Buffing attachment with high stability for leather shoe factories

A high stability, polishing device technology, applied in the direction of grinding/polishing safety device, grinding drive device, grinding/polishing equipment, etc., can solve the problems of low work efficiency, insufficient polishing, low operation stability, etc. To achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

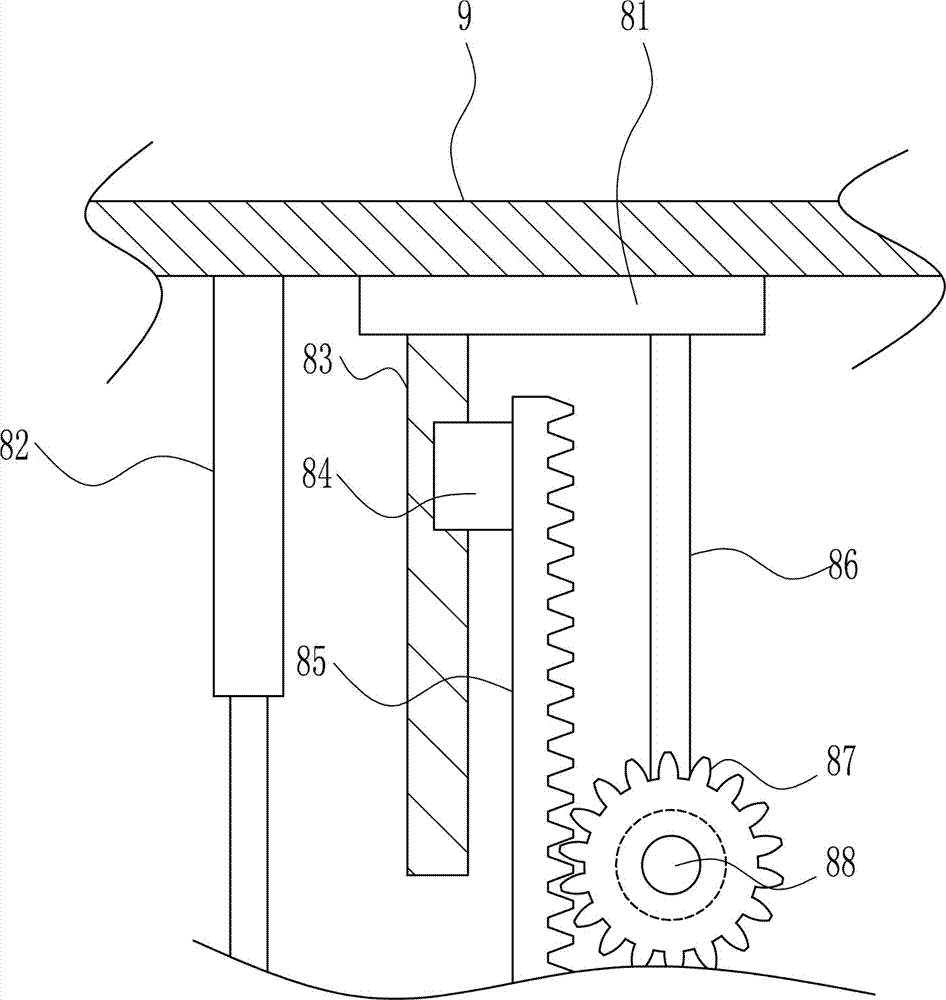

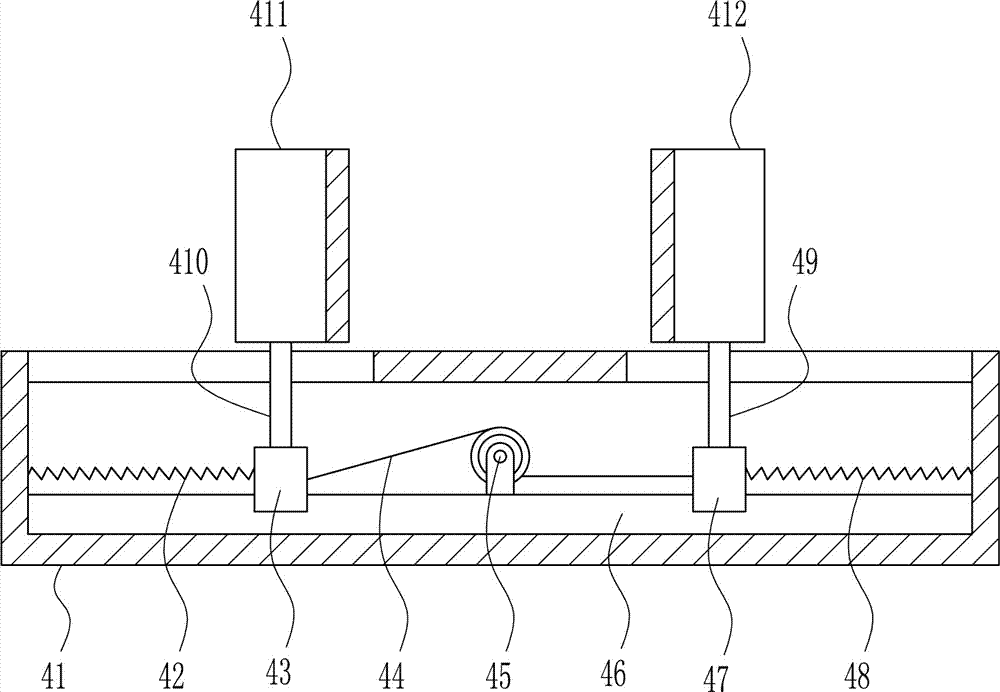

[0035] A leather shoe factory uses a high-stability polishing device, such as Figure 1-7 As shown, it includes a pillar 1, a base plate 2, a moving mechanism 3, a fixing mechanism 4, a storage frame 5, a covering mechanism 6, a polishing mechanism 7, a lifting mechanism 8 and a mounting frame 9, and the two pillars 1 are fixedly connected to the bottom of the base plate 2; The moving mechanism 3 and the mounting frame 9 for moving the leather shoes are all affixed to the top of the bottom plate 2; the storage frame 5 is affixed to the output end of the moving mechanism 3; the fixing mechanism 4 for fixing the leather shoes is affixed to the inner bottom of the storage frame 5; The covering mechanism 6 covering the storage frame 5 is fixedly connected to the top of the storage frame 5; the lifting mechanism 8 for adjusting the height of the polishing position is fixedly connected to the inner top of the mounting frame 9; the polishing mechanism 7 for polishing leather shoes is ...

Embodiment 2

[0037] A leather shoe factory uses a high-stability polishing device, such as Figure 1-7 As shown, it includes a pillar 1, a base plate 2, a moving mechanism 3, a fixing mechanism 4, a storage frame 5, a covering mechanism 6, a polishing mechanism 7, a lifting mechanism 8 and a mounting frame 9, and the two pillars 1 are fixedly connected to the bottom of the base plate 2; The moving mechanism 3 and the mounting frame 9 for moving the leather shoes are all affixed to the top of the bottom plate 2; the storage frame 5 is affixed to the output end of the moving mechanism 3; the fixing mechanism 4 for fixing the leather shoes is affixed to the inner bottom of the storage frame 5; The covering mechanism 6 covering the storage frame 5 is fixedly connected to the top of the storage frame 5; the lifting mechanism 8 for adjusting the height of the polishing position is fixedly connected to the inner top of the mounting frame 9; the polishing mechanism 7 for polishing leather shoes is ...

Embodiment 3

[0040] A leather shoe factory uses a high-stability polishing device, such as Figure 1-7 As shown, it includes a pillar 1, a base plate 2, a moving mechanism 3, a fixing mechanism 4, a storage frame 5, a covering mechanism 6, a polishing mechanism 7, a lifting mechanism 8 and a mounting frame 9, and the two pillars 1 are fixedly connected to the bottom of the base plate 2; The moving mechanism 3 and the mounting frame 9 for moving the leather shoes are all affixed to the top of the bottom plate 2; the storage frame 5 is affixed to the output end of the moving mechanism 3; the fixing mechanism 4 for fixing the leather shoes is affixed to the inner bottom of the storage frame 5; The covering mechanism 6 covering the storage frame 5 is fixedly connected to the top of the storage frame 5; the lifting mechanism 8 for adjusting the height of the polishing position is fixedly connected to the inner top of the mounting frame 9; the polishing mechanism 7 for polishing leather shoes is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com