Quick interchanging mechanism for inspection device

A fast, inspection tool technology, applied in the field of machinery, can solve the problems of non-compliance of digital-analog comparison measurement, stuck disassembly and assembly, and high difficulty, so as to improve the guiding effect and positioning accuracy, facilitate disassembly and replacement, and reduce the difficulty of processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

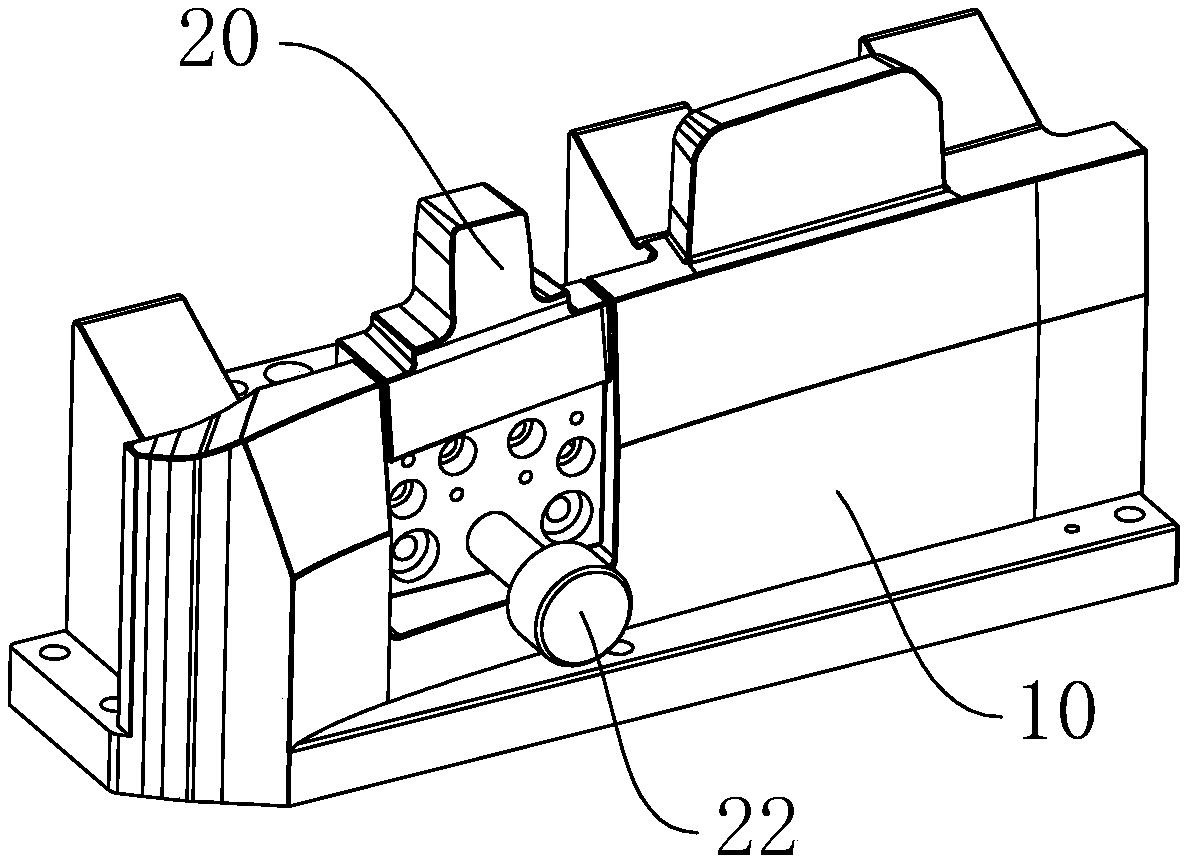

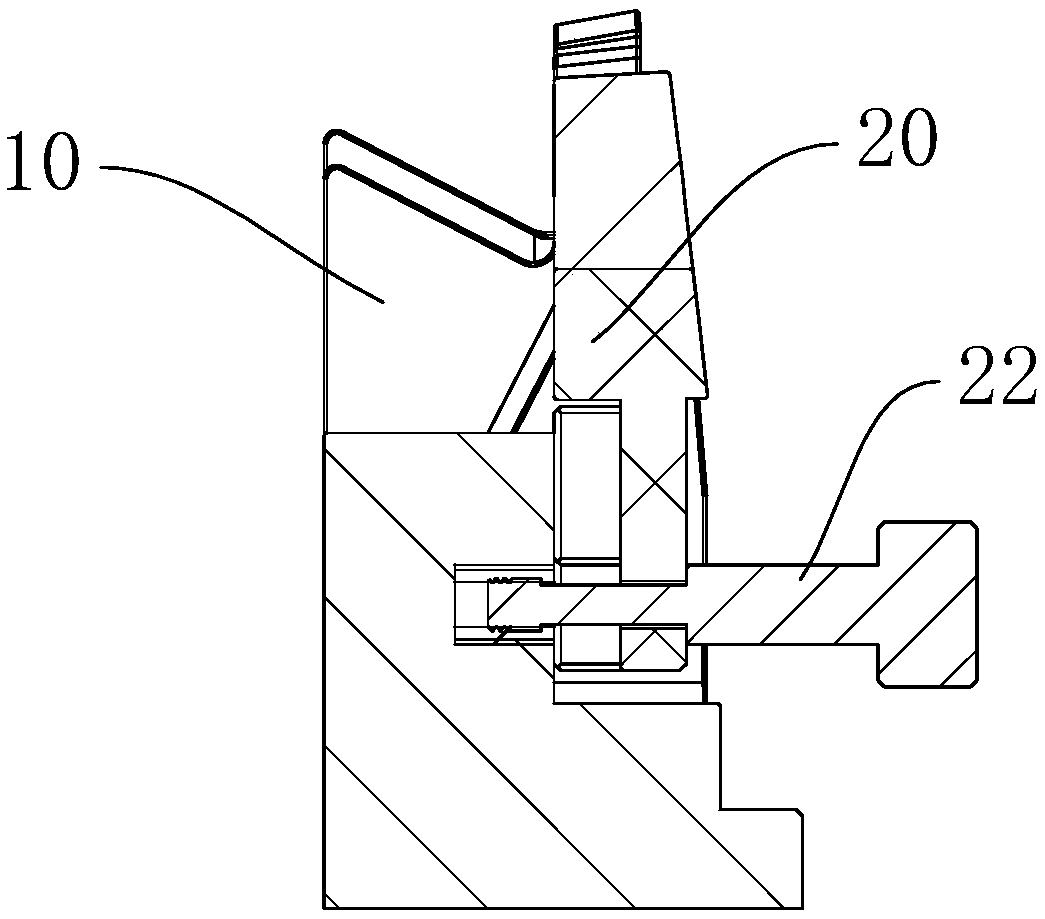

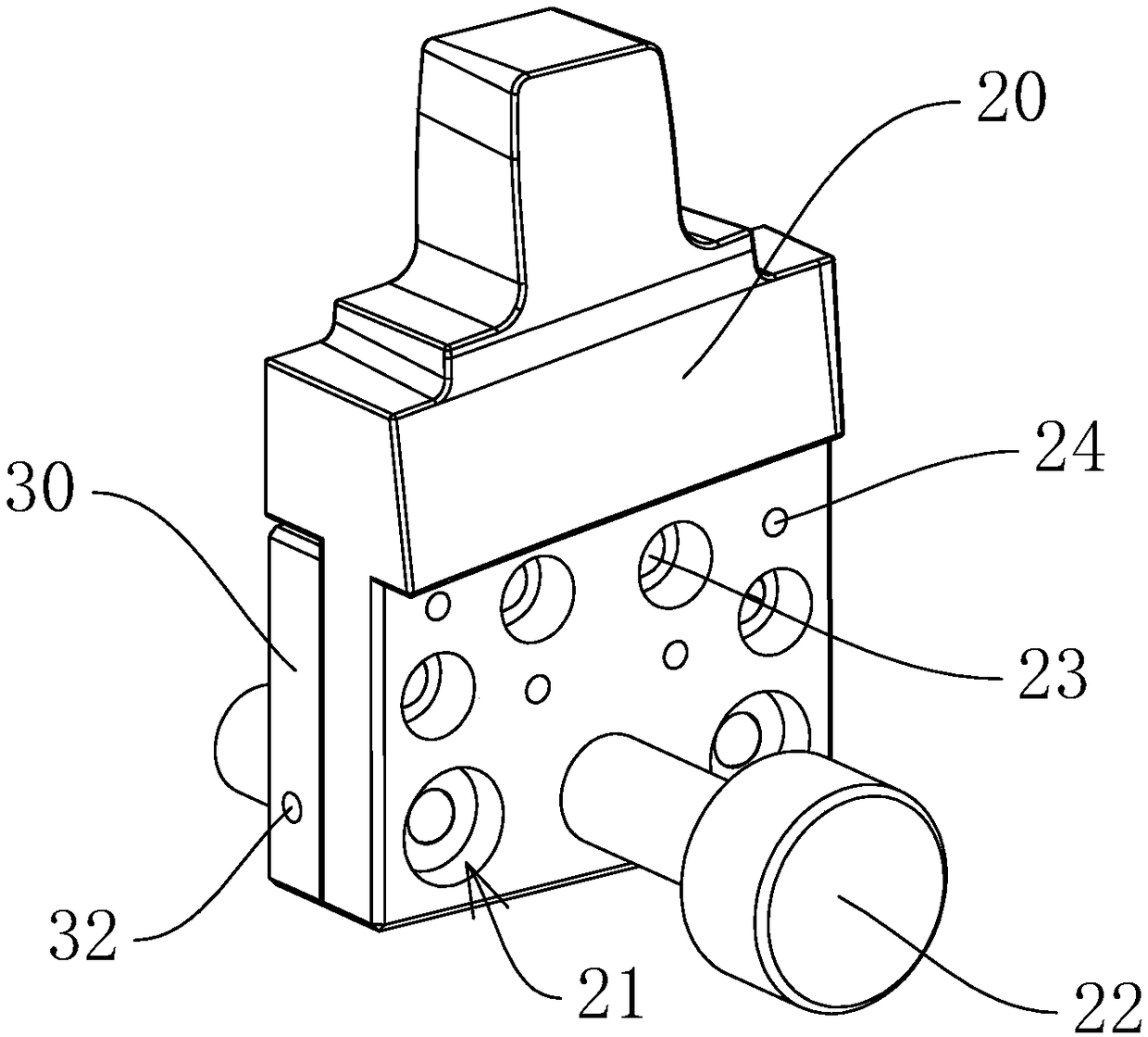

[0028] Such as Figure 1 to Figure 6 As shown, the quick exchange mechanism for this inspection tool includes:

[0029] The base 10 has a locking hole 11 in the middle, and two positioning pins 12 are arranged symmetrically on both sides of the locking hole 11;

[0030] The interchangeable block 20 covers the base 10, and the interchangeable block 20 is provided with two through holes 21 corresponding to the two positioning pins 12;

[0031] The adjustment block 30 is located between the base 10 and the exchange block 20. The adjustment block 30 is provided with two installation holes corresponding to the two through holes 21, and a linear bearing 31 is embedded in the installation hole. Each positioning pin 12 all pass through the corresponding linear bearing 31;

[0032] The handle 22 passes through the exchange block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com