A method for improving the strength and toughness of titanium-aluminum-nitrogen coating on the surface of cemented carbide

A hard alloy, titanium aluminum nitrogen technology, applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of large difference in thermodynamic properties, low bonding strength of coating, easy to fall off, etc., to achieve Improve the bonding force and fracture toughness, good toughness, good toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

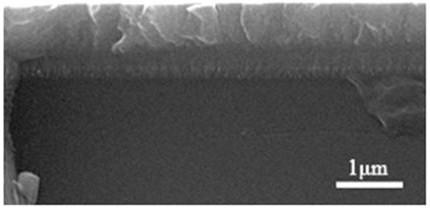

[0041] This embodiment provides a method for improving the strength and toughness of the titanium-aluminum-nitrogen coating on the surface of the cemented carbide by using the device as described above, comprising the following steps:

[0042] (1) Pretreatment of cemented carbide samples: mechanically grind and polish the YG8 cemented carbide sheet with a length and width of 16mm and a thickness of 4.5mm, and then immerse it in acetone, alcohol and distilled water for 10 minutes respectively for ultrasonic cleaning , dry with cold air for later use;

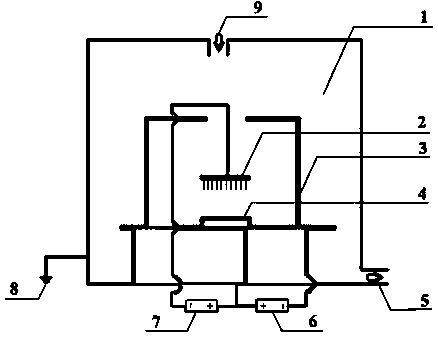

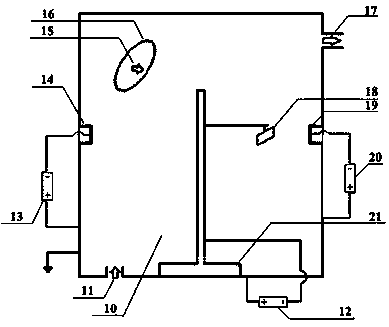

[0043] (2) Put the pretreated cemented carbide sample into such as figure 1 On the sample stage 4 of the double-glow plasma metallization equipment shown, the source 2 is fixed with a self-made tantalum wire target with a purity of 99.9%, a diameter of 2 mm and a length of 20 mm, and the source 2 is facing the sample stage 4. The distance between the sample stage 4 is 12mm, and then the auxiliary cathode cover 3 is placed, and a...

Embodiment 2

[0050] This embodiment provides a method for improving the strength and toughness of the titanium-aluminum-nitrogen coating on the surface of the cemented carbide by using the device described in Embodiment 1, comprising the following steps:

[0051] (1) Pretreatment of cemented carbide samples: mechanically grind and polish YG8 cemented carbide sheets with a length and width of 16mm and a thickness of 4.5mm, and then immerse them in acetone, alcohol and distilled water for 10 minutes respectively for ultrasonic cleaning , dry with cold air for later use;

[0052] (2) Put the pretreated cemented carbide sample into the figure 1 On the sample stage 4 of the double-glow plasma metallization equipment shown, the source 2 is fixed with a self-made tantalum wire target with a purity of 99.9%, a diameter of 2 mm and a length of 20 mm, and the source 2 is facing the sample stage 4. The distance between the sample stage 4 is 12mm, and then the auxiliary cathode cover 3 is placed, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com