Arc-shaped cutting machine for paving marble slabs on roads

A technology of marble slabs and cutting machines, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve problems such as difficult arc cutting, time-consuming and labor-intensive cutting, large and unsightly cutting gaps, etc., and achieve the effect of avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

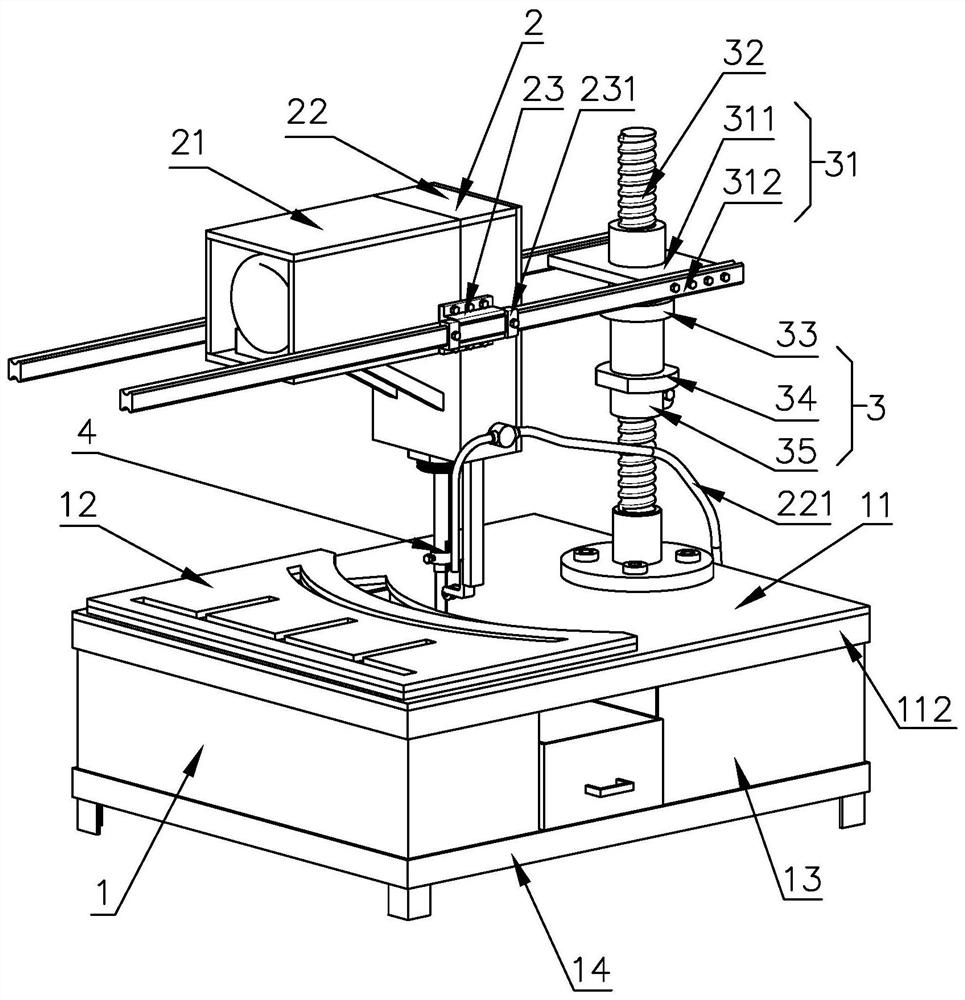

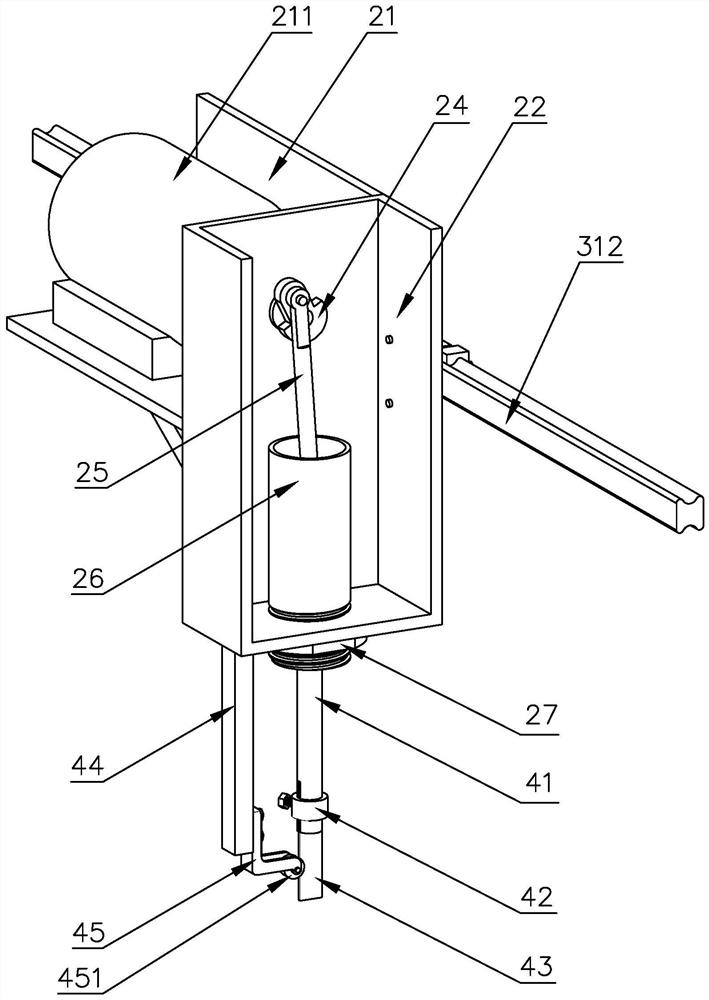

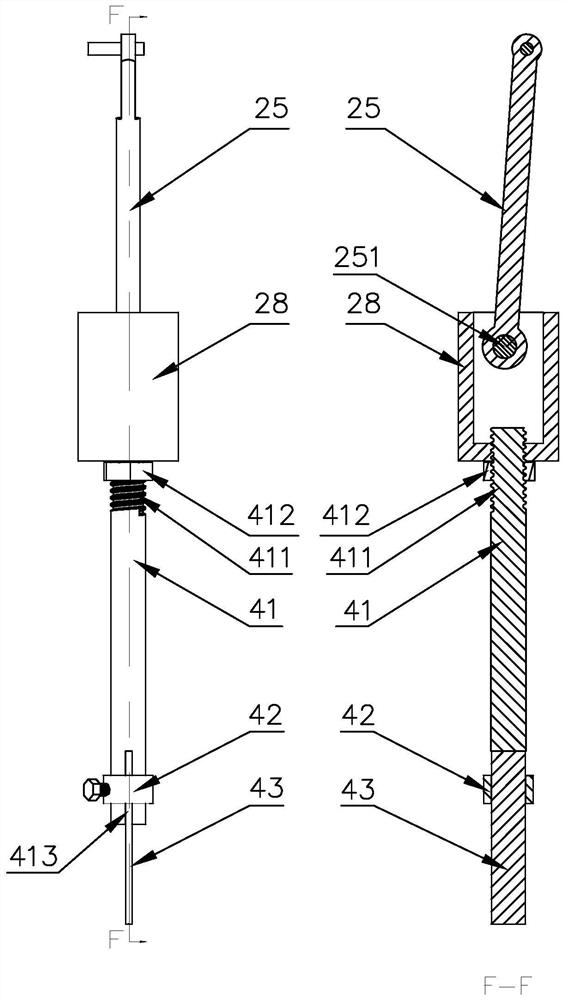

[0028] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-5 , to further specifically describe the technical solution of the present invention.

[0029] An arc-shaped cutting machine for marble slabs for road paving, comprising a base 1, a workbench 12, a power transmission mechanism 2, a column 32, a cutting mechanism 4 and a rotating support frame 31; the column 32 is fixed on one end of the base 1, and the working The table 12 is fixed on the other end of the base 1; one end of the rotating support frame 31 is sleeved with the column 32 through a sleeve, the power transmission mechanism 2 is fixed on the other end of the rotating support frame 31, and the cutting mechanism 4 is fixed on the bottom of the power transmission mechanism 2 .

[0030] The base 1 includes a fixed platform 11, a water tank 13, and a chassis 14; the upper part of the chassis 14 is provided with a water tank 13, the fixed platform 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com