Automatic heat sealing and edge wrapping device for automobile sun visor and preparation method of sun visor

A technology of automobile sun visor and hemming device, which is applied in the field of automatic heat-sealing and hemming device of automobile sun visor, and the field of sun visor preparation, which can solve the problems of low work efficiency, product scrap rate, complicated operation, etc., so as to improve work efficiency, Easy to operate, no scrap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

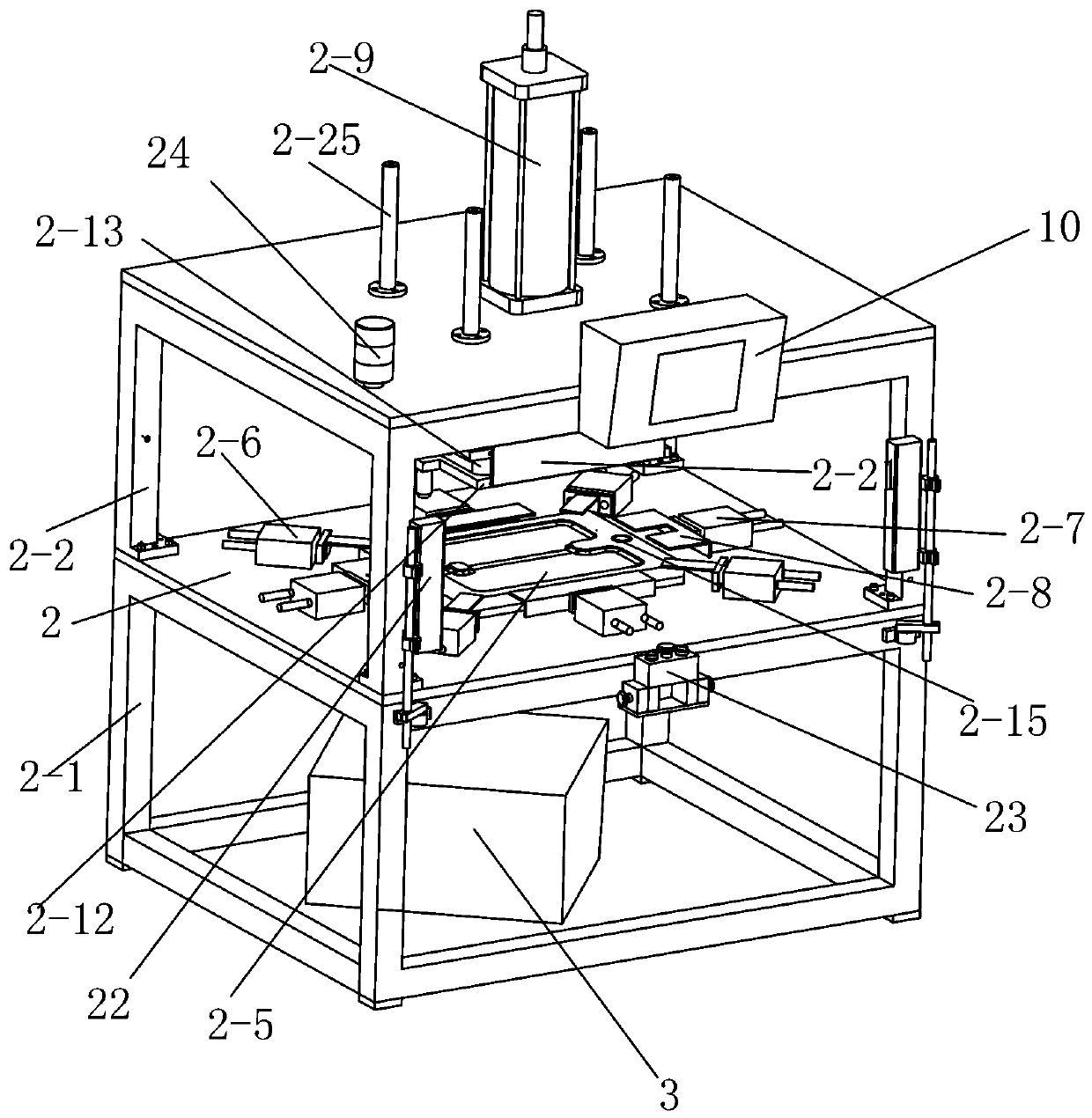

[0037] An automatic heat-sealing and hemming device for an automobile sun visor provided in this embodiment includes a power supply box 3, and a hemming mechanism 2 electrically connected to the power supply box 3 and used for hemming the upper frame and the lower frame, and The heat-sealing mechanism 1 for heat-sealing the upper frame and the lower frame after the mechanism 2 is completed,

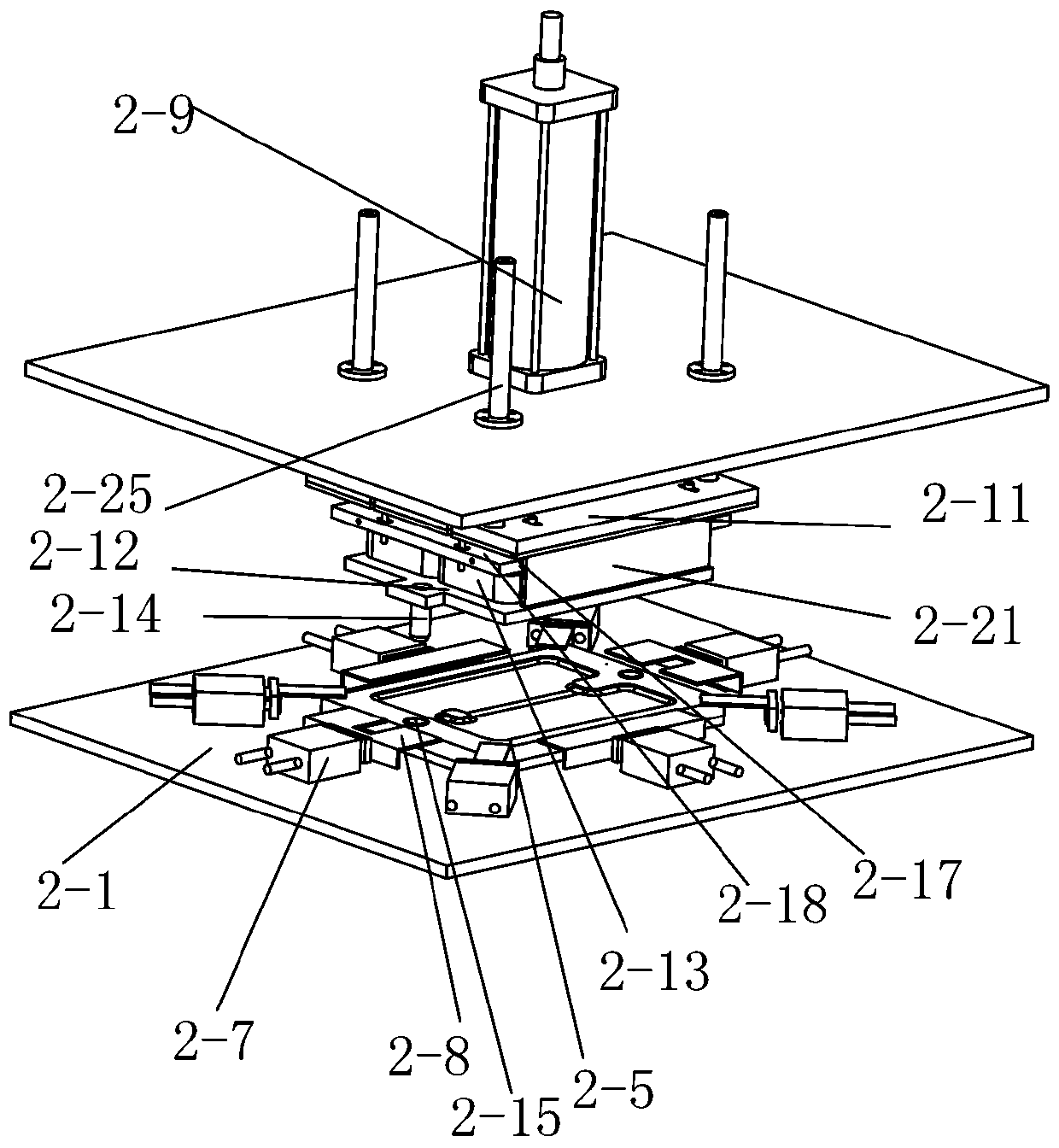

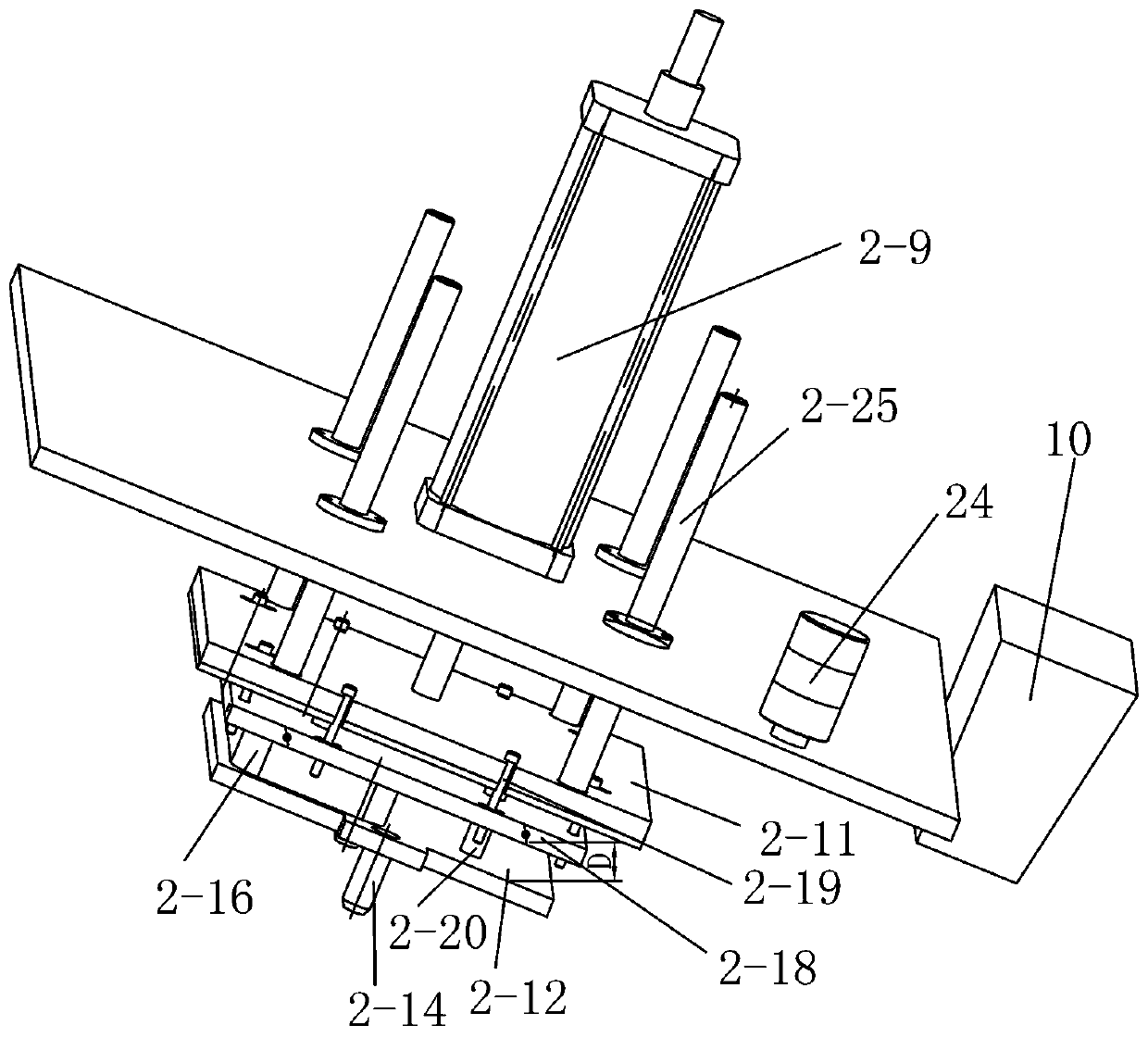

[0038] like figure 1 , figure 2 , image 3 , Figure 4As shown, the hemming mechanism 2 includes a first lower bracket 2-1 and a first upper bracket 2-2 fixed to each other, and the first lower bracket 2-1 is provided with a product for placing a foamed polypropylene skeleton. The lower die 2-5 is equipped with a device that moves to the lower die 2-5 of the product and pushes the fabric to the surroundings and corners of the expanded polypropylene skeleton around the lower die 2-5 of the product and between the four diagonal corners. The cylinder advances the pressing mechanism 2-6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com