Cover device with dust suction device when used with electric tool

A technology of electric tools and suction tubes, which is applied in the direction of portable motorized devices, manufacturing tools, grinding/polishing safety devices, etc., can solve problems such as laborious installation, and achieve the effect of simplified installation and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

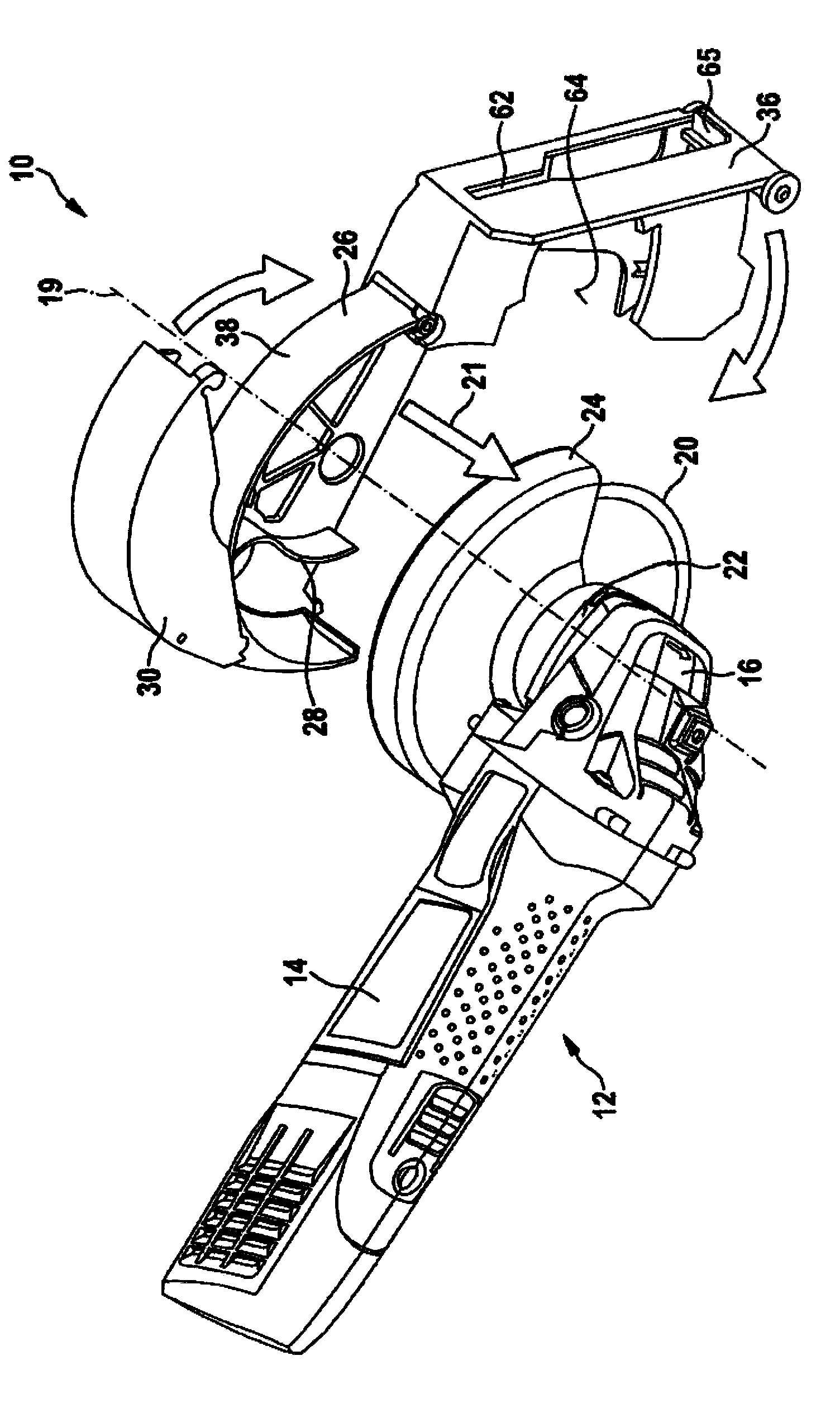

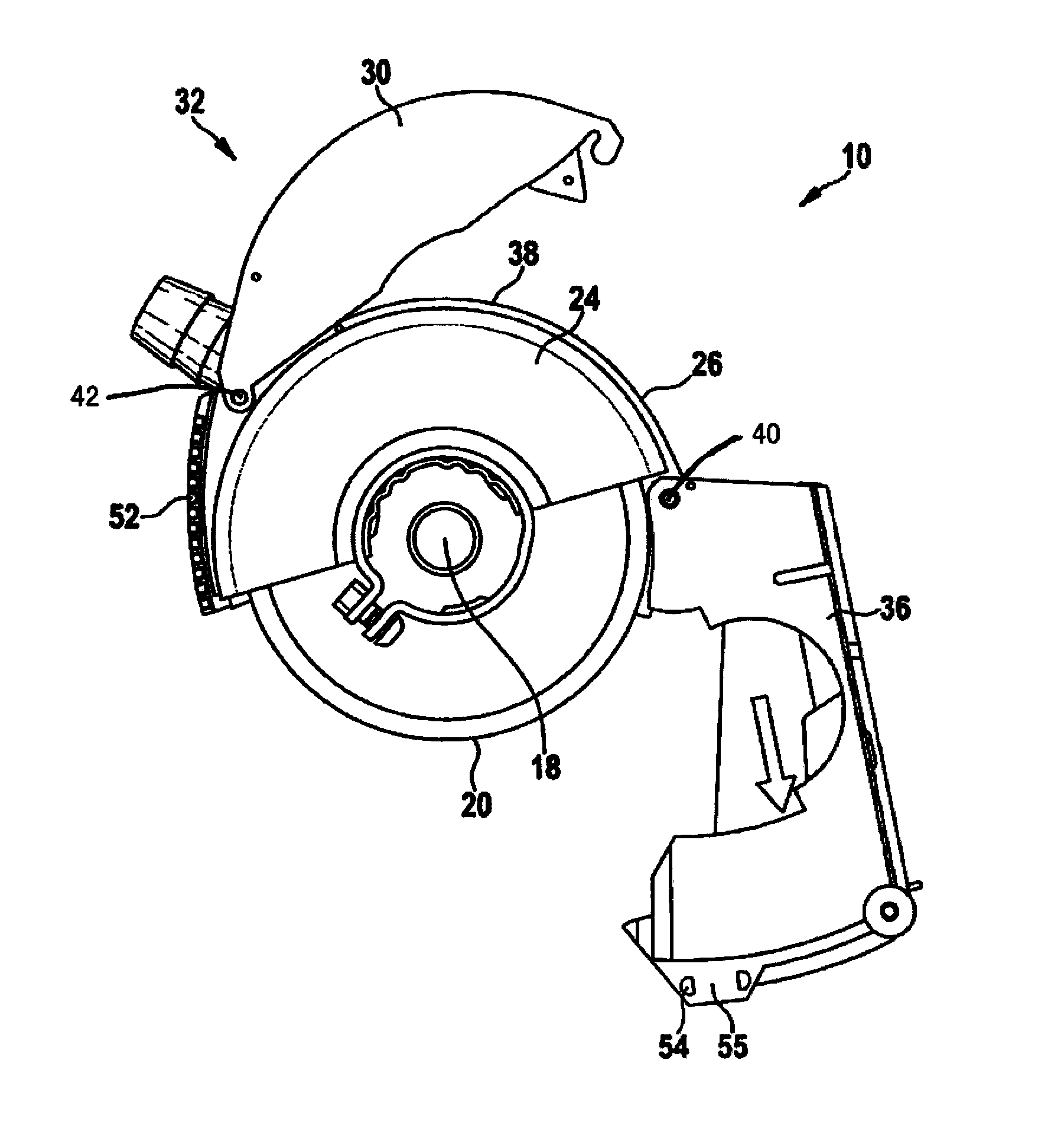

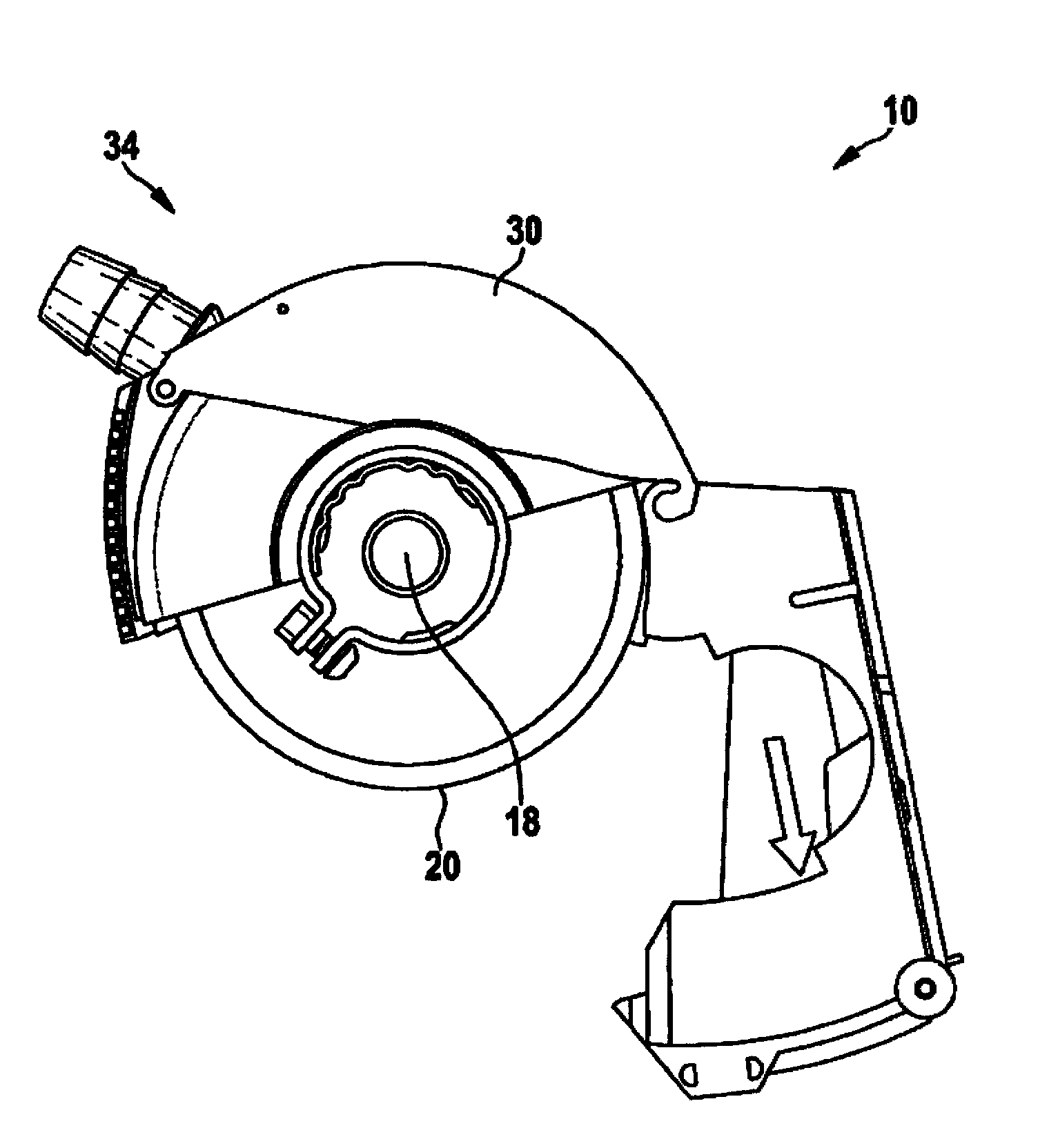

[0026] exist figure 1 A cover device 10 and a power tool 12 are shown in an oblique view, wherein the cover device 10 has not yet been mounted on the power tool 12 . The power tool 12 is an angle grinder which generally has a first housing part 14 for receiving a motor (not shown) and a second housing part 16 which accommodates a bevel gear. A driven shaft 18 ( FIG. 2 ) extends from the bevel gear, which extends along an axis 19 and on which a grinding and cutting tool 20 is attached in the exemplary embodiment.

[0027] A protective cover 24 , which partially surrounds the grinding and cutting tool 20 , is attached to the second housing part 16 via a flange 22 .

[0028] as in figure 1 As can be seen in the figure, the cover device 10 is constructed in multiple parts and has a receiving part 26 as a central part. The receptacle 26 is designed in such a way that it can receive the protective hood 24 in a suitable manner. The receiving part has a rear wall 28 and is open on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com