Friction heat furnace

A friction heat generation and friction block technology, applied in the field of heating furnaces, can solve problems such as hidden safety hazards, high cost, and large pollution, and achieve the effects of smooth friction, increased rotational speed, and frictional heating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

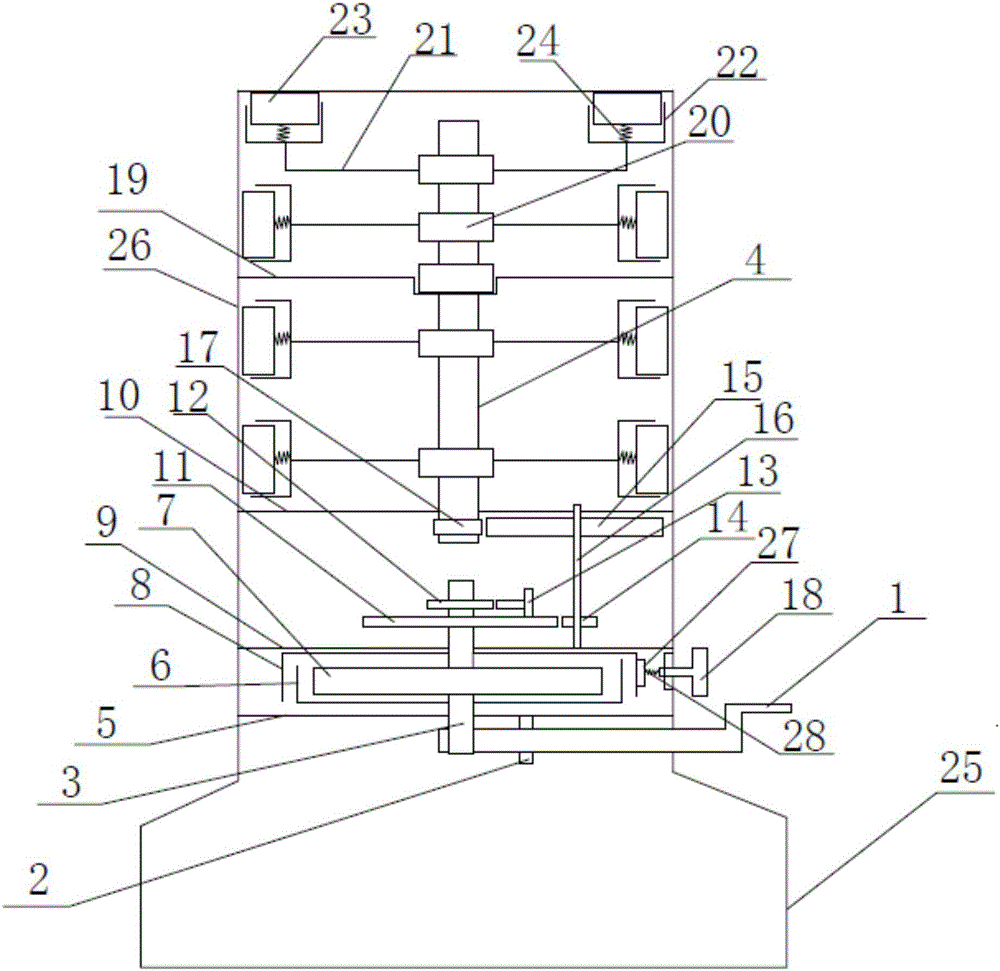

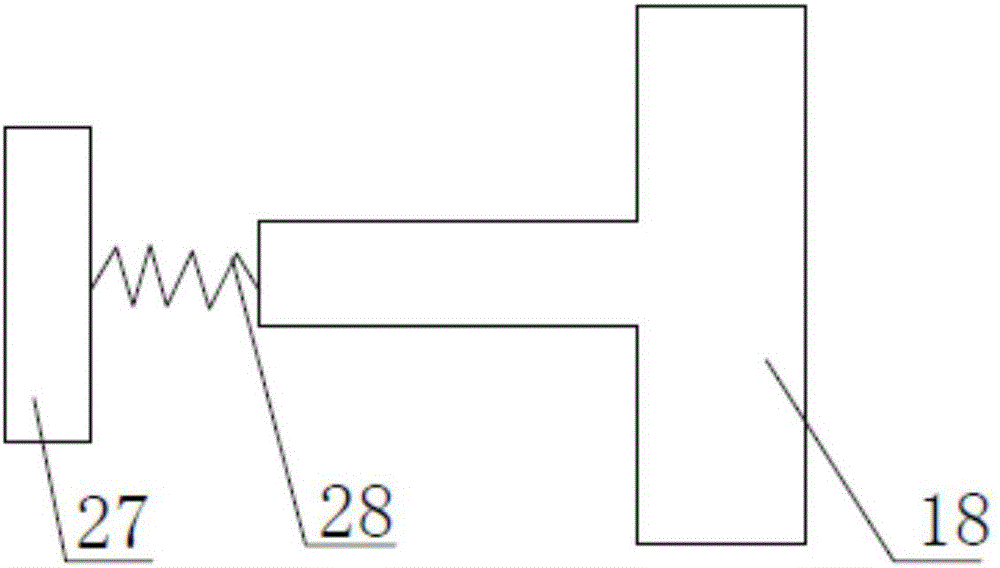

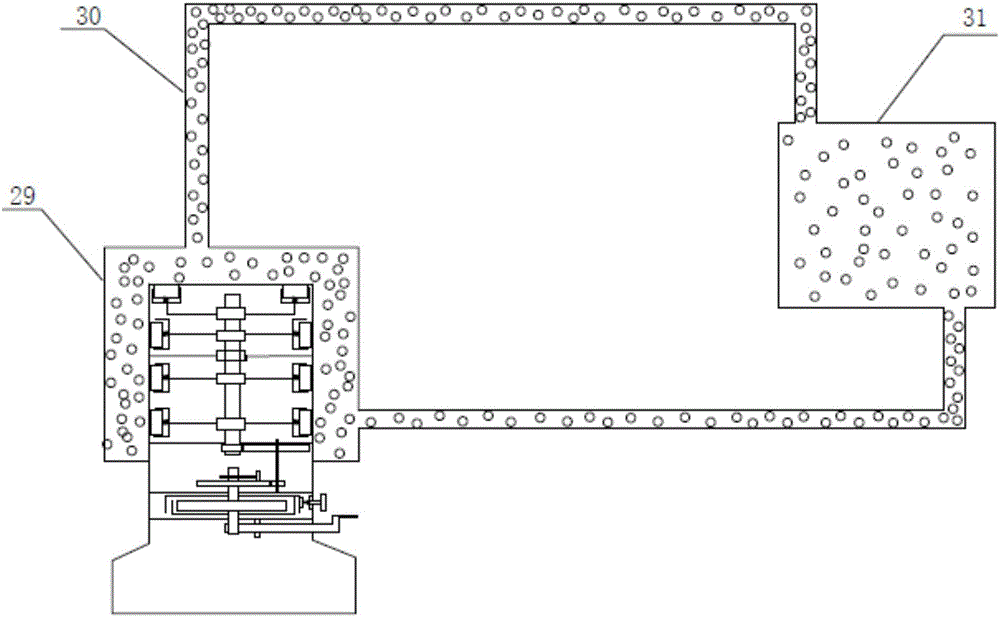

[0013] like figure 1 and figure 2 As shown, a friction heating furnace includes a base 25 and a housing 26 arranged on the base 25, wherein: it also includes a crank handle 1, a clockwork gear shaft 3, a central shaft 4, a clockwork case 6, a clockwork spring 7. Speed regulating shell 8, No. 1 gear 11, No. 2 gear 12, non-return plate 13, No. 3 gear 14, No. 4 gear 15, gear shaft 16, central shaft gear 17 speed regulating switch 18, speed regulating friction plate 27 and the rotating assembly, the lower fixed bracket plate 5, the middle fixed bracket plate 9 and the upper fixed bracket plate 10 are successively provided in the shell 26 from bottom to top, and the crank handle 1 is arranged on the bottom of the lower fixed bracket plate 5 through the crank handle bracket 2. On the surface, the handle end of the crank handle 1 extends to the outer end of the shell, and the inner end of the crank handle 1 is connected to the lower end of the clockwork gear shaft 3 to drive the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com