Small radius forming tool for large-diameter guide tube

A large-diameter, small-radius technology, applied in the field of small-radius forming tools, can solve the problems of low forming quality, scratches, increased repair rate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

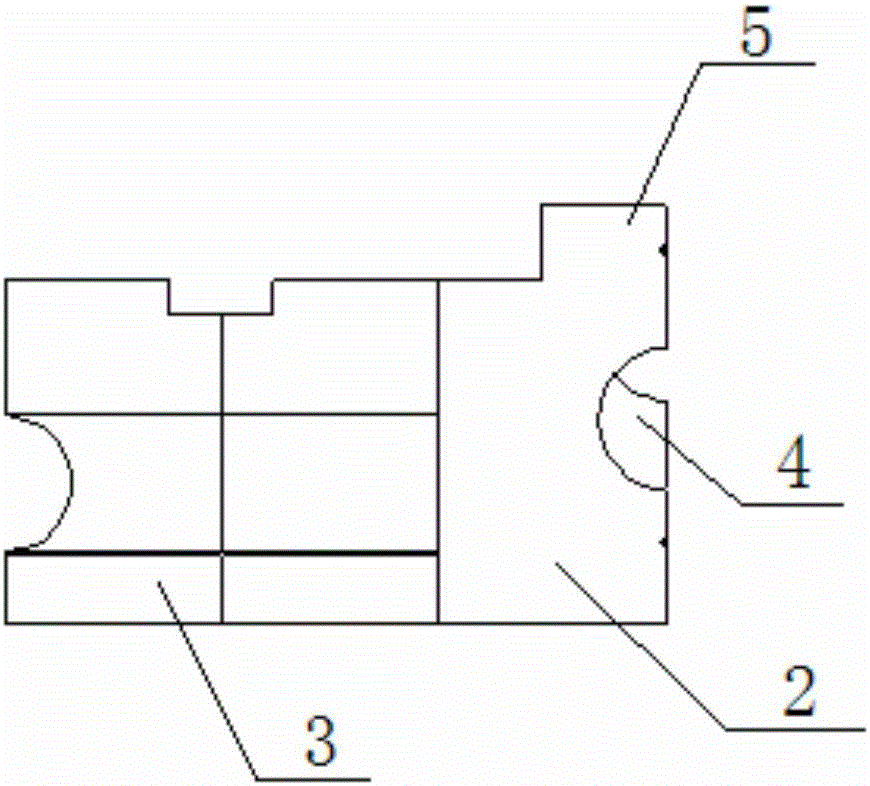

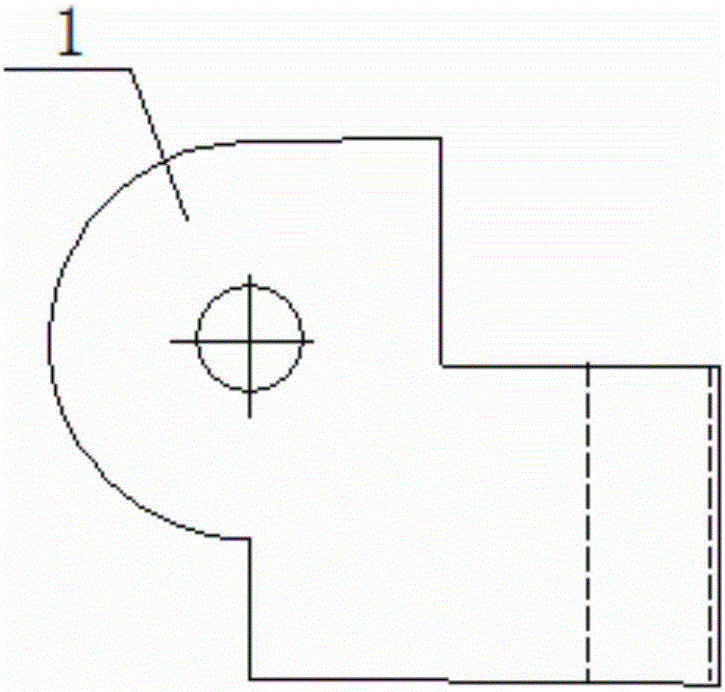

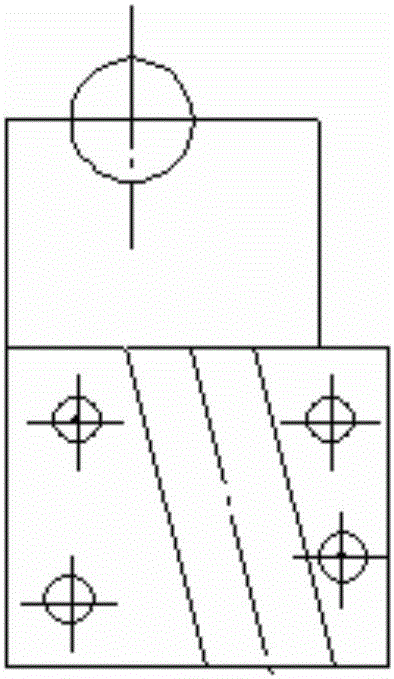

[0018] The small-radius forming tool of the large-diameter conduit includes a bending die and clamping blocks; wherein, the bending die includes a forming die 1, a first clamping die 2 and a clamping die 3, and the first clamping die 2 is connected to the second clamping die. The clamping molds 3 are all connected with the forming mold 1 to form an integrated structure. The outer surfaces of the forming mold 1, the first clamping mold 2 and the second clamping mold 3 are provided with a first groove structure 4, and the first clamping mold 2 is The side is fixedly connected with an auxiliary clamping mechanism 5, and the length of the first clamping die 2 is consistent with the length of the straight line section of the large-diameter conduit to be processed; the clamping block includes a hard shell 6 and a nylon inner core 7, and the nylon inner core 7 is fixedly connected On the inner side of the hard shell 6, the outer surface of the inner core 7 made of nylon is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com