Error-proofing monitoring system and method for automobile engine valve assembling process

A technology of automobile engine and monitoring system, applied in the direction of electrical program control, program control in sequence/logic controller, metal processing, etc., can solve the problems of increasing engine manufacturing cost, wasting human resources, and low accuracy rate, and achieves the goal of overcoming Sloppy and careless hidden dangers, elimination of installation errors and error transmission, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

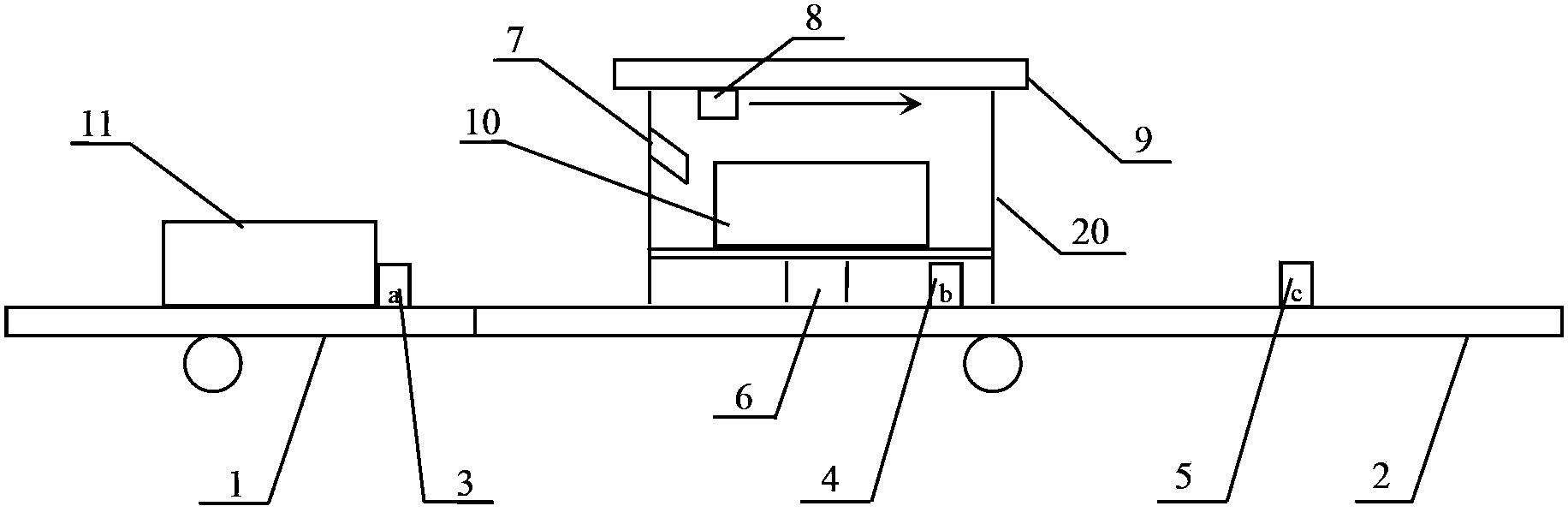

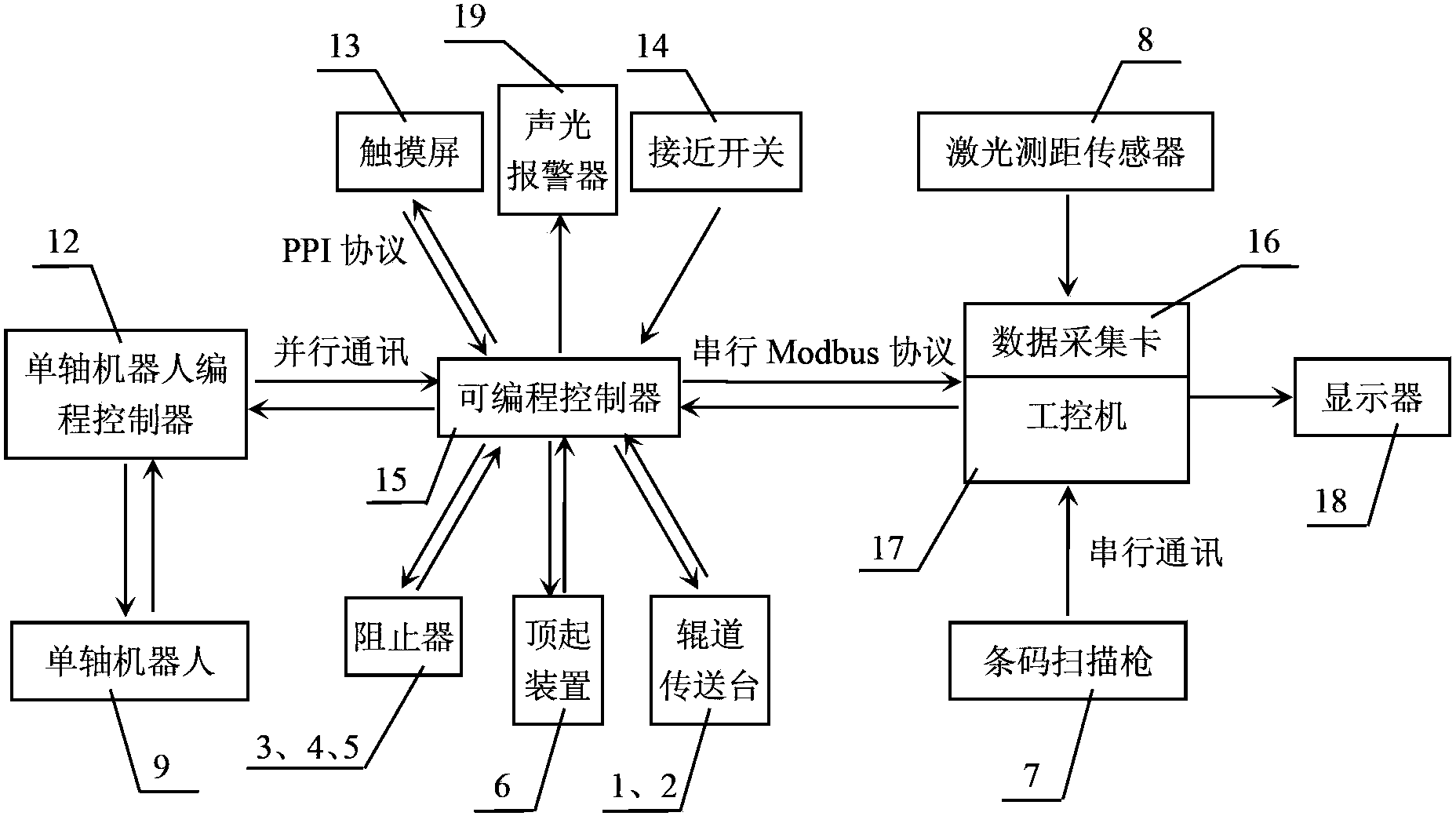

[0027] The present invention will be further described below in conjunction with accompanying drawing. Such as Figure 1-2 As shown, an error-proof monitoring system for the assembly process of the automobile engine valve group, including a detection platform, a control system and a human-machine information exchange panel;

[0028]The detection platform includes No. 1 roller table 1, No. 2 roller table 2, stopper a3, stopper b4, stopper c5, jacking device 6, barcode scanning gun 7, laser distance measuring sensor 8, The single-axis robot 9 and the four-legged metal frame 20, the No. 1 roller table 1 and the No. 2 roller table 2 are installed sequentially, and the No. 2 roller table 2 is on the right side of the No. 1 roller table 1 , close to each other; the blocker a3 is installed on the right side of the centerline of the length direction of the No. The middle position in the length direction of No. 2 roller conveyor table 2, the stopper c5 is installed on the right side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com