A long-life composite drill bit for repairing damaged casing wells

A composite drill bit, long-life technology, used in drill bits, earth-moving drilling, drilling equipment, etc., can solve the problems of increased tooth impact, grinding out casing, fast wear speed, etc., to reduce the temperature generated by friction, prevent Fast wear and improved overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and examples.

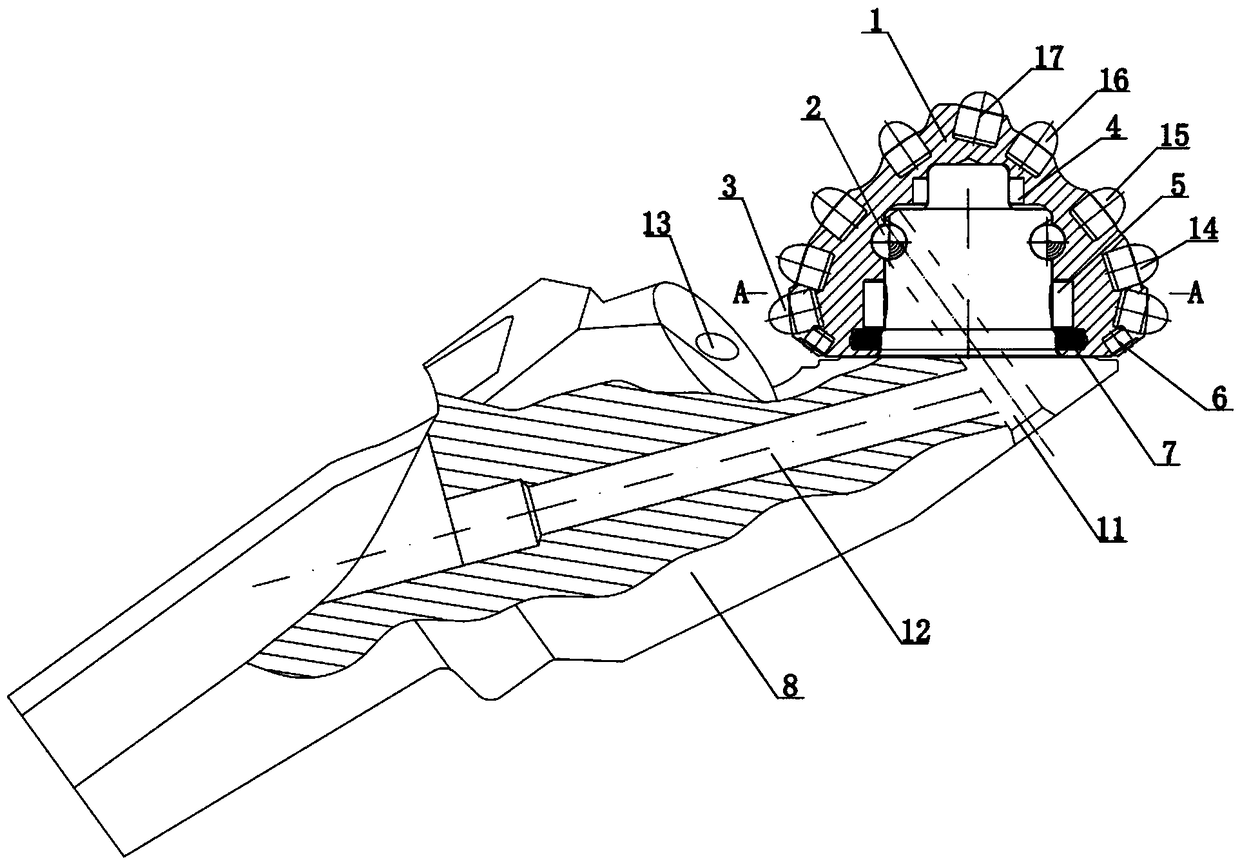

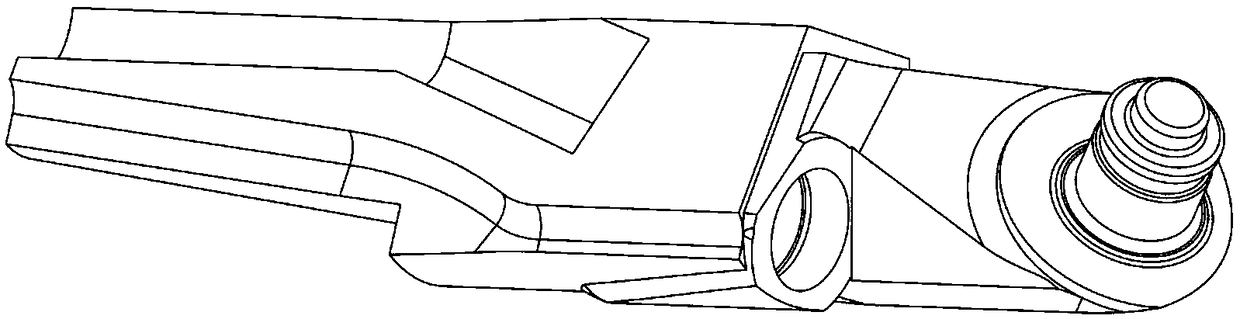

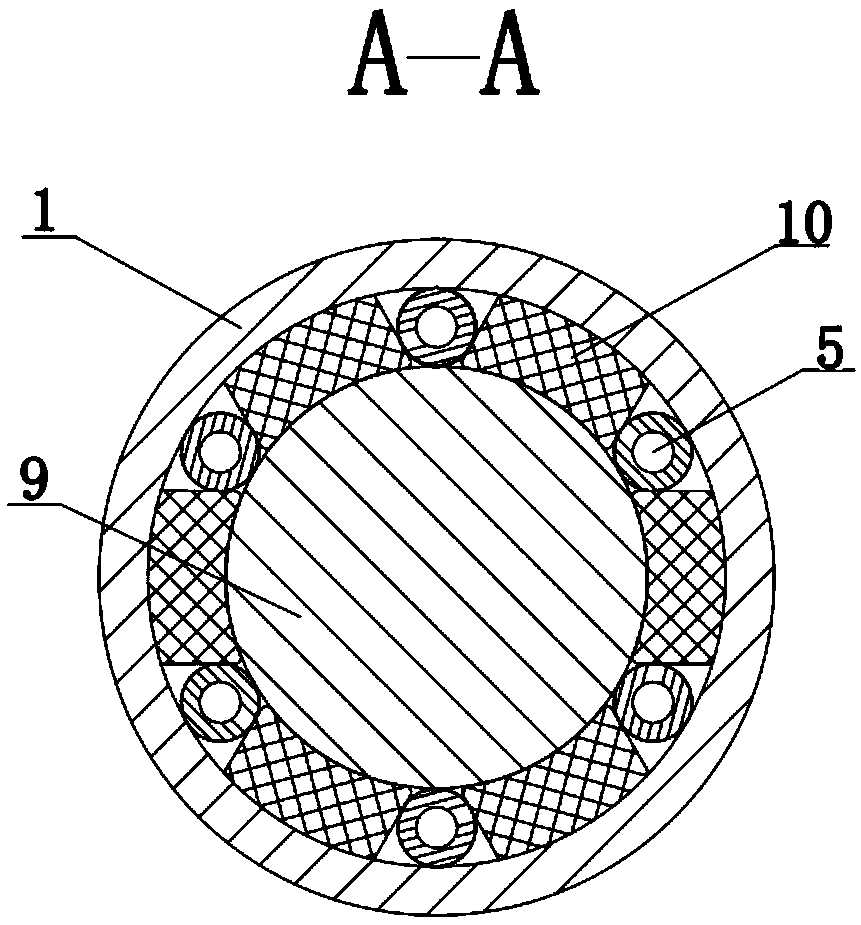

[0034] Such as figure 1 , 2 As shown, a long-life composite drill bit for repairing damaged casing wells, including: gear bearing 1, locking steel ball 2, a row of teeth 3, small roller 4, hollow roller 5, back cone teeth 6, seal Combination 7, tooth palm body 8, tooth palm bearing 9, rubber slider 10, plug hole 11, oil inlet hole 12, water hole 13, second row of teeth 14, third row of teeth 15, fourth row of teeth 16 and five rows of teeth 17;

[0035] The tooth palm body 8 is forged and shaped, and the five-axis linkage combined milling machine is used to drill the plug hole 11, the oil inlet hole 12, and the water hole 13; The oil hole 12 is located at the groove position of the tooth palm body 8 bottom, and the water hole 13 is at the protruding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com