Composition for liquid crystal alignment layer and liquid crystal alignment layer

A technology of liquid crystal alignment film and composition, which is applied in the direction of liquid crystal materials, instruments, chemical instruments and methods, etc., which can solve the problems of alignment itself shaking, poor stability, liquid crystal afterimage, etc., and achieve the effect of excellent characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

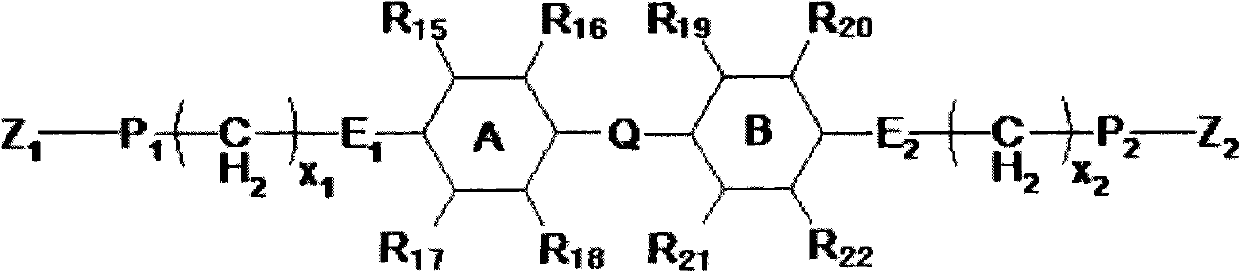

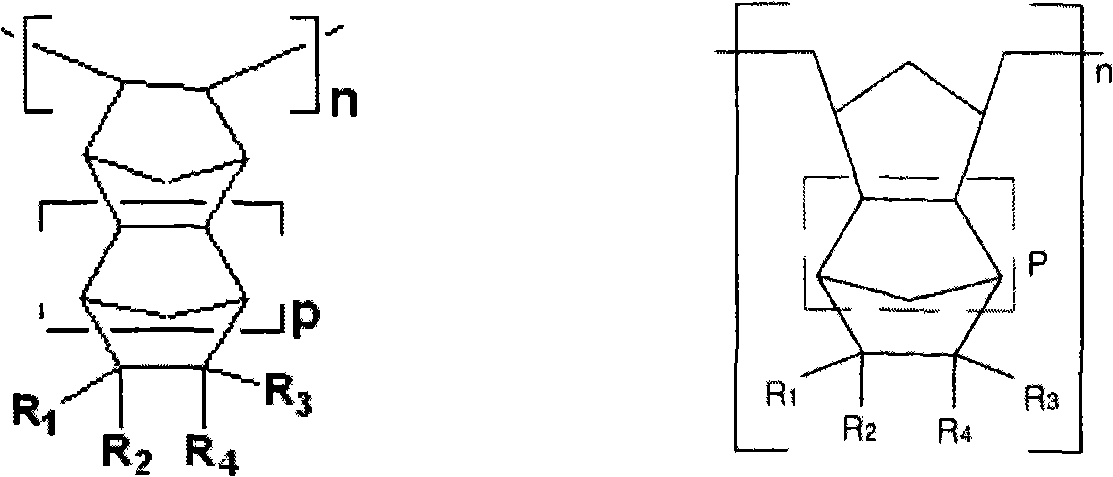

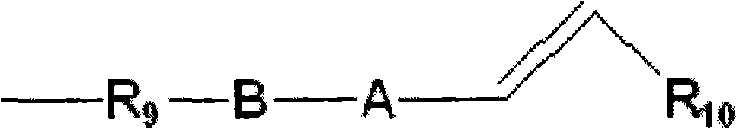

Method used

Image

Examples

preparation example 1

[0121] Preparation Example 1: Synthesis of 4-fluorocinnamic acid (4-fluorocinnamic acid)

[0122] 4-fluorobenzaldehyde (4-fluorobenzaldehyde) (10g, 80.6mol), malonic acid (malonic acid) (29.5g, 2 equivalents), piperidine (1.21g, 0.1 equivalents) were put into pyridine ( pyridine) (33.7 g, 3 equivalents), and stirred at room temperature for about 1 hour. The temperature was raised to 80°C and stirred for 12 hours. After the reaction, the temperature was lowered to room temperature, and 1 mol of HCl was slowly added for titration so that the pH of the solution became about 4. After the resulting powder was filtered and washed with water, the powder was dried in a vacuum oven. The yield was 90%, and the purity (GC) was 98%.

[0123] 1 H-NMR (CDCl3, ppm): 6.42 (d, 1H) 7.44 (d, 2H) 7.75 (d, 2H) 7.80 (d, 1H).

preparation example 2

[0124] Preparation example 2: 2-(4-fluorocinnamate)-5-norbornene (2-(4-fluorocinnamic ester)-5-norbornene) synthesis

[0125] 4-fluorocinnamic acid (4-fluorocinnamic acid) (10g, 60mmol), 5-norbornene-2-methanol (5-norbornene-2-methanol) (7.45g, 60mol), zirconium hydroxide acetate (zirconium (IV) acetate hydroxide) (0.3 g, 0.02 equivalents) were put into 50 ml of toluene together and stirred. Under a nitrogen atmosphere, the temperature was raised to 145° C. and azeotropic reflux was performed for 24 hours. After the reaction, the temperature was lowered to room temperature, and 100% by volume of ethyl acetate (Ethyl acetate) was added. Extract with 1 mol HCl and wash again with water. After drying the organic layer with sodium sulfate and evaporating the solvent, a highly viscous liquid substance was obtained. The yield is 68%, and the purity (GC): 92%.

preparation example 3

[0126] Preparation Example 3: 2-(4-fluorocinnamate)-5-norbornene (2-(4-fluorocinnamic ester)-5-norbornene) polymerization

[0127] After dissolving 2-(4-fluorocinnamate)-5-norbornene (2-(4-fluorocinnamic ester)-5-norbornene) in toluene (toluene) (15ml), blow into nitrogen and stir 30 minute. The temperature was raised to 90 °C and Pd(C) dissolved in methylene chloride (1 ml) was added. 2 h 3 o 2 ) 2 (Pd(acetate) 2 , 4.13 mg, 18.4 μmol), three (cyclohexyl) hydrogen phosphino tetrakis (pentafluorobenzene) borate (tris (cyclohexyl) hydrogen phosphino tetrakis (pentafluorobenz) borate) (37.2 mg, 38.6 μmol), and at 90 ° C Stir at temperature for 15 hours. After the reaction, the temperature was lowered to room temperature, and ethanol was used to obtain a precipitate, which was filtered and then dried in a vacuum oven to obtain the final product NB1. Yield: 85%, Mw: 158k (PDI=2.88).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com