Electric brush for ABS system and preparation method thereof

A technology of anti-lock braking system and electric brush, which is applied in the direction of brush manufacturing, circuit, current collector, etc., to achieve low noise, ensure normal and safe use, and smooth friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] This brush for ABS braking anti-lock braking system includes a brush body and lead wires, and the brush body includes ultrafine electrolytic copper powder, cementing powder, modifier, ultrafine electrolytic copper powder, cementing powder, modifier The weight ratio is: 46 to 52 parts of ultrafine electrolytic copper powder, 52 to 46 parts of cementing powder, and 2 parts of modifier; the cementing powder includes high-purity carbon fiber powder, artificial graphite powder, high-purity sub-nanometer graphite powder, crystal Graphite powder, graphitized carbon black powder, rare earth tungsten disulfide composite material, high temperature resistant phenolic resin, the weight ratio is as follows:

[0040] High-purity carbon fiber powder 1.0-3.0 parts,

[0041] 23-27 parts of artificial graphite powder,

[0042]25-35 parts of high-purity sub-nanometer graphite powder,

[0043] 18-22 parts of crystal graphite powder,

[0044] 3-8 parts of graphitized carbon black powder,...

Embodiment 2

[0073] cementing powder preparation

[0074] 1. Preparation of cementing powder and modifier

[0075] ① The preparation process of cementing powder is the same as that in Example 1.

[0076] ② The ratio of each component of cementing powder is:

[0077] 1.0 parts of high-purity carbon fiber powder,

[0078] 23 parts of artificial graphite powder,

[0079] 25 parts of high-purity sub-nanometer graphite powder,

[0080] 18 parts of crystal graphite powder,

[0081] 3 parts of graphitized carbon black powder,

[0082] Rare earth tungsten disulfide composite material 2.5 parts,

[0083] High temperature resistant phenolic resin 5 parts.

[0084] ③ The ratio of each component of the modifier is:

[0085] 0.20 parts of silver sulfide powder,

[0086] 0.20 parts of antimony powder,

[0087] Zinc powder 0.5 parts.

[0088] 2, the molding powder preparation and follow-up process are the same as embodiment one.

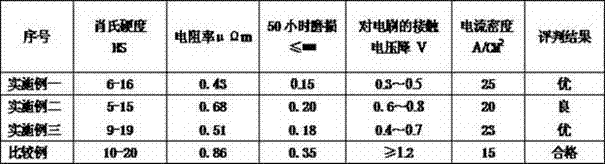

[0089] The results of the final product are shown in Table 1 a...

Embodiment 3

[0091] cementing powder preparation

[0092] 1. Preparation of cementing powder and modifier

[0093] ① The preparation process of cementing powder is the same as that in Example 1.

[0094] ② The ratio of each component of cementing powder is:

[0095] 3.0 parts of high-purity carbon fiber powder,

[0096] 27 parts of artificial graphite powder,

[0097] 35 parts of high-purity sub-nanometer graphite powder,

[0098] 22 parts of crystal graphite powder,

[0099] 8 parts of graphitized carbon black powder,

[0100] Rare earth tungsten disulfide composite material 4.5 parts,

[0101] High temperature resistant phenolic resin 15 parts.

[0102] ③ The ratio of each component of the modifier is:

[0103] 1.30 parts of silver sulfide powder,

[0104] Antimony powder 1.5 parts,

[0105] Zinc powder 1.5 parts.

[0106] 2, the molding powder preparation and follow-up process are the same as embodiment one.

[0107] The results of the final product are shown in Table 1 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com