Cable stripping machine

A stripping machine and cable technology, which is applied in the direction of cable installation, cable installation device, dismantling/armouring cable equipment, etc., which can solve the problems that the fixing force and method are difficult to control, and the cutting depth cannot be adjusted separately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

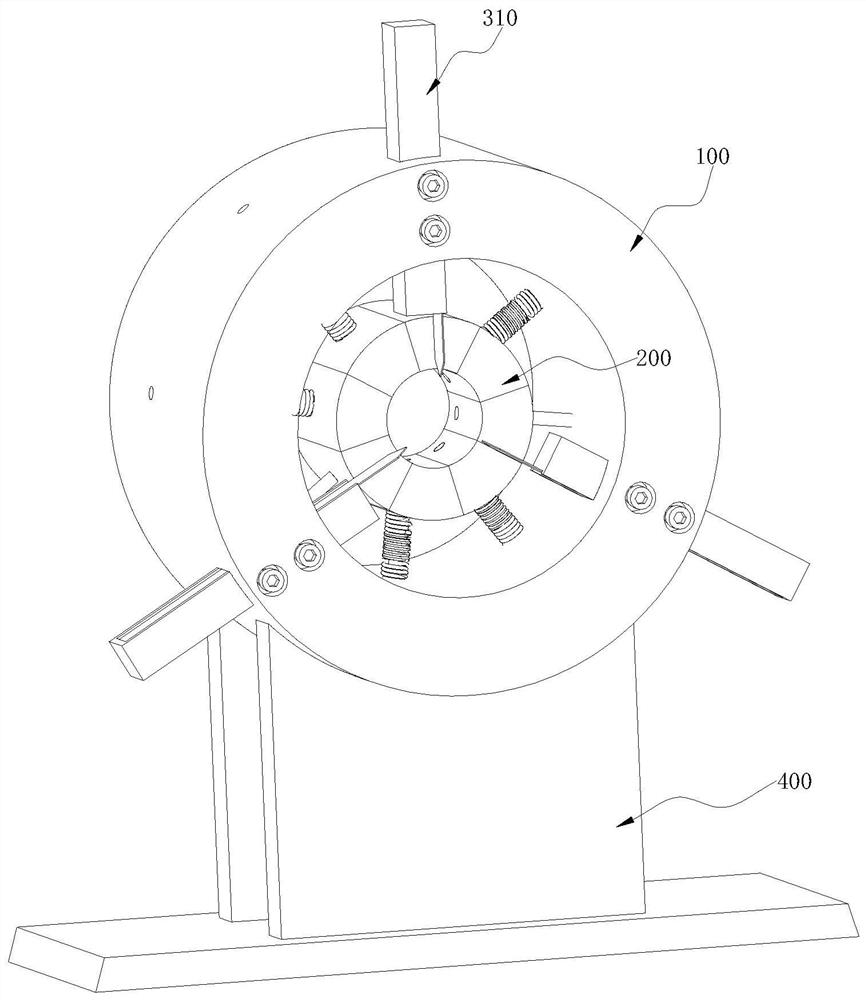

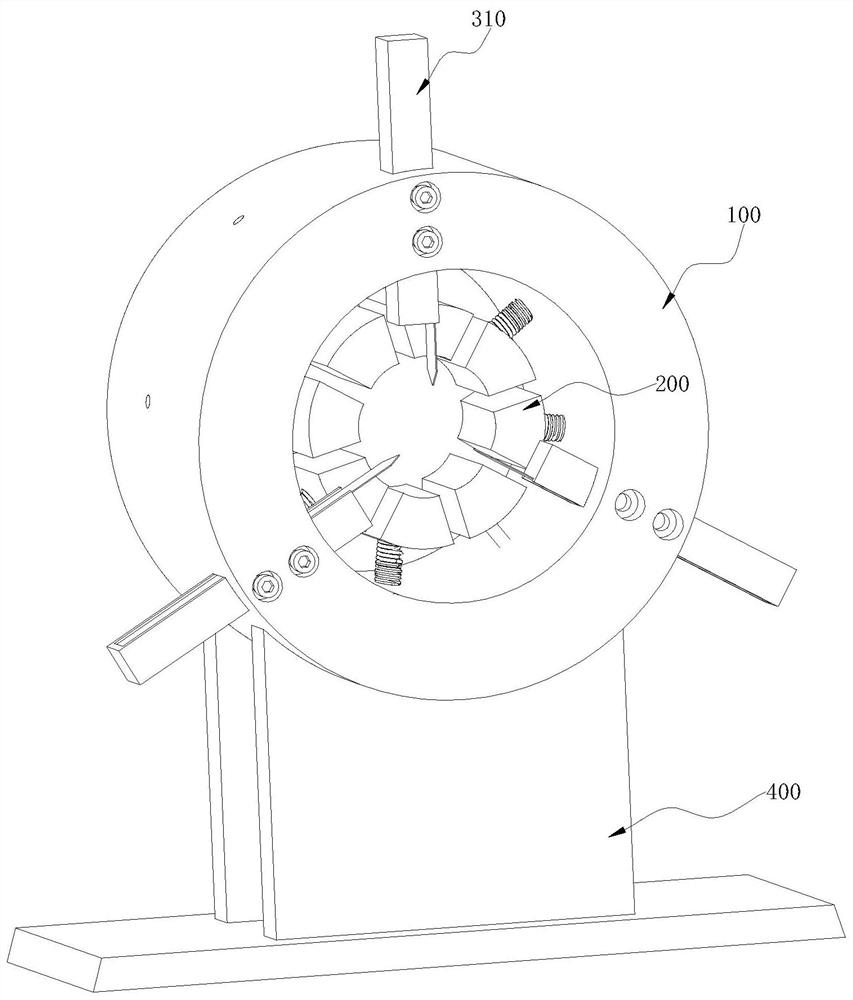

[0032] Please refer to Figure 1-Figure 7 , the invention discloses a cable stripping machine, comprising:

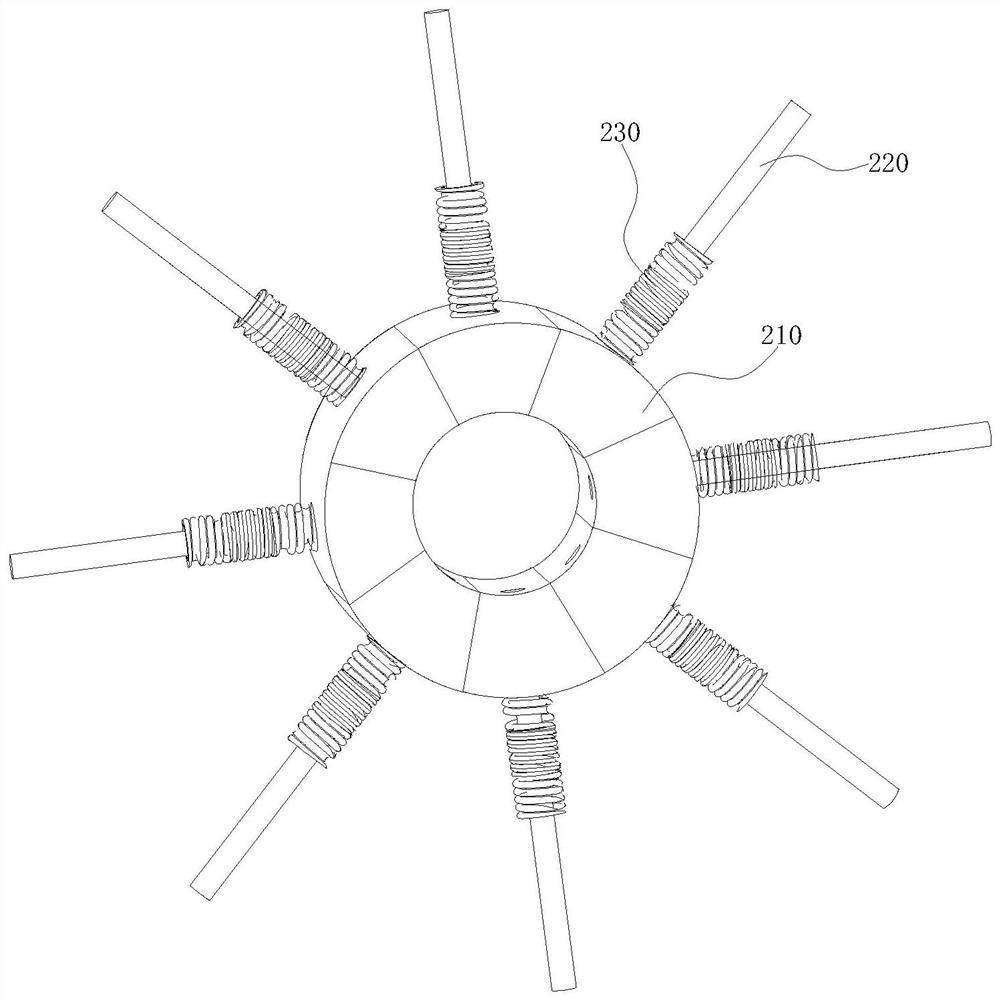

[0033] The clamping assembly 200 has an inlet end 211 and an outlet end 212. The inlet end 211 of the clamping assembly 200 is provided with a guide portion, and the thickness of the guide portion gradually extends from the inlet end 211 to the outlet end 212. increase to form a guide bevel 211a;

[0034] The stripping assembly is arranged at the outlet end 212 of the clamping assembly 200 , the stripping assembly includes several cutting knives 310 , and each of the cutting knives 310 is retractable to adjust the cutting depth of the cable.

[0035] In this embodiment, the cable is inserted from the inlet end 211...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com