading, low cost and high cost performance.

Owner:徐州吉瑞合金铸造有限公司

Production method of optical fiber preset core insert and positioning device

The invention relates to a production method of an optical fiber preset core insert, which has the characteristics that the insertion loss of the optical fiber core insert in the production process can be detected by an instrument. The technical scheme is as follows: the production method of the optical fiber preset core insert is characterized by comprising the following steps: (a) horizontally fixing a ceramic core insert on a workbench of a core insert grinder; (b) sheathing a protective sleeve on a bare optical fiber which is not cut; (c) inserting the bare optical fiber into an optical fiber hole from the tail part of the ceramic core insert; (d) starting the core insert grinder to grind the end surface of the head part of the ceramic core insert and the end surface of the bare optical fiber; (e) conducting return loss test on a light guiding surface; (f) if the test result is disqualified, repeating the steps (d-e) until the test is qualified; and (g) if the test result is qualified, stripping the protective sleeve of the bare optical fiber, and taking the core insert out of the core insert grinder, and preserving a tail fiber with a certain length, and cutting with a cutter.

Owner:WANMA TECH CO LTD

Method for manufacturing motor rotor and self-aligning positioning mechanism used thereby

ActiveCN101599674BImprove manufacturing precisionSolve the difficulty of coatingMagnetic circuit rotating partsManufacturing stator/rotor bodiesEngineeringScrew thread

Owner:NINGBO YUNSHENG +3

Inner wall smearing auxiliary device for corrugated pipe manufacturing and using method of inner wall smearing auxiliary device

PendingCN113385387AAvoid breakingGuaranteed service lifeLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses an inner wall smearing auxiliary device for corrugated pipe manufacturing and a using method of the inner wall smearing auxiliary device, and relates to the technical field of corrugated pipe manufacturing. The inner wall smearing auxiliary device for corrugated pipe manufacturing comprises a device body, and a controller is arranged on the front surface of the device body. According to the inner wall smearing auxiliary device for corrugated pipe manufacturing and the using method of the inner wall smearing auxiliary device, groove expanding treatment is conducted on the inner wall of the corrugated pipe before smearing operation, so that an air layer communicating with the coating layer and a corrugated pipe body exists between a coating layer and a corrugated pipe body, when the corrugated pipe is bent, part of coating is squeezed into the air layer, therefore external coating stress is relieved, and thus the effect of preventing cracking and falling of the coating layer is achieved; and during groove expansion treatment, threaded rod extrusion treatment instead of cutting treatment is adopted, so that the density of the corrugated pipe body on the top of the inner cavity of the air layer is relatively large, the position where the air layer is located is not prone to deformation when the corrugated pipe is bent, and therefore the service life of the air layer can be well guaranteed.

Owner:安徽塑茂管道科技有限公司

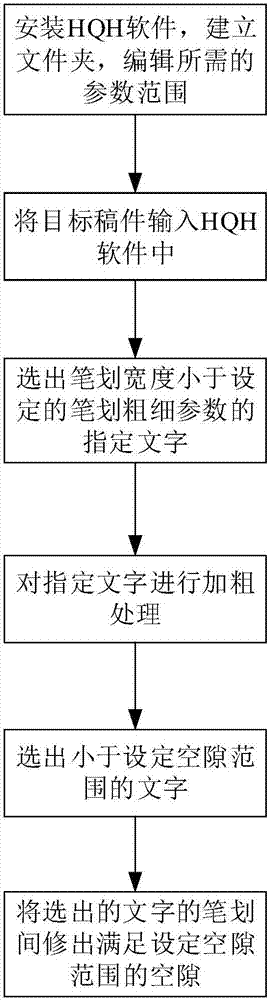

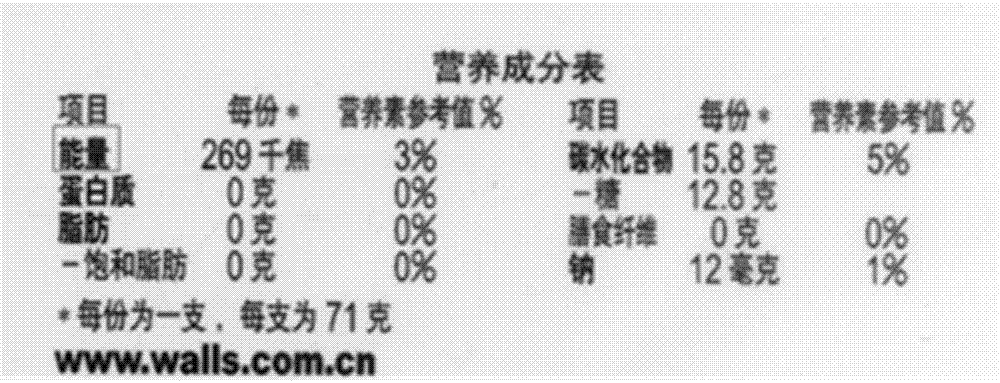

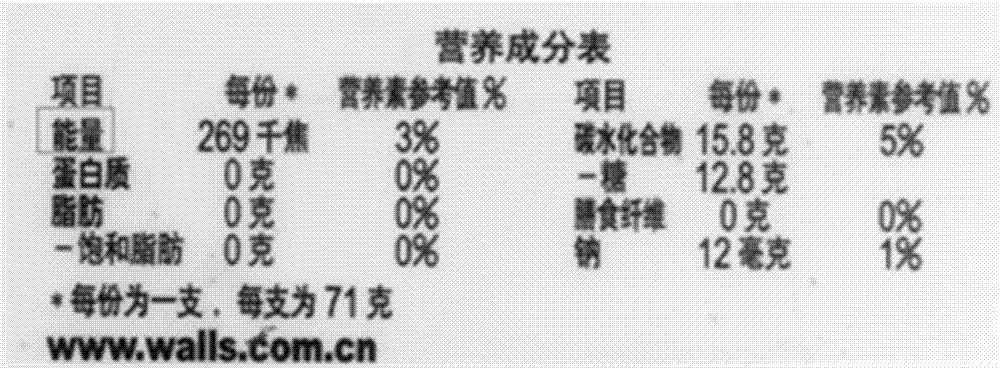

HQH-based automatic text overstriking and text gap forming method

InactiveCN107463535AReduce mismark quality issuesGood reputationNatural language data processingSpecial data processing applicationsAlgorithmStroke width

The invention relates to an HQH-based automatic text overstriking and text gap forming method. The method comprises the steps of (1) installing HQH software, establishing a folder, and editing a required parameter range; (2) determining that a target manuscript is not artificially processed, and inputting the target manuscript to the HQH software; (3) reading the current target manuscript by a file manager, and selecting out a specified text with a stroke width smaller than a set stroke thickness parameter; (4) performing overstriking processing on the specified text; (5) judging a gap between strokes of the overstriked text, and selecting out a text with a gap range smaller than a set gap range; and (6) forming a gap, in the set gap range, between strokes of the selected text. Compared with the prior art, the method has the advantages that the occurrence of artificial quality problems can be geometrically reduced while the manpower cost is reduced; and more benefits are obtained for clients and printing companies.

Owner:SHANGHAI YUNCHENG PLATE MAKING

Positioning pin positioning buckle mechanism for gauge

PendingCN110763100AOutstanding and Beneficial Technical EffectsReduce processing difficultyMechanical measuring arrangementsInterference fitAxial displacement

The invention discloses a positioning pin positioning buckle mechanism for a gauge. The mechanism comprises an adjustment block which is provided with a pin bush hole, a pin bush which is assembled inthe pin bush hole in an interference fit manner, a positioning pin which comprises a positioning pin body, and a limiting mechanism which limits the axial displacement of the positioning pin and limits the positioning pin to rotate only within a set angle range, wherein one end of the positioning pin body is provided with a positioning part, the other end of the positioning pin body penetrates through the pin bush to be connected with a rotating part, and the maximum size of the positioning part is not smaller than the diameter of the positioning pin body. The effect of part expansion takingcan be achieved by rotating the positioning pin by 90 degrees, the limiting block and the adjustment block are connected into a whole, the debugging is convenient, the structure is simple, and the cost is low.

Owner:浙江信正精密科技有限公司

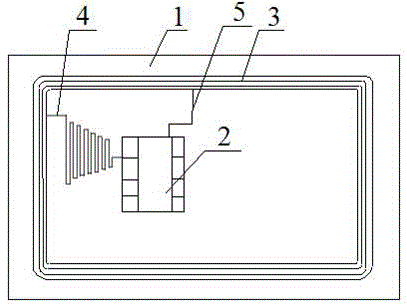

A kind of smart card capable of measuring the tension value of solder joint and its measurement method for the tension value of solder joint

ActiveCN103226725BNo scrappingEasy to produceForce measurementRecord carriers used with machinesSmart cardEngineering

The invention discloses a smart card capable of measuring welding spot tension and a welding spot tension measuring method thereof. The smart card comprises a substrate and a chip, wherein the chip is welded in the substrate; a coil is arranged inside the substrate; a first outgoing wire and a second outgoing wire are arranged on the coil; the first outgoing wire is longer than the second outgoing wire; and the first outgoing wire and the second outgoing wire are welded with the chip respectively. Through the technical scheme, the smart card can precisely measure the welding spot tensions of the outgoing wires of the chip in the production process, so that the quality abnormality of a welding spot can be found as early as possible; the production process is effectively simplified, so that the production efficiency is improved; and the unqualified rate of products is reduced.

Owner:SHANGHAI ORIENTAL MAGNETIC CARD ENG

Double-blade boring cutter head without radial motion for cutter bar

ActiveCN101786175BReduce self-excited vibrationImprove stabilityTool holdersRadial motionSelf excited

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP +1

Female massager intermediate layer flexible rubber filling forming process and assembly method

PendingCN110181753AFit tightlyReduce assembly processVibration massageGenitals massageEngineeringSilica gel

The invention relates to the technical field of female massagers, in particular to a female massager intermediate layer flexible rubber filling forming process and an assembly method. The female massager intermediate layer flexible rubber filling forming process is characterized by comprising the steps of mounting a pre-assembled inner core shell into a silicone skin; connecting and fixing the inner core shell to an upper mold through a first connecting part and a second connecting part via screws; connecting an air extraction hose and a feed hose to a filling space between the inner core shell and the silicone skin; inflating the air into the filling space for pressurization to enable the silicone skin to be completely attached to the surface of an inner cavity of the mold; and injectingliquid silicone into the filling space through the feed hose and pumping out the air synchronously through the air extraction hose from the other end of the feed hose. Compared with the prior art, thefemale massager intermediate layer flexible rubber filling forming process has the advantages that it can be guaranteed that an intermediate flexible rubber layer is tightly attached to both the surface silicone layer and the inner core shell; and the situation that untight attachment during laser assembling, bubbles are generated and assembling is not implemented in place is avoided.

Owner:IMOTION SHANGHAI PROD DESIGN

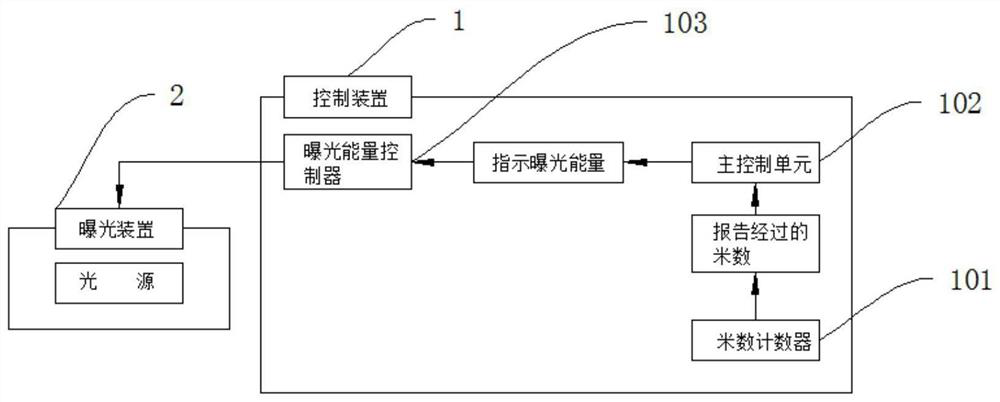

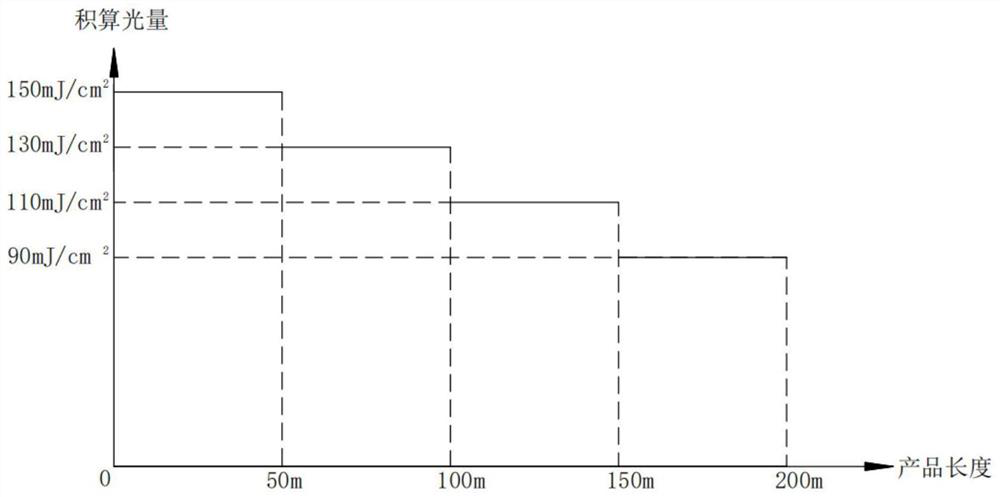

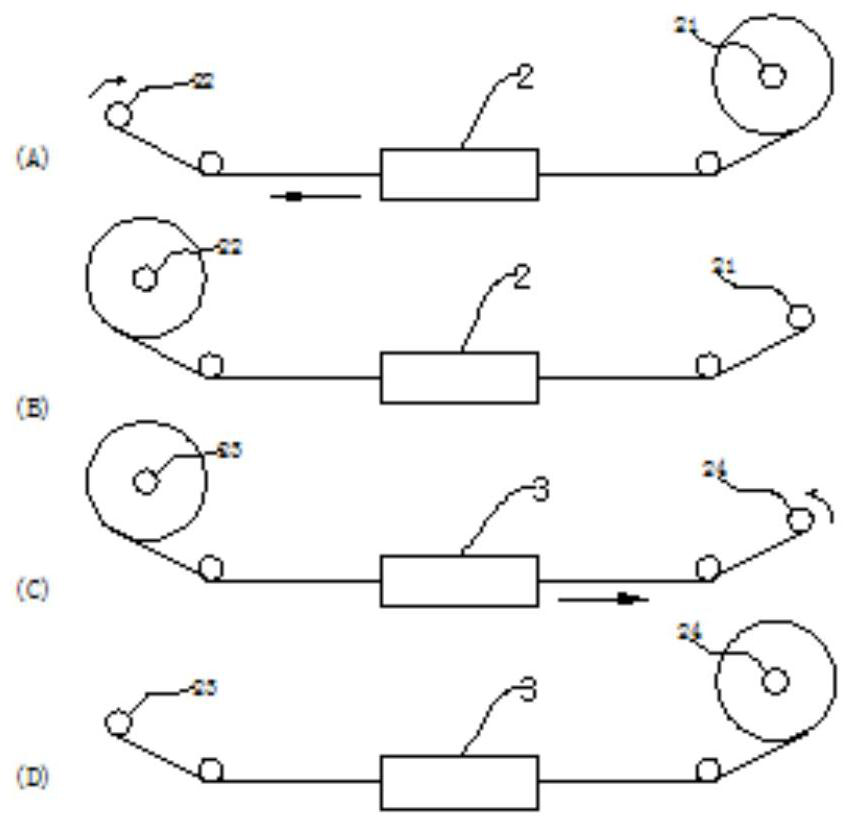

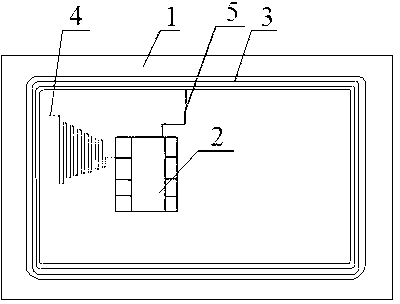

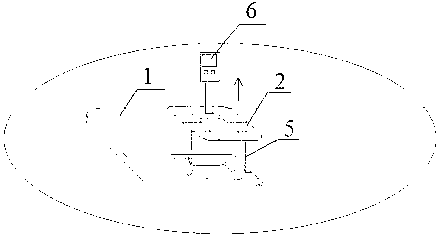

An exposure method for controlling batch line width differences of flexible circuit boards

ActiveCN110750036BNo scrappingControl the amount of accumulated lightPhotomechanical exposure apparatusMicrolithography exposure apparatusFlexible circuitsLine width

Owner:江苏上达半导体有限公司

Smart card capable of measuring welding spot tension and welding spot tension measuring method thereof

ActiveCN103226725ANo scrappingEasy to produceForce measurementRecord carriers used with machinesEngineeringSmart card

The invention discloses a smart card capable of measuring welding spot tension and a welding spot tension measuring method thereof. The smart card comprises a substrate and a chip, wherein the chip is welded in the substrate; a coil is arranged inside the substrate; a first outgoing wire and a second outgoing wire are arranged on the coil; the first outgoing wire is longer than the second outgoing wire; and the first outgoing wire and the second outgoing wire are welded with the chip respectively. Through the technical scheme, the smart card can precisely measure the welding spot tensions of the outgoing wires of the chip in the production process, so that the quality abnormality of a welding spot can be found as early as possible; the production process is effectively simplified, so that the production efficiency is improved; and the unqualified rate of products is reduced.

Owner:SHANGHAI ORIENTAL MAGNETIC CARD ENG

Easy-to-use high-pressure oil pipe pressure test tooling device

ActiveCN109443939BEasy to operateEasy to installMaterial strength using tensile/compressive forcesMechanical engineeringPiston rod

Owner:南京海王汽车零部件有限公司

A Simple Stamping Die for U-shaped Bending Parts

InactiveCN103357748BNo scrappingSimple, practical and reliable operationShaping toolsEjection devicesPunch pressMaterials science

The invention aims to provide a simple U-shaped bending piece stamping mould and belongs to the technical field of stamping moulds. By means of arranging rubber below a lower mould base, the problem that parts cannot be demoulded smoothly in a bending process, an upper mould and a lower mould cannot be clamped, and the upper mould and the lower mould of the stamping mould cannot be displaced. The simple U-shaped bending piece stamping mould comprises an upper mould base (1), screws (2), a mould shank (3), a stop pin (4), a pin (5), a guide sleeve (6), a cushion plate (7), a guide column (8), a male mould fixing plate (9), a positioning plate (10), screws (11), a female mould (12), the lower mould base (13), a pin (14), a screw (15), an upper cushion plate (17), the rubber (17), screws (18), a lower cushion plate (19), an ejection rod (20), screws (21), a male mould (22) and an ejection plate (23). The simple U-shaped bending piece stamping mould is basically free from maintenance, simple to operate, practical and reliable, and acts with cooperation of a special punch press.

Owner:朱敏忠

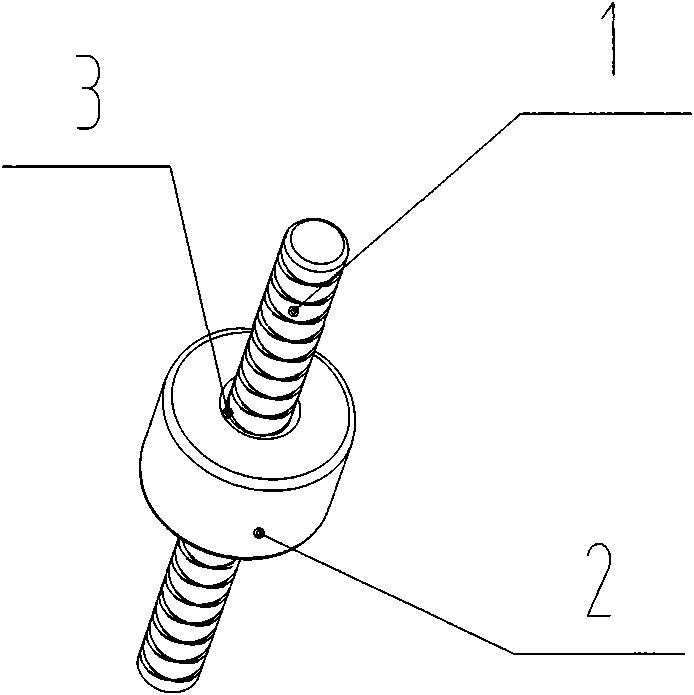

Small radius forming tool for large-diameter guide tube

The invention discloses a small radius forming tool for a large-diameter guide tube. The small radius forming tool for the large-diameter guide tube comprises a bending mold and a clamping block, wherein the bending mold comprises a forming mold (1), a first clamping mold (2) and a second clamping mold (3). Both the first clamping mold (2) and the second clamping mold (3) are connected to the forming mold (1) to form an integrated structure; a first groove structure (4) is arranged on the outer surfaces of the forming mold (1), the first clamping mold (2) and the second clamping mold (3); and an auxiliary clamping mechanism (5) is fixedly connected to the upper side of the first clamping mold (2). The small radius forming tool for the large-diameter guide tube is used for numerically controlled brake forming of the guide tube, so that the machining efficiency and quality are improved; the deviation value between the formed guide tube and a theoretical shape is reduced to meet a specified value; a tubular product is not scrapped, the repair rate is zero, and the machining quality is greatly enhanced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com