Production method of optical fiber preset core insert and positioning device

A production method and ferrule technology, applied in the field of optical fibers, can solve the problems of easy damage, reduced qualification rate, large insertion loss, etc., and achieve the effects of reducing production cost, ensuring alignment, and ensuring qualified rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

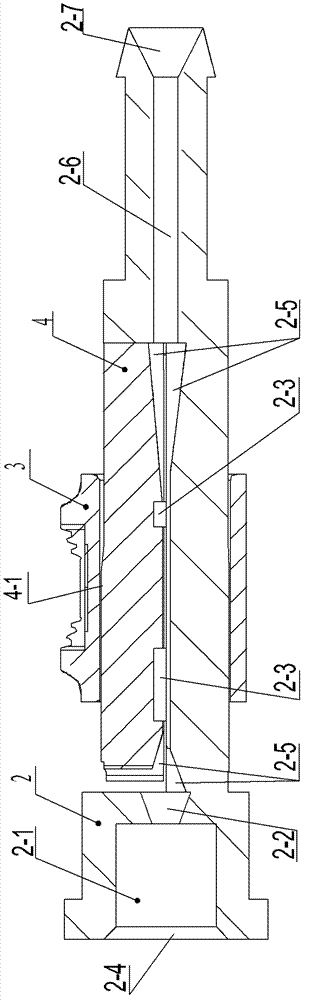

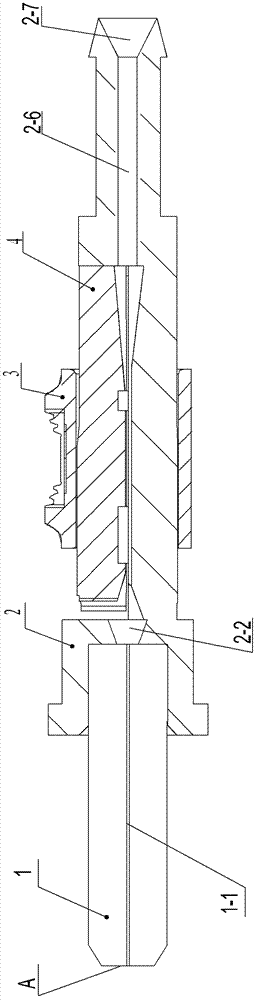

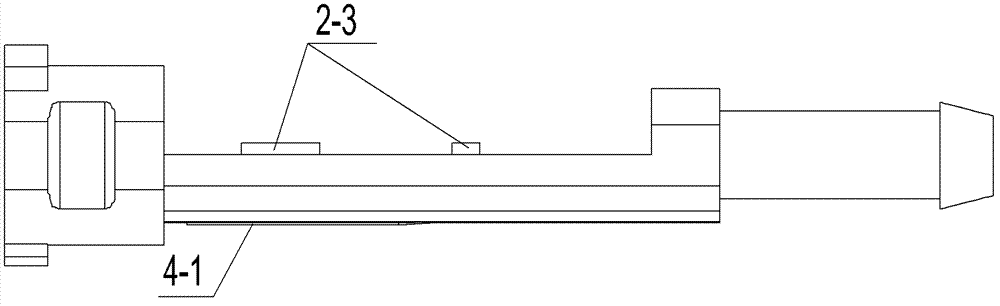

[0037] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

[0038] The current conventional production method is to cut the bare optical fiber to a fixed length, and then insert it into the ceramic ferrule for grinding. Due to the short length of the bare optical fiber, the insertion loss and return loss cannot be tested after grinding, so the quality of the product is difficult to control. , the product qualification rate is not high.

[0039] A production method of an optical fiber preset ferrule proposed by the present invention comprises the following steps:

[0040] a. Fix the ceramic ferrule 1 horizontally on the working table of the ferrule grinder;

[0041] b. Set a section of protective sleeve on the uncut bare optical fiber, and the end of the bare optical fiber is exposed from the protective sleeve;

[0042] c. Insert the end of the bare fiber hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com