Rotor support shaft-pressing tool

A technology for rotor brackets and finalizers, which is applied in electromechanical devices, manufacturing tools, metal processing, etc., can solve problems such as difficulty in continuous batch manufacturing, high surface temperature of workpieces, and poor production site environment, so as to reduce single-person operations The effect of cost reduction, labor intensity reduction, and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

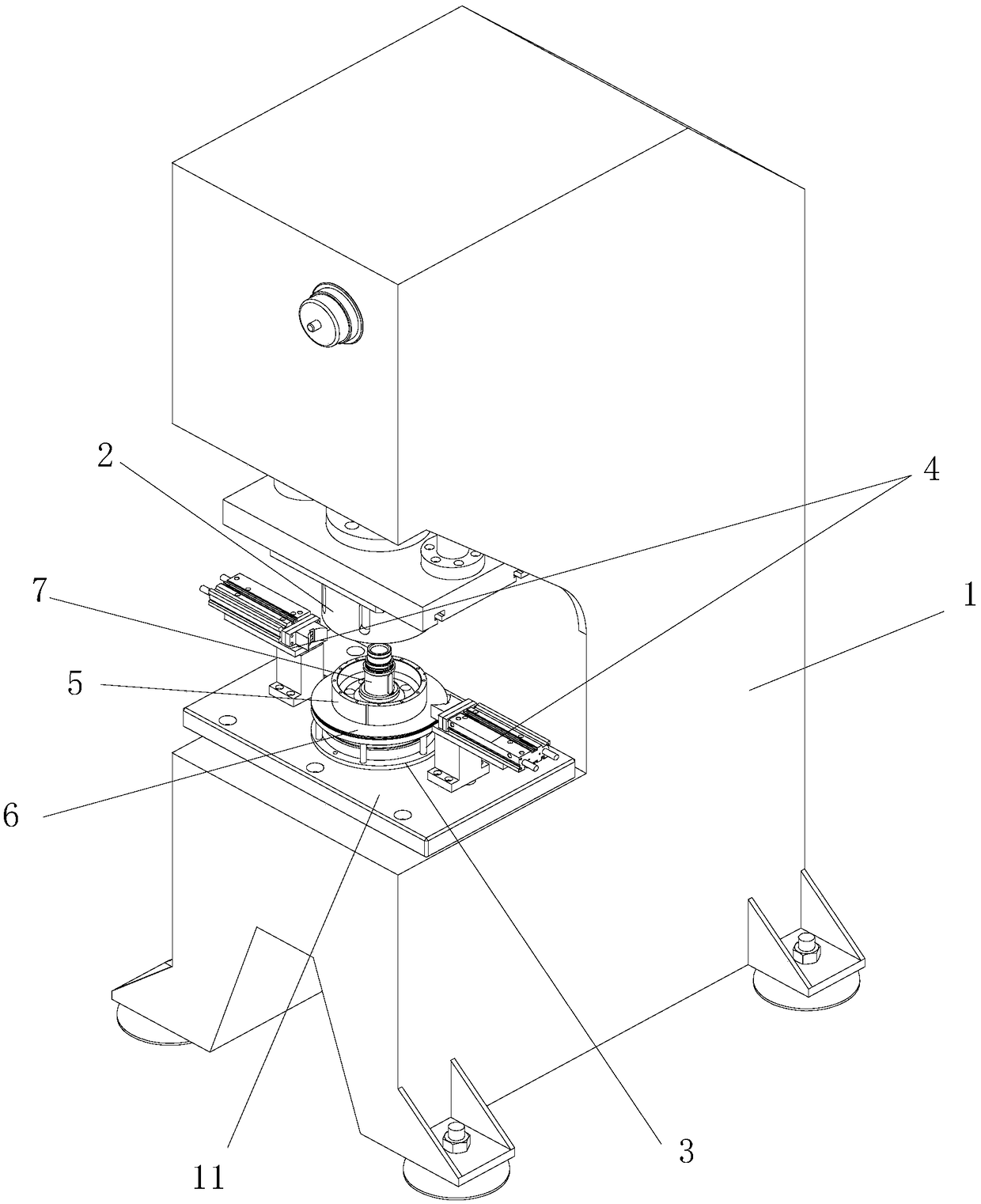

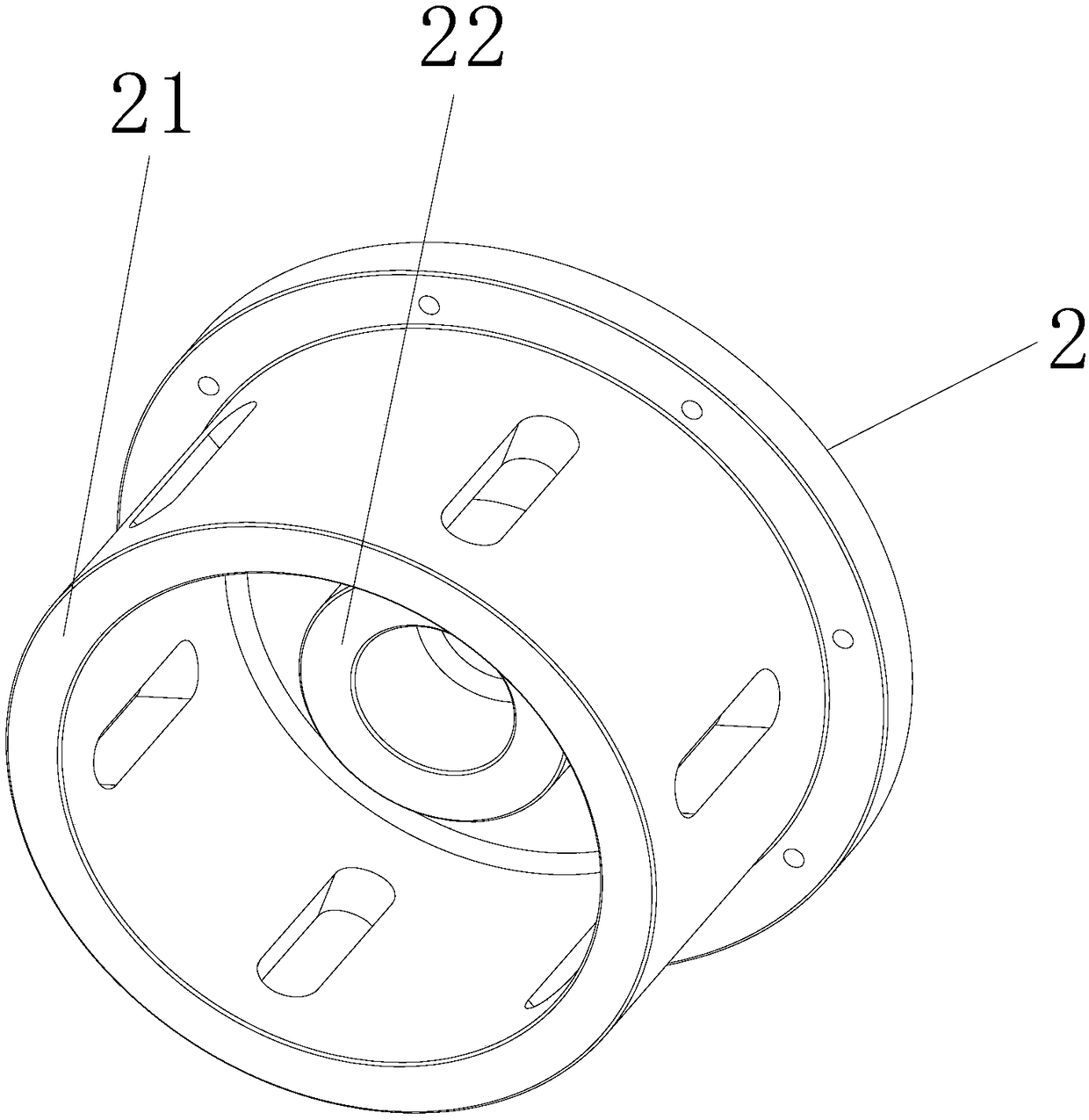

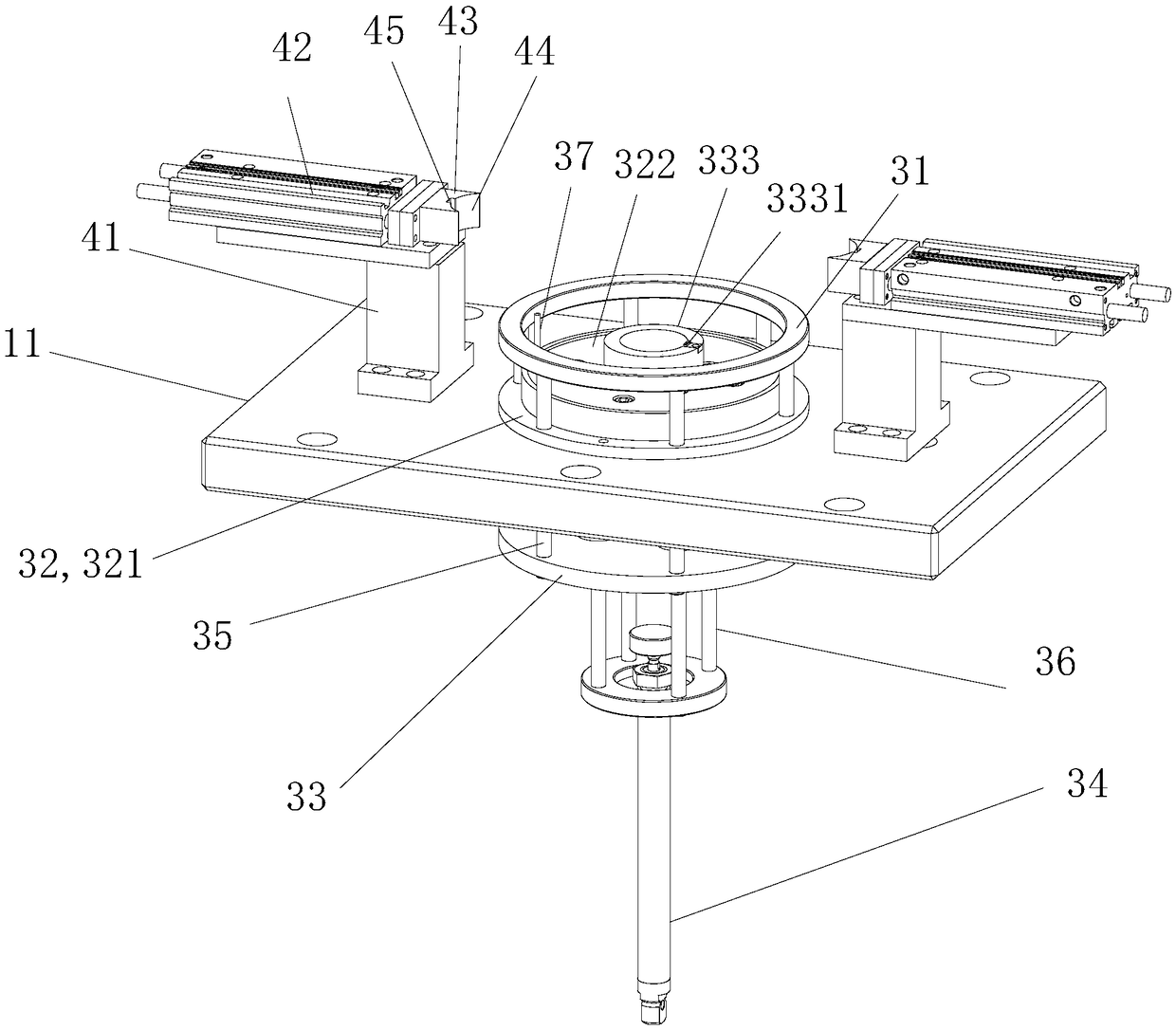

[0032] See Figure 1 to Figure 4 , the rotor bracket finale tooling of this embodiment includes a press 1 , a pressure head 2 , a balance end plate positioning mechanism 3 and a rotating shaft positioning mechanism 4 .

[0033] The press 1 is provided with a support platform 11, and the support platform 11 is fixed on the press by bolts and can be disassembled and assembled independently. The balanced end plate positioning mechanism 3 is installed on the supporting platform 11 , and the balanced end plate positioning mechanism 3 is used to carry the rotor bracket 5 and the balanced end plate 6 sheathed on the rotor bracket 5 . The balance end plate positioning mechanism 3 includes a support plate 31, a positioning plate 32, a bottom plate 33 and a driver 34. In this embodiment, the support plate 31 is an annular component, and the driver 34 is an oil cylinder. The balance end plate 6 is placed on the support plate 31 , and the rotor bracket 5 is placed on the positioning plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com