Patents

Literature

40results about How to "Frictional stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

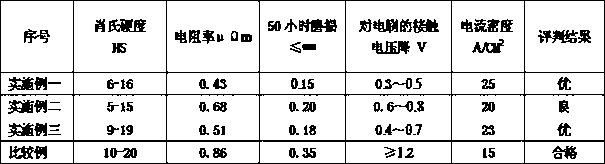

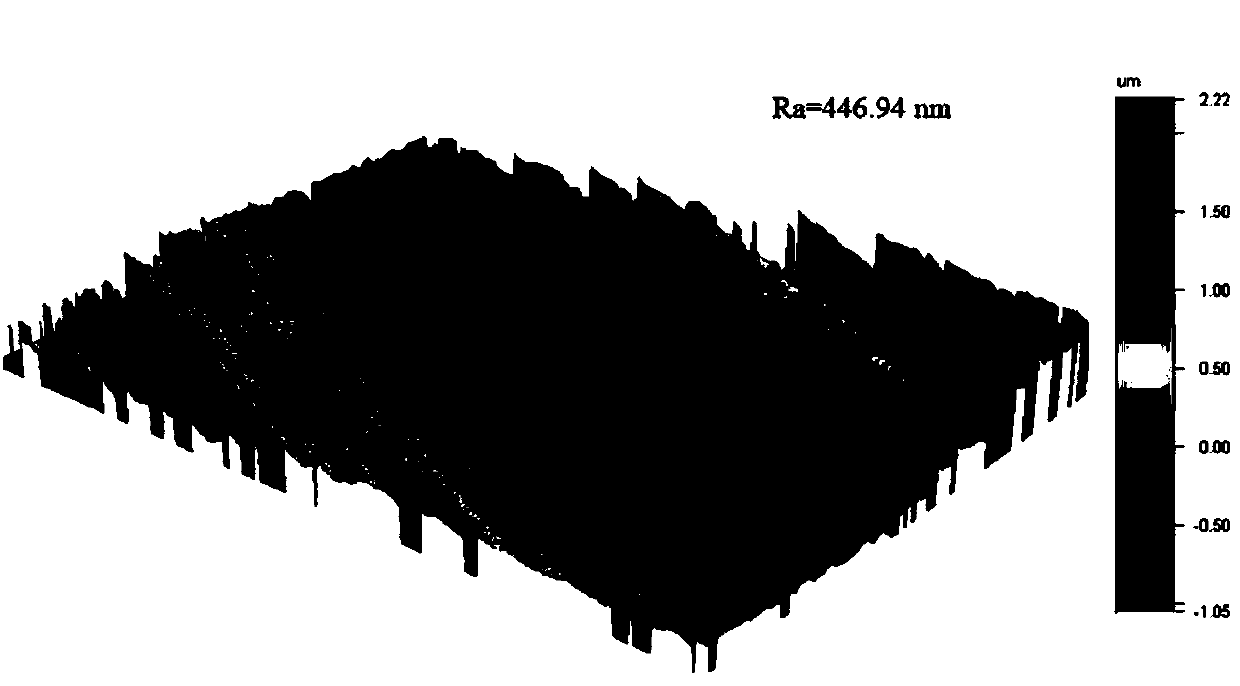

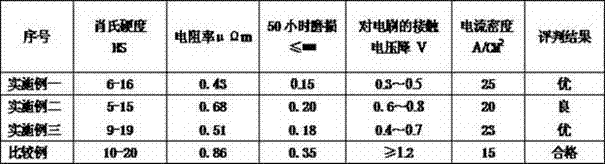

Electric brush for ABS system and preparation method thereof

ActiveCN102856758AFrictional stabilityStable service lifeRotary current collectorBrushes manufactureFiberElectrolysis

An electric brush for ABS (Anti-skid Brake System) comprises a brush body and a lead-out wire, wherein the brush body comprises 46 to 52 parts by weight of superfine electrolytic copper powder, 52 to 46 parts by weight of cementing powder and 2 parts by weight of modifier at; the cementing powder comprises 1.0 to 3.0 parts of high-purity carbon fiber powder, 23 to 27 parts of artificial graphite powder, 25 to 35 parts of high-purity sub-nanometer graphite powder, 18 to 22 parts of crystal graphite powder, 3 to 8 parts of graphitized carbon black powder, 2.5 to 4.5 parts of rare-earth tungsten disulfide composites and 5 to 15 parts of high-temperature resistant phenolic resin; and the modifier comprises 0.20 to 1.30 parts of vulcanization silver powder, 0.20 to 1.5 parts of stibonium powder and 0.5 to 1.5 parts of zinc powder. The chemical stability, the lubricating property, the electrical conductivity, the high-temperature resistance and the abrasion resistance of the electric brush provided by the invention are much better than that of the existing products.

Owner:丽水市长新电器制造有限公司

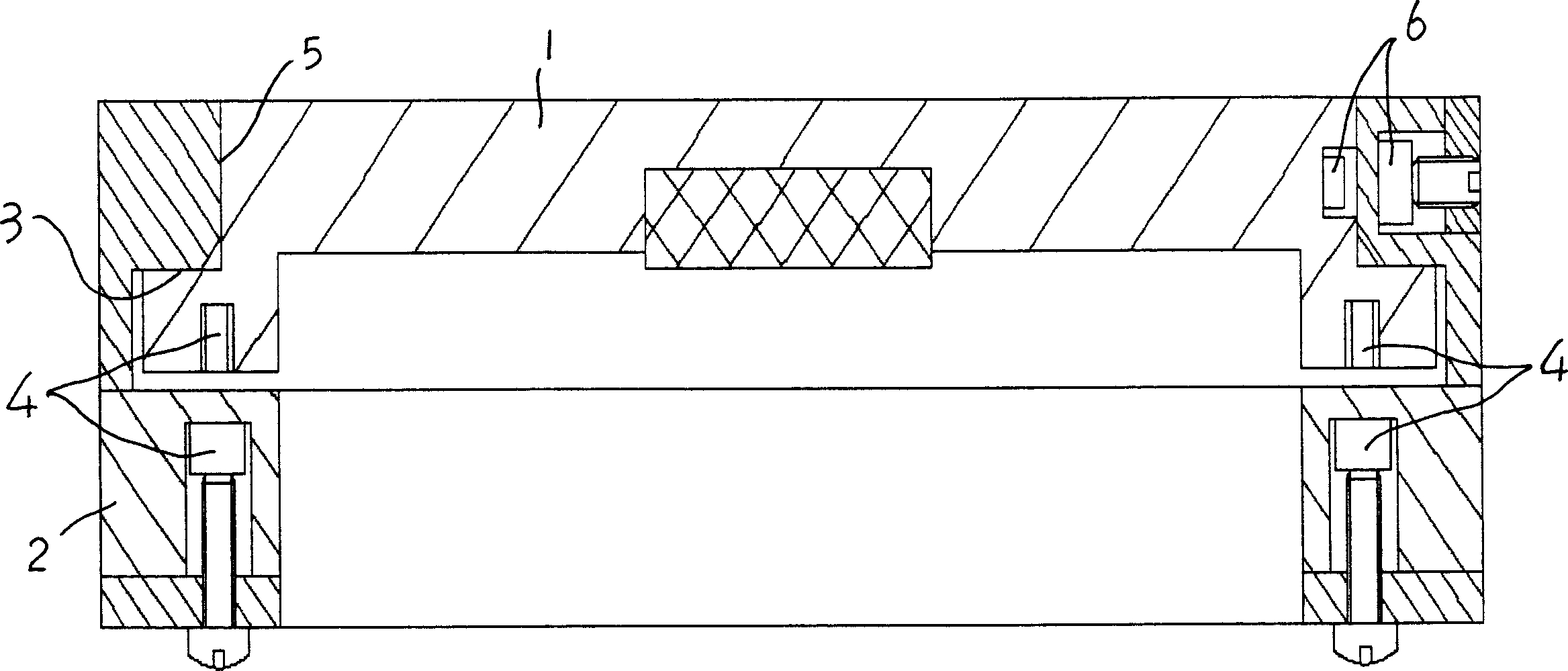

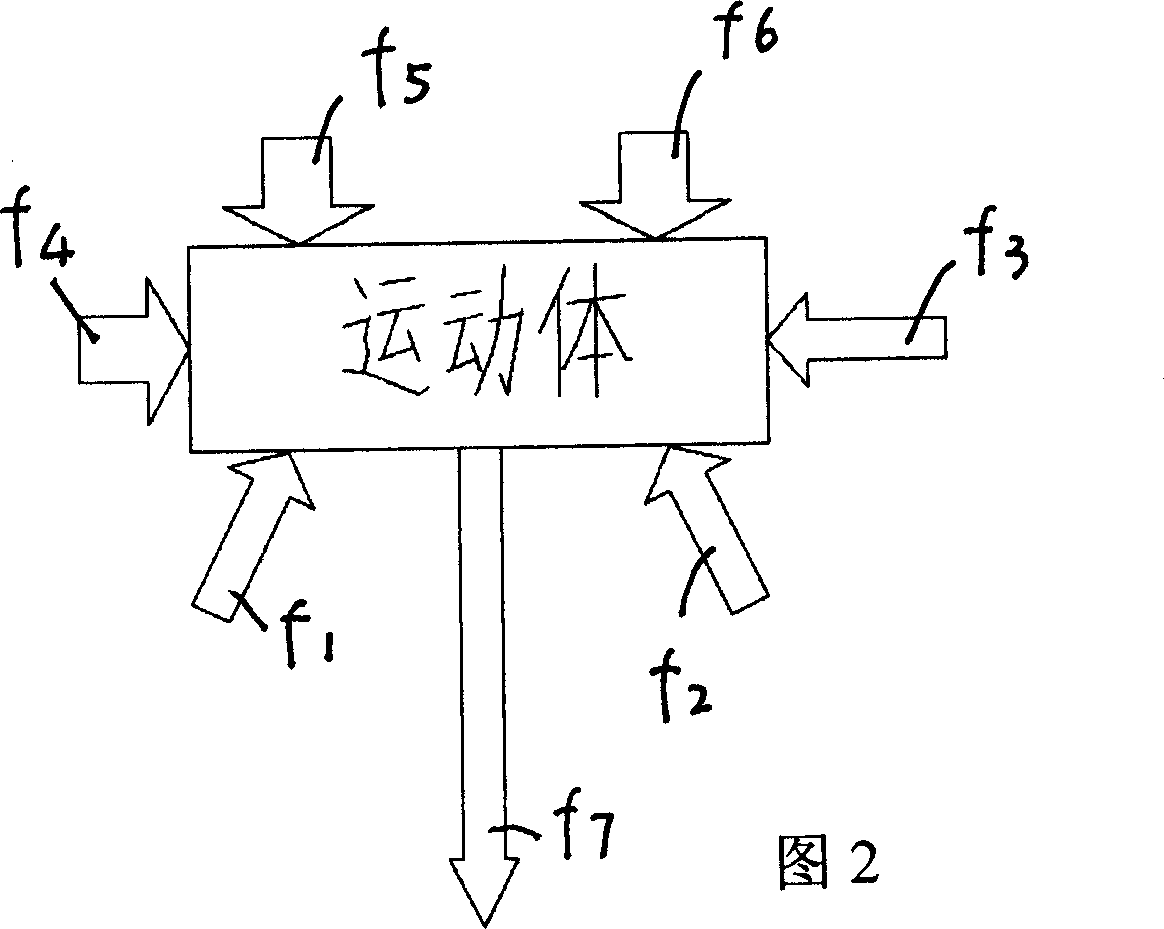

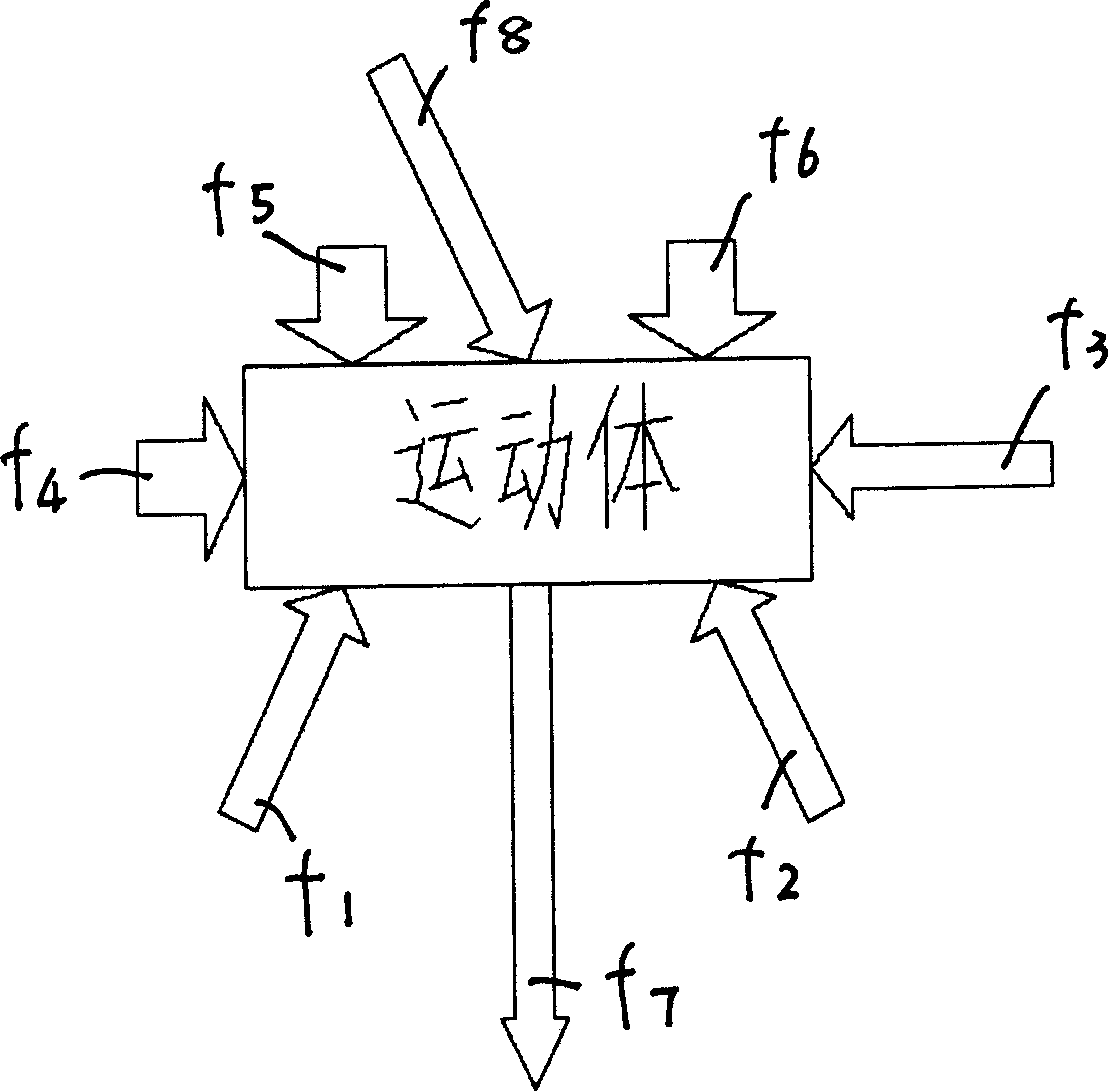

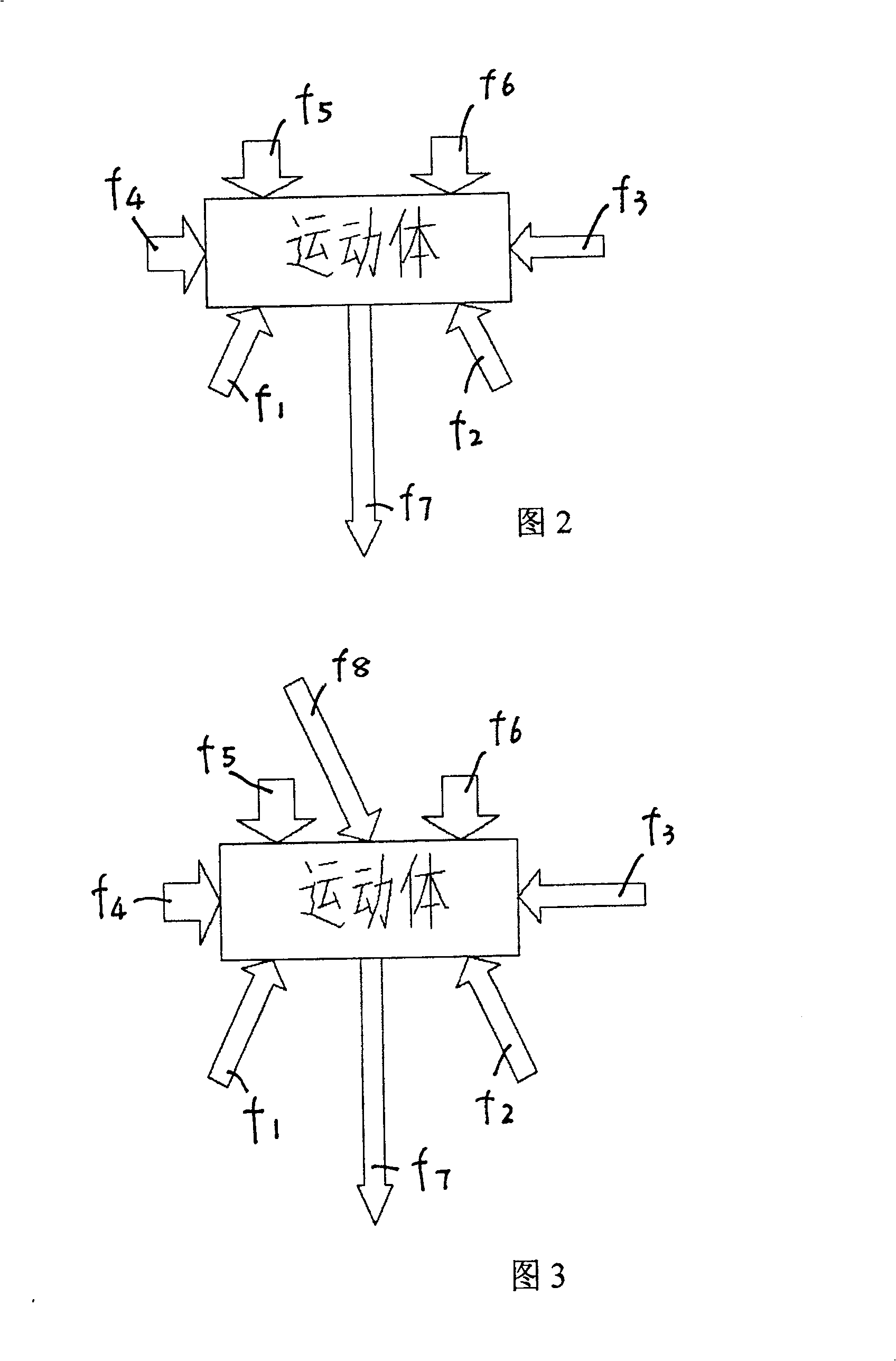

High-precision low-friction magnetic suspension sliding composite guid rail

InactiveCN1852019ASimple structureFrictional stabilityInstrumental componentsLarge fixed membersPositive pressureEngineering

This invention relates to a high accuracy low friction magnetic suspension-sliding compound guideway characterizing in mounting a pair of base like magnets oppositely between the end face of the bottom of a mobile piece and the supporting face of the guideway to keep them at an un-contact state by the repulsive force formed by it and form a positive pressure between the top guide faces of the mobile piece and the guideway, taking a side end face of the mobile piece and the guideway as the side guide face to mount a pair of like side magnets oppositely on the other end face opposite to the guide face of the side to keep the mobile piece and the guideway at an un-contact state at the side end face with the repulsive force formed by the pair of magnets to form a positive pressure on the guide face of the side part.

Owner:HEFEI UNIV OF TECH

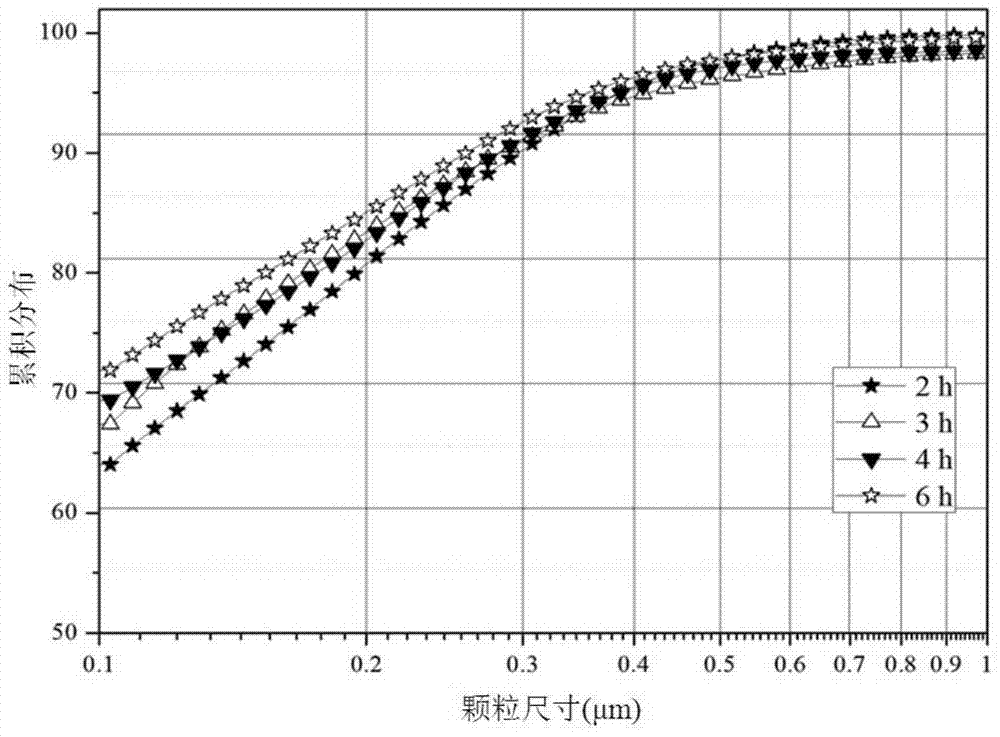

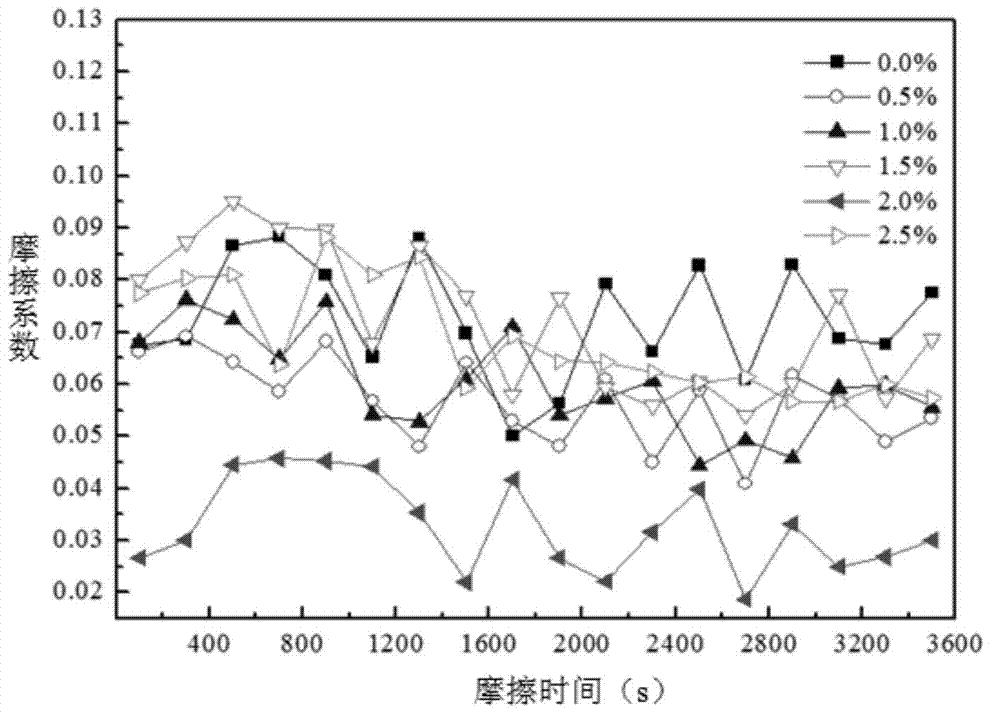

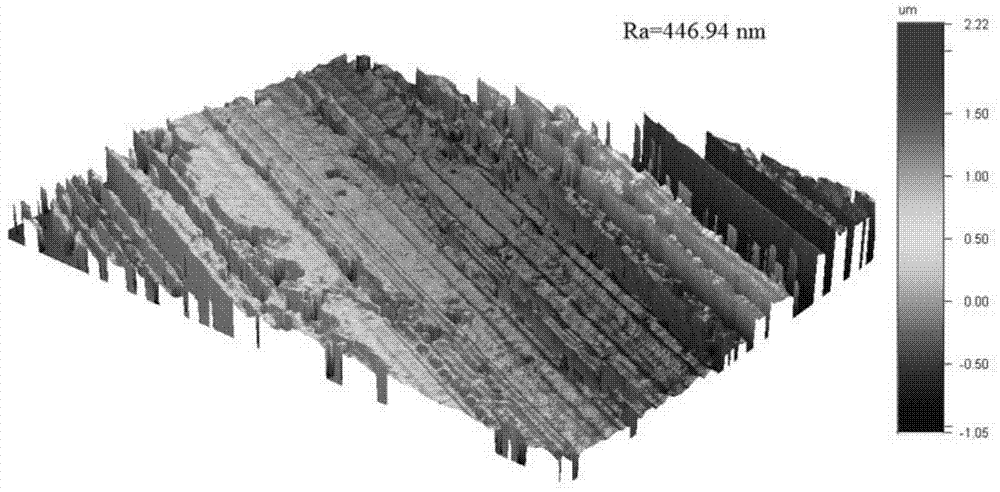

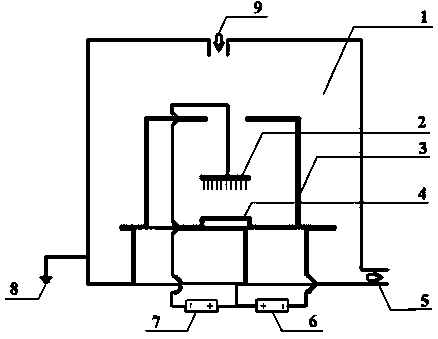

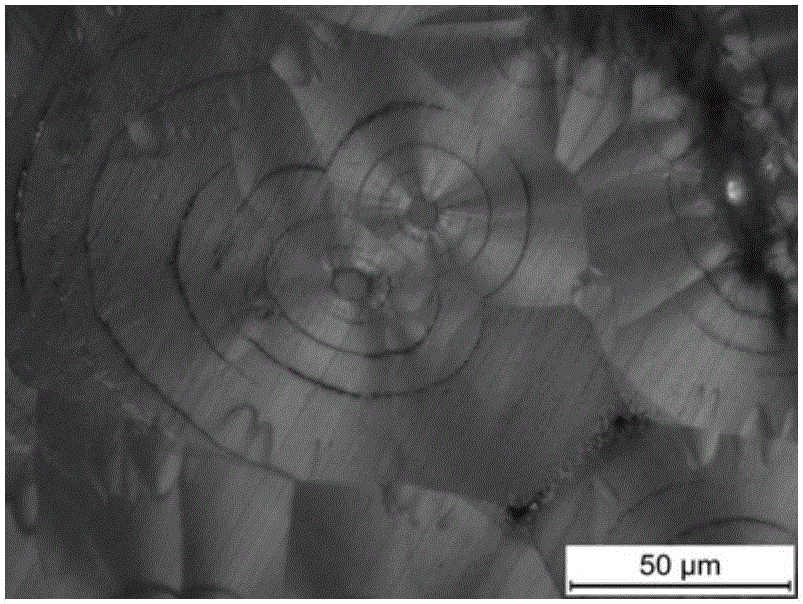

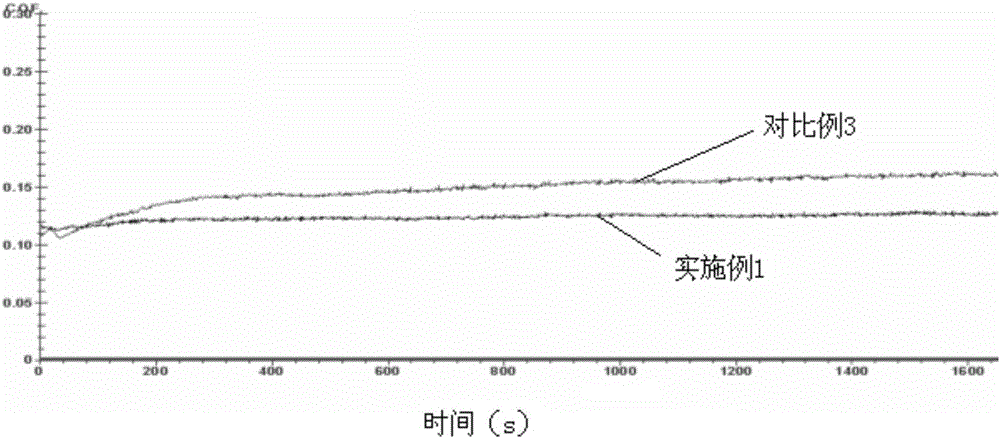

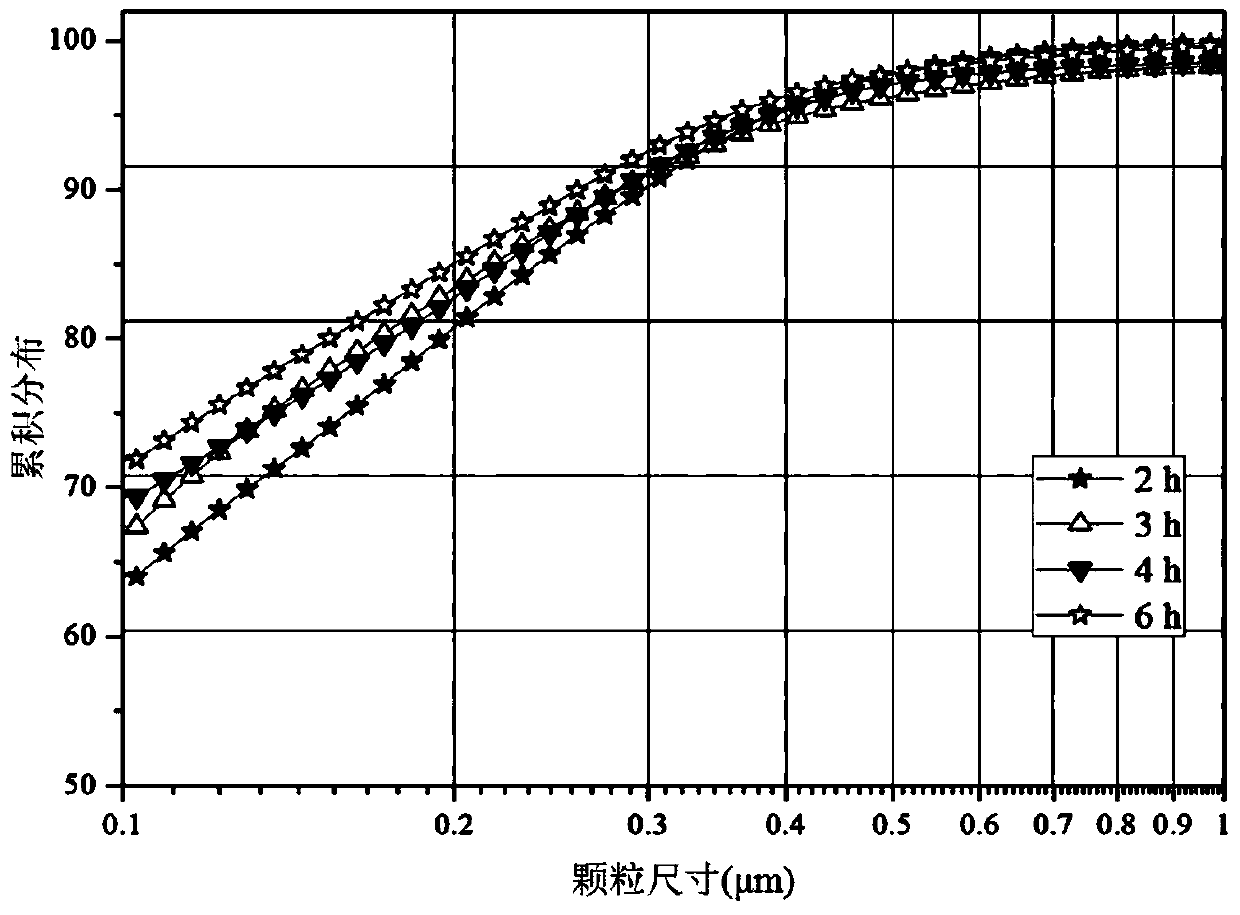

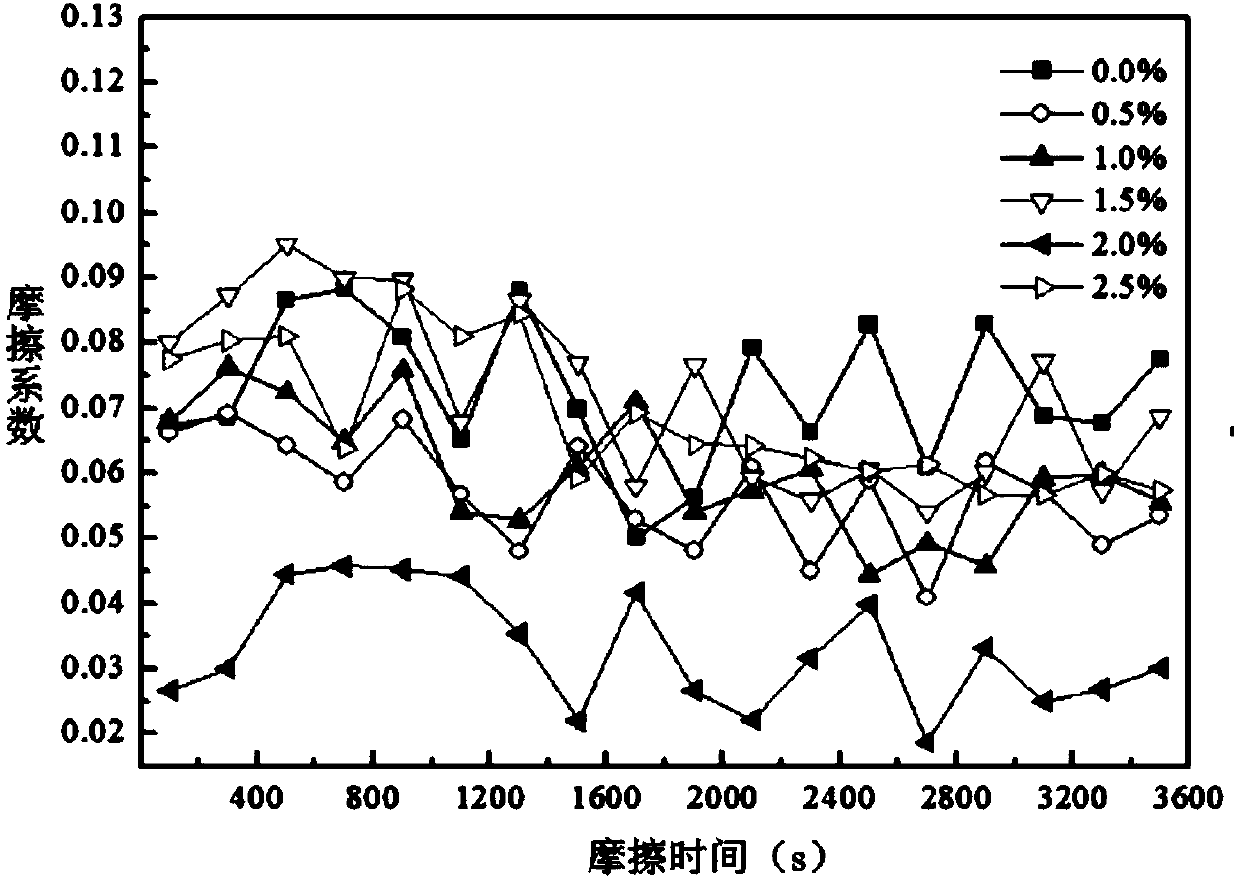

Lubricating oil containing illite/montmorillonite clay nano powder and preparation method thereof

InactiveCN103589478AEnvironmentally friendlyAvoid direct contactAdditivesPigment treatment with macromolecular organic compoundsOleic Acid TriglycerideSieve

The invention discloses a lubricating oil containing illite / montmorillonite clay nano powder and a preparation method thereof, belonging to the field of new application of phyllosilicate clay minerals. The lubricating oil is composed of oleic acid modified illite / montmorillonite clay nano powder and III type base oil, wherein the oleic acid modified illite / montmorillonite clay nano powder accounts for 0.5-2.5 wt% of the lubricating oil. The preparation method comprises the following steps: (1) crushing natural illite / montmorillonite clay minerals, and adding water to obtain a slurry; (2) regulating the pH value of the slurry, and dispersing; (3) screening the slurry through a sieve; (4) grinding the undersieve slurry to obtain a nano slurry; (5) adding oleic acid for modification; (6) drying the modified nano slurry to obtain nano dry powder; and (7) mixing the nano dry powder with III type base oil to obtain the lubricating oil containing illite / montmorillonite clay nano powder. By using the illite / montmorillonite clay nano powder as the additive, the lubricating oil has the advantages of favorable friction and wear resistance, environment friendliness and no pollution.

Owner:SOUTH CHINA UNIV OF TECH +1

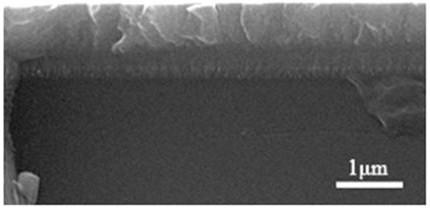

Method for improving high toughness of titanium aluminum nitrogen coating on surface of hard alloy

ActiveCN109338319AImprove bindingGood toughnessVacuum evaporation coatingSputtering coatingCemented carbideAluminum composites

The invention discloses a method for improving the high toughness of a titanium aluminum nitrogen coating on the surface of a hard alloy. The method comprises the following steps of placing a pretreated hard alloy sample onto a double-glow plasma surface alloying furnace sample table, suspending a self-made target material, and placing an auxiliary cathode; feeding argon after vacuumizing, applying high voltage to a cathode and a source electrode, maintaining a certain differential pressure, carrying out tantalum impregnation treatment on the sample after re-sputter cleaning; then taking a tantalum-impregnated sample out, loading onto a substrate table of a magnetron sputtering device, installing a titanium aluminum composite target, adjusting the distance between the target material and the sample, carrying out ion beam sputtering cleaning, then enabling the substrate table to directly face a direct-current pulse magnetron sputtering target, feeding argon and nitrogen, adjusting to acertain proportion, starting a grid bias power supply and a direct-current pulse power supply, and preparing the titanium aluminum nitrogen coating. The titanium aluminum nitrogen composite coating prepared through the method has high fracture toughness and bonding strength.

Owner:TAIYUAN UNIV OF TECH

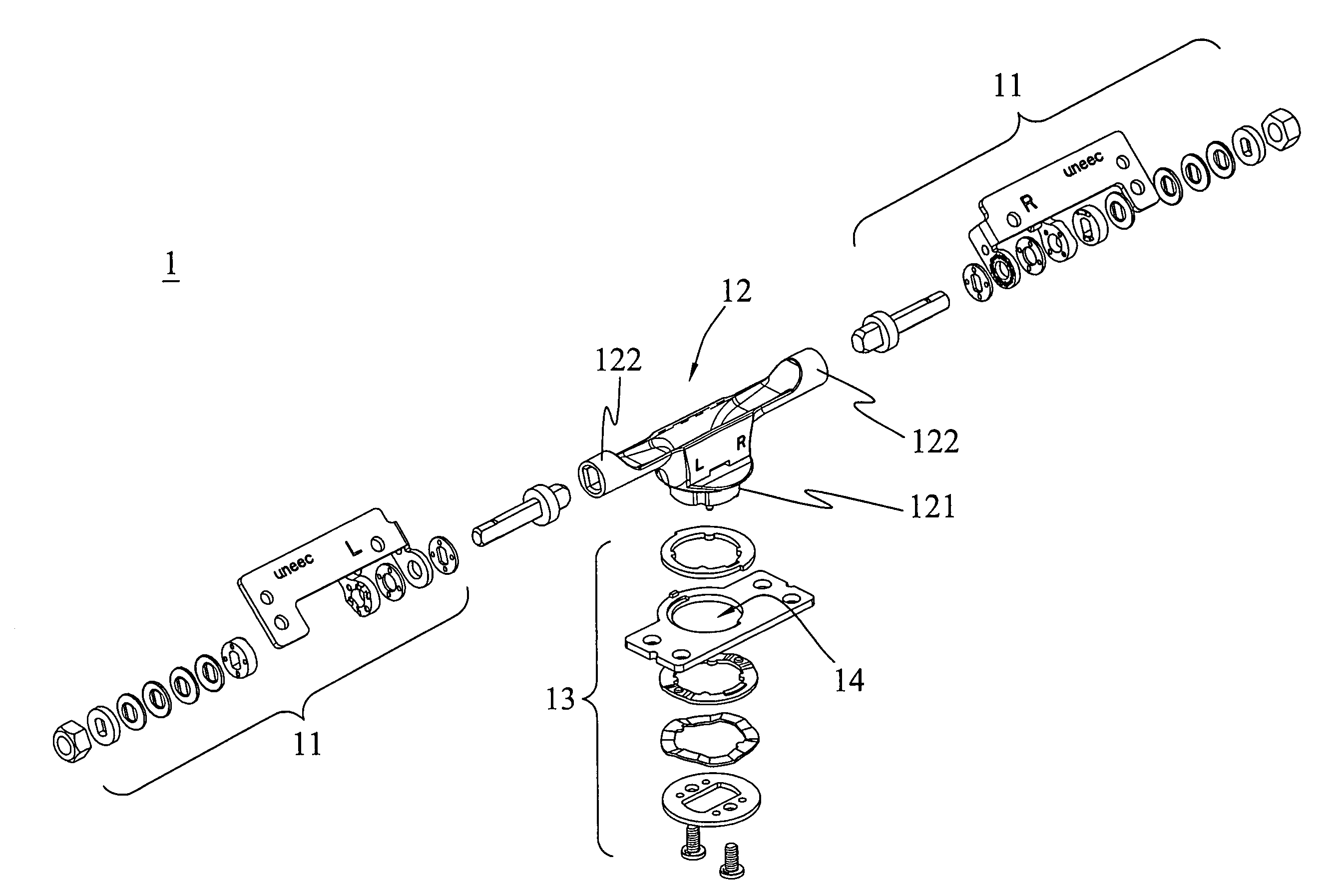

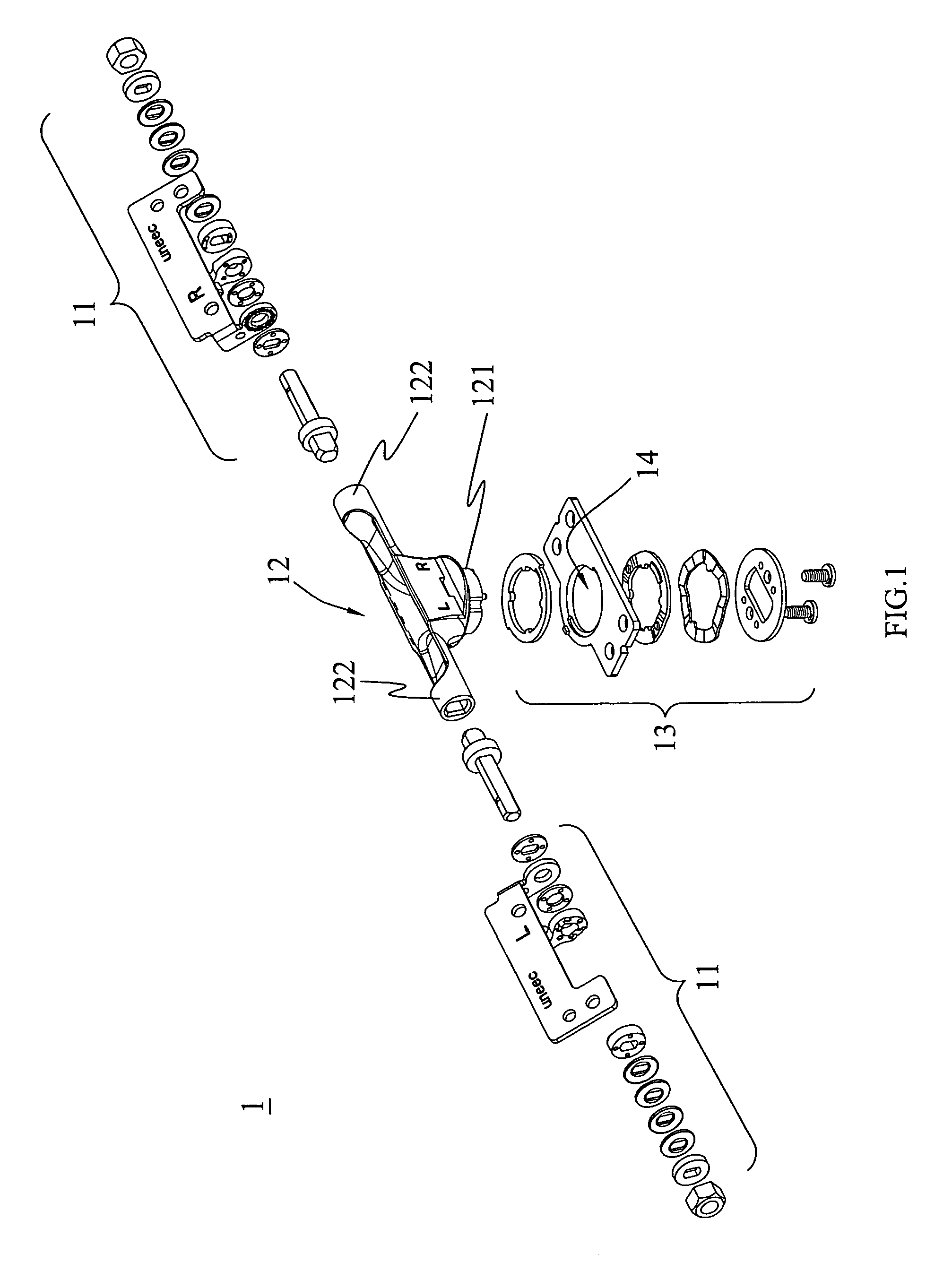

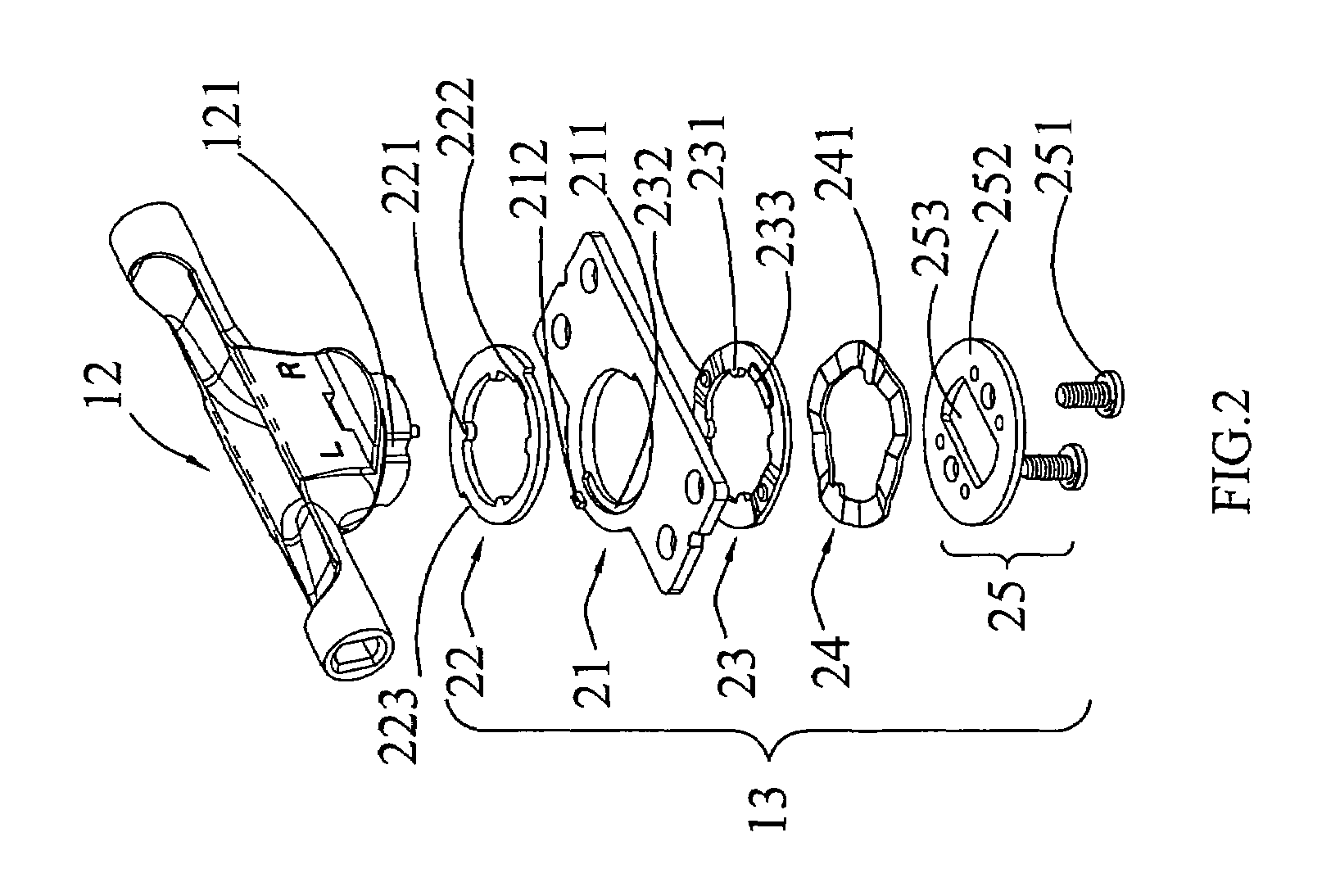

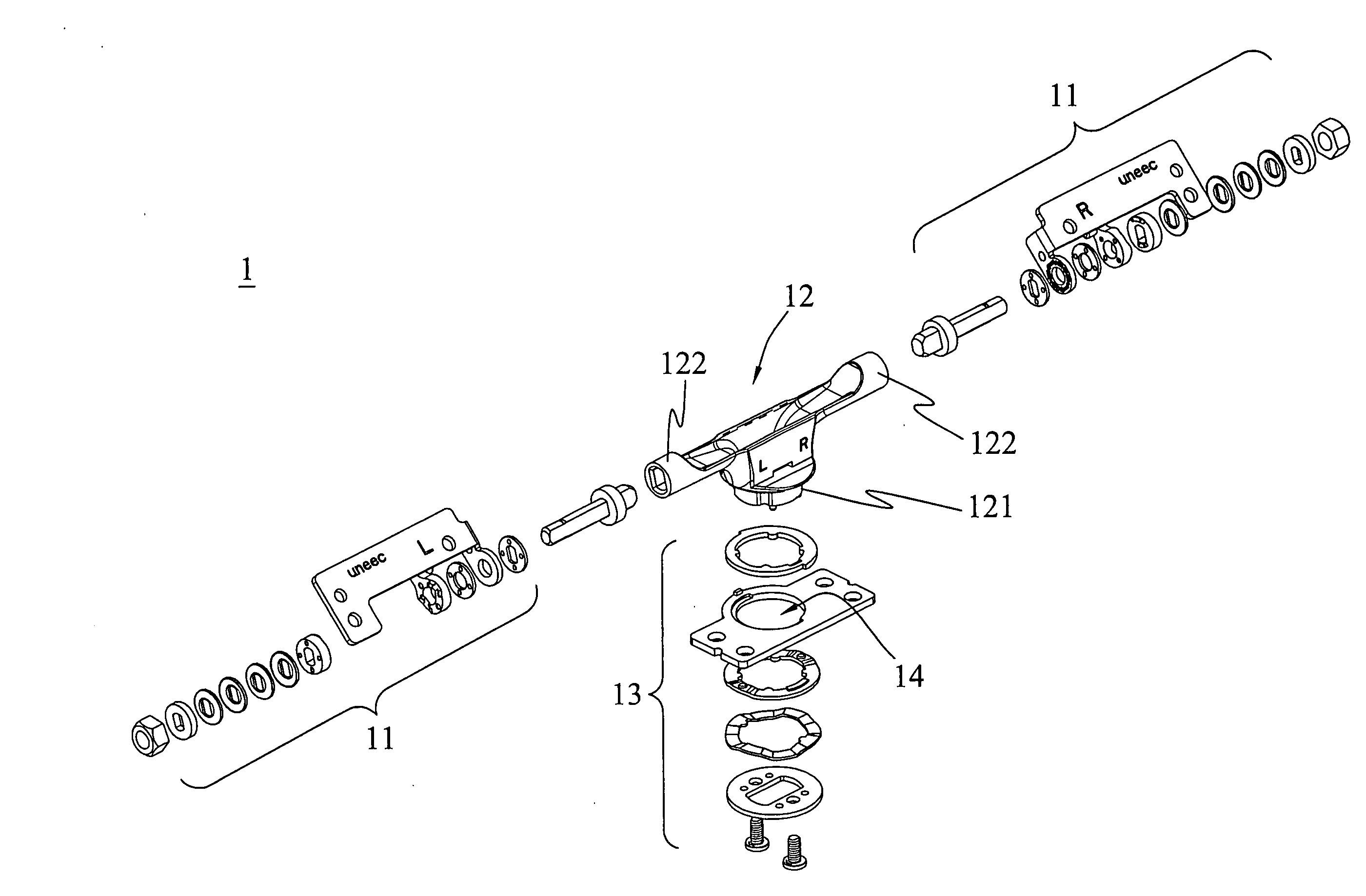

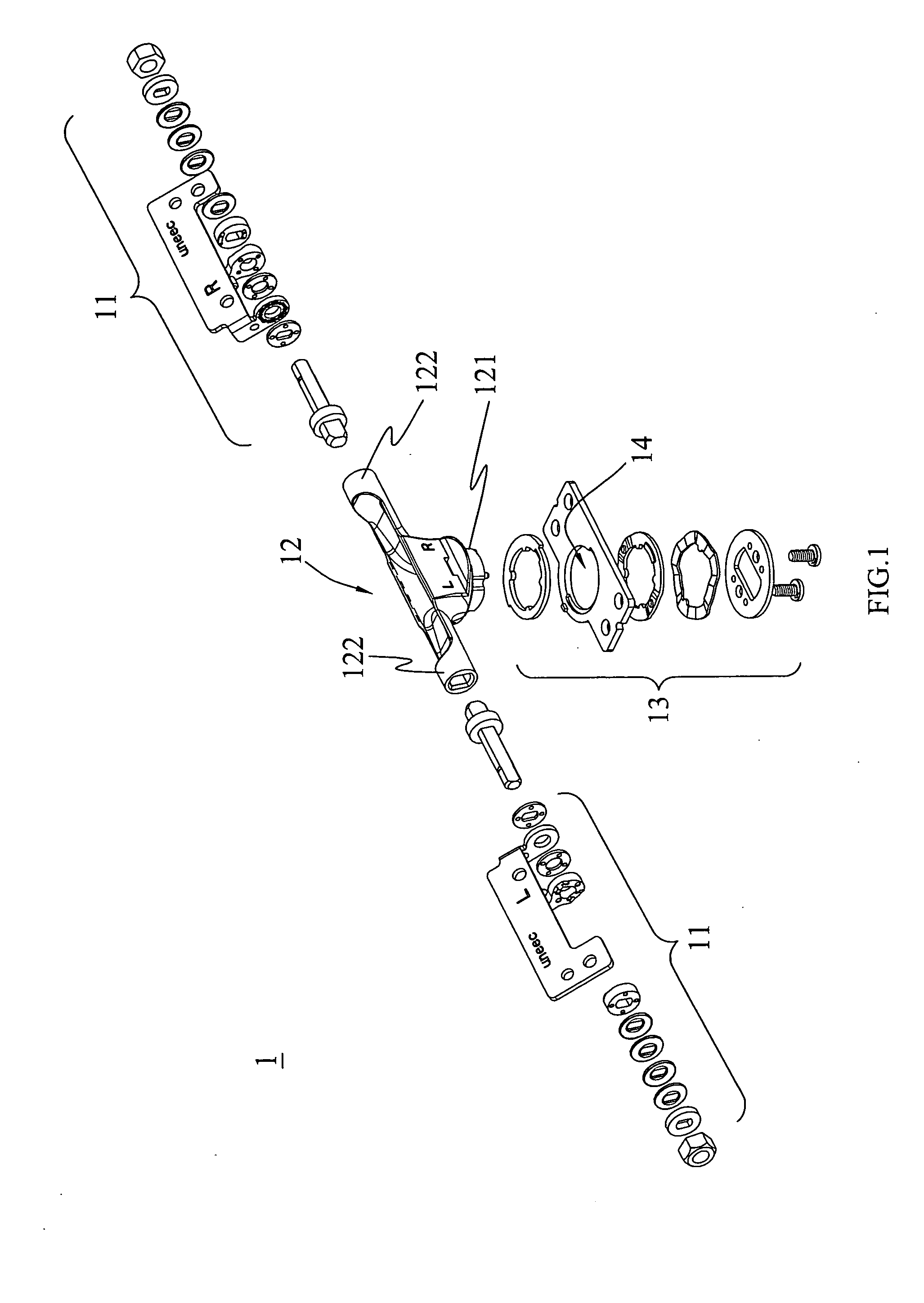

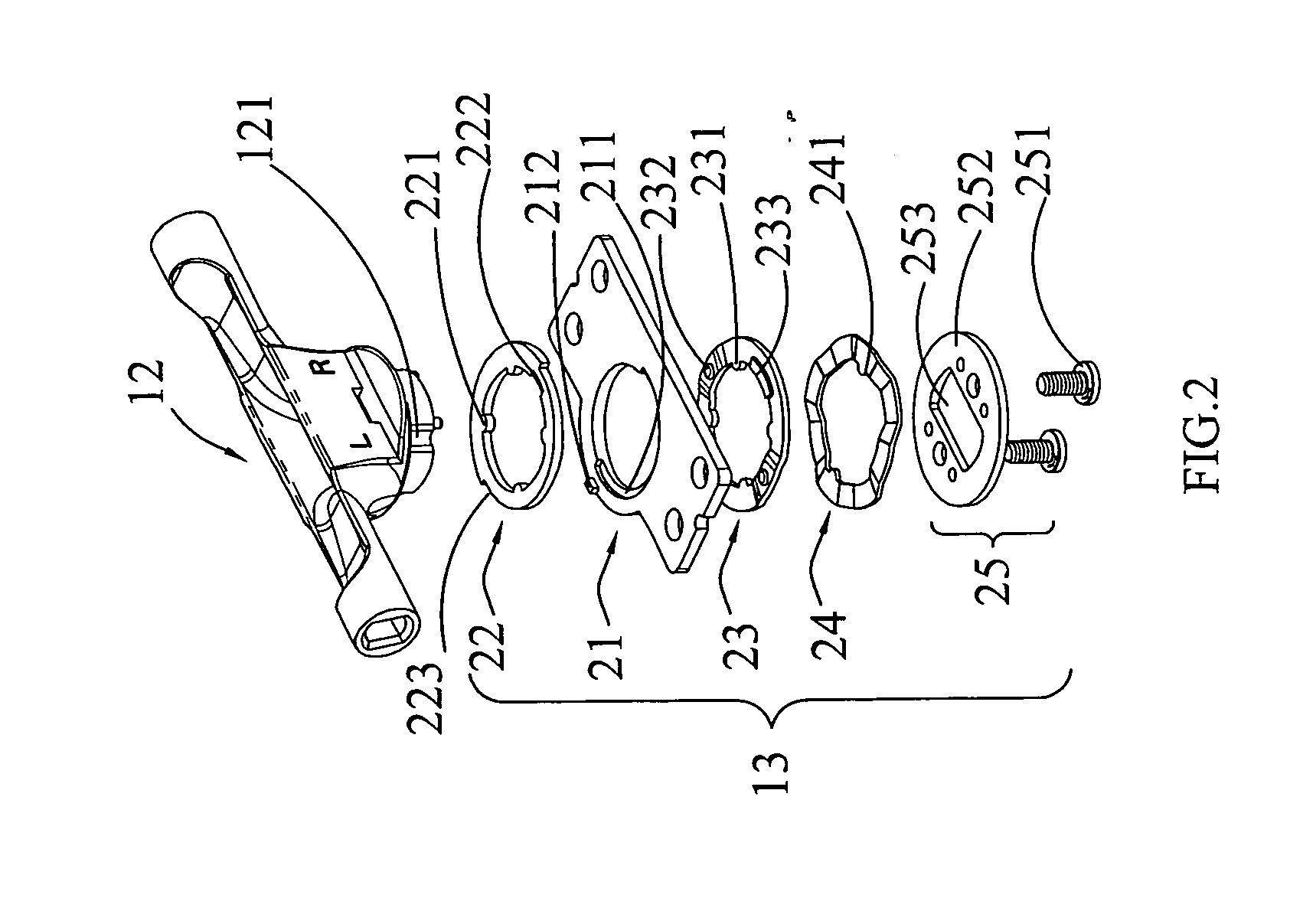

Bidirectional pivot structure

InactiveUS7591047B2Minimized volumeFrictional stabilityTelevision system detailsPin hingesEngineering

Owner:CHENMING MOLD IND CORP

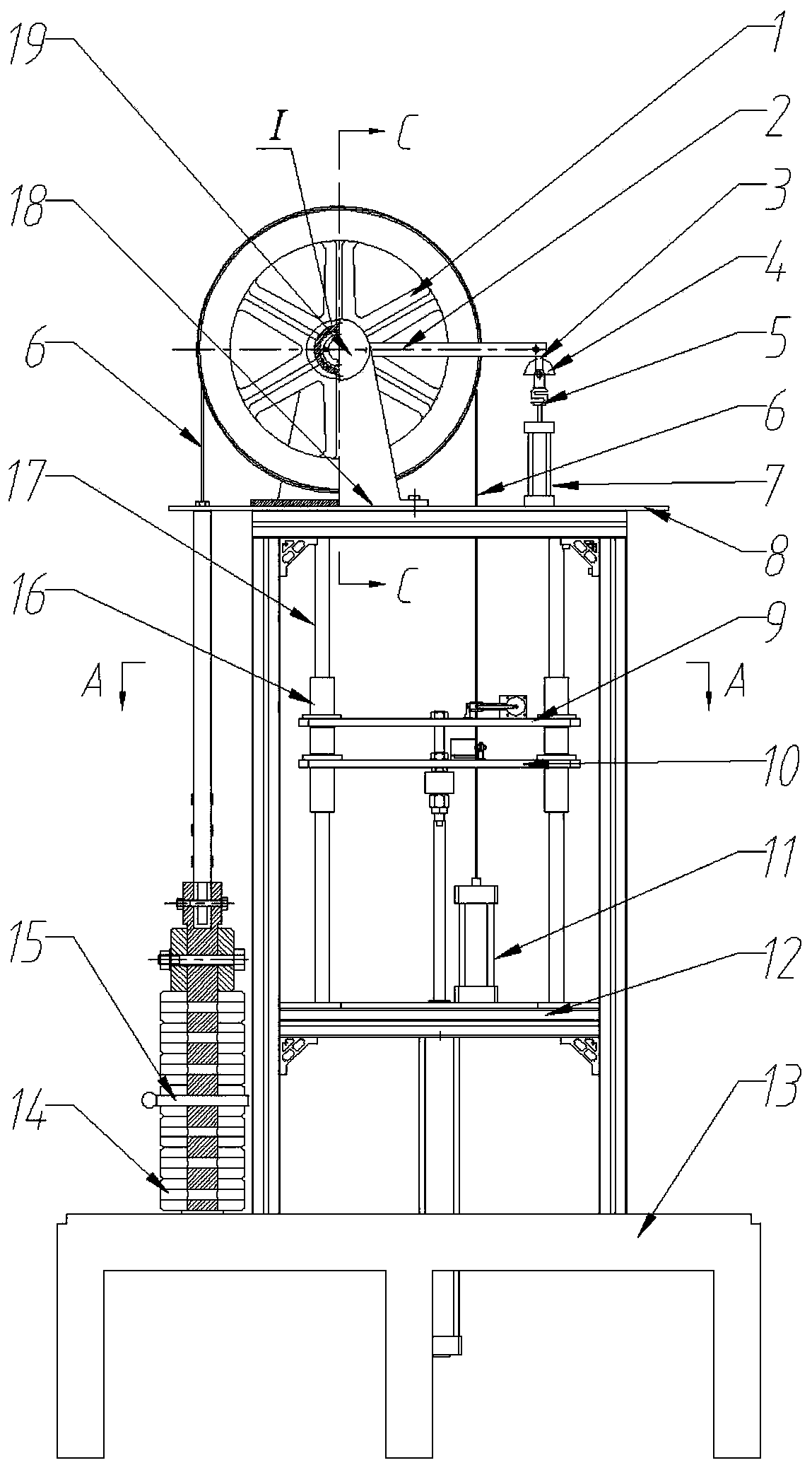

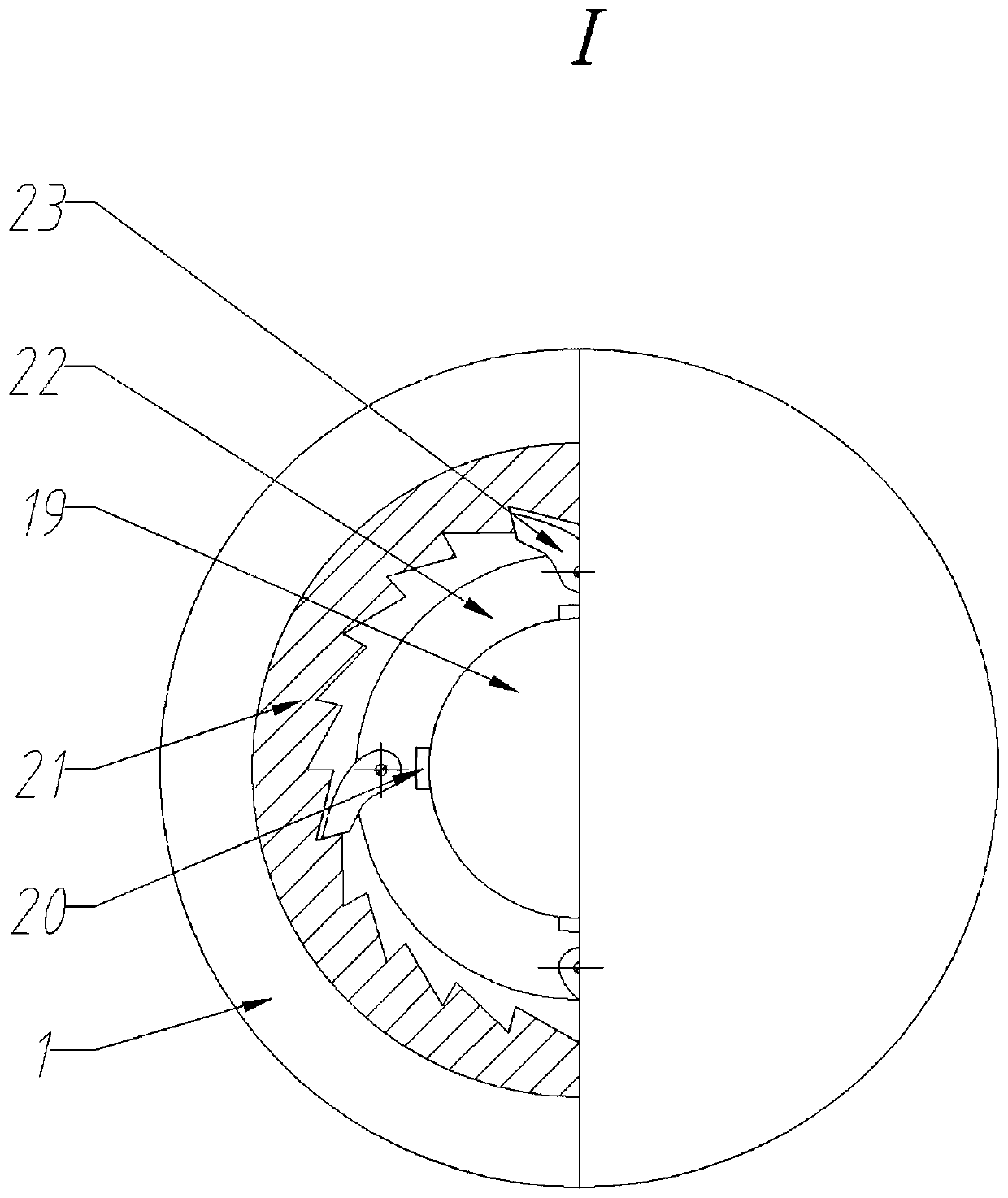

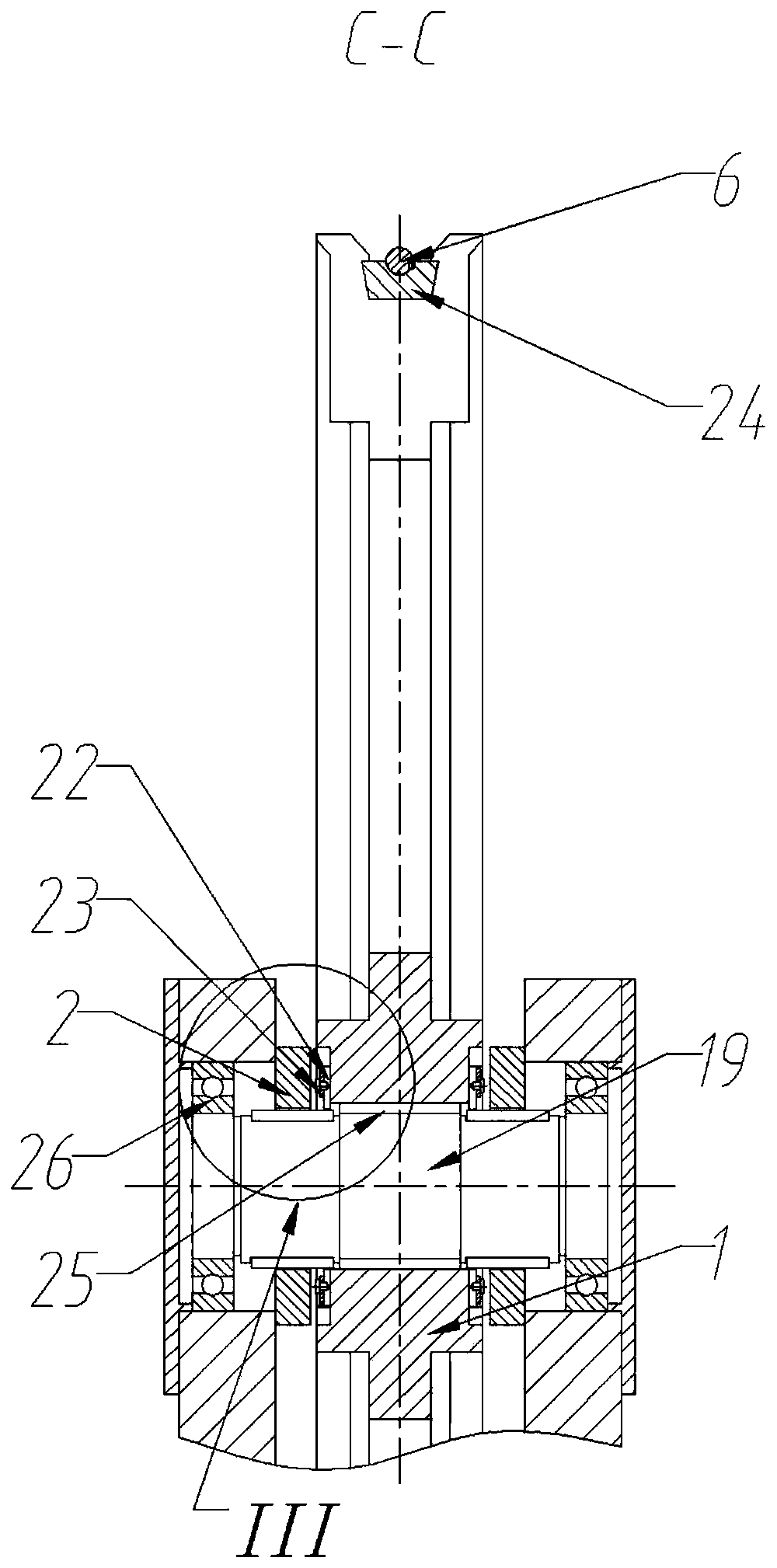

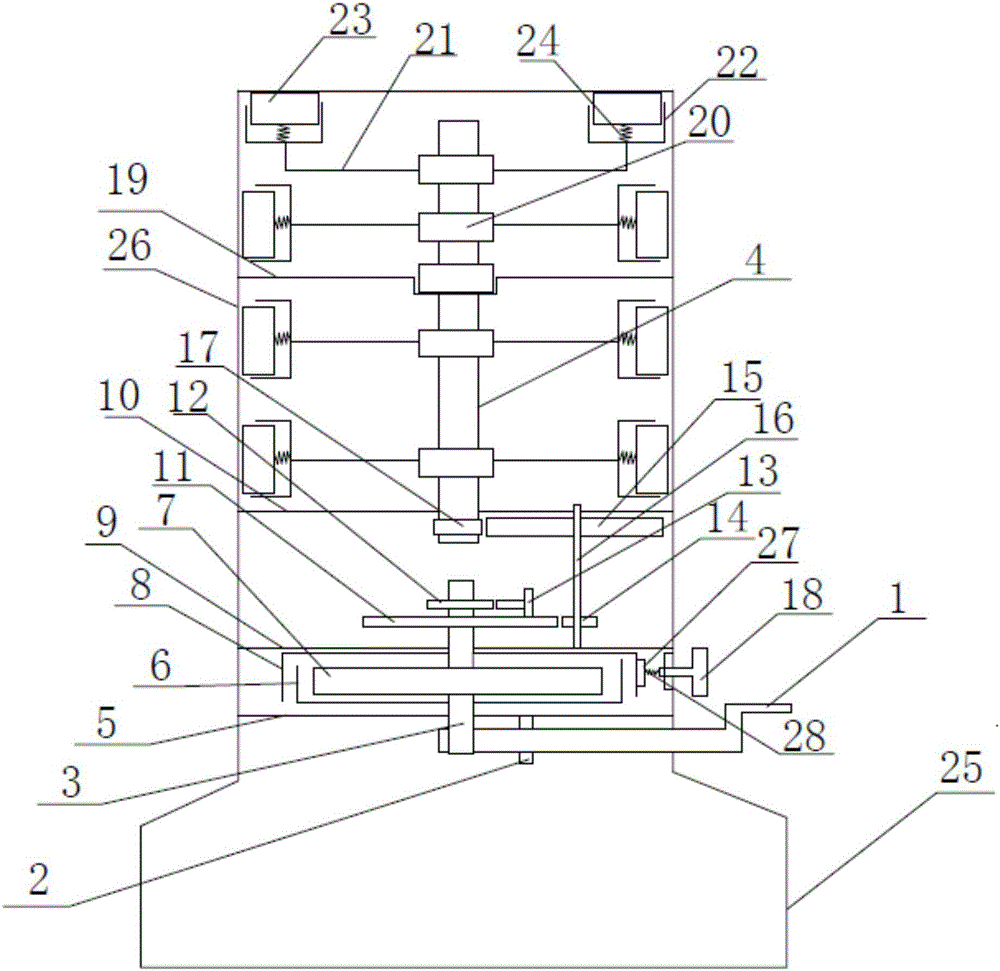

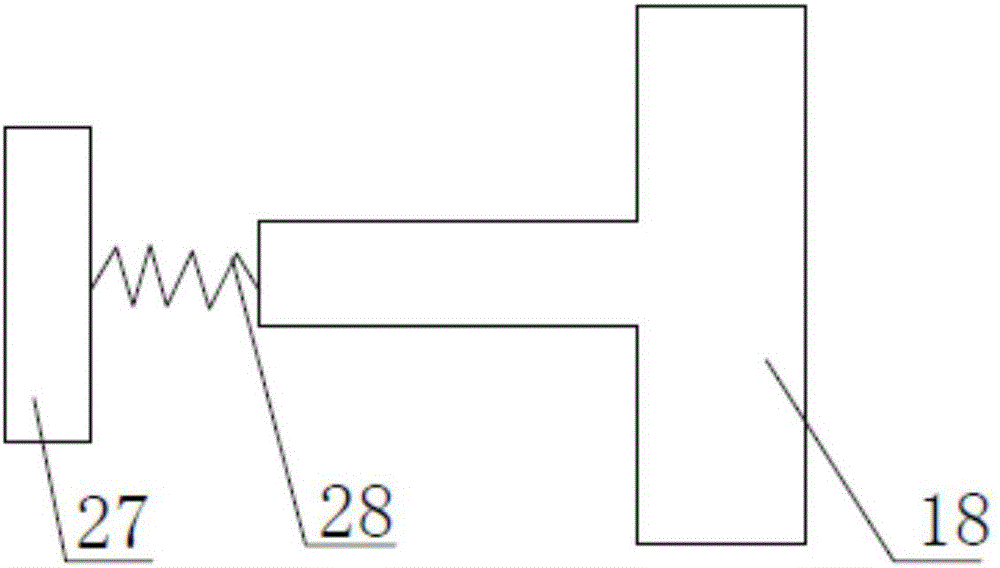

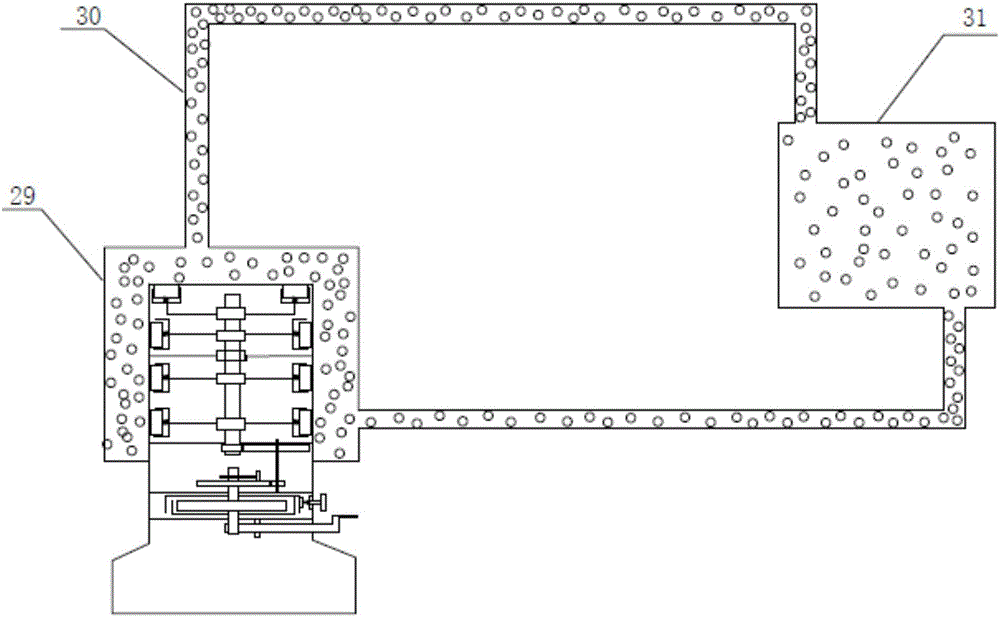

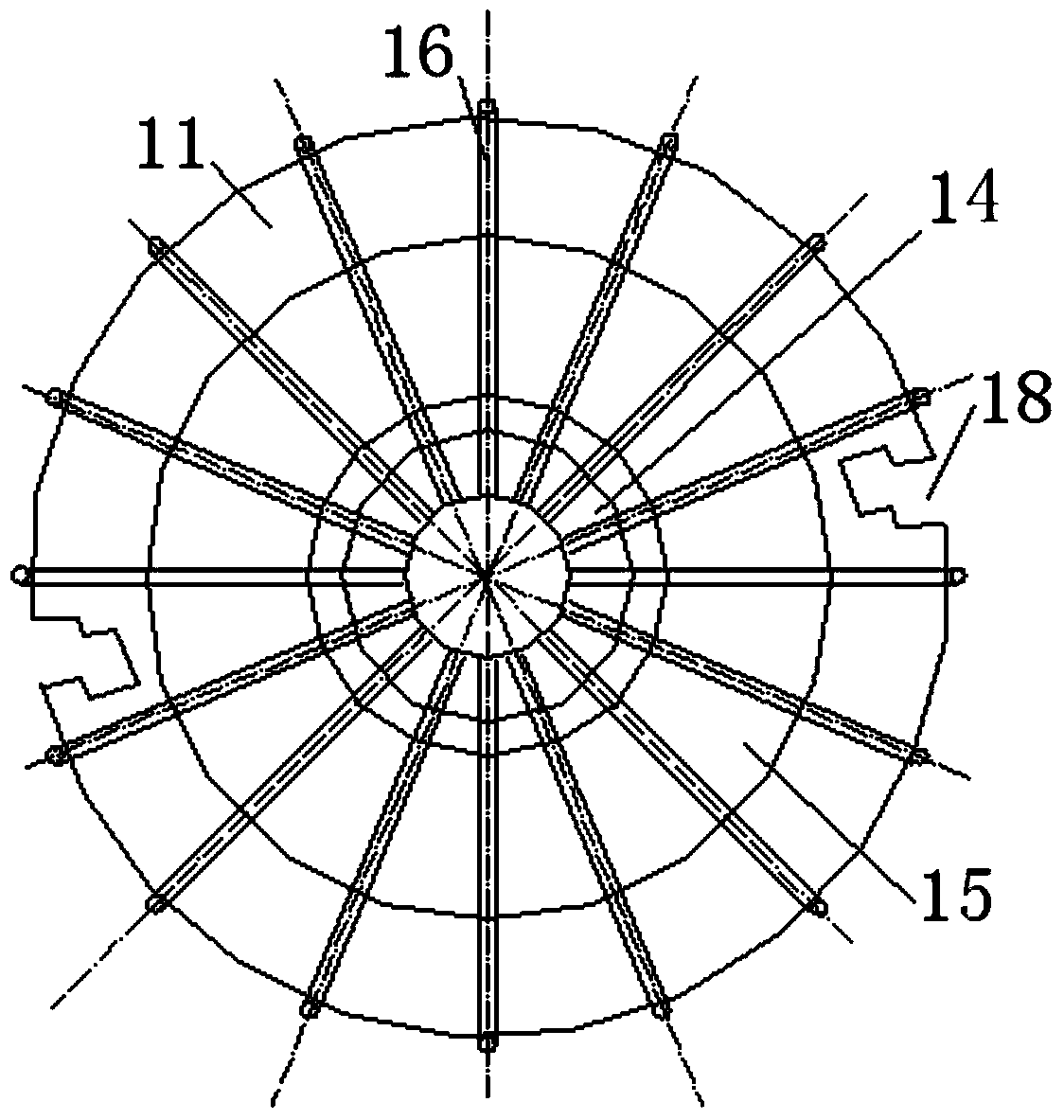

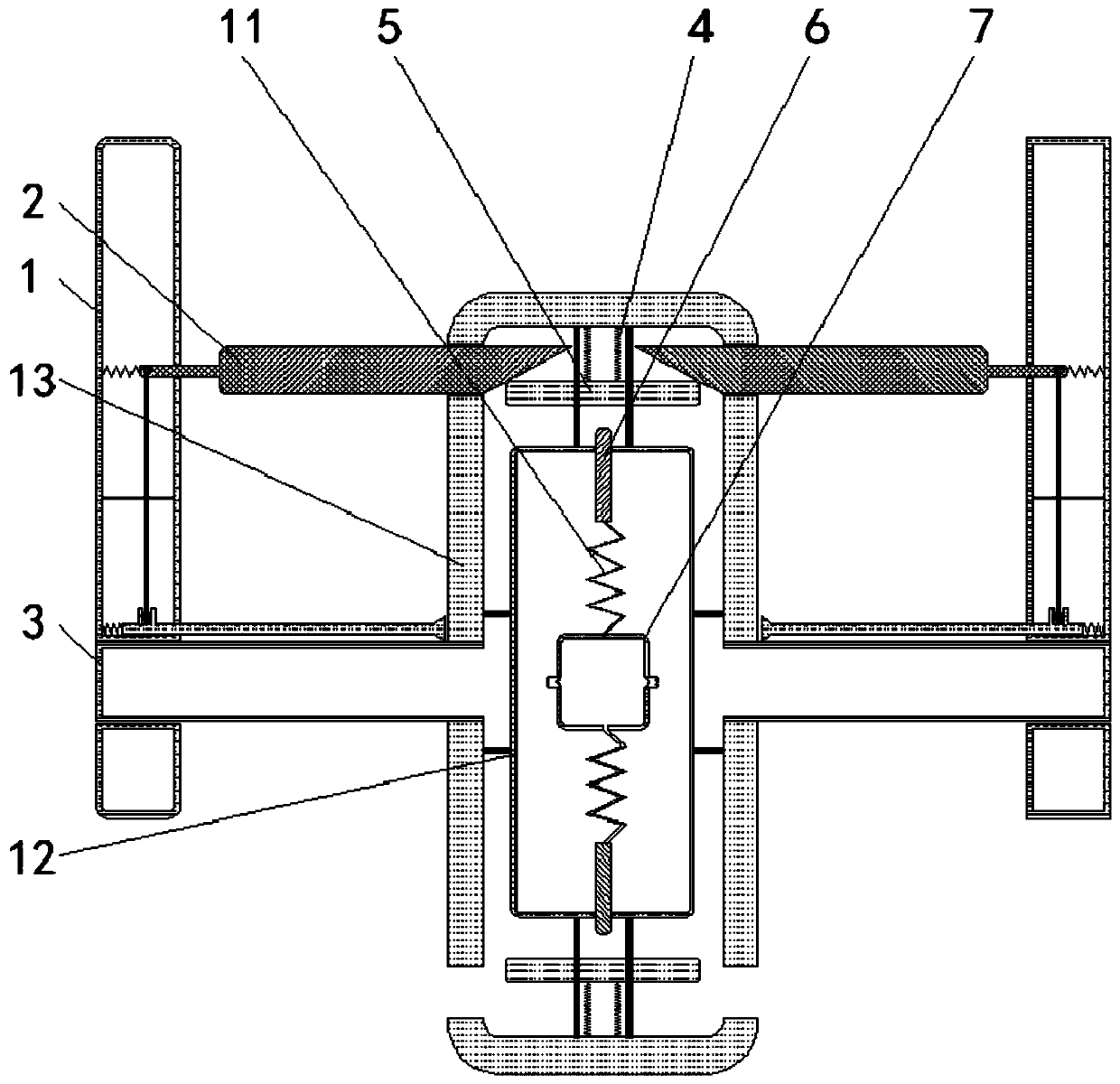

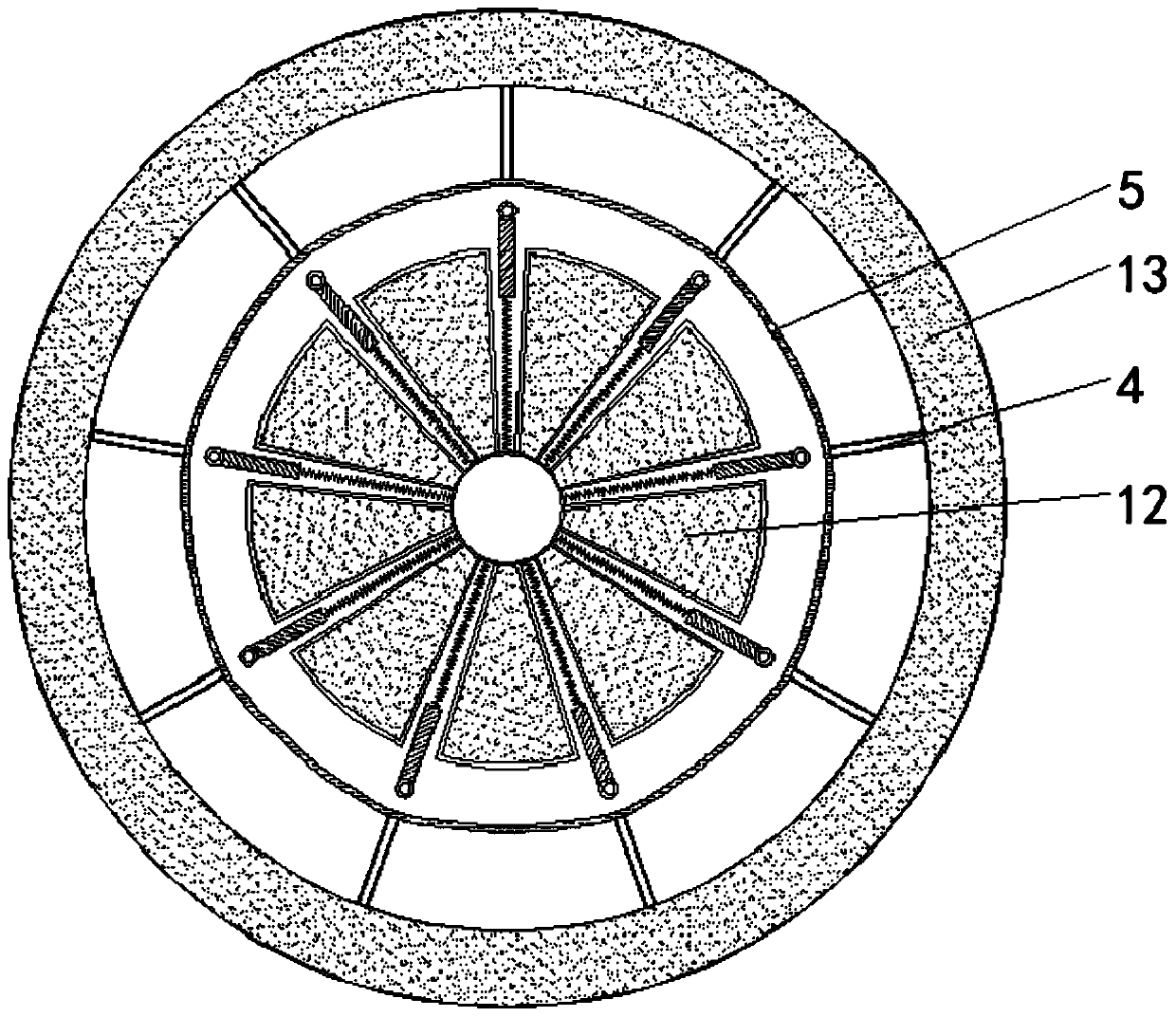

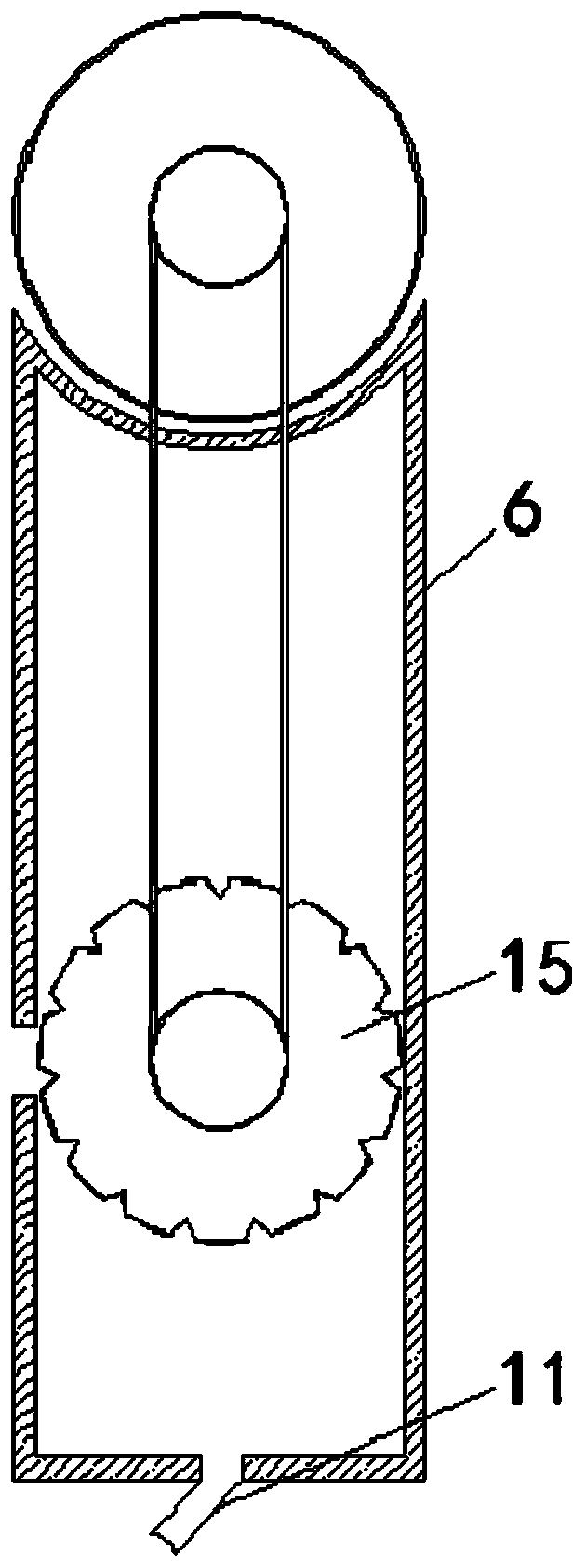

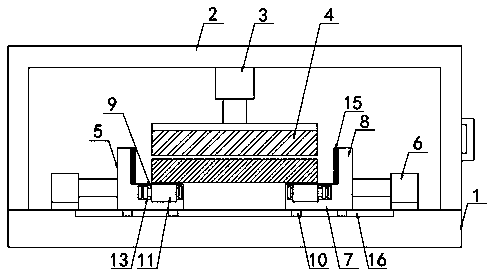

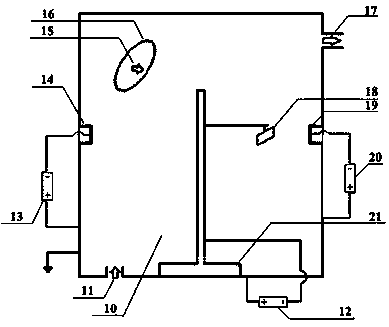

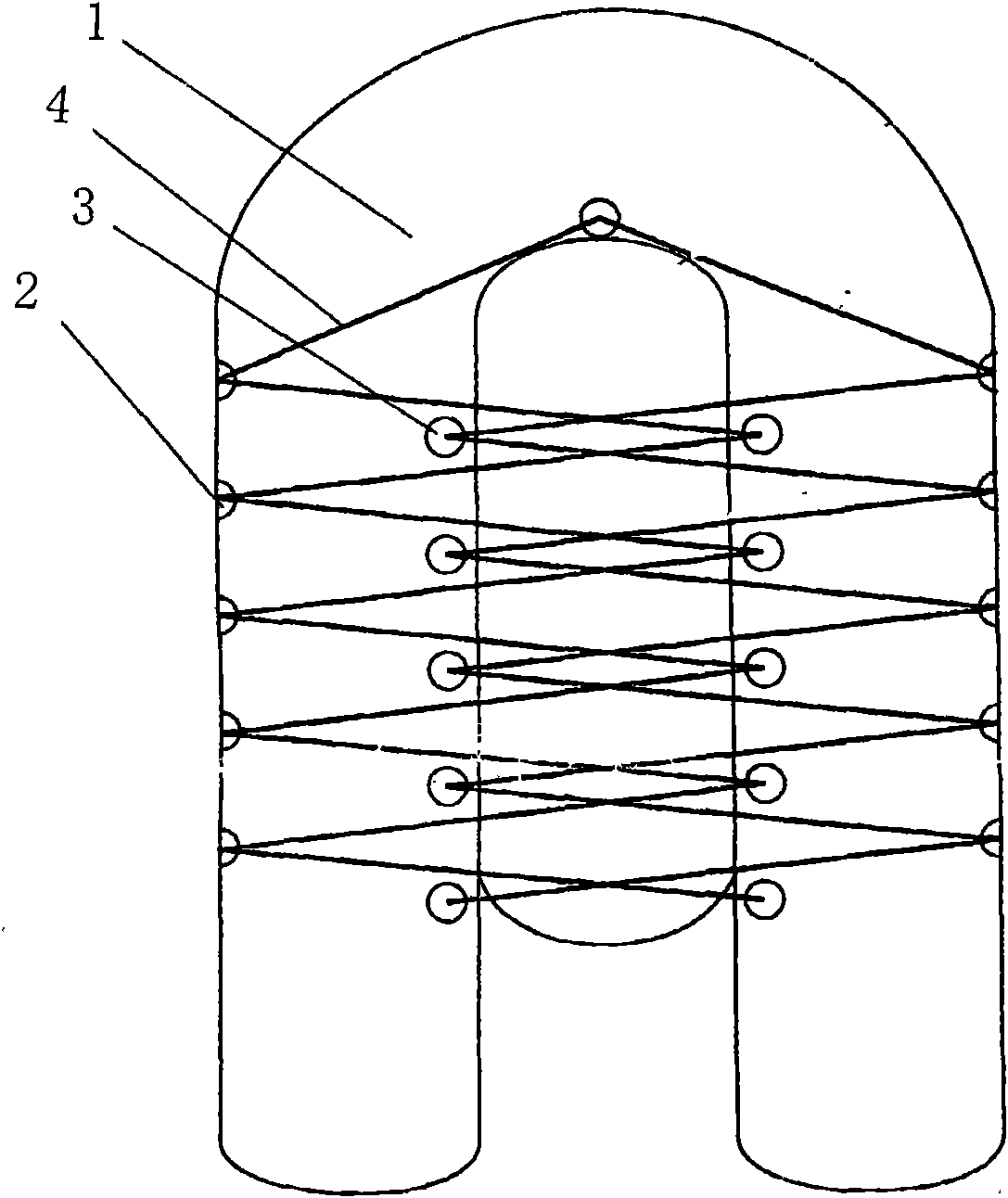

Friction loss experiment device and method under multidirectional vibration of steel wire rope and gasket

ActiveCN111141514ATo achieve lateral excitationEasy to adjustMachine part testingVibration testingVibration amplitudeControl system

The invention relates to the field of mining mechanical equipment, in particular to a friction loss experiment device and method under multidirectional vibration of a steel wire rope and a gasket. Thedevice comprises a base, a rack fixed at the upper part of the base, and a friction mechanism fixed on the rack. A steel wire rope is wound on the friction mechanism; friction gaskets are arranged onthe surfaces, making contact with the steel wire rope, of the friction mechanism. One end of the steel wire rope is fixedly connected with a counterweight mechanism; the other end of the steel wire rope is connected with a vibration excitation mechanism for generating three-dimensional vibration at the other end; the rack is provided with a measuring mechanism used for measuring the ultimate friction force between the steel wire rope and the gasket. The vibration excitation mechanism and the measuring mechanism are controlled by the control system. The friction force measurement under different steel wire rope vibrations can be realized, and the rope-gasket limit friction force loss degree under different amplitudes, directions, positions and different pre-tightening forces can be analyzed.

Owner:XUZHOU NORMAL UNIVERSITY

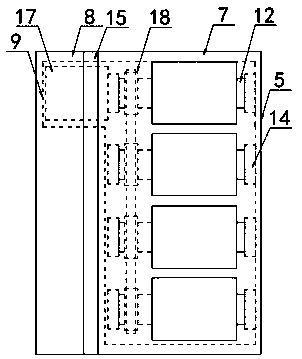

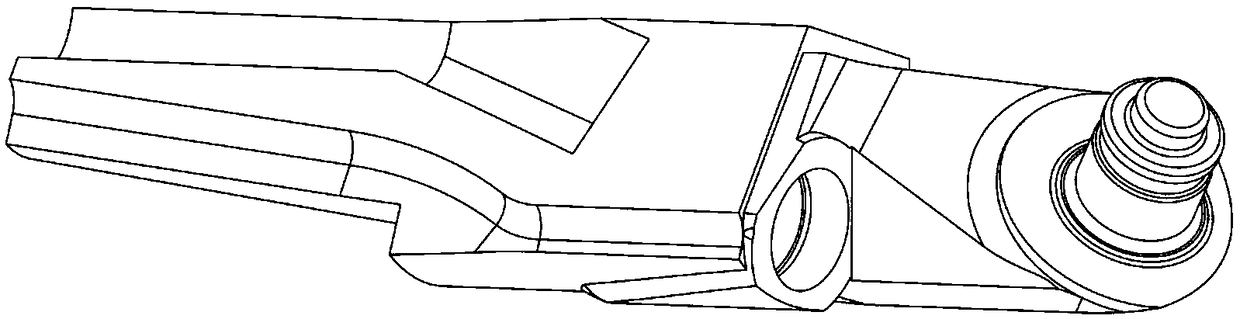

Two-shaft backfill type friction stir spot welding device

ActiveCN108817641AEasy to integrateBackfillNon-electric welding apparatusFriction weldingSystem stability

The invention relates to a two-shaft backfill type friction stir spot welding device, and relates to a friction stir welding device. The two-shaft backfill type friction stir spot welding device comprises a shell, stirring needles, a sleevelet and a jacket, the shell is internally provided with a first lead screw pair, a nut of the first lead screw pair is provided with a sleevelet sleeve, and thesleevelet sleeve is connected with the sleevelet through a first bearing and a sleevelet rolling spline nut; a second lead screw pair is arranged, the upper end of a screw of the second lead screw pair is arranged in the lower end of a screw of the first lead screw pair in a manner of free sliding in the axial direction, a nut of the second lead screw pair is fixedly connected with the lower endof the screw of the first lead screw pair, the screw of the second lead screw pair is connected with a stirring needle shaft through a second bearing, and the lower end of the stirring needle shaft isconnected with the stirring needle; the rotating directions of the first lead screw pair and the second lead screw pair are opposite, and the ratio of the screw pitches is equal to the inverse ratioof the sleevelet cross sectional area and the stirring needle lower portion cross sectional area; and a first power source for driving a motor rolling spline nut to rotate and a second power source for driving the screw of the first lead screw pair to rotate are arranged. The two-shaft backfill type friction stir spot welding device is light and handy in structure, high in system stability, high in welding accuracy, good in effect and long in service life.

Owner:HARBIN INST OF TECH AT WEIHAI

Pressure sensor, preparation method and application thereof, and wearable intelligent fabric comprising the pressure sensor

ActiveCN110606981AIncrease loadImprove adhesionForce measurement using piezo-resistive materialsEngineeringGraphene

The invention provides a pressure sensor, a preparation method and application thereof, and a wearable intelligent fabric comprising the pressure sensor. The pressure sensor is made of graphene modified polyurethane foam; wherein on the basis that the total mass of the graphene modified polyurethane foam is 100%, the mass percentage of the graphene is 0.8-2.5%. The wearable intelligent fabric prepared by the sensor provided by the invention is a wearable platform completely based on the fabric, and has a wide application value.

Owner:XIAN JIAOTONG LIVERPOOL UNIV

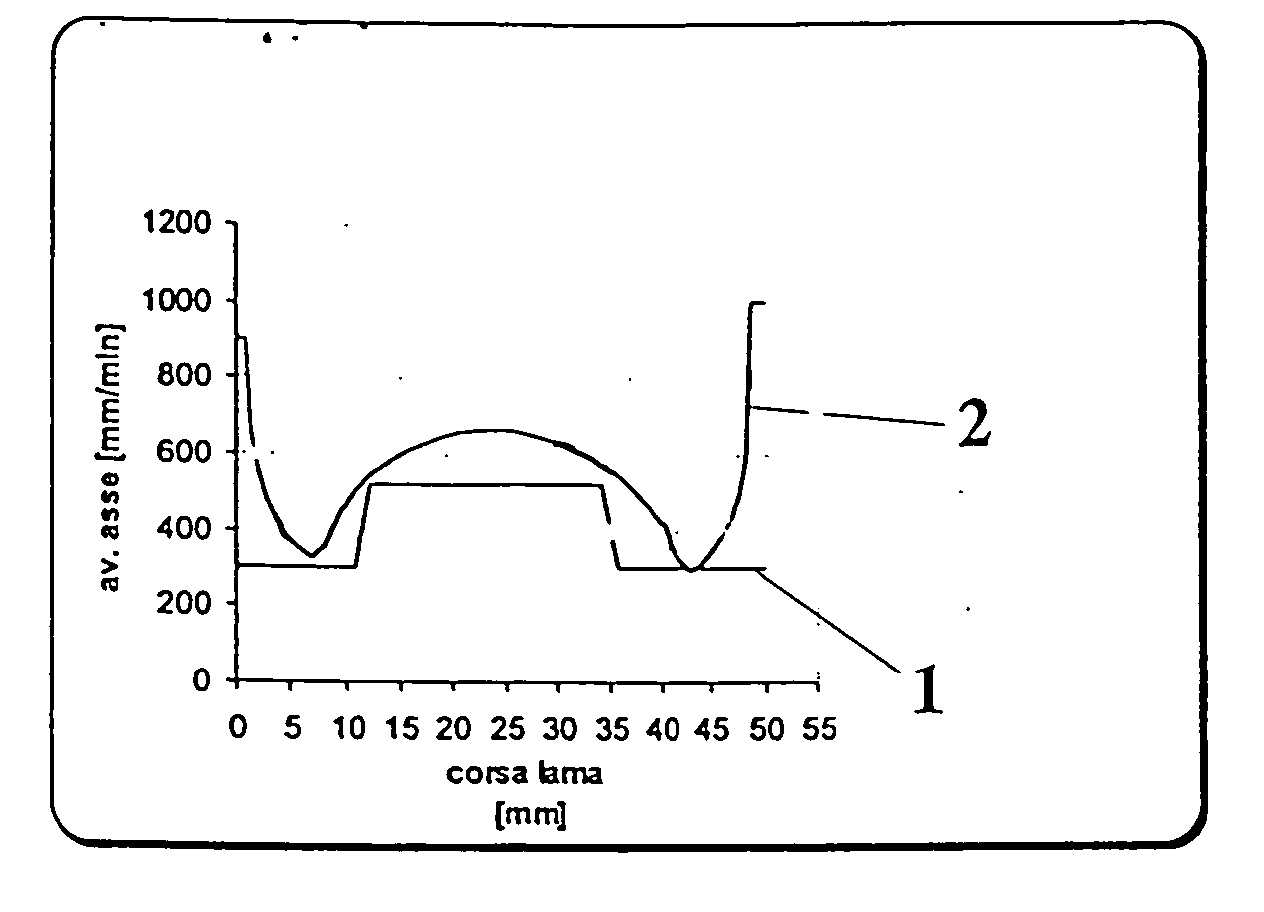

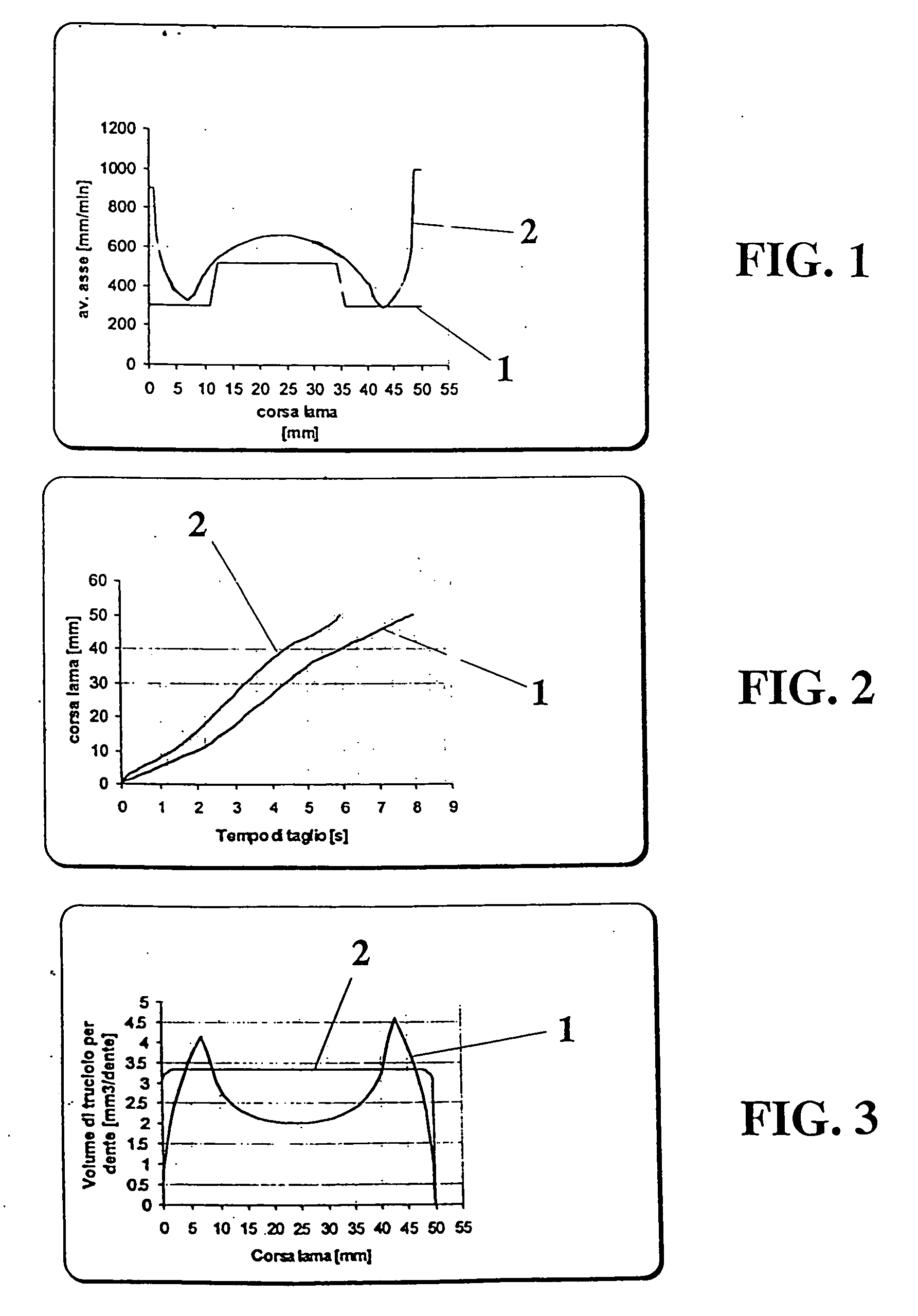

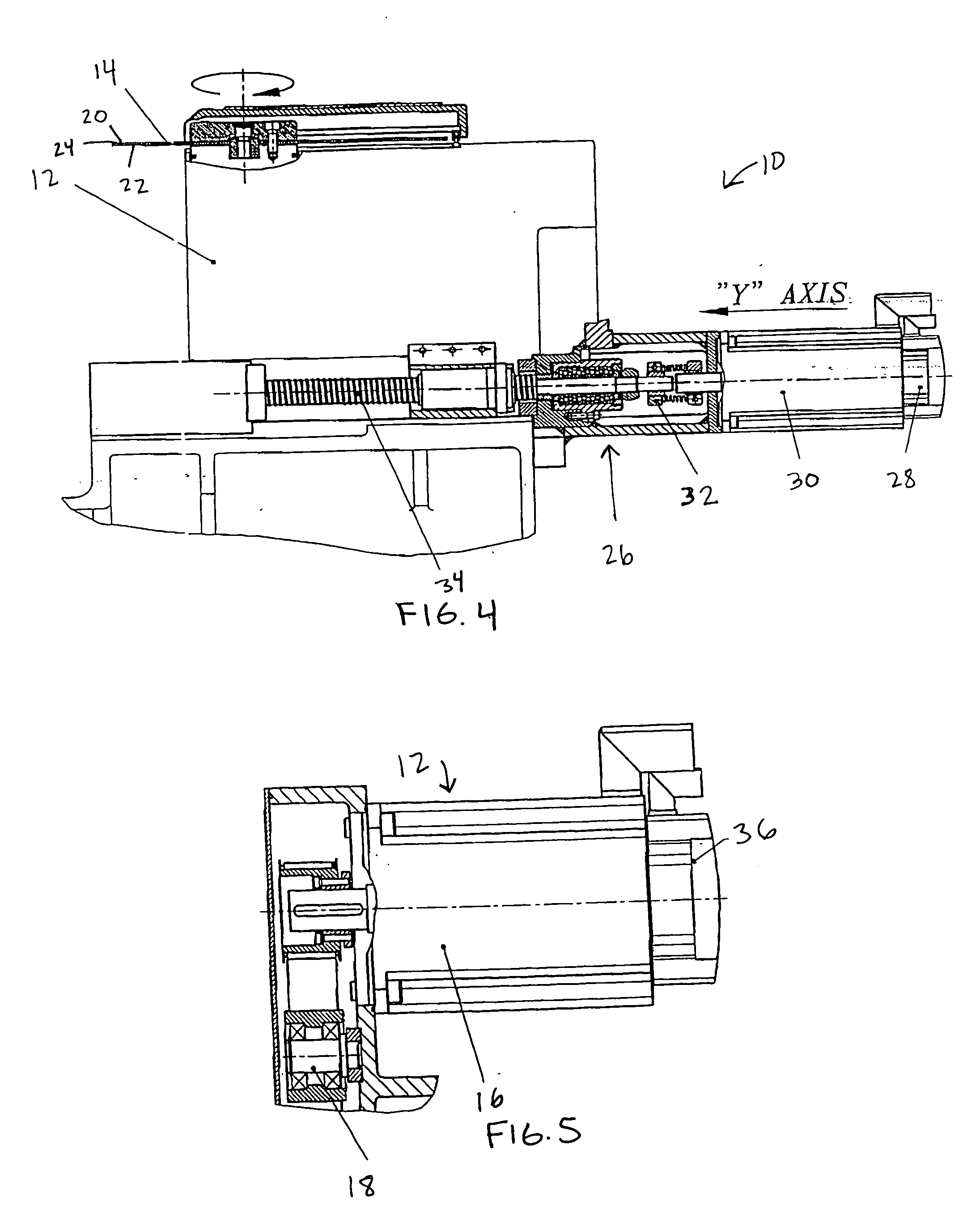

Cut-off unit with constant chip volume cutting for machine tools

InactiveUS20060212159A1Extend work lifeIncrease time efficiencyAutomatic control devicesMetal sawing accessoriesWorking lifeKnife blades

The present invention is a cut-off unit with constant chip volume cutting for machine tools. The cut-off unit maintains a constant chip volume during cutting, which stabilizes friction between the blade of the cutting disk, the teeth of the cutting disk and the chips in between the teeth. In this manner, the working life of the blade and the speed metal bars at the cut-off unit can be controlled for extending the working life of the blade and for increasing the efficiency of time required for cutting or shearing at the cut-off unit. Advancement speed of the cut-off unit, which is guided by a logic-control unit, is continuously and regularly adapted, to keep the volume of chip cut away and accumulated in each gap between the teeth of the blade constant. When cutting a bar, the advancement speed will be higher at the beginning and at the end of the cut, and lower in the central part.

Owner:SINICO

Bidirectional pivot structure

InactiveUS20090183342A1Effectively minimizing volumeMinimized volumeTelevision system detailsPin hingesEngineering

Owner:CHENMING MOLD IND CORP

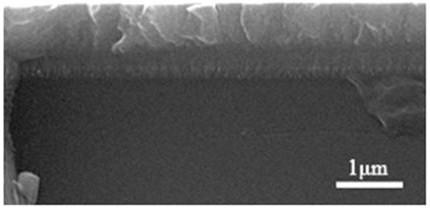

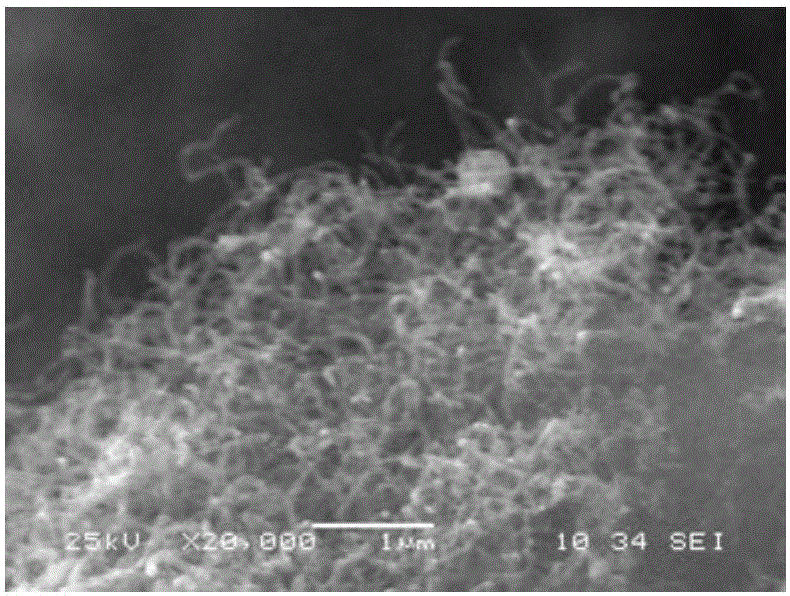

Nanometer silicon carbide fiber-modified C/C sealing material and preparation method thereof

The invention relates to a nano-silicon carbide fiber modified C / C sealing material and a preparation method thereof, belonging to the technical field of high-performance friction sealing material development. The sealing material designed by the present invention includes the following components in terms of mass percentage: carbon fiber prefabricated body + deposited carbon 86.5-96.99%, nano-Ni0.01-0.5%, nano-silicon carbide fiber 3-13%; the nano-carbonized The silicon fiber is evenly attached to the carbon fiber preform, and the deposited carbon is coated on the surface of the carbon fiber preform, nano-silicon carbide fiber, and Ni to form a dense carbon layer; the Ni is evenly distributed between the dense carbon layer and the carbon In the interval formed by the fiber preform. The preparation method is as follows: first, nano-nickel powder is synthesized in a carbon fiber prefabricated body, and then nano-silicon carbide fibers are obtained by in-situ generation; finally, a finished product is obtained by depositing pyrolytic carbon. The preparation process of the invention is simple, the obtained material has excellent friction performance, and is convenient for industrial application.

Owner:CENT SOUTH UNIV

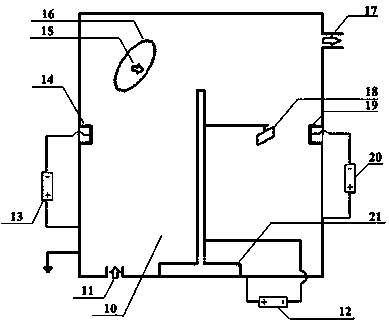

Friction heat furnace

InactiveCN105910164AContact stable average speedFrictional stabilityLighting and heating apparatusWaste gas energyFixed frameEngineering

The invention belongs to the technical field of heating furnaces, in particular, relates to a friction heat furnace, and mainly solves the problems of potential safety hazards, high cost and heavy pollution in traditional heating. The friction heat furnace comprises such parts as a rocking handle, a spring gear shaft, a center shaft and a spring shell; the rocking handle is arranged on the lower surface of a lower fixed bracket plate through a rocking handle bracket; the spring shell is arranged on the upper surface of the lower fixed bracket plate; a spring is mounted in the spring shell; a speed adjusting shell is arranged on the spring gear shaft; a gear 1 is arranged at the middle upper part of the spring gear shaft; a gear 2 is fixedly arranged at the upper part of the spring gear shaft; a rotating disc coats the center shaft and rotates along with the center shaft; a friction block fixed frame is arranged at the outer end part of each connecting rod; friction blocks are arranged in the friction block fixed frames; and the inner end surfaces of the friction blocks are connected into the friction block fixed frames through springs.

Owner:王海龙

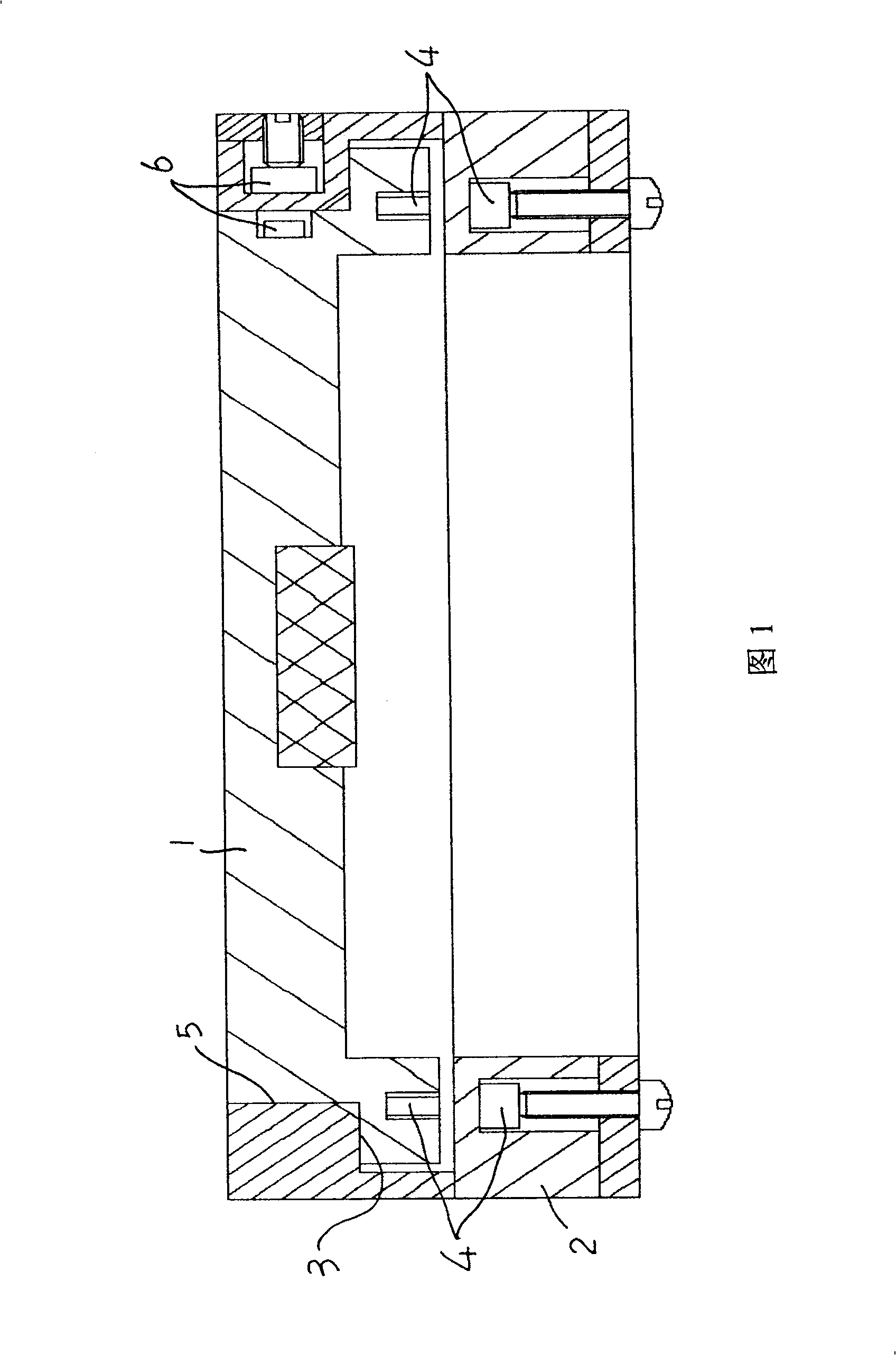

Adjusting device with a sealed guide cylinder

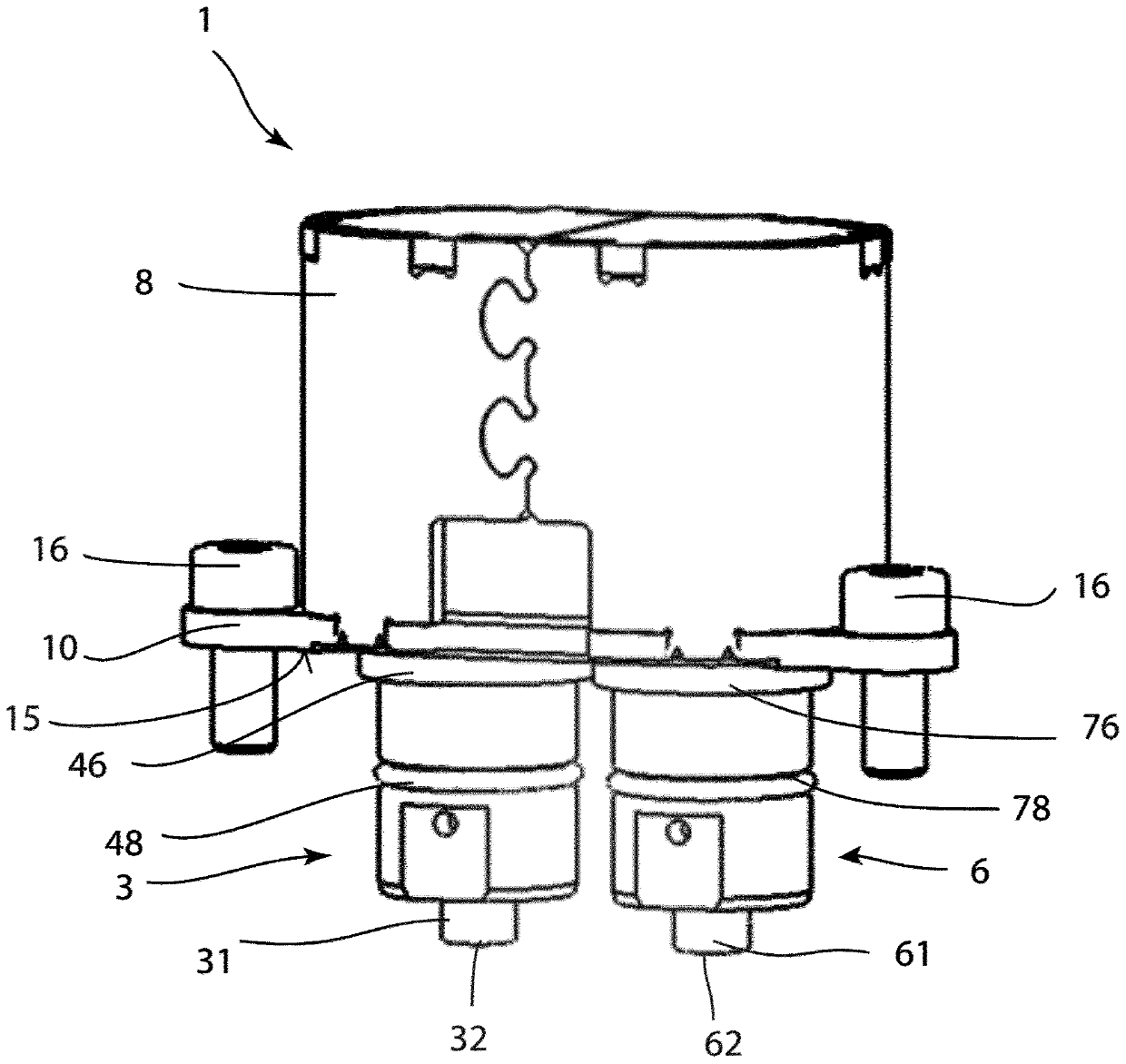

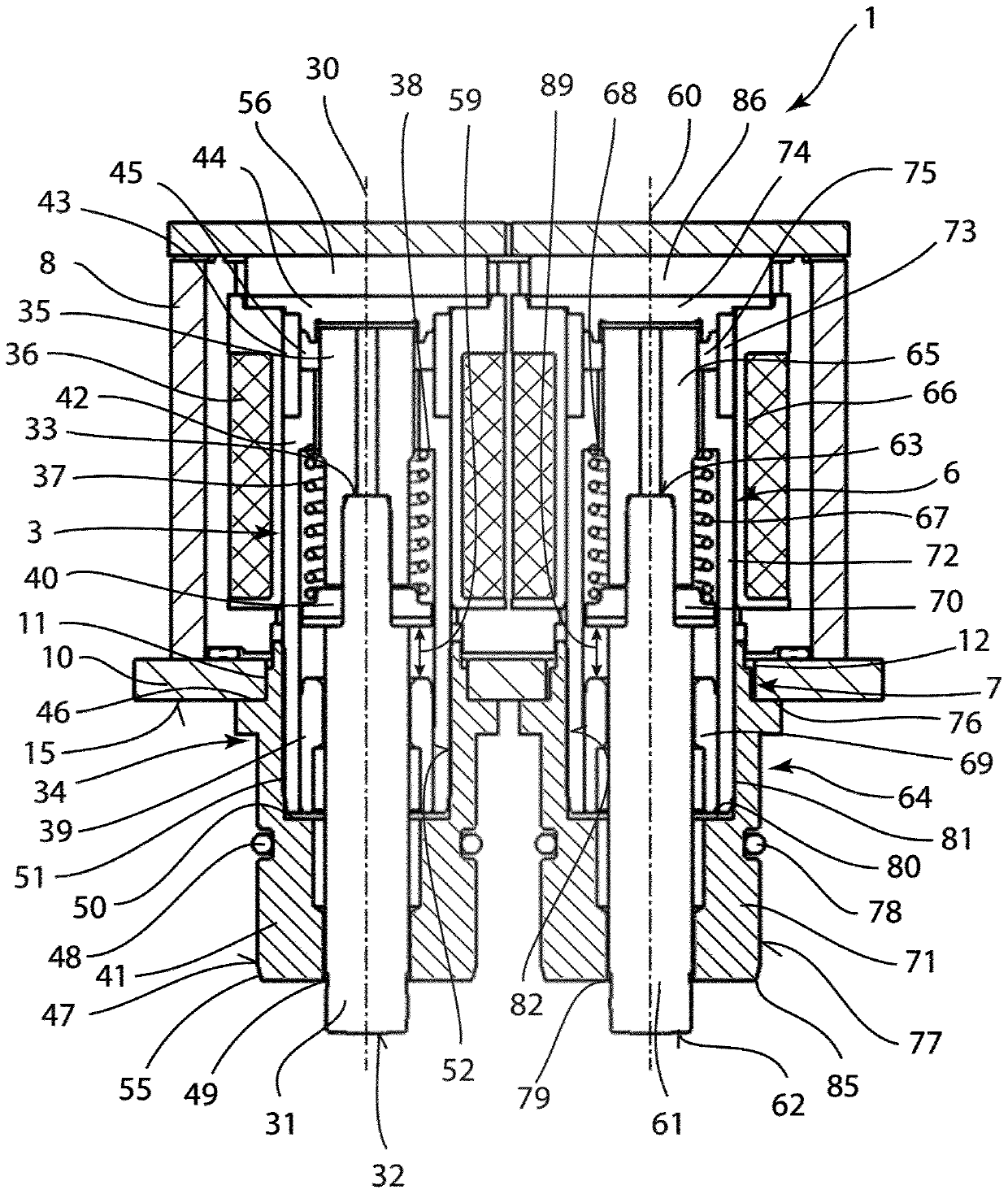

InactiveCN111094707ALarge manufacturing tolerancesObvious cost advantageValve arrangementsMachines/enginesEngineeringMechanical engineering

The invention relates to an adjusting device (1) having at least one tappet assembly (3, 6). The at least one tappet assembly (3, 6) comprises a tappet (31, 61), at least one guide cylinder (34, 64),and a pole core (44, 74). The tappet (31, 61) is arranged in the guide cylinder (34, 64) in a movable manner along a longitudinal axis (30, 60), and a non-magnetic connection socket (43, 73) is arranged between the guide cylinder (34, 64) and the pole core (44, 74). The guide cylinder (34, 64) and the pole core (44, 74) are arranged at a distance to each other in the longitudinal axis (30, 60) bymeans of the connection socket (43, 73).

Owner:KENDRION VILLINGEN GMBH

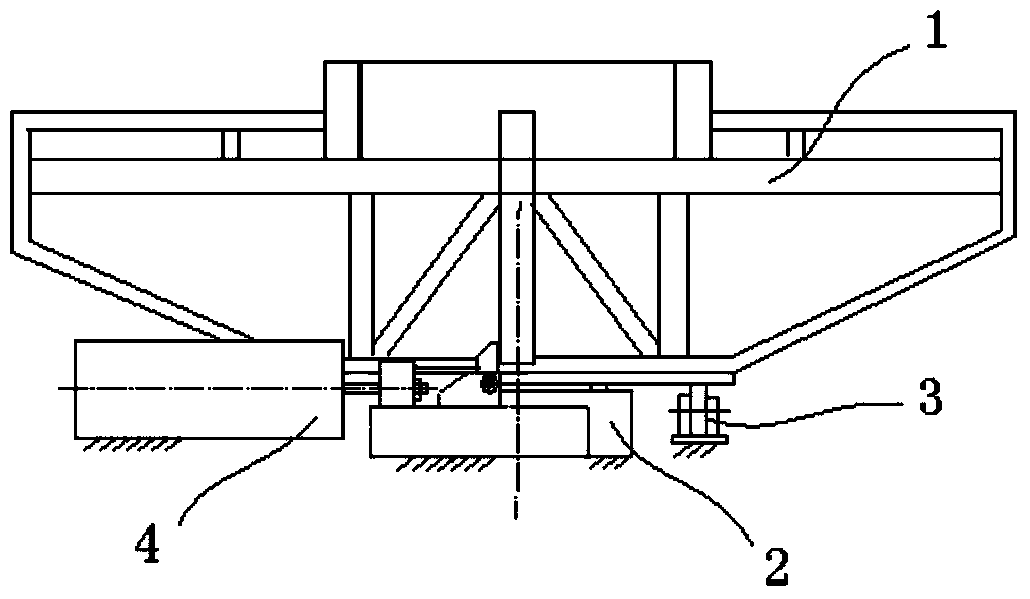

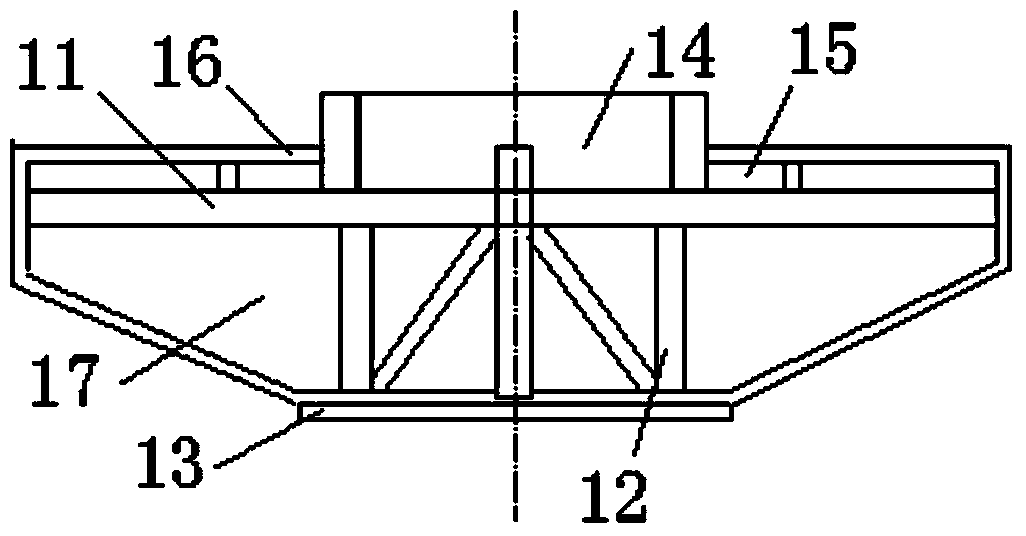

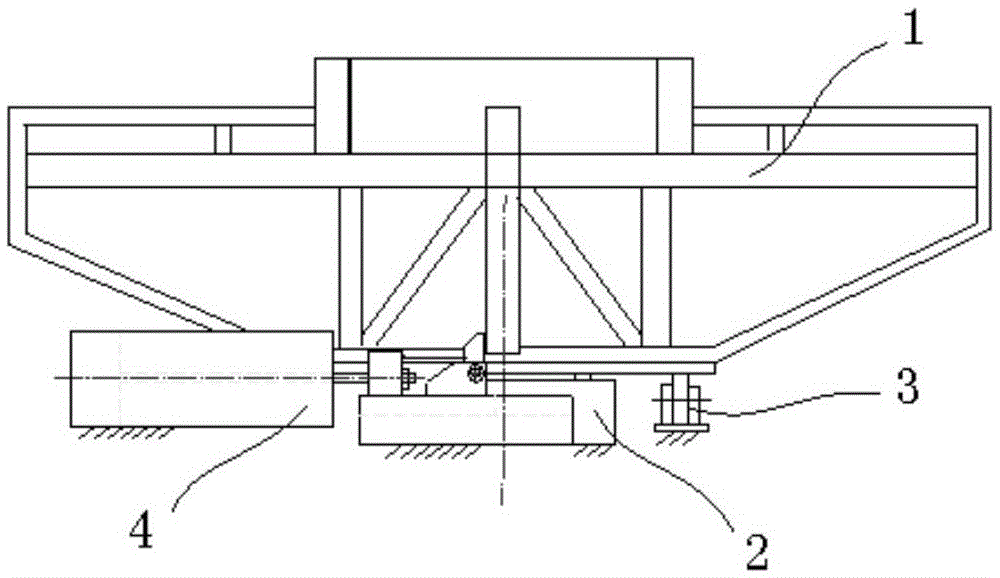

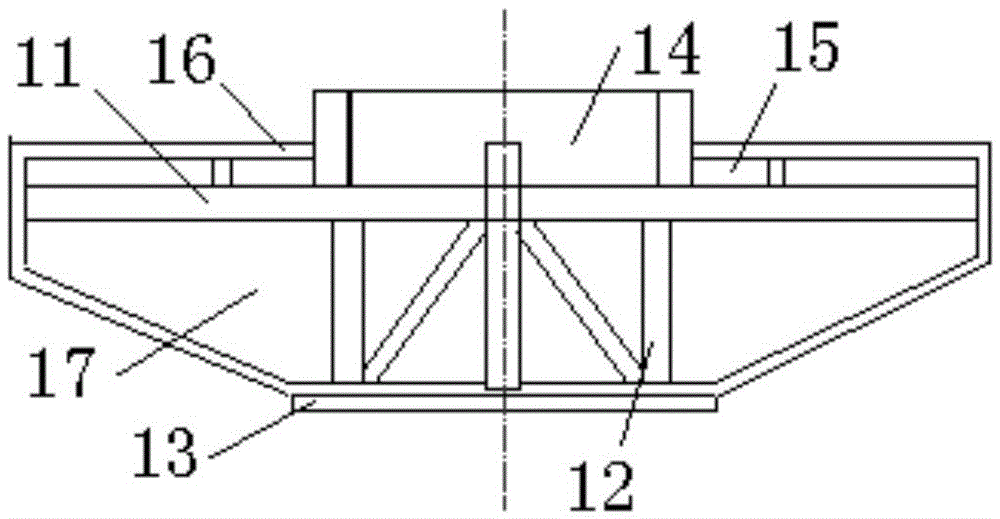

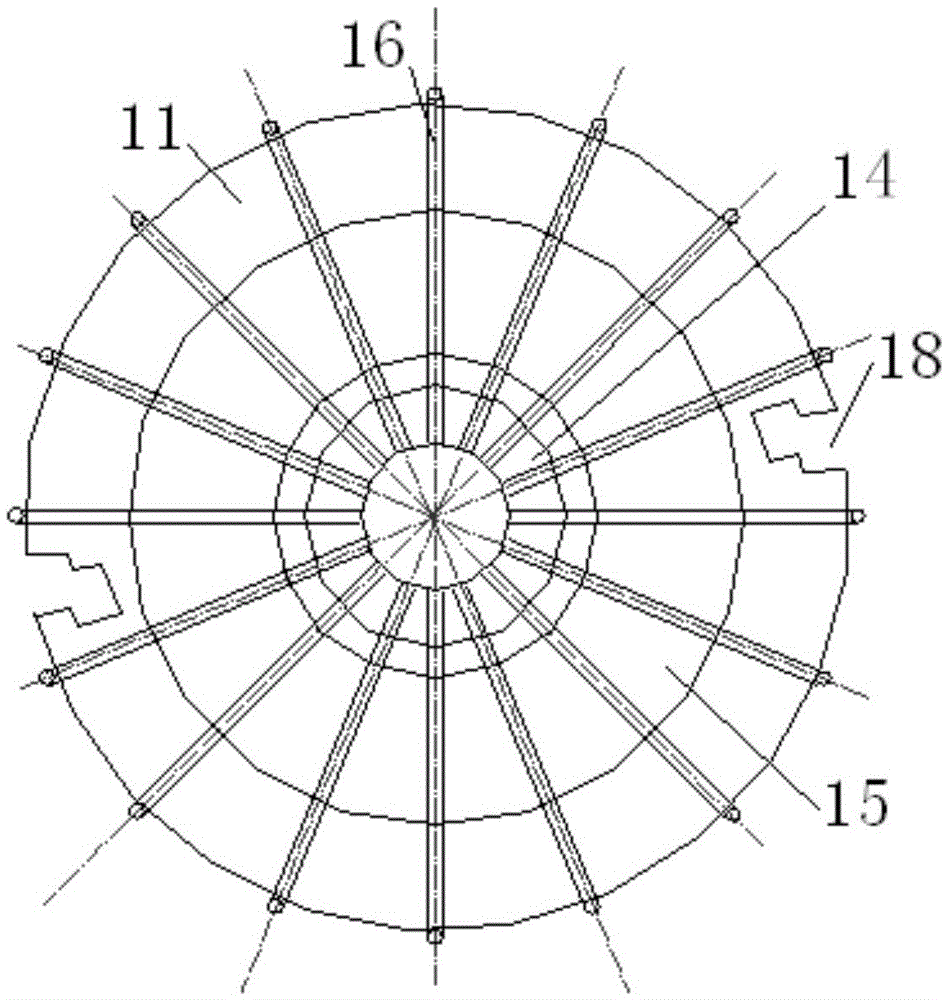

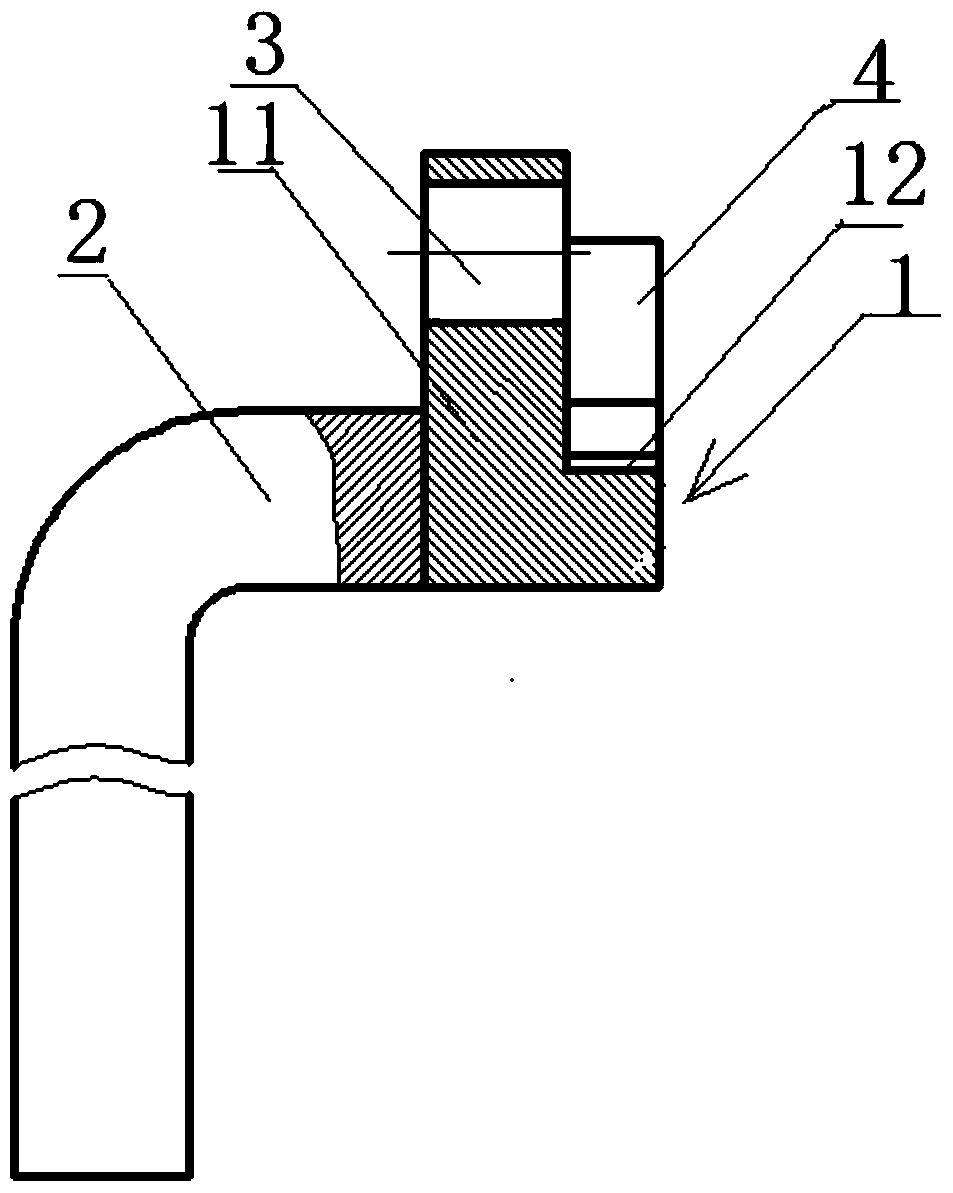

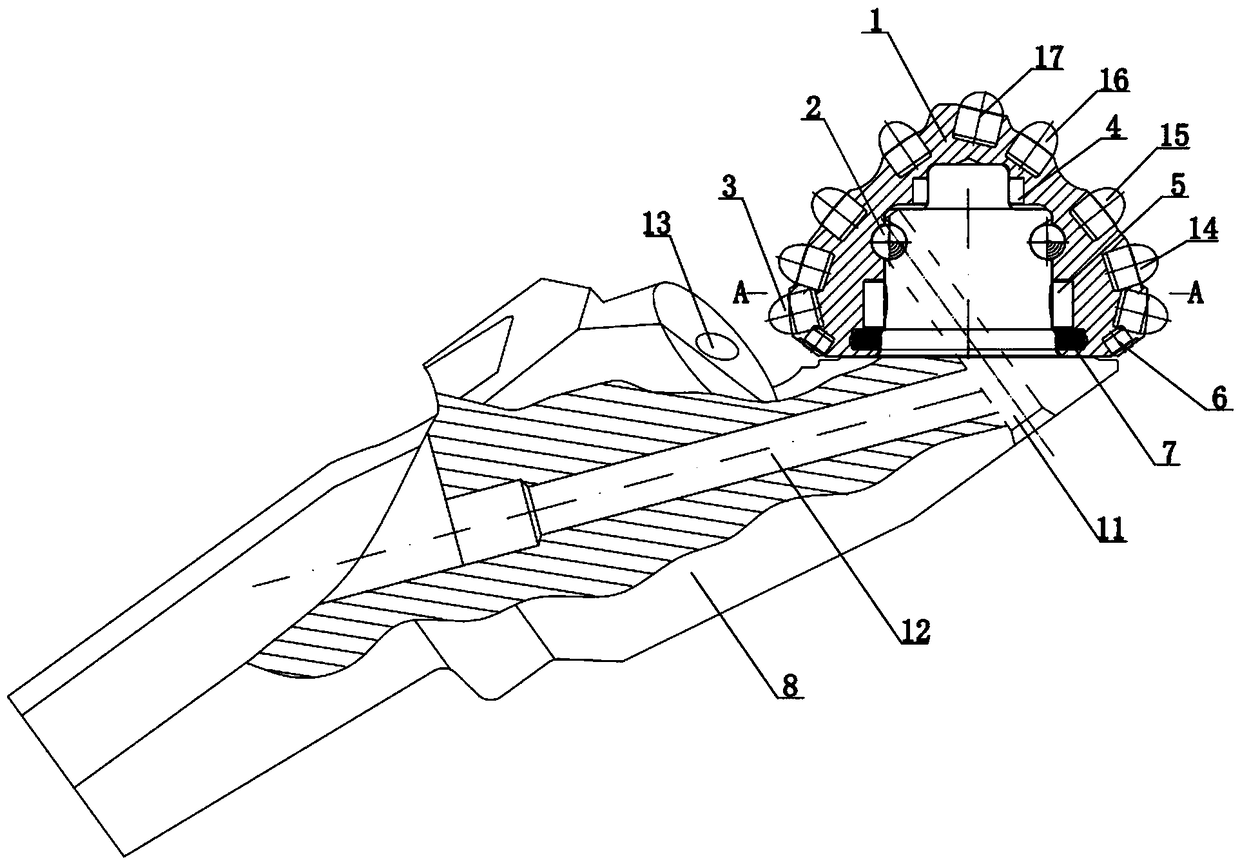

Assembling device and using method thereof for railway vehicle coupler assembly

The invention related to an assembling device and a using method thereof for a railway vehicle coupler assembly. The assembling device comprises a working table, a rotary plate mechanism, a plurality of auxiliary supporting mechanisms and a push arm mechanism; the working table comprises a working table board, a baffle board, a protective board and a plurality of supporting frameworks; the rotary plate mechanism comprises a rotary plate connecting seat, a thrust bearing and a rotary plate base; each auxiliary supporting mechanism comprises a base and a supporting pulley, and the tops of the supporting pulleys are in contact with a bottom plate; the push arm mechanism comprises a translational motion driving device, a horizontal sliding chute and a sliding block, the translational motion driving device is fixed on a foundation, and the sliding block is disposed in the horizontal sliding chute; the top of one end of the sliding block is fixedly connected with a connecting block, and the top of the other end of the sliding block is fixedly connected with a push arm seat; a piston rod is arranged at an output end of the translational motion driving device, and the piston rod is fixedly connected with the connecting block; the push arm seat is rotatably connected with a roughly vertical push arm, and the upper end of the push arm is in contact with bottoms of the supporting frameworks; the push arm is connected with the connecting block through a reset spring, and a connecting point is located on the inner side of the push arm above a rotating shaft.

Owner:CRRC QIQIHAR ROLLING CO LTD

Intelligent equipment for automatic speed control over industrial conveyor belt

ActiveCN110902318AThere will be no lagCaton will not causeConveyorsControl devices for conveyorsControl engineeringControl theory

The invention discloses intelligent equipment for automatic speed control over an industrial conveyor belt. The intelligent equipment comprises a support shaft. Bearing inclined rods are inserted intothe side surface of the support shaft in a penetrating manner. Return springs are fixedly connected to the reverse sides of the two bearing inclined rods. Support springs are fixedly connected to theinner wall of a bearing wheel. A stress plate is fixedly connected to the opposite sides of the two support springs. Rotating shafts are fixedly connected to the two sides where the bearing wheel isdamaged. A transition wheel is fixedly connected to the interior of the bearing wheel through a connecting rod. Centrifugal rods are inserted in the surface of the transition wheel in a penetrating manner, hollow springs are fixedly connected to the opposite sides of the two centrifugal rods, and a water tank is fixedly connected between the two hollow springs. Concave wheels are arranged in the centrifugal rods. According to the intelligent equipment for automatic speed control over the industrial conveyor belt, through matched use of the bearing inclined rods and the stress plate, the effectof preventing the conveyor belt from being jammed when controlling the speed of the conveyor belt is achieved.

Owner:绍兴市华获智能装备有限公司

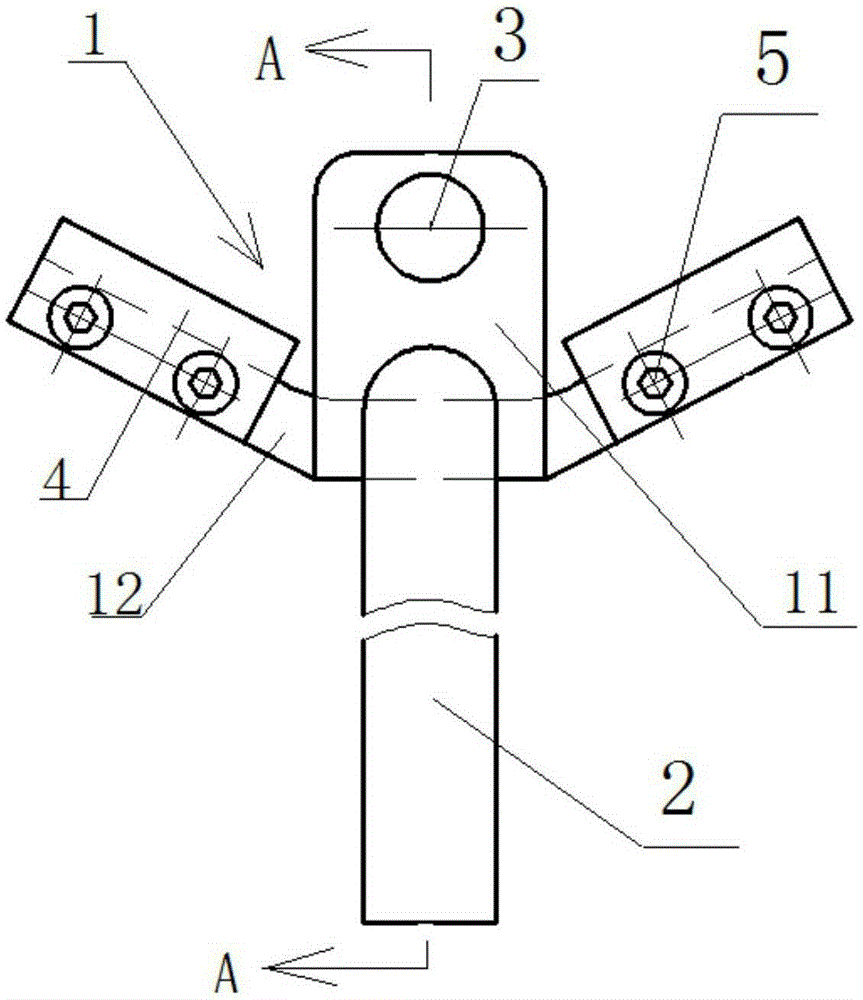

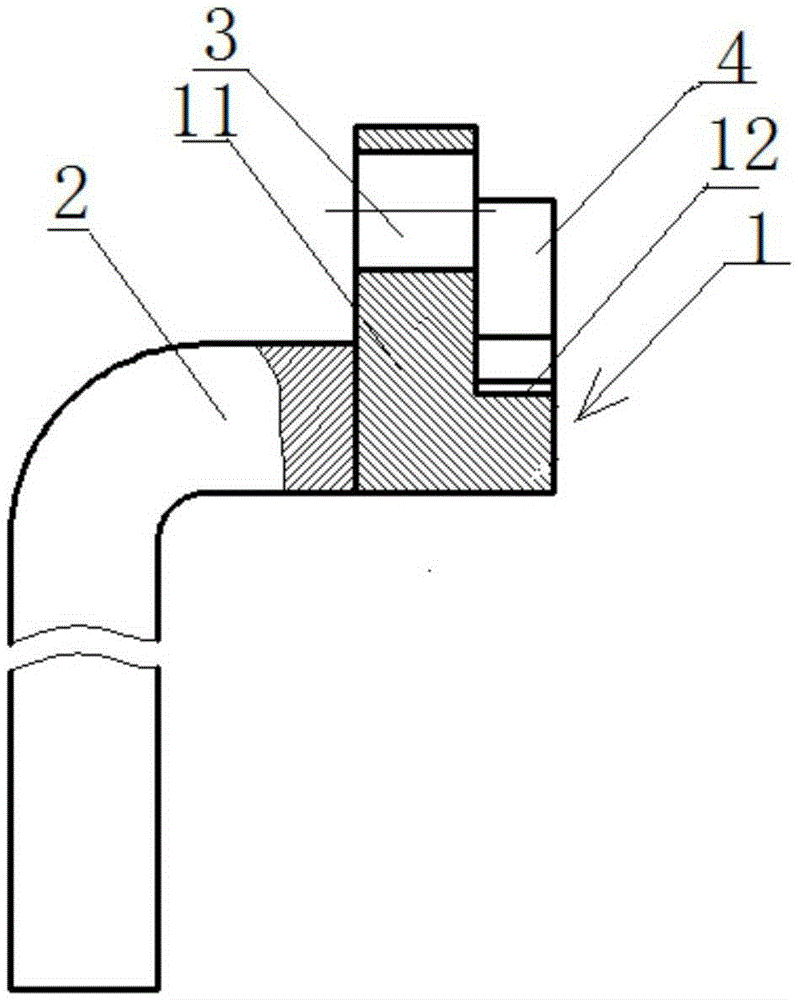

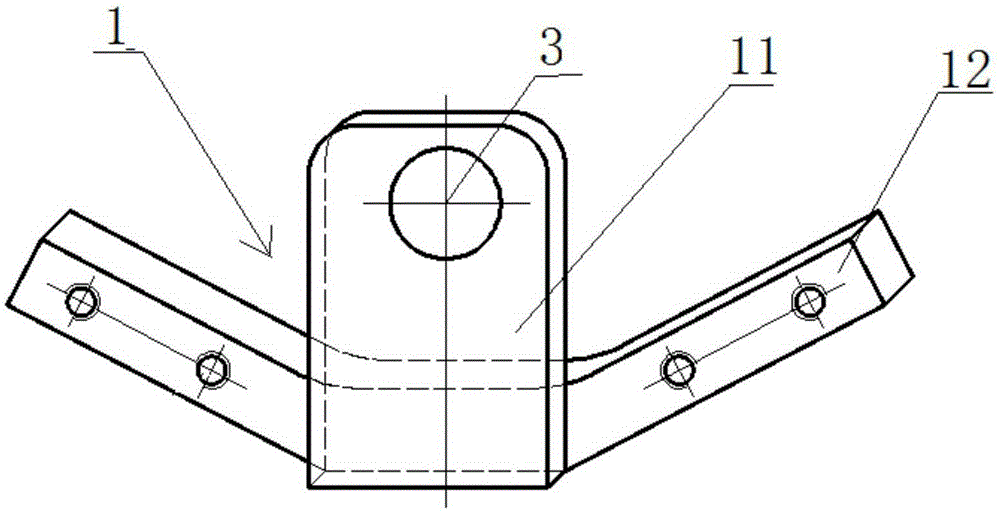

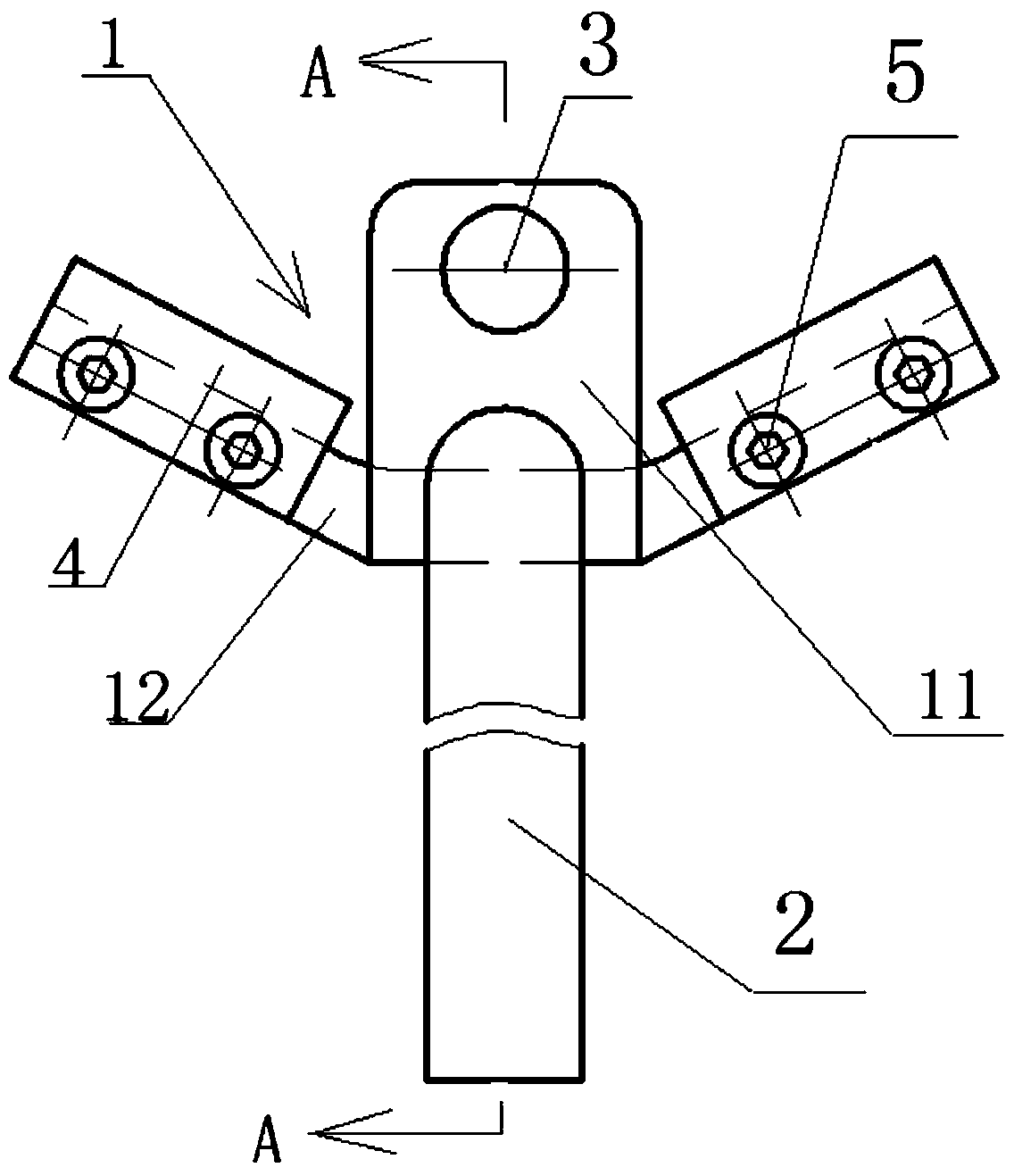

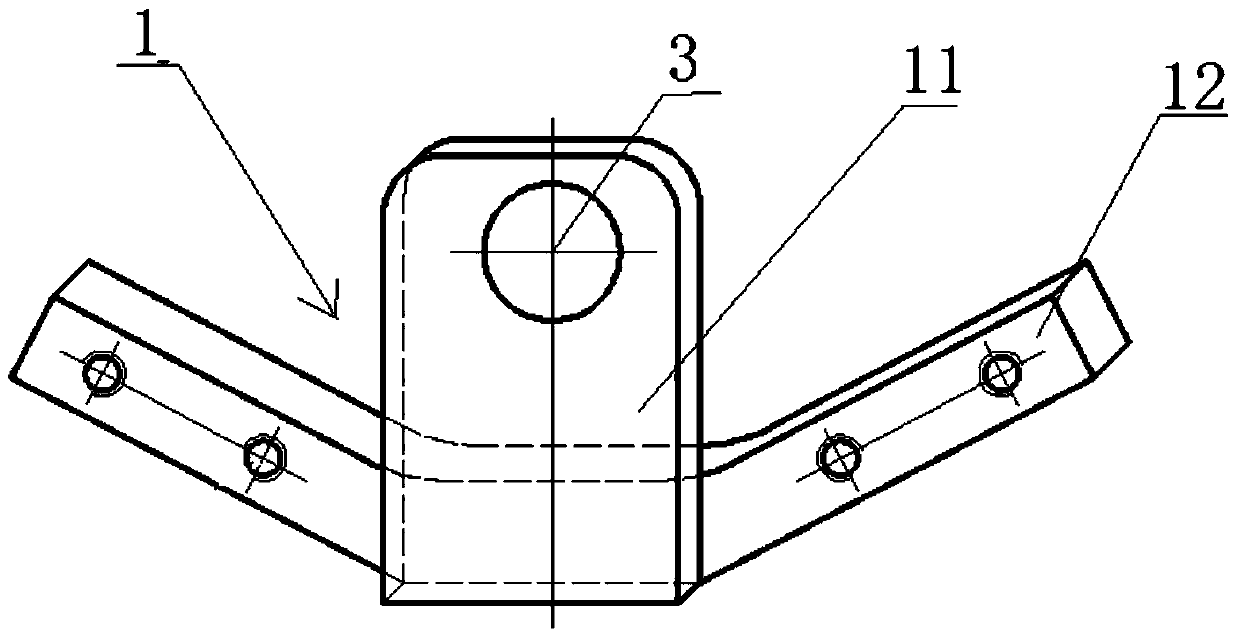

Crankshaft rotation tool and method for rotating crankshaft

ActiveCN105258667ASimple structureEasy to useMeasurement devicesReciprocating piston enginesElastic componentEngineering

The present invention discloses a crankshaft rotation tool, comprising a locating block and a handle connected with the locating block, wherein the locating block comprises a main locating block and two auxiliary locating blocks arranged at two sides of the main locating block, each auxiliary locating block is provided with an elastic component used for being tightly contacted with an excircle of a big end of a crankshaft, and the main locating block is provided with a locating hole used for cooperating with a locating pin at the end face of the big end of the crankshaft. The present invention aims to provide the crankshaft rotation tool which is simple in structure, convenient and reliable in use, and capable of forwards and reversely rotating the crankshaft, at the same time, the present invention also provides a method for rotating the crankshaft by adopting the crankshaft rotation tool.

Owner:GUANGXI YUCHAI MASCH CO LTD

Building board cutting device

The invention discloses a building board cutting device. The device comprises a workbench. A framework is fixed to the top of the workbench. A hydraulic cylinder is fixedly arranged at the bottom of the framework. A cutter is fixedly arranged at the bottom of the hydraulic cylinder. Movable clamping plates are arranged in the positions, corresponding to the two sides of the bottom of the cutter, of the workbench correspondingly. Electric push rods are fixedly arranged on the outer sides of the movable clamping plates correspondingly and fixedly connected with the workbench. Each movable platecomprises a bottom plate and a top plate, wherein the top plate is arranged on the outer side of the top of the bottom plate. Caulking grooves are formed in the tops of the bottom plates, gliding feetare arranged at the four corners of the bottoms of the bottom plates correspondingly, and driving rollers are arranged in the caulking grooves correspondingly. According to the building board cuttingdevice, the width size is input through a touch display screen, accordingly, a PLC controls the whole distance of moving of the movable clamping plates pushed by the electric push rods, whatever thewidth of a board is, the driving rollers can convey the board, the electric push rods only need to be controlled to adapt to boards with different widths, application is convenient, conveying and cutting work can be performed at the same time, and the practicability is higher.

Owner:江苏金弘建筑科技有限公司

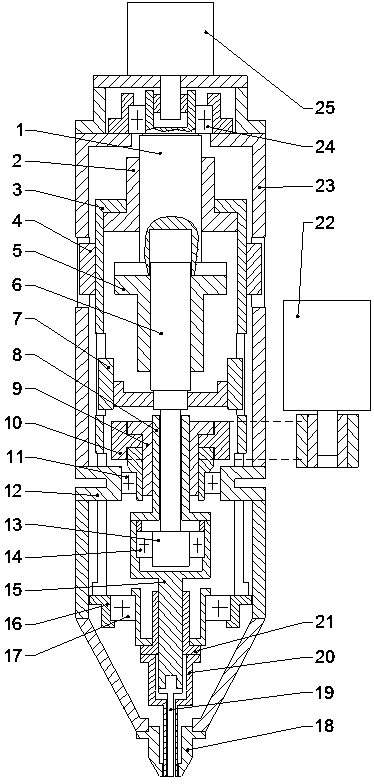

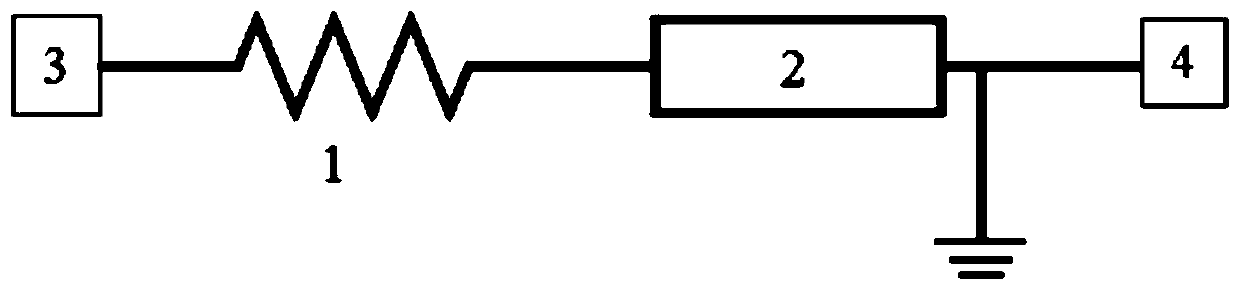

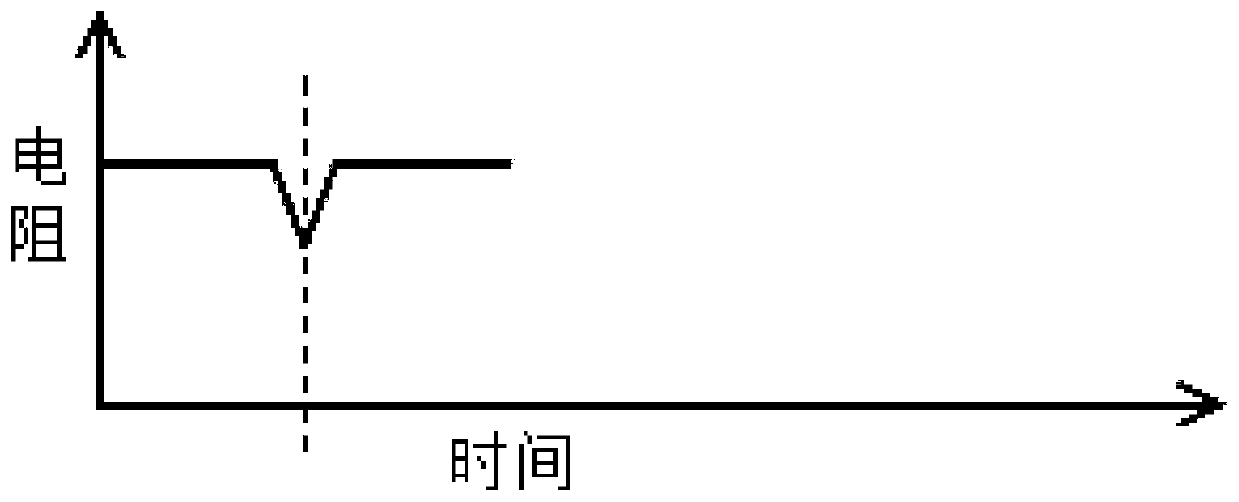

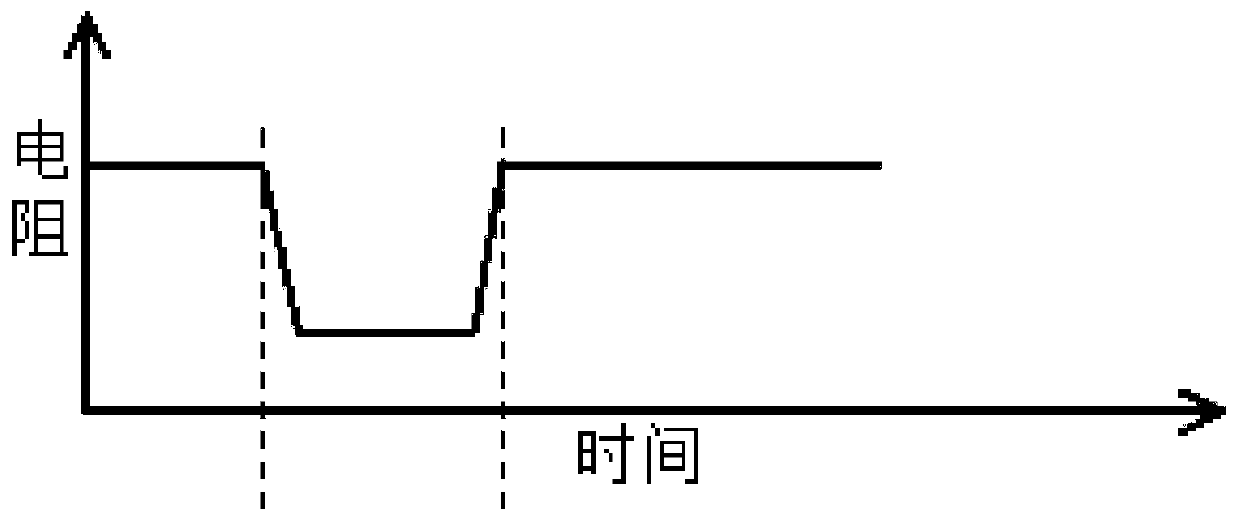

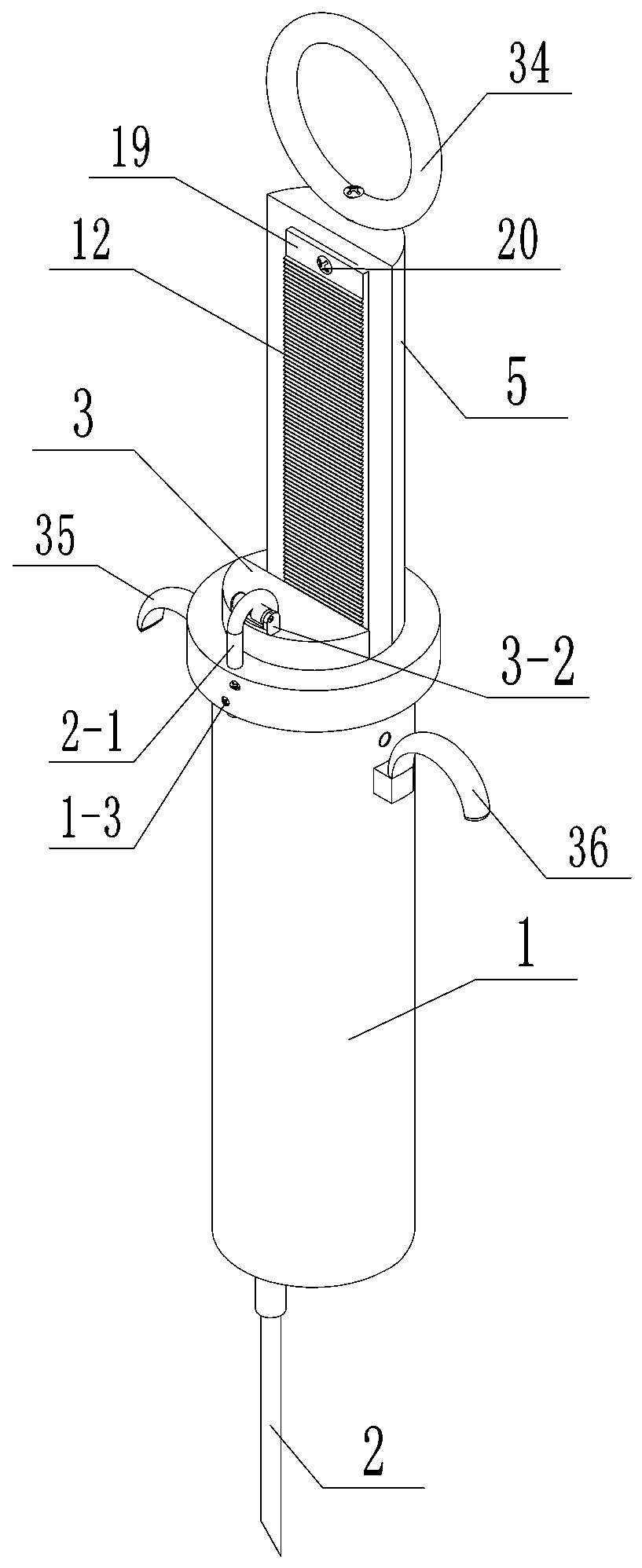

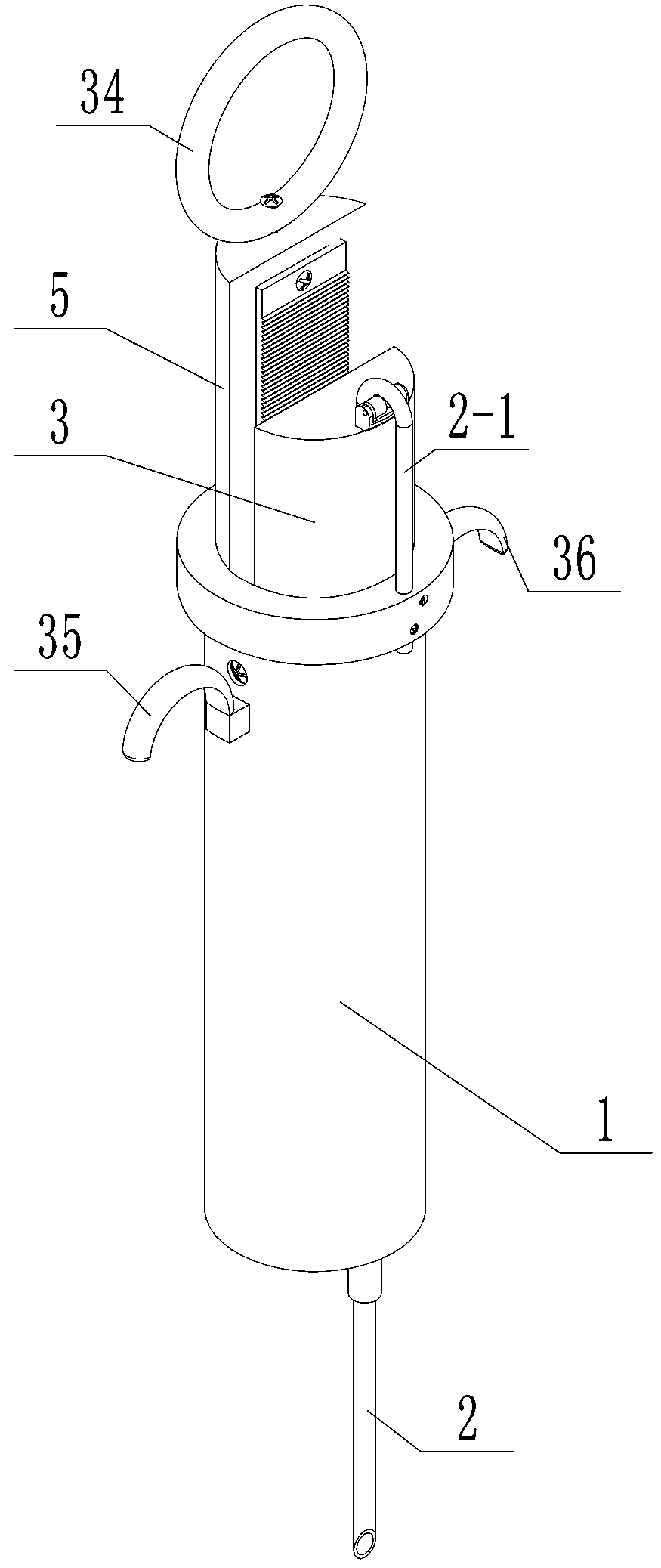

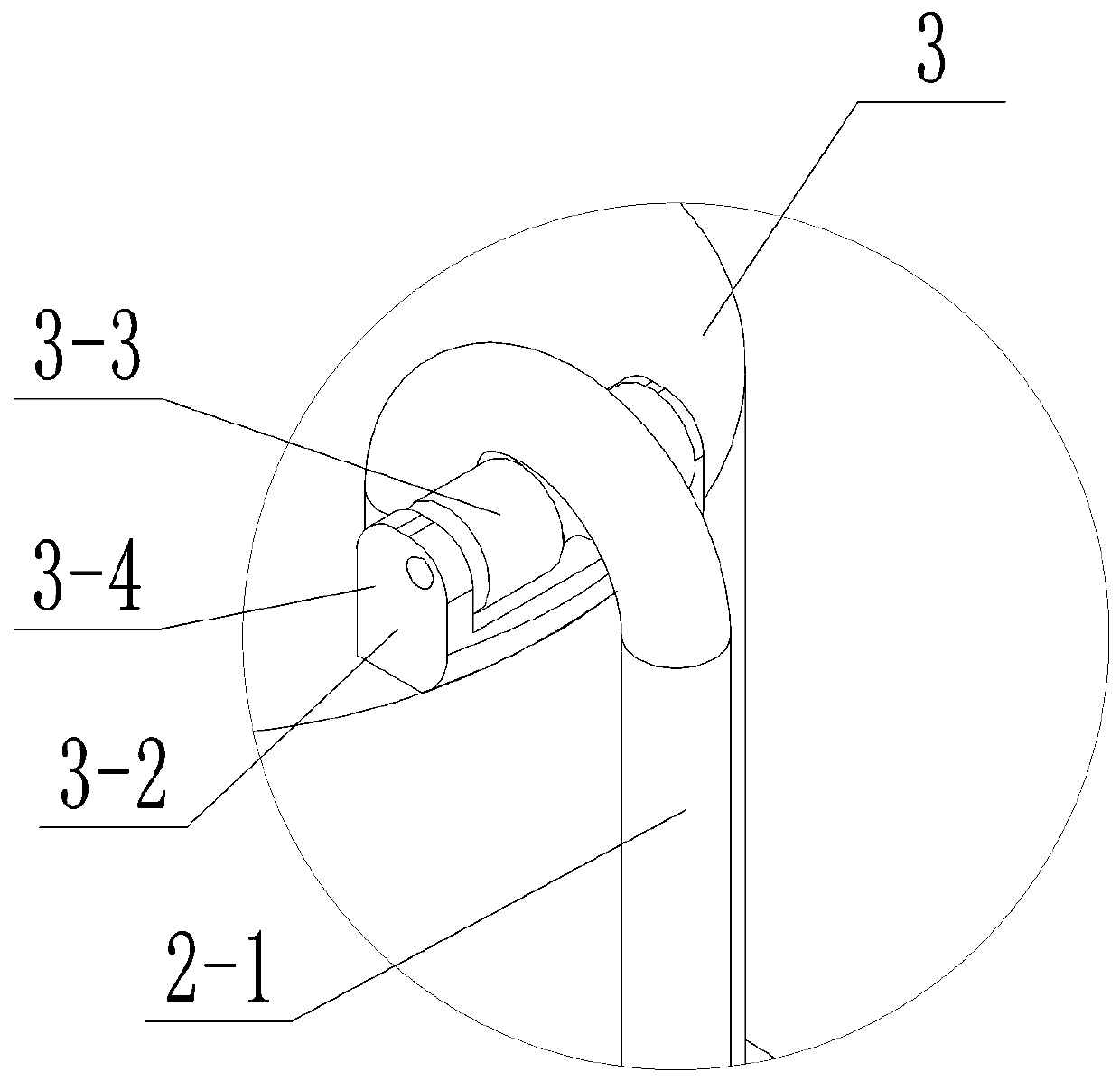

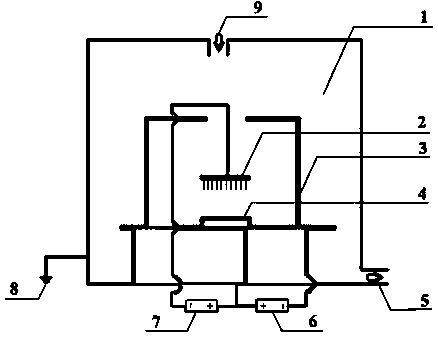

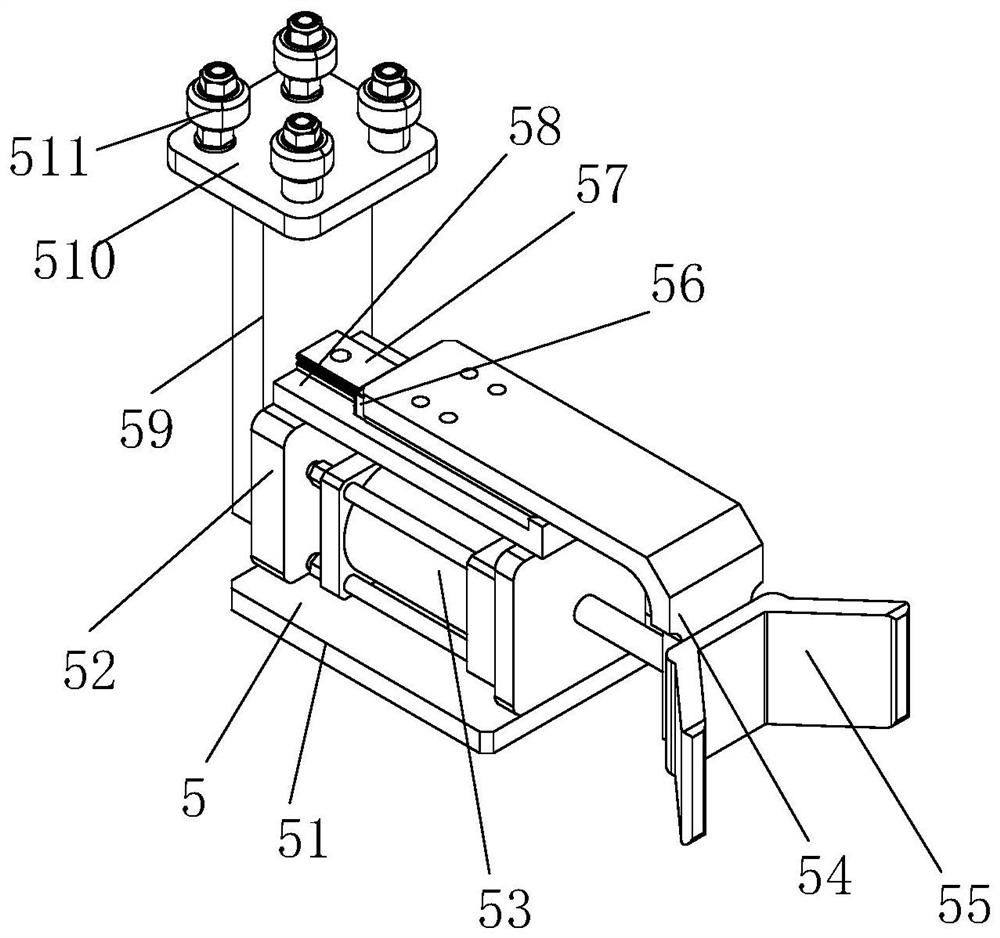

Device for needle core withdrawing together with vacuum suction in one-handed performance for puncture biopsy

PendingCN109965915ASmooth rotationFrictional stabilitySurgical needlesVaccination/ovulation diagnosticsPuncture BiopsyEngineering

The invention discloses a device for needle core withdrawing together with vacuum suction in one-handed performance for puncture biopsy, including a tube body, a hollow puncture needle, a flexible puncture needle core, a piston rod, a rubber piston sleeve, a piston driving rod and a gear component; a division plate divides the space in the tube body into a piston rod socket and a piston driving rod socket, the puncture needle is mounted on a needle connection tube, the piston rod includes piston rod teeth, the piston driving rod includes piston driving rod teeth, the piston rod is provided with a piston rod needle core socket, the rubber piston sleeve is provided with a rubber piston sleeve needle core socket, a tube body needle core socket and tube body needle core thread holes are arranged on the tube body, tube body needle-core clamping screws are arranged on the tube body needle-core thread holes, and a needle core guide pulley device is arranged on the piston rod. Therefore, lifting and thrusting of the puncture needle can be realized, and the puncture needle core withdrawing together with vacuum suction can be carried out at the same time.

Owner:THE SECOND HOSPITAL AFFILIATED TO WENZHOU MEDICAL COLLEGE

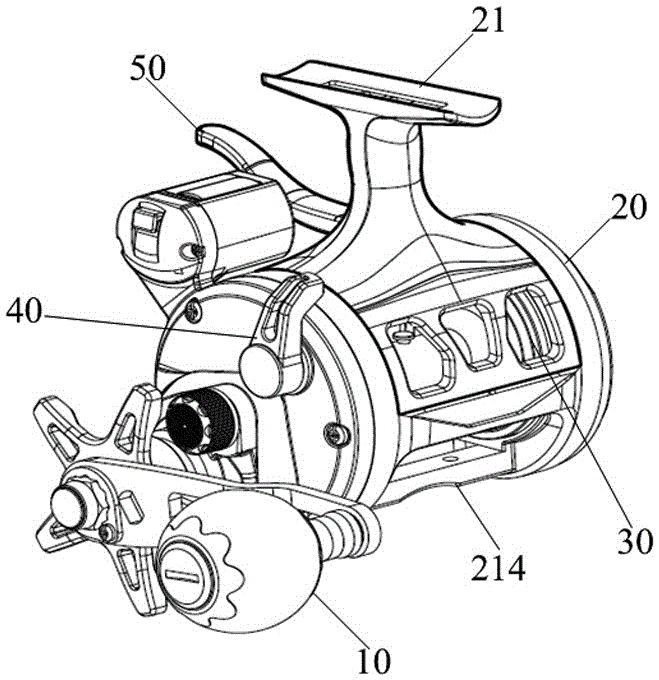

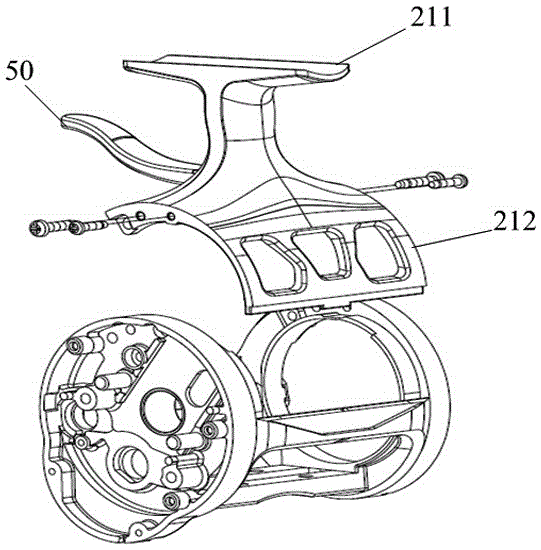

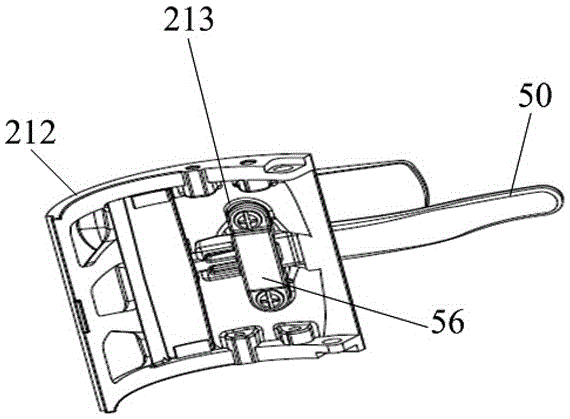

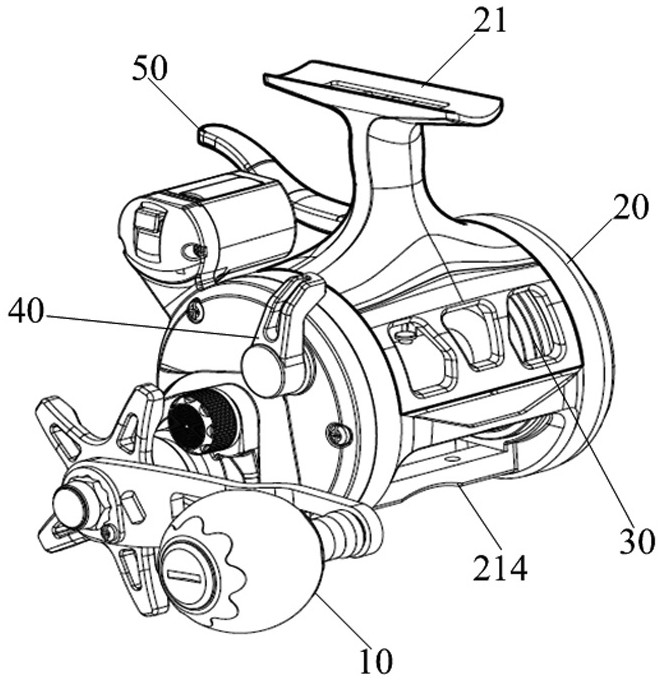

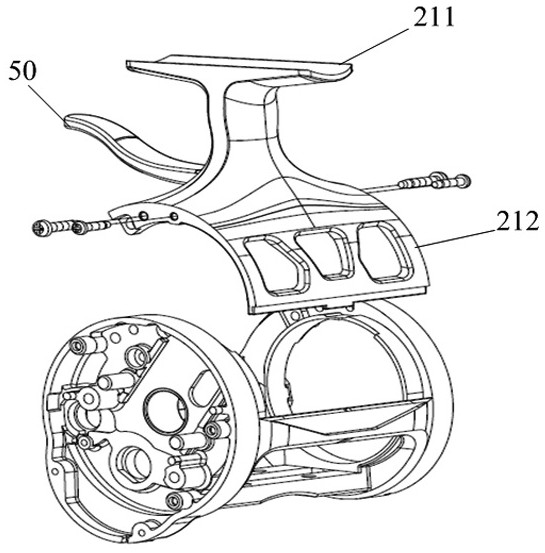

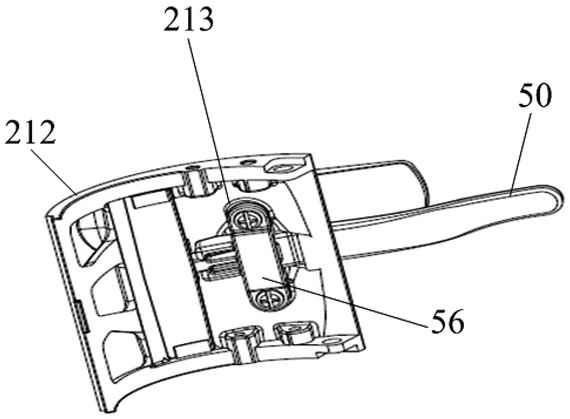

Double-disc type movable hand brake fishing line reel

The invention provides a double-disc type movable hand brake fishing line reel. The double-disc type movable hand brake fishing line reel comprises a rocker rotating part, a body part, a line winding part and a brake part, and further comprises a body support part and a wrench part. The body support part is connected with the body part, and the wrench part is connected with the body support part. The wrench part comprises a wrench, a wrench spring, a wrench bolt, a brake drum bolt and a brake drum part, the wrench comprises a pressing part, a supporting hole part, a protruding part and a drum pin hole, the pressing part, the supporting hole part and the protruding part are connected in sequence, and the protruding part and the drum pin hole are connected. The wrench spring is connected with the supporting hole part, the wrench bolt is connected with the supporting hole part in an inserted mode, the wrench bolt is connected with the wrench spring is a penetrating mode, and the wrench spring is limited in the supporting hole part. The brake drum part and the wrench are connected through the brake drum bolt. Supporting spring lines at the two ends of the wrench spring are connected with the supporting hole part and the body support part respectively. The double-disc type movable hand brake fishing line reel is diversified, a soft brake pad is in stable contact and friction with a line reel body, damage to the line reel body can be avoided, and the product service life can be prolonged.

Owner:NINGBO ZHONGYUAN ALLJOY FISHING TACKLE

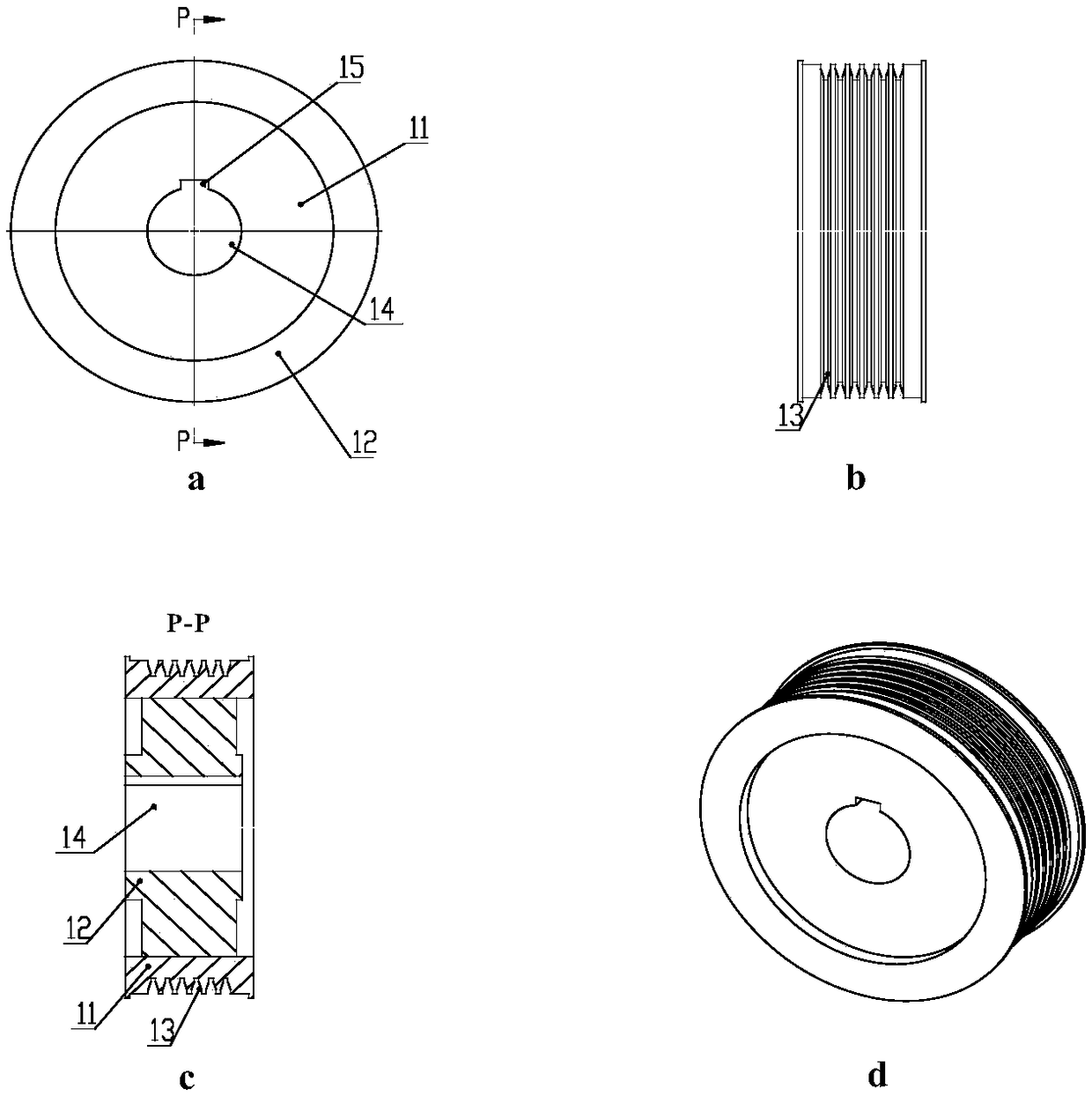

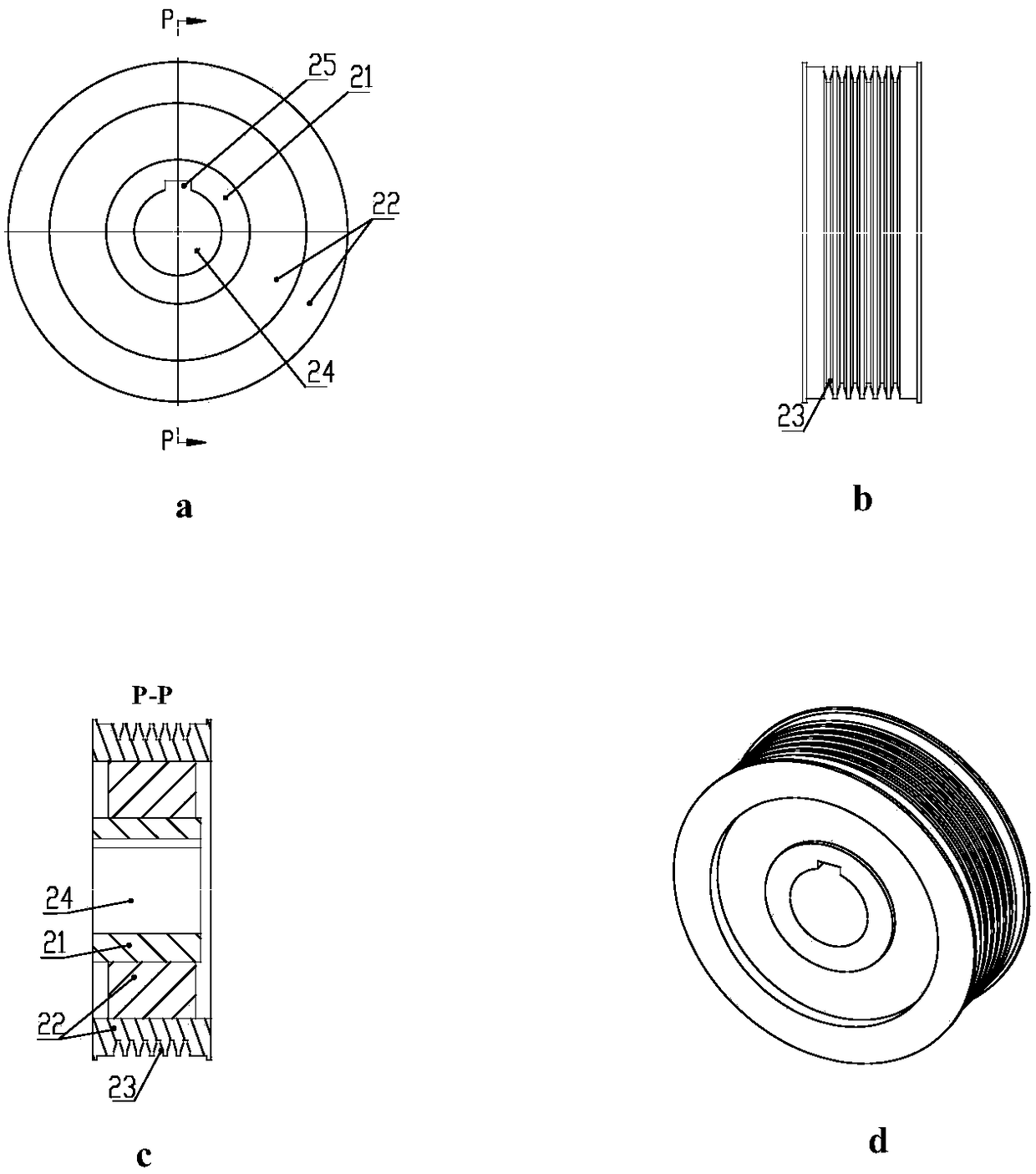

Traction wheel structure

PendingCN108657915AIncrease coefficient of frictionIncrease frictionBuilding liftsTraction systemMetallic materials

The invention provides a traction wheel structure which comprises a traction wheel connecting body provided with an outer circle working face. The traction wheel connecting body is made of a metal material. The traction wheel structure is characterized by further comprising a composite material layer. The composite material layer is arranged on the outer circle working face of the traction wheel connecting body and forms a traction wheel groove or a traction wheel face. In an existing traction system, abrasion to the contact face between a traction rope or a traction belt and a traction rope groove or a traction belt is inconsistent, the phenomenon of severe uneven abrasion is usually caused, the life of the traction rope or the traction belt and the traction wheel is influenced, the safety risk is brought to an elevator, and the cost is high. According to the traction wheel structure, the equivalent friction coefficient of the surface of the traction wheel can be improved remarkably,comprehensive properties of abrasion resistance, strength, toughness and the like are improved, the diameter of the traction wheel rope or the traction belt and the traction wheel is reduced, the weight of the traction system is reduced, and the miniaturization design of the elevator traction system and the whole elevator is achieved.

Owner:HANGZHOU HUNING ELEVATOR PARTS CO LTD

Double Disc Active Handbrake Fishing Reel

The invention provides a double-disc type movable handbrake fishing reel, which includes a rocker rotating part, a main body part, a reel and a brake part, as well as a main body bracket part and a wrench part, the main body bracket part and the main body part are connected, and the wrench part and the The main body bracket part is connected; the wrench part includes a wrench, a wrench spring, a wrench pin, a brake drum pin and a brake drum part; The parts are connected in sequence, the protruding part is connected with the drum pin hole; the spanner spring is connected with the support hole, the spanner pin is inserted into the connection support hole, the spanner pin is inserted into the connection spanner spring, and the spanner spring is limited to the support hole; the brake drum The spring part and the wrench are connected by the brake drum pin; the support spring wires at both ends of the wrench spring are respectively connected to the support hole part and the main body bracket part. The products of the invention are diversified, and the flexible brake pads stably contact and rub against the reel, so that the reel will not be damaged, and the service life of the product is improved.

Owner:NINGBO ZHONGYUAN ALLJOY FISHING TACKLE

An assembly device composed of railway vehicle couplers and its use method

Owner:CRRC QIQIHAR ROLLING CO LTD

A method for improving the strength and toughness of titanium-aluminum-nitrogen coating on the surface of cemented carbide

ActiveCN109338319BImprove toughnessAvoid generatingVacuum evaporation coatingSputtering coatingHigh fractureSputter cleaning

The invention discloses a method for improving the high toughness of a titanium aluminum nitrogen coating on the surface of a hard alloy. The method comprises the following steps of placing a pretreated hard alloy sample onto a double-glow plasma surface alloying furnace sample table, suspending a self-made target material, and placing an auxiliary cathode; feeding argon after vacuumizing, applying high voltage to a cathode and a source electrode, maintaining a certain differential pressure, carrying out tantalum impregnation treatment on the sample after re-sputter cleaning; then taking a tantalum-impregnated sample out, loading onto a substrate table of a magnetron sputtering device, installing a titanium aluminum composite target, adjusting the distance between the target material and the sample, carrying out ion beam sputtering cleaning, then enabling the substrate table to directly face a direct-current pulse magnetron sputtering target, feeding argon and nitrogen, adjusting to acertain proportion, starting a grid bias power supply and a direct-current pulse power supply, and preparing the titanium aluminum nitrogen coating. The titanium aluminum nitrogen composite coating prepared through the method has high fracture toughness and bonding strength.

Owner:TAIYUAN UNIV OF TECH

Crankshaft turning tool and method of turning a crankshaft

ActiveCN105258667BSimple structureEasy to useMeasurement devicesReciprocating piston enginesElastic componentEngineering

The present invention discloses a crankshaft rotation tool, comprising a locating block and a handle connected with the locating block, wherein the locating block comprises a main locating block and two auxiliary locating blocks arranged at two sides of the main locating block, each auxiliary locating block is provided with an elastic component used for being tightly contacted with an excircle of a big end of a crankshaft, and the main locating block is provided with a locating hole used for cooperating with a locating pin at the end face of the big end of the crankshaft. The present invention aims to provide the crankshaft rotation tool which is simple in structure, convenient and reliable in use, and capable of forwards and reversely rotating the crankshaft, at the same time, the present invention also provides a method for rotating the crankshaft by adopting the crankshaft rotation tool.

Owner:GUANGXI YUCHAI MASCH CO LTD

Sports shoes double-row buckle

The invention provides a sports shoes double-row buckle. The surface of a sports shoe is provided with an inner row buckle and an outer row buckle capable of lacing the lace through the buckles. Whenwearing and using the sports shoes, the double-row buckle can be used to better bind up the shoes to match the feet, thus the supporting, stretching, twisting and rubbing in movement can be more stable.

Owner:杨伞

High-precision low-friction magnetic suspension sliding composite guid rail

InactiveCN100530932CSimple structureFrictional stabilityInstrumental componentsLarge fixed membersPositive pressureEngineering

Owner:HEFEI UNIV OF TECH

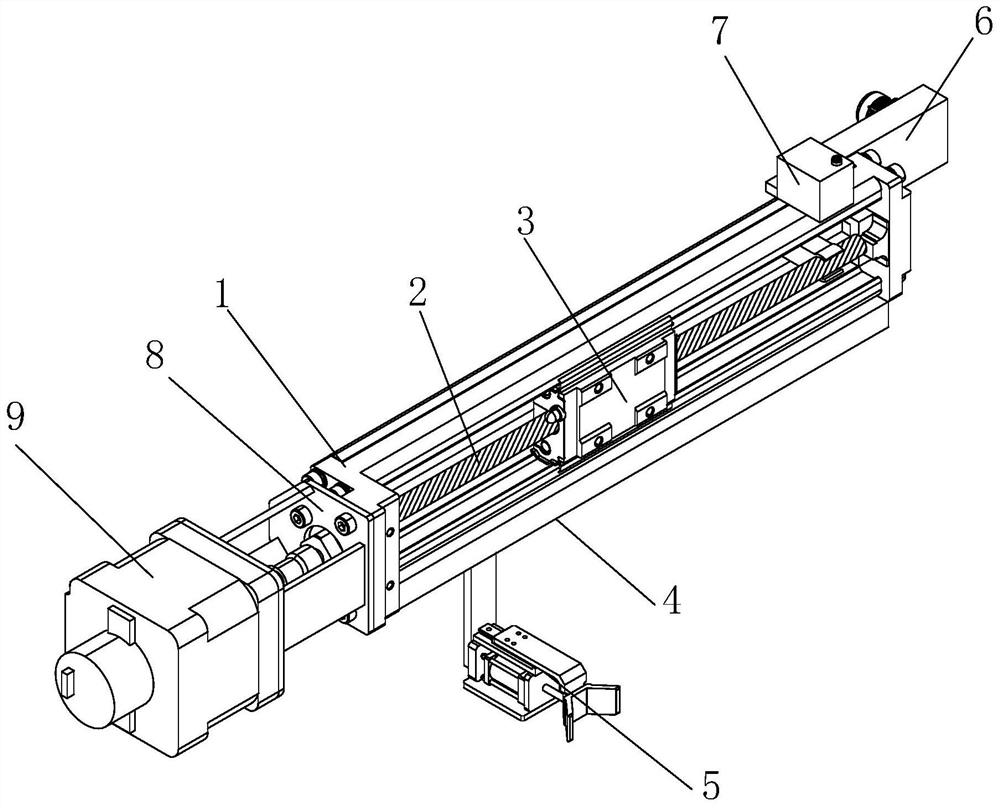

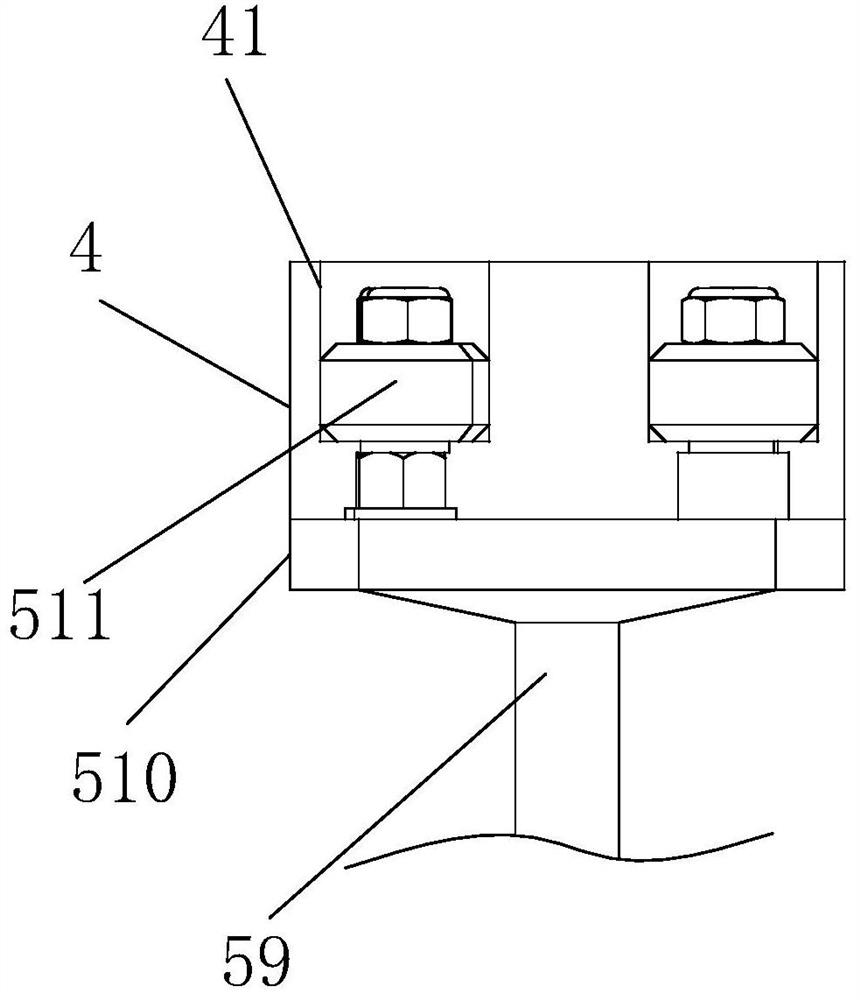

Telescopic conveying mechanism of pipeline burying device for water conservancy project

PendingCN112879658AStrong stabilityStable lubricationPipe laying and repairPush outEnvironmental geology

The invention discloses a telescopic conveying mechanism of a pipeline burying device for a water conservancy project. The telescopic conveying mechanism of the pipeline burying device for the water conservancy project comprises a fixing piece, a lead screw, a sliding block, a bottom plate, a supporting device, a pushing device and an oil outlet mechanism. According to the telescopic conveying mechanism of the pipeline burying device for the water conservancy project, the supporting device is installed at the bottom of the bottom plate, an air cylinder is installed in the supporting device, the air cylinder drives a sliding piece at the front end to be pushed out, the supporting piece at the front end can make contact with an external clamping mechanism supporting arm to stably support the external clamping mechanism supporting arm, a guide wheel is installed at the upper end of the supporting device, the guide wheel can slide at the lower end in the bottom plate, the guide wheel is matched with a moving clamping mechanism to slide and continuously support the clamping mechanism, and stability is high; and the oil outlet mechanism is installed at the right end of the top of the fixing piece, the pushing device is installed at the right end of the back face of the fixing piece, an oil outlet mechanism shell stores lubricating oil and discharges the lubricating oil into a lubricating mechanism connected with the front end of the pushing device, the lubricating mechanism makes contact with the lead screw, the lubricating mechanism achieves reciprocating motion under the action of the pushing device, and the screw rod is efficiently and stably lubricated.

Owner:泉州泉港创鹏工业设计有限公司

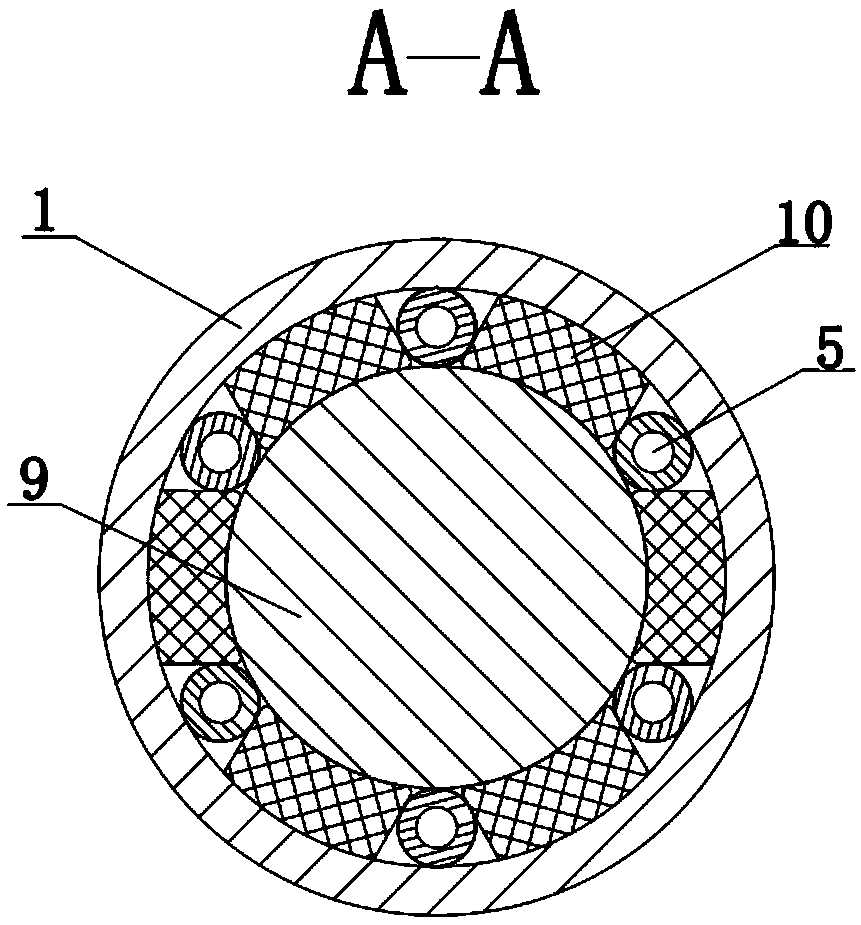

A long-life composite drill bit for repairing damaged casing wells

ActiveCN107620571BIncrease speedGuaranteed lifeDrill bitsRotary combination bearingsContact pressureHigh heat

The invention relates to a long-service-life composite drill bit for repairing a casing damaged well. The long-service-life composite drill bit for repairing the casing damaged well is mainly composedof a plurality of rows of teeth, a rolling and sliding composite bearing, a sealing combination, a tooth palm body, a water hole and the like. The lower portion of the rolling and sliding composite bearing adopts a hollow roller structure, and the rolling and sliding composite bearing has the high heat dissipation capability, and can operate at a high speed. A rubber slide block is low in abrasion speed, and reduction of the contact pressure on a shaft neck is facilitated. The sealing combination has the advantages that rotary sealing, axial and radial sealing are achieved. The rolling and sliding composite bearing can bear the high revolution speed and high load, and has a high impact resistant property, and thus the bearing service life of the composite drill bit under the conditions ofthe high revolution speed and the medium and high drilling pressure is ensured. The revolution speed of the composite drill bit is increased, and the rotary sealing and axial and radial sealing effects are outstanding. The service life of the bearing under the dynamic load is longer than that under the maximal loading capacity, compared with a homogeneous composite drill bit for well repairing, the rubber slide block is arranged, and thus the bearing is prevented from being rapidly abraded.

Owner:SOUTHWEST PETROLEUM UNIV

Lubricating oil containing illite/montmorillonite clay nano powder and preparation method thereof

InactiveCN103589478BAvoid direct contactEasy to coverAdditivesPigment treatment with macromolecular organic compoundsMontmorilloniteSlurry

The invention discloses a lubricating oil containing illite / montmorillonite clay nano powder and a preparation method thereof, belonging to the field of new application of phyllosilicate clay minerals. The lubricating oil is composed of oleic acid modified illite / montmorillonite clay nano powder and III type base oil, wherein the oleic acid modified illite / montmorillonite clay nano powder accounts for 0.5-2.5 wt% of the lubricating oil. The preparation method comprises the following steps: (1) crushing natural illite / montmorillonite clay minerals, and adding water to obtain a slurry; (2) regulating the pH value of the slurry, and dispersing; (3) screening the slurry through a sieve; (4) grinding the undersieve slurry to obtain a nano slurry; (5) adding oleic acid for modification; (6) drying the modified nano slurry to obtain nano dry powder; and (7) mixing the nano dry powder with III type base oil to obtain the lubricating oil containing illite / montmorillonite clay nano powder. By using the illite / montmorillonite clay nano powder as the additive, the lubricating oil has the advantages of favorable friction and wear resistance, environment friendliness and no pollution.

Owner:SOUTH CHINA UNIV OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com