Bias guiding mechanism of static pointing type rotary steering well drilling tool and control method

A technology of rotary steerable drilling and steering mechanism, which is applied in directional drilling, driving devices for drilling in boreholes, drilling equipment, etc. It can solve problems such as increasing system complexity, prone to fatigue damage, and impact on service life, and achieves control and The cost of measurement is low, the implementation scheme is simple and easy, and the effect of reducing the demand for electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

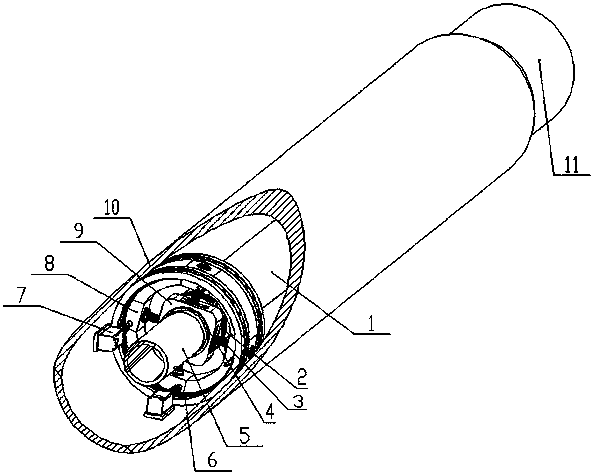

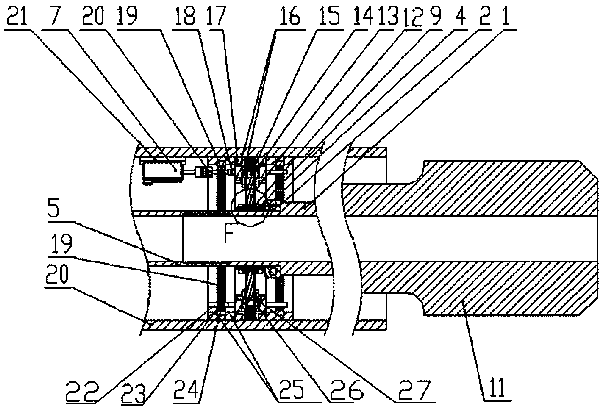

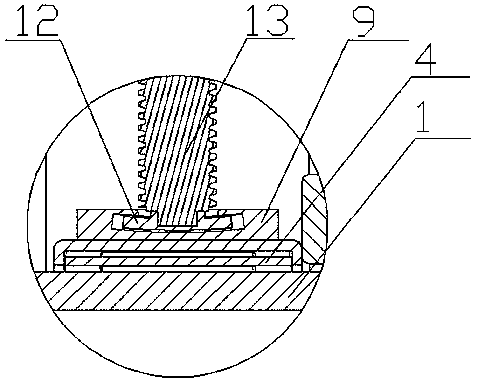

[0046] Such as Figure 1 to Figure 3 As shown, the offset guide mechanism of the static pointing rotary steerable drilling tool includes a non-rotating outer cylinder 10, a drill bit 11, a drill bit connecting shaft 1, a flexible hose 5, a slider connector 9, a guide mechanism housing 17 and a bias mechanism , The biasing mechanism is provided with two groups, and is installed in the non-rotating outer cylinder 10 perpendicular to each other, and the adjustment directions of the two biasing mechanisms are the X direction and the Y direction.

[0047] Specifically, the drill bit connecting shaft 1 is a hollow body, and the hollow part is used as a circulation channel for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com