Two-shaft backfill type friction stir spot welding device

A friction stir and spot welding device technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as short service life, complex power transmission system, and too long lead screw

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

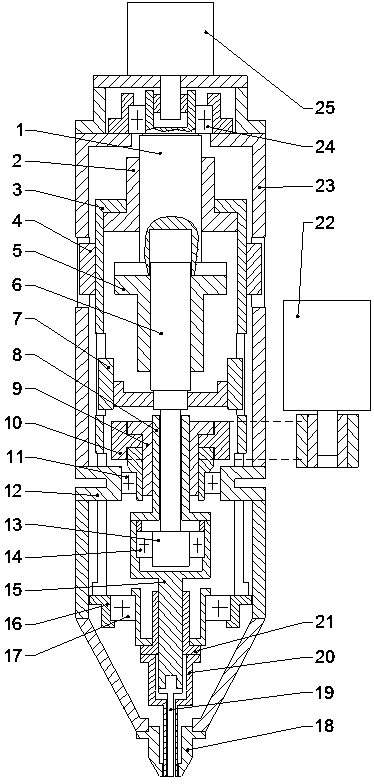

[0016] like figure 1 The shown two-axis backfill friction stir spot welding device includes an outer shell 23 and a stirring head made up of a stirring pin 19, a tubular sleeve 20, and a jacket 18. The jacket 18 is fixed on the lower end of the outer shell 23 for Compress the workpiece to be welded, the sleeve 20 can slide up and down in the sleeve 18, the stirring needle 19 can rotate freely and slide up and down in the sleeve 20, the lower part of the sleeve is a round tube, and the lower part of the stirring needle is inserted The part in the lower part of the sleeve is a cylinder that cooperates with it. The contact surface between the sleeve 20 and the stirring needle 19 and the contact surface between the sleeve 20 and the jacket 18 are all mirror surfaces. A screw pair, the outer side of the nut 2 lower end of the first lead screw pair is provided with a sleeve sleeve 3 that can slide up and down in the outer casing 23, and the upper side wall of the outer casing 23 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com